SGH100-TFM86

Installation and Maintenance Manual

Coolant Valve

Series : SGH100/200/300/400

1 Safety Instructions

• This manual contains essential information for the protection of users

and others from possible injury and/or equipment damage.

• Read this manual before using the product, to ensure correct handling,

and read the manuals of related apparatus before use.

• Keep this manual in a safe place for future reference.

• These instructions indicate the level of potential hazard by label of

“DANGER”, “WARNING” or “CAUTION”, followed by important safety

information which must be carefully followed.

• To ensure safety of personnel and equipment the instructions in this

manual and the product catalogue must be observed, along with other

relevant safety practices.

WARNING

• The compatibility of pneumatic equipment is the responsibility of

the person who designs the pneumatic system or decides its

specifications.

Since the product specified here is used under various operating

conditions, its compatibility with specific equipment must be decided by

the person who designs the equipment or decides its specifications

based on necessary analysis and test results. The expected

performance and safety assurance of the equipment will be the

responsibility of the person who has determined its compatibility with

the product. This person should also continuously review all

specifications of the product referring to its latest catalog information,

with a view to giving due consideration to any possibility of equipment

failure when configuring the equipment.

• Only trained personnel should operate pneumatically operated

machinery and equipment.

The product specified here may become unsafe if handled incorrectly.

The assembly, operation and maintenance of machines or equipment

including our products must be performed by an operator who is

appropriately trained and experienced.

• Do not service machinery/equipment or attempt to remove

components until safety is confirmed.

1) The inspection and maintenance of machinery/equipment should

only be performed after measures to prevent falling or prevention of

the danger by the fluid have been confirmed.

2) When the product is to be removed, confirm that the safety measures

as mentioned above are implemented and the power from any

appropriate source is cut, and read and understand the specific

product precautions of all relevant products carefully.

3) Before machinery/equipment is restarted, take measures to prevent

unexpected operation and malfunction.

• Contact SMC beforehand and take special consideration of safety

measures if the product is to be used in any of the following

conditions.

1) Conditions and environments beyond the given specifications, or if

product is used outdoors or with direct sunlight.

2) With fluids whose application causes concern due to the type of fluid

or additives, etc.

1 Safety Instructions (continued)

3) An application that has the possibility of having negative effects on

people, property, or animals, requiring special safety analysis.

1. The product is provided for use in manufacturing industries.

The product herein described is basically provided for peaceful use in

manufacturing industries.

If considering using the product in other industries, consult SMC

beforehand and exchange specifications or a contract if necessary.

If anything is unclear, contact your nearest sales branch.

Limited warranty and Disclaimer/Compliance Requirements

The product used is subject to the following “Limited warranty and

Disclaimer” and “Compliance Requirements”.

Read and accept them before using the product.

Limited warranty and Disclaimer

1. The warranty period of the product is 1 year in service or 1.5 years after

the product is delivered.*3)

Also, the product may have specified durability, running distance or

replacement parts. Please consult your nearest sales branch.

2. For any failure or damage reported within the warranty period which is

clearly our responsibility, a replacement product or necessary parts will

be provided. This limited warranty applies only to our product

independently, and not to any other damage incurred due to the failure

of the product.

3. Prior to using SMC products, please read and understand the warranty

terms and disclaimers noted in the specified catalog for the particular

products.

*3) Vacuum pads are excluded from this 1 year warranty.

A vacuum pad is a consumable part, so it is warranted for a year after it

is delivered. Also, even within the warranty period, the wear of a product

due to the use of the vacuum pad or failure due to the deterioration of

rubber material are not covered by the limited warranty.

CAUTION

• Ensure that the air supply system is filtered to 5 micron.

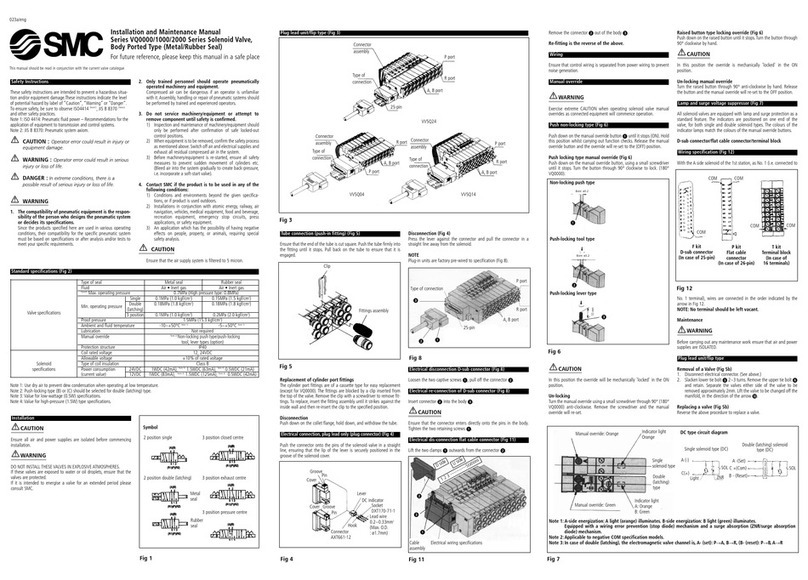

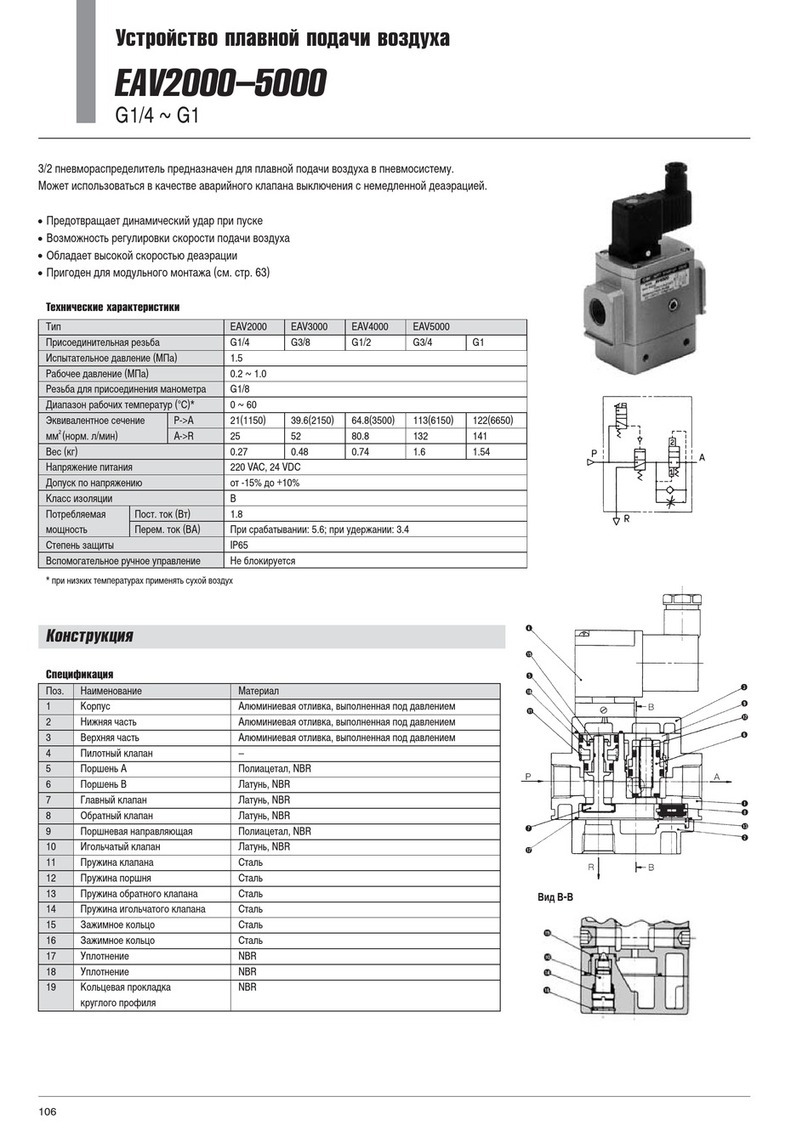

2 Specifications

2.1 Valve specifications

Note :

Impact resistance: No malfunction occurred when it was tested with a drop

tester in the axial direction and at right angles to the main valve & armature;

in both energized & de-energised states and for every time in each condition

(Values at the initial period.)

Vibration resistance: No malfunction occurred in a one-sweep test between

45 and 2000 Hz. Tests ere performed at both energized and de-energized

states in the axial direction and at right angles to the main valve & armature.

(Valves at the initial period.)

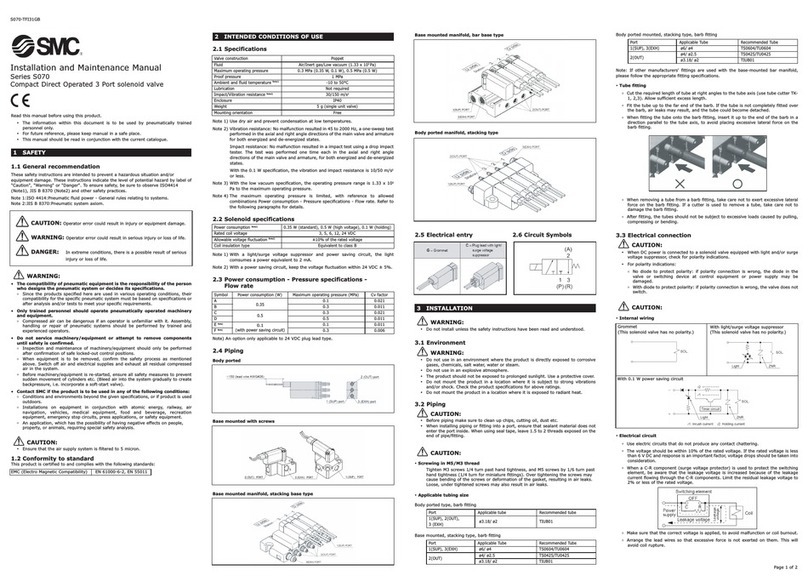

2.2 Solenoid Specifications

2 Specifications (continued)

Note) In common between 110 VAC and 115 VAC, and between 220 VAC and 230 VAC.

For 115 VAC and 230 VAC, the allowable voltage is -15% to +5% of rated

voltage.

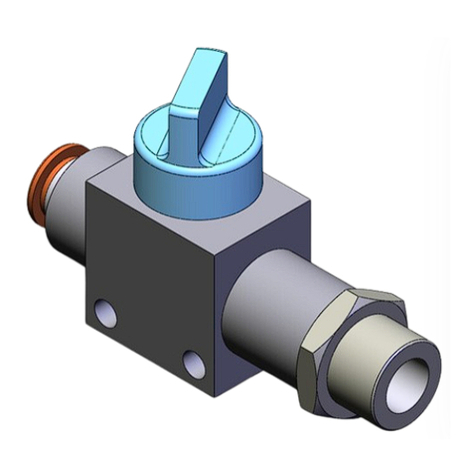

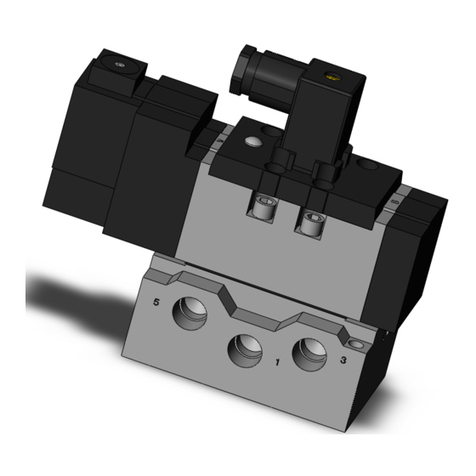

2.3 Circuit symbol

Note)

The Reverse pressurization type valve can be used as a N.C. valve or as a Selector

valve. See below for piping method:

•N.C. valve use 1 port : output port

2 port : waste fluid port

3 port : supply port

•Selector valve use 1 port : output port

2 port : low pressure supply port

3 port : high pressure supply port

3 Installation

3.1 Environment

WARNING

1. Do not use in an environment where the product is directly exposed to

corrosive gases, chemicals, salt water, water or steam.

2. Products with IP65 and IP67 enclosures (based on IEC60529) are

protected against dust and water, however, these products cannot be used

in water.

3. Incorrect mounting of the product violates the IP65 rating. Be sure to read

the Precautions for each product.

4. Do not use in explosive atmospheres.

5. The product should not be exposed to prolonged sunlight. Use a protective

cover.

6. Do not mount the product in a location where it is subject to strong

vibrations and/or shock. Check the product specifications.

7. Remove emissive heat.

8. If using in an atmosphere where there is possible contact with water

drop-lets, oil, weld spatter, etc., take suitable preventative measures.

9. When the product is mounted in a control panel, or when it's energized for

a long time, make sure that the ambient temperature is within the specified

range.

3.2 Piping

1. Preparation before piping

Before piping is connected, it should be thoroughly blown out with air

(flushing) or washed to remove chips, cutting oil and other debris from

inside the pipe.

Install piping so that it does not apply pulling, pressing, bending or other

forces the valve body.

2. Sealant tape

When installing piping or fitting into a port, ensure that sealant material

does not enter the port internally. Furthermore, when sealant tape is

used, leave 1.5 to 2 thread ridges exposed at the end of the threads.

<For AC>

3 Installation (continued)

3. Avoid connection of ground lines to piping, as this may cause electric

corrosion of the system.

4. Always tighten threads with the proper tightening torques.

When screwing fittings into valves, tighten with the proper tightening

torque shown below.

Tightening Torque for Piping

5. Connection of piping to products.

When connecting piping to a product, avoid mistakes regarding the

supply port, etc.

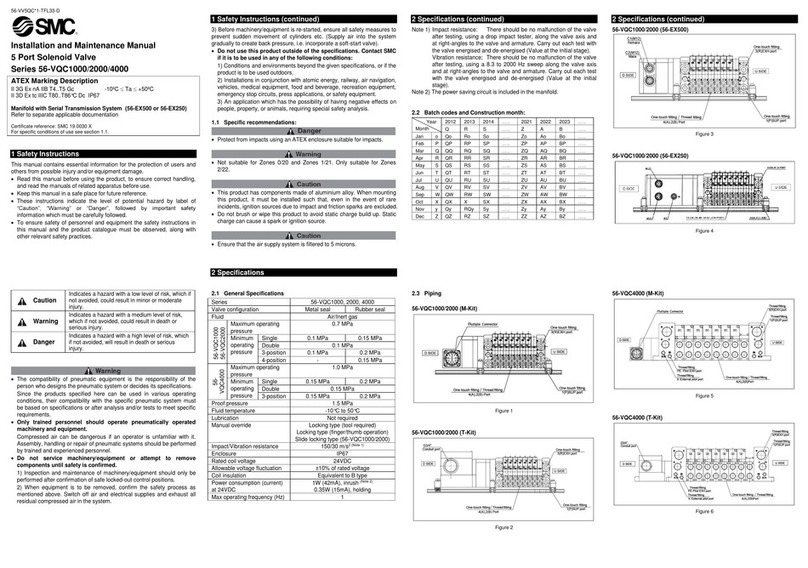

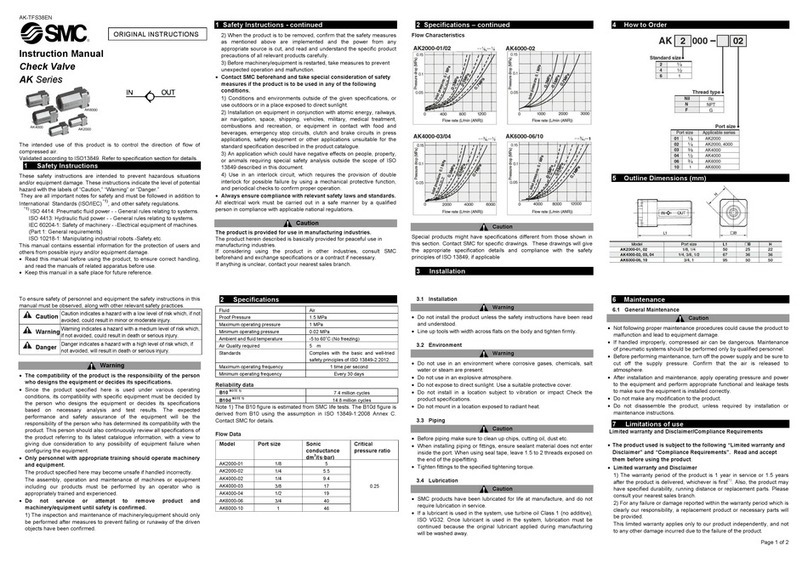

3.3 Light/Surge Voltage Suppressor

<For DC>

In extreme conditions, there is a possibility of

serious injury or loss of life.

WARNING If instructions are not followed there is a

possibility of serious injury or loss of life.

CAUTION If instructions are not followed there is a

possibility of injury or equipment damage.

DANGER

trop2trop3

1port

pressurization

Reverse

pressurization N.C. N.O.

External

pilot

solenoid

type

004/003/002/001HGSepyT

tnalooCdiulfgnitarepO

Fluid temperature °)gnizeerfoN(06ot5-C

Ambient temperature °C-5 to 50 (No freezing)

SGH A,B-30 4.5

Proof pressure

MPa SGH A,B-70 10.5

Leakage from the valve seat 100cm3/min of less (water pressure)

SGH A,B-30 0 to 3

Operating pressure range

MPa SGH A,B-70 0 to 7

Manual override Non-locking type, push turn-

locking slotted type

Pressure MPa 0.25 to 0.7

Lubrication Not required (Use turbine oil Class 1

(ISO VG32), if lubricated.

External pilot

Te m p e r a t ure °C-5 to 50 (No freezing)

!!!

!!!

!!!

!!!

Connection thread Appropriate tightening torque (N•m)

9ot78/1

42ot228/3

03ot822/1

03ot824/3

83ot631

Conduit terminal, DINterminal (non-polar type)

Surge voltage suppressor (TS/DS) Light/surge voltage suppressor(TZ,DZ)

M12 connector (non-polar type)

Surge voltage suppressor(WS/VS) Light/surge voltage suppressor(WZ/VZ)

Coil

Vari s t o r

Coil

Varistor

Varistor Varistor

Coil Coil

Conduit terminal

Surge voltage suppressor(TS) Light/surge voltage suppressor(TZ)

DINterminal

Surge voltage suppressor(DS) Light/surge voltage suppressor(DZ)

M12 connector

Surge voltage suppressor(WS/VS) Light/surge voltage suppressor(WZ/VZ)

lioClioC

Varistor Varistor

Varistor Varistor lio

C

lio

C

rotsiraVrotsiraVlioClioC

Pilot solenoid valve specification V116- -1

rotcennoc21M,lanimretNID,lanimrettiudnoCyrtnelacirtcelE

DC 12V, 24V

Coil rated voltage AC(50/60Hz) 100V, 110V, 200V, 220V

Allowable voltage fluctuation ±10%of rated voltage Note)

Power consumption WDC 0.35 (With indicator light : 0.58)

100V0.78(With indicator light : 0.87)

110 V[115V] 0.86 (With indicator light : 0.97)

0.94 (With indicator light : 1.07)

200V1.15 (With indicator light : 1.30)

Apparent

voltage VA AC

220V[230V] 1.27 (With indicator light : 1.46)

1.39 (With indicator light : 1.60)

Surge voltage suppressor ZNR (Varistor)

Indicator light LED (Neon bulbwhen AC with DINterminal

and M12 connector)

!!!