1. Lubrication

Do not supply oil.

1. Type of fluids

Please consult with SMC when using the product in applications

other than compressed air.

2. Large amount of condensate

Compressed air containing a large amount of condensate can

cause malfunction of pneumatic equipment. An air dryer or

water droplet separator should be installed upstream from

filters.

3. Draining control

If condensate in the drain bowl is not emptied on a regular basis,

the condensate will overflow and enter the compressed air lines.

This will cause a malfunction of pneumatic equipment. If the

drain bowl is difficult to check or remove, installation of a drain

bowl with an auto drain option is recommended.

4. Use clean air.

Do not use compressed air that contains chemicals, synthetic

oils, including organic solvents, salt or corrosive gases, etc., as

it can cause damage or malfunction.

For detailed information regarding the quality of the compressed

air described above, refer to SMC's "Air Cleaning Systems".

1. If ultra dry air is used as a fluid, the lubrication

characteristics of the equipment will deteriorate and

this can affect the reliability (life) of the product.

Contact SMC beforehand, if using ultra dry air.

2. Install air filters.

Install air filters close to valves on the upstream side.

It is strongly recommended to use a filter with a filtration rating

of 0.01 μm or less. Be careful to prevent the supply pressure to

the valve from decreasing.

3. Take appropriate measures to ensure air quality,

such as by providing an after cooler, air dryer, or

water separator.

Compressed air that contains excessive drainage may cause

malfunction of valves and other pneumatic equipment.

Therefore, take appropriate measures to ensure air quality,

such as by providing an after cooler or water separator.

4. If excessive carbon powder is seen, install a mist

separator on the upstream side of the valve.

When the amount of carbon particles generated from the

compressor is excessive, they will stick inside of the valve, and

may cause malfunction or internal leakage.Refer to SMC’s Best

Pneumatics catalog for further details on compressed air

quality.

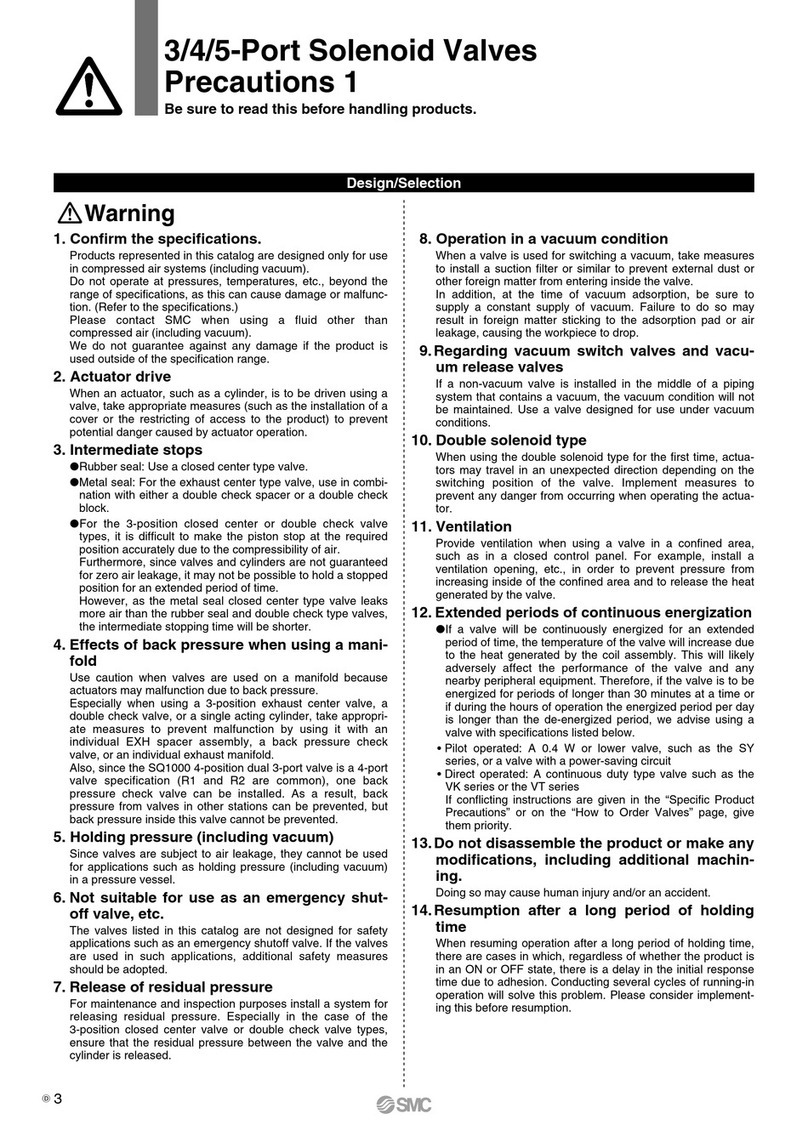

1. Do not use in an environment where corrosive gases,

chemicals, sea water, water or steam are present.

2. Do not use in an atmosphere containing flammable

or explosive gases. Fire or an explosion can result.

The product is not designed to be explosion proof.

3. Do not operate in a location subject to vibration or

impact.

4. The valve should not be exposed to prolonged

sunlight. Use a protective cover, if necessary.

5. Shield the product from radiated heat generated by

nearby heat sources.

6. Employ suitable protective measures in locations

where there is contact with oil and welding spatters,

etc.

7. When the solenoid valve is mounted onto a control

panel and energizing time is long, take measures

against radiation in order to keep the valve

temperature within the specified range.

1. Maintenance should be performed according to the

procedure indicated in the Operation Manual (this

copy).

Improper handling may cause an injury, damage and/or

malfunction of equipment and machinery.

2. Low frequency operation

Operate valves at least once every 30 days to prevent

malfunction. (Refer to the precautions for "Air Supply" and

follow the instructions)

3. Removal of product

Valves will reach high temperatures after operation. Confirm

that the valve temperature has lowered sufficiently, before

removing the product. If touched inadvertently, there is a danger

of being burnt.

1. Shut off the fluid supply and release the fluid pressure in the

system.

2. Shut off the power supply.

3. Remove the product.

1. Discharging condensate

Exhaust the drainage from an air filter periodically.

2. Filter

1. Make sure that the filer is not clogged.

2. Replace filter elements after a year of use, or earlier if the

pressure drop reaches 0.1MPa.

3. Storage

In case of long term storage after use with heated water,

thoroughly remove all moisture to prevent rust and deterioration

of rubber materials, etc.

SX10 Series

Be sure to read this before handling.

- 5 -

No.SX10-OMR0002-A