ITV2-TF2Z358EN

Page 1 of 2

Instruction Manual

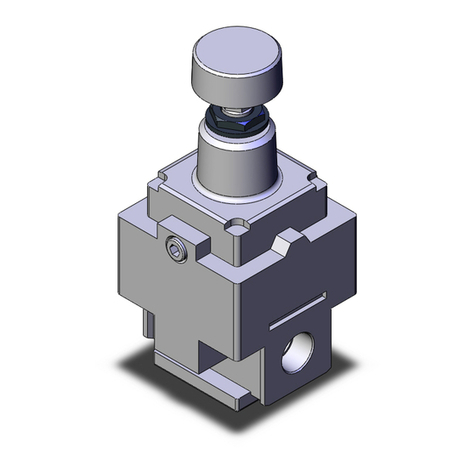

Electro-Pneumatic Regulator

PROFIBUS DP

ITV*0*0-RC**** Series

The intended use of the electro-pneumatic regulator is tocontrol the flow

and pressure of fluid while connected to RS-232C communication.

1 Safety Instructions

These safety instructions are intended to prevent hazardous situations

and/or equipment damage. These instructions indicate the level of

potential hazard with the labels of “Caution,” “Warning” or “Danger.”

They are all important notes for safety and must be followed in addition

to International Standards (ISO/IEC)*1), and other safety regulations.

*1) ISO 4414: Pneumatic fluid power - General rules relating to systems.

ISO 4413: Hydraulic fluid power - General rules relating to systems.

IEC 60204-1: Safety of machinery - Electrical equipment of machines.

(Part 1: General requirements)

ISO 10218-1: Robots and robotic devices - Safety requirements for

industrial robots - Part 1: Robots.

Refer to product catalogue, Operation Manual and Handling

Precautions for SMC Products for additional information.

Keep this manual in a safe place for future reference.

Caution indicates a hazard with a low level of risk which, if

not avoided, could result in minor or moderate injury.

Warning indicates a hazard with a medium level of risk

which, if not avoided, could result in death or serious injury.

Danger indicates a hazard with a high level of risk which, if

not avoided, will result in death or serious injury.

Warning

Always ensure compliance with relevant safety laws and

standards.

All work must be carried out in a safe manner by a qualified person in

compliance with applicable national regulations.

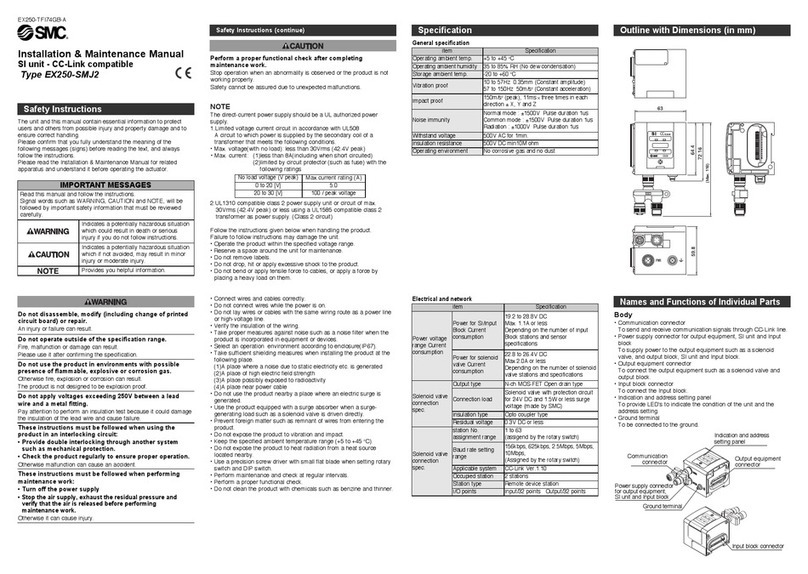

This product is class A equipment intended for use in an industrial

environment. There may be potential difficulties in ensuring

electromagnetic compatibility in other environments due to conducted

or radiated disturbances.

Caution

Ensure that the air supply system is filtered to 5 microns.

Refer to the SMC website (URL: https//www.smcworld.com) for more

information about Safety Instructions.

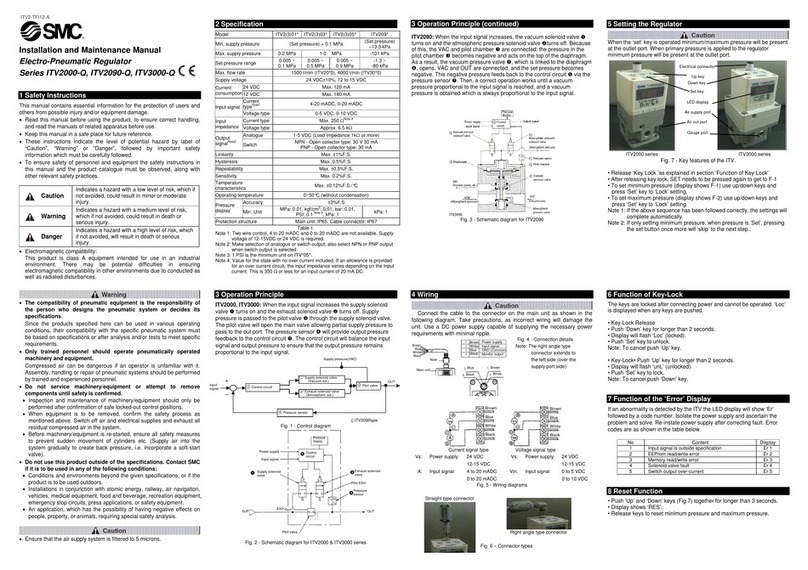

2 Specifications

2.1 General specifications

10 bit / 10 bit

(data 1023 corresponds to 100% F.S.)

Temperature

characteristics

Ambient and fluid

temperature

0 to 50°C (no condensation)

Note 1) Excluding current consumption of communication line for PROFIBUS DP.

2.2 Size / Weight specifications

2.3 Communication specifications

Warning

Special products (-X) might have specifications different from those

shown in this section. Contact SMC for specific drawings.

3 Installation

3.1 Installation Warning

Do not install the product unless the safety instructions have been read

and understood.

This product is pre-set at the factory and must not be dismantled by

the user. Contact your local SMC office for advice.

Ensure, when installing this product, that it is kept clear of power lines

to avoid noise interference.

Ensure that load surge protection is fitted when inductive loads are

present (i.e. solenoid, relay etc.).

3.2 Environment Warning

Do not use in an environment where corrosive gases, chemicals, salt

water or steam are present.

Do not use in an explosive atmosphere.

Do not expose to direct sunlight. Use a suitable protective cover.

Do not install in a location subject to vibration or impact. Check the

product specifications.

Do not mount in a location exposed to radiant heat.

3.3 Piping Caution

Before piping make sure to clean up chips, cutting oil, dust etc.

When installing piping or fittings, ensure sealant material does not

enter inside the port. When using seal tape, leave 1 thread exposed

on the end of the pipe/fitting.

Tighten fittings to the specified tightening torque.

3.4 Lubrication Caution

Do not use a lubricator on the input side of this product. If lubrication

is required, place the lubricator on the ‘output’ side so that it does not

enter the product.

SMC products have been lubricated for life at manufacture, and do not

require lubrication in service.

If a lubricant is to be used in the system, refer to the catalogue for

details.

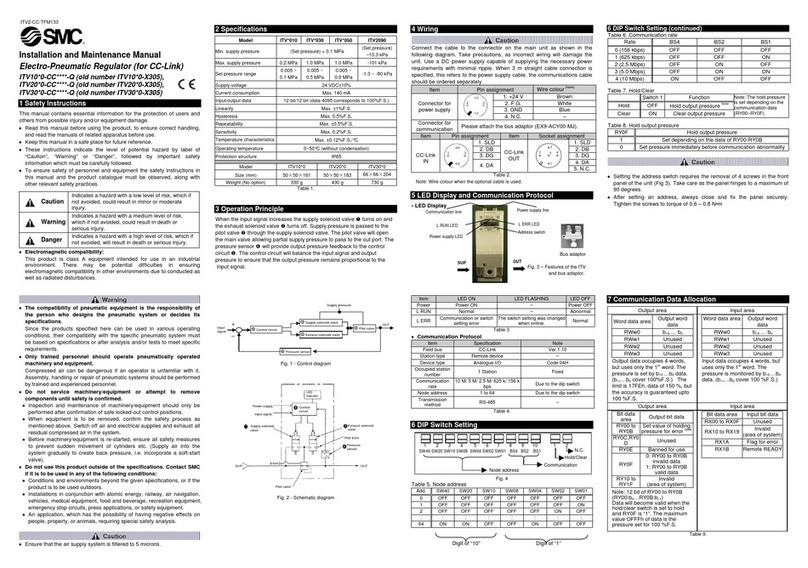

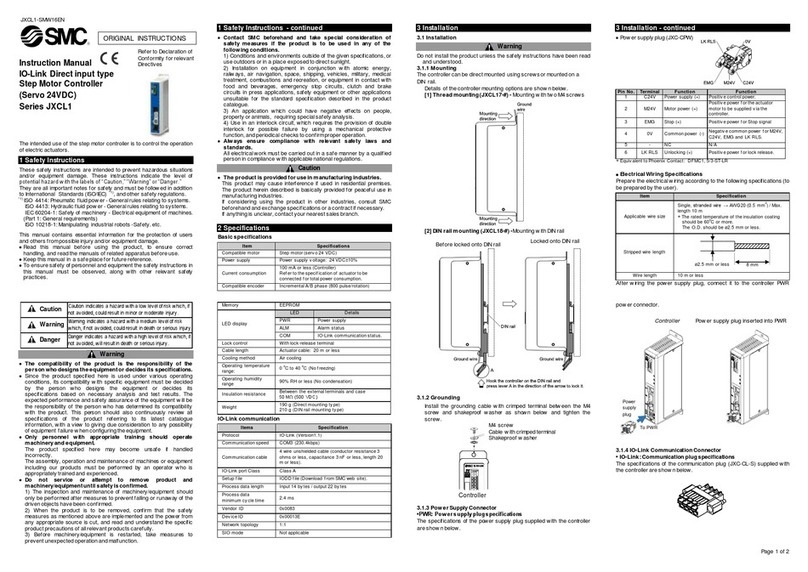

4 Wiring

Caution

Connect the cable to the connector on the main unit as shown in the

following diagram. Take precautions, as incorrect wiring will damage the

unit. Use a DC power supply capable of supplying the necessary power

requirements with minimal ripple.

The 3 m straight cable specified refers to the power supply cable. The

communication cable should be ordered separately.

4.1 Power supply connector

Connector for

power supply

4.2 Communication connector

Connector for

communication

Note: Wire colours shown are when the optional cable is used.

S type: P398020-500-3, -502-3. L type: P398020-501-3, -503-3.

5 LED Display

Waiting for Input / error

6 Pressure Setting and Output Monitoring

Set Output Pressure

Set output

pressure

(0 - 1023)

Note) nn is limited to integral values from 0 to 1023.

Increase setting for output pressure

Adds 2 to the set data

of output pressure

Indicates the

set data plus 2

Note) When set data nn is >= 1021, the value is set as nn=1023.

Decrease setting for output pressure

Subtracts 2 from the

output pressure set

data.

Indicates the set

data minus 2

Note) When set data nn is <= 2, the value is set as nn=0.

Request for set data

Request of output pressure data

Request for output

pressure data

Displays output

pressure data

Pressure setting can be done by sending input data using 10 bit as F.S.

to the electro-pneumatic regulator through the master PLC.

Ex.) To set pressure at 0.3 MPa with ITV2030 (for 0.5 MPa type)

(0.3 MPa / 0.5 MPa) × 1023 = 614DEC

A pressure of 0.3 MPa is set by sending input data of “614” to the electro-

pneumatic regulator through the master PLC. Send "SET 614".

Pressure

100%

75%

50%

25%

0%

0 256 512 767 1023 (DEC)

Input data