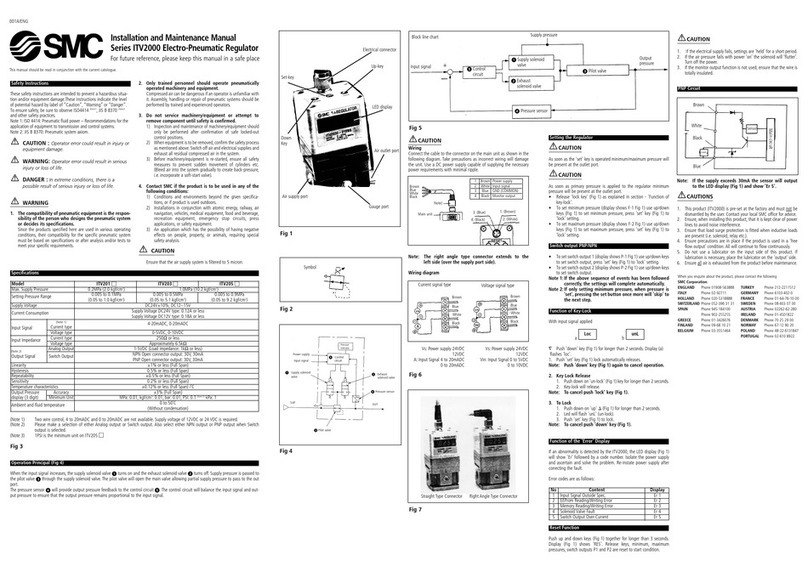

Specifications

Model PSE200

NPN open collector

PSE201

PNP open collector

Output specification

Power supply voltage

Current consumption

Power supply voltage for sensor

Power supply current for sensor Note 1)

Sensor input

Hysteresis

Switch output

Response time

Repeatability

Setting/Display accuracy

Display

Indication light

Auto shift input

Auto identification function Note 2)

Resistance

Temperature characteristics

Connection

Material

Weight

12 to 24 VDC ±10%, Ripple (p-p) 10% or less (With power supply polarity protection)

55 mA or less (Current consumption for sensor is not included.)

[Power supply voltage] –1.5 V

40 mA maximum (100 mA maximum for the total power supply current when 4 sensors are input.)

1 to 5 VDC (Input impedance: Approx. 800 kΩ)

4 inputs

With excess voltage protection (Up to 26.4 V)

Variable

3-digit fixed

5 outputs (CH1: 2 outputs, CH2 to 4: 1 output)

80 mA

30 VDC (With NPN)

1 V or less (With load current of 80 mA)

With short circuit protection

5 ms or less

With anti-chattering function, Response time selection: 20 ms, 160 ms, 640 ms

±0.1% F.S. or less

±0.5% F.S. ±1 digit or less (at ambient temperature of 25°±3°C)

For measured value display: 4-digit, 7-segment indicator, Display color: Yellow

For channel display: 1-digit, 7-segment indicator, Display color: Red

Red (Lights up when output is ON.)

Non-voltage input (Reed or Solid state), Input 10 ms or more, Independently controllable auto shift function ON/OFF

With auto identification function

Front face: IP65, Other: IP40

Operating: 0°to 50°C, Stored: –10°to 60°C (No freezing or condensation)

Operating/Stored: 35 to 85% RH (No condensation)

10 to 500 Hz at whichever is smaller of 1.5 mm amplitude or 98 m/s2acceleration, in X, Y, Z directions for 2 hrs. each (De-energized)

980 m/s

2

in X, Y, Z directions, 3 times each (De-energized)

±0.5% F.S. or less based on 25°C

Power supply/Output connection: 8P connector, Sensor connection: 4P connector

Enclosure: PBT; Display: Transparent nylon; Back rubber cover: CR

Approx. 60 g (Power supply/output connecting cable not included)

No. of inputs

Input protection

Hysteresis mode

Window comparator mode

No. of outputs

Maximum load current

Maximum load voltage

Residual voltage

Output protection

Anti-chattering function

Enclosure

Ambient temperature range

Ambient humidity range

Vibration resistance

Impact resistance

PSE530 (F

or high pressure)

–0.1 to 1 MPa

—

0.001

0.01

0.01

0.1

—

—

PSE531 (For vacuum)

10 to –101 kPa

0.1

—

0.001

0.001

0.01

1

0.1

PSE532 (For low pressure)

–10 to 101 kPa

0.1

—

0.001

0.001

0.01

—

—

PSE533 (F

or compound pressure)

–101 to 101 kPa

0.1

—

0.001

0.001

0.02

1

0.1

Applicable pressure sensor

Regulating pressure range

Set pressure

resolution

kPa

MPa

kgf/cm2

bar

psi

mmHg

InHg

Note 3)

Note 1) If the Vcc and 0 V side of the sensor input connector are short circuited, the inside of the controller will be damaged.

Note 2) Auto identification function comes with “Series PSE53” pressure sensor only. Other SMC series (PSE510 and PSE520) are not equipped with this

function.

Note 3) For controllers with unit display switching function. (Either of SI units, [kPa] or [MPa], will be the set unit for those controllers without unit switching

function.)