9

CONTENTS

D-sub Connector, Flat Ribbon Cable [IP20/40/67]

How to Order ··············································································· p. 21

Dimensions

D-sub Connector (IP40/Connector Entry Direction Adjustable): F

······ p. 23

D-sub Connector (IP67): FW ···················································· p. 27

D-sub Connector (IP20/Compact Type): FC ····························· p. 29

Flat Ribbon Cable

(IP40/Connector Entry Direction Adjustable): P/PG/PH ······· p. 32

Flat Ribbon Cable (IP20/Compact Type): PC/PGC/PHC ········· p. 36

Electrical Wiring Specifications: D-sub Connector Cable ············ p. 39

Electrical Wiring Specifications: Flat Ribbon Cable Connector

······ p. 40

Spring Type Terminal Block Box, Terminal Block Box

How to Order ··············································································· p. 43

Dimensions

Spring Type Terminal Block Box: TC ········································ p. 45

Terminal Block Box: T······························································ p. 49

Connection/Electrical Wiring Specifications ································ p. 53

Lead Wire

How to Order ··············································································· p. 55

Dimensions ·················································································· p. 57

Electrical Wiring Specifications ···················································· p. 61

EX600 Integrated Type (For Input/Output)

Serial Transmission System

How to Order ··············································································· p. 63

Dimensions ·················································································· p. 65

EX245 Integrated Type (For Input/Output)

Serial Transmission System

How to Order ··············································································· p. 73

Dimensions ·················································································· p. 75

EX250 Integrated Type (For Input/Output)

Serial Transmission System

How to Order ··············································································· p. 77

Dimensions ·················································································· p. 79

EX260 Integrated Type (For Output)

Serial Transmission System

How to Order ··············································································· p. 83

Dimensions ·················································································· p. 87

EX120 Integrated Type (For Output)

Serial Transmission System

How to Order ··············································································· p. 91

Dimensions ·················································································· p. 93

Type 10/Side Ported: Common Dimensions

(External Pilot, Built-in Silencer/Mixed Size, Straight Port Type)

······ p. 97

Manifold Exploded View [By Wiring] ························· p. 101

D-sub Connector/Flat Ribbon Cable

(IP40/Connector Entry Direction Adjustable) ························· p. 102

D-sub Connector (IP67) ························································· p. 103

D-sub Connector/Flat Ribbon Cable (IP20/Compact Type)

······ p. 104

Spring Type Terminal Block Box ············································· p. 105

Terminal Block Box ································································ p. 106

Lead Wire ··············································································· p. 107

EX600 ···················································································· p. 108

EX245 ···················································································· p. 110

EX250 ···················································································· p. 112

EX260 ···················································································· p. 113

EX120 ···················································································· p. 114

Manifold Exploded View [Common Parts] ··············· p. 115

Type 10: How to Increase Connector Type Manifolds ············ p. 115

For the JJ5SY1-10, JJ5SY3-10, JJ5SY5-10/

Manifold Parts Nos. ···························································· p. 116

Vacuum Unit ZK2 Combination Manifold

How to Order ············································································· p. 119

Dimensions ················································································ p. 123

ZK2 Combination Manifold Exploded View ············· p. 126

For the JJ5SY3-10-M (ZZK2A) ··········································· p. 126

Manifold Parts Nos. ································································ p. 127

ZK2A Vacuum Ejector Manifold Exploded View

How to Increase Manifold Stations ········································· p. 128

One-touch Fittings, Plug, Clip, Port Plate,

Tube Releasing Tool ······················································· p. 130

Manifold Options ·································································· p. 131

Made to Order ····································································· p. 135

Specific Product Precautions ············································ p. 136

Model Index ··········································································· p. 141

Safety Instructions ······················································ Back cover

D-sub connector

Flat ribbon cable Lead wire

EX600 EX250

EX245

EX120

Terminal block box

EX260

Optimum Actuation Size Chart of Air Cylinder ······························· p. 9

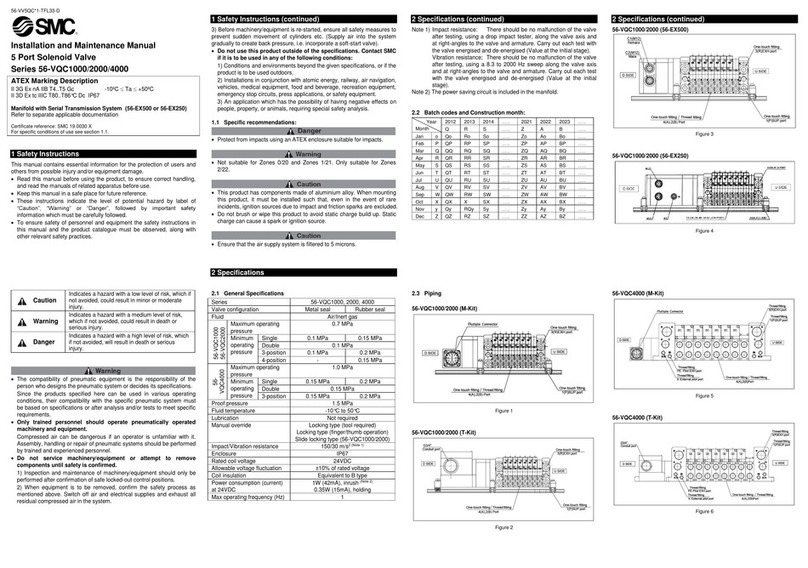

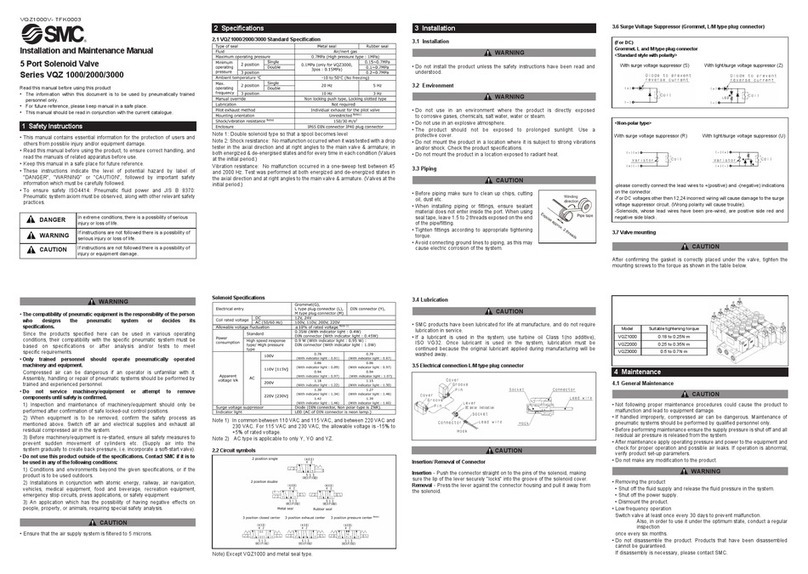

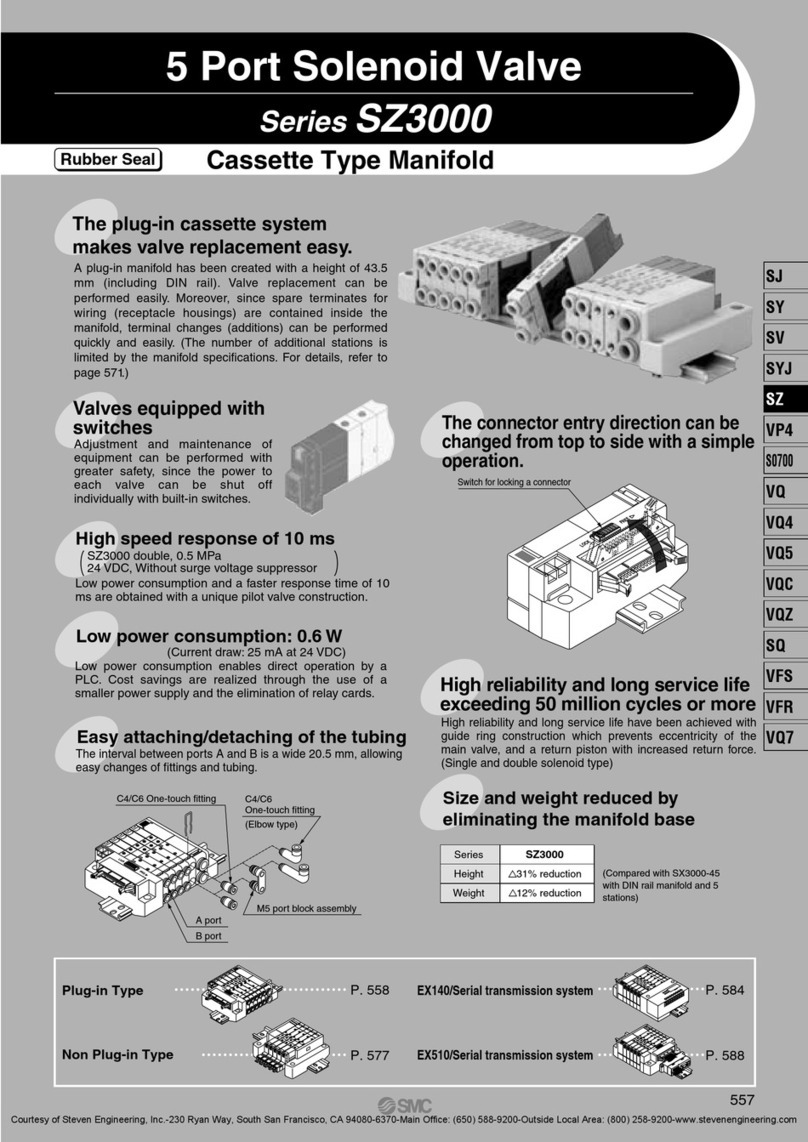

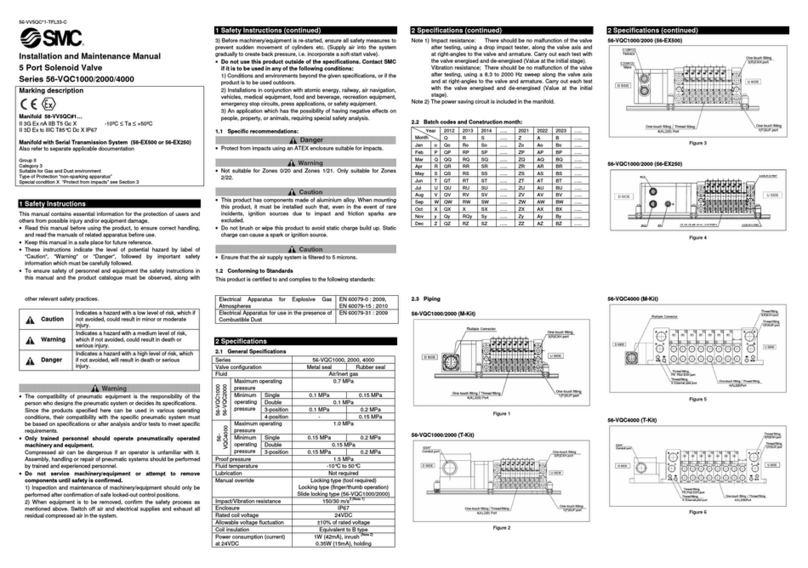

Valve Specifications ···································································· p. 13

Response Time ··········································································· p. 14

Valve Weight ··············································································· p. 14

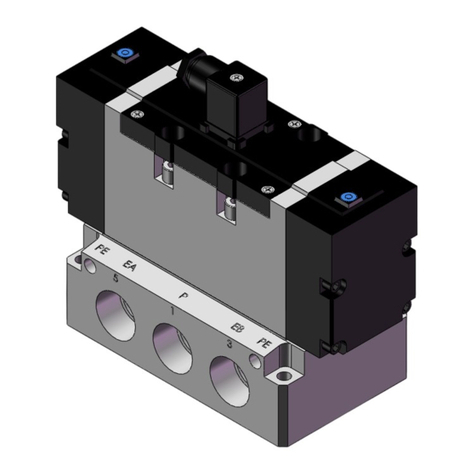

Valve Construction ······································································ p. 15

Valve Replacement Parts: Pilot Valve ········································· p. 16

Plug-in Connector Connecting Base

Manifold Specifications ································································ p. 17

Manifold Weight ··········································································· p. 17

Manifold Flow Rate Characteristics ············································· p. 17

ZK2 Combination Manifold Weight ·············································· p. 18

Connector Wiring Layout ····························································· p. 19

ZK2 combination manifold