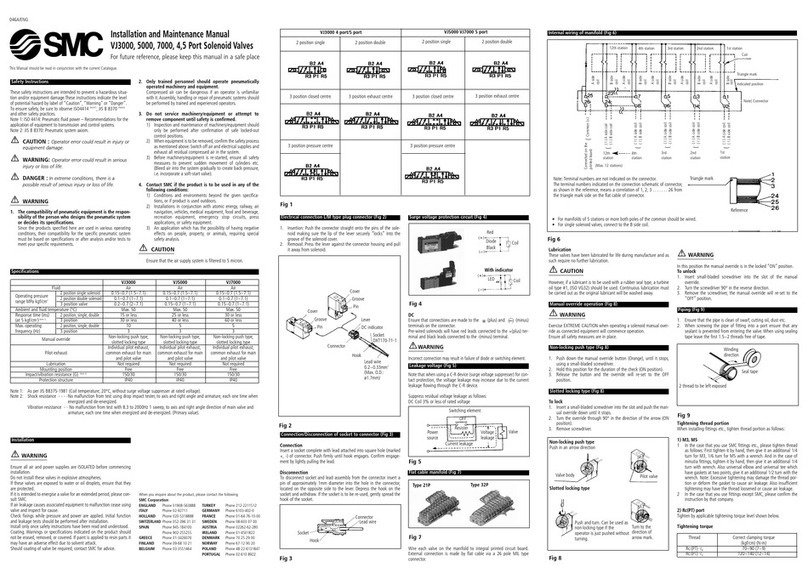

Table 2.

3 Installation

3.1 Installation Warning

•Do not install the product unless the safety instructions have been read

and understood.

•Do not install the product if it appears to have been damaged during

transport.

•Do not paint the product.

•Do not remove or cover up warnings or specifications printed or affixed

to the product.

•Ensure sufficient space for maintenance activities. When installing the

products, allow access for maintenance.

•Ensure that the connections of pipework to the unit do not result in a

residual trip hazard to system operators or maintainers.

•If air leakage increases or equipment does not operate to specification,

stop operation.

•Check mounting conditions when air supplies are connected. Initial

function and leakage tests should be performed after installation.

3.2 Environment Warning

•Do not use in an environment where corrosive gases, chemicals, salt

water or steam are present.

3 Installation - continued

•Do not use in an explosive atmosphere.

•Do not expose to direct sunlight. Use a suitable protective cover.

•Do not install in a location subject to vibration or impact in excess of

the product’s specifications.

•Do not mount in a location exposed to radiant heat that would result in

temperatures in excess of the product’s specifications.

•Employ suitable protective measures in locations where there is

contact with oil or welding spatter etc.

•Ambient humidity

When using the valve in environments with low humidity, take

measures to prevent static.

If the humidity rises, take measures to prevent the adhesion of water

droplets on the valve.

Do not use in high humidity environment where condensation occurs.

•Altitude limitation is 1000 m above sea level.

Caution

Avoid using in places where there is splashing oil, coolant or water. In

addition, avoid using where dust may adhere.

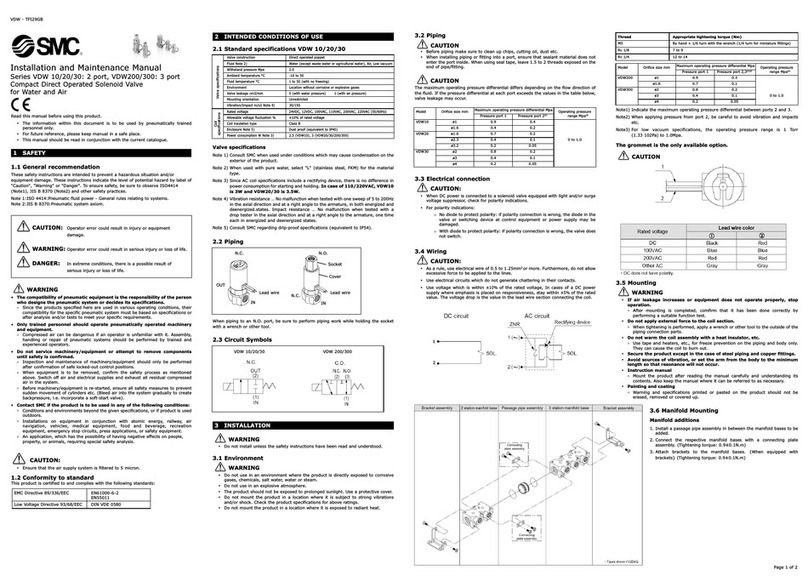

3.3 Piping Caution

•Before connecting piping make sure to clean up chips, cutting oil, dust

etc.

•When installing piping or fittings, ensure sealant material does not

enter inside the port. When using seal tape, leave 1 thread exposed

on the end of the pipe/fitting.

•Tighten fittings to the specified tightening torque.

•Connect tubing with a longer length than required to prevent torsion,

stretching or moment loads. Damage of the fittings or flattening, as

well as bursting or releasing of the tubing may occur if the instructions

are not followed.

•Tubing connected to the VR51 should be used at more than its

minimum bend radius. If used under the minimum bend radius,

bending or flattening of the tubing may occur. Refer to catalogue for

additional information.

3.3.1 Piping length for secondary side

To help avoid output timing delay;

•Use the same tubing length and diameter between the VR51 and each

control actuating device: L1=L2, L1’=L2’.

•Use the same control valve type for each input port: V1=V2

•Operate the control valves with the same pressure: P1=P2

Figure 8.

3.4 Lubrication Caution

•SMC products have been lubricated for life at manufacture, and do not

require lubrication in service.

•If a lubricant is used in the system, use turbine oil Class 1 (no additive),

ISO VG32. Once lubricant is used in the system, lubrication must be

continued because the original lubricant applied during manufacturing

will be washed away.

3.5 Air supply Warning

•When there is a large amount of condensate.

Compressed air containing a large amount of water vapour can cause

malfunction of pneumatic equipment such as valves. An air dryer or

water separator should be installed upstream from filters.

•Drain flushing

If condensation in the drain bowl is not emptied on a regular basis, the

bowl will overflow and allow the condensation to enter the compressed

air lines. It causes malfunction of pneumatic equipment.

3 Installation - continued

If the drain bowl is difficult to check and remove, installation of a drain

bowl with an auto drain option is recommended.

•Type of air

Do not use compressed air that contains chemicals, synthetic oils

including organic solvents, salt or corrosive gases, etc., as it can cause

damage or malfunction. Caution

•When extremely dry air is used as the fluid, degradation of the

lubrication properties inside the equipment may occur, resulting in

reduced reliability (or reduced service life) of the equipment. Please

consult with SMC.

•Install an air filter upstream near the valve. Select an air filter with a

filtration size of 5 μm or smaller.

•Take measures to ensure air quality, such as by installing an

aftercooler, air dryer, or water separator.

•If excessive carbon powder is seen, install a mist separator on the

upstream side of the valve.

If excessive carbon dust is generated by the compressor it may adhere

to the inside of a valve and cause it to malfunction.

Warning

•Minimise the distance between the valve and the air supply and

between the valve and the protected system.

•Do not place any devices between the valve and the protected system

that might interfere with the safety function.

•The exhaust ports of the valve should not be left unconnected.

•The exhaust ports of the valves should never be blocked and must be

protected from ingress ofcontamination by asuitable silencer or device

which does not affect the valve function.

3.6 Mounting

•The valve can be mounted using 2 x M5 x 0.8 bolts (thread depth:

5 mm) or using a bracket with 2 x ∅6.5 mm diameter holes. Tightening

torque for M5 thread is 1.5 to 3 N∙m.

•Refer to catalogue for more details.

3.7 One-touch fittings Caution

Refer to catalogue for specific precautions.

4 Settings

4.1 Operating button setup Caution

•Design and prepare the buttons in accordance with instruction

manuals. Install the buttons according to ISO 13851 Safety of

machinery - Two-hand control devices - Functional aspects - Principles

for design and other applicable standards.

•If the operating buttons are incorrectly arranged, an unexpected

motion is likely to occur and safety cannot be maintained.

•Principle precautions (reference only):

- Configure the buttonsso only 2 hand operation is possible, ensure

it is not possible to operate by 1 hand only.

- Configure the buttonsso only 2 hand operation is possible, ensure

it is not possible to operate by forearm(s) or elbow(s).

- Configure the buttonsso only 2 hand operation is possible, ensure

it is not possible to operate by 1 hand and any other part of the

body (knee or hip for example).

•Example of button setup:

- Ensure a safe spacing of the buttons so they cannot be operated

by 1 hand.

Figure 9.

- Install an isolating object between the buttons so they cannot be

operated by 1 hand.

Figure 10.

- Place a cover over both buttons so they cannot be operated by 1

hand.

4 Settings - continued

Figure 11.

5 How to Order

Refer to catalogue for ‘How to Order’.

6 Outline Dimensions

Refer to catalogue for outline dimensions.

7 Maintenance

7.1 General maintenance Caution

•Not following proper maintenance procedures could cause the product

to malfunction and lead to equipment damage.

•If handled improperly, compressed air can be dangerous.

•Maintenance of pneumatic systems should be performed only by

qualified personnel.

•Before performing maintenance, turn off the power supply and be sure

to cut off the supply pressure. Confirm that the air is released to

atmosphere.

•After installation and maintenance, apply operating pressure and

power to the equipment and perform appropriate functional and

leakage tests to make sure the equipment is installed correctly.

•If any electricalconnections are disturbed during maintenance, ensure

they are reconnected correctly and safety checks are carried out as

required to ensure continued compliance with applicable national

regulations.

•Do not make any modification to the product.

•Do not disassemble the product, unless required by installation or

maintenance instructions.

7.2 Periodic testing

•The product should be tested regularly for proper operation of the

safety functions.

•Testing should be conducted at start-up and then at regular intervals

determined by the end user depending on complete system

requirements. Thetest shouldconsist of operation of the safety system

and observation of the following, replace product if necessary:

- There are no scratches, dents, corrosion, loose screws, or damage

to the valve body.

- The one-touch fitting is not damaged.

- The tube should not be kinked, crushed or damaged.

- The tube should not be hardened, deteriorated or softened.

- No air leaks.

- The air pressure is in the range of 0.25 MPa to 1 MPa.

- Operate the two operating devices installed on the ‘Input’ side at

the same time and ensure that there is output from port A of VR51.

- The operation timings of the two operating devices installed on the

‘Input’ side are shifted by 0.5 seconds or more, and there is no

output from port A of VR51.

- When one of the operating devices is cancelled while there is

output from port A of VR51, there is no output from port A.

7.2 Maintainable parts Warning

There are no replaceable parts.

8 Limitations of Use

Warning

•The system designer should determine the effect of the possible failure

modes of the product on the system.

•VR51 only offers protection for the person operating it.

8.1 Limited warranty and disclaimer/compliance requirements

Refer to Handling Precautions for SMC Products.

8.2 Type of fluid and pneumatic pressure

•Do not use fluids other than those specified. The only fluid that can be

used is air.