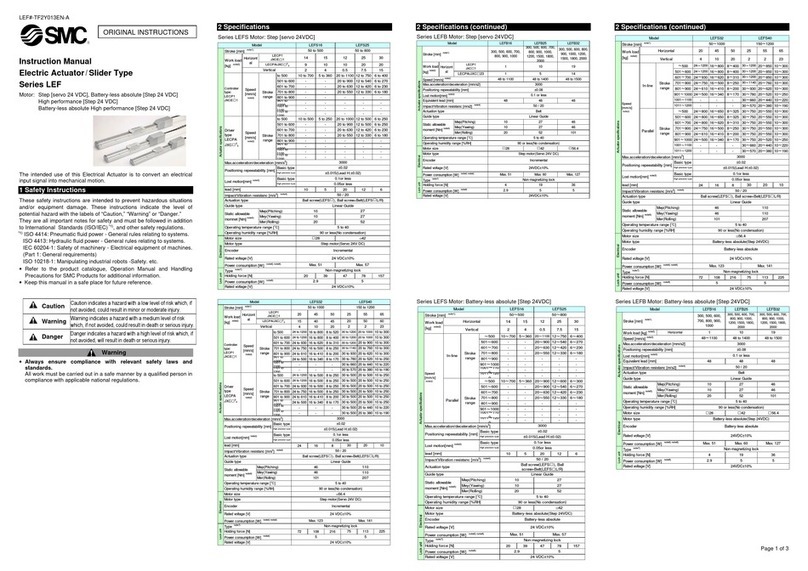

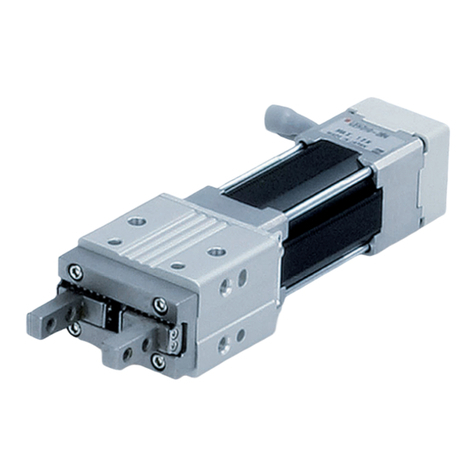

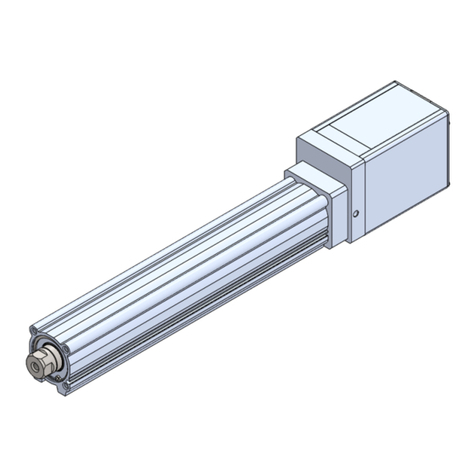

SMC Networks LEG Series User manual

Other SMC Networks Controllers manuals

SMC Networks

SMC Networks JXCP1 User manual

SMC Networks

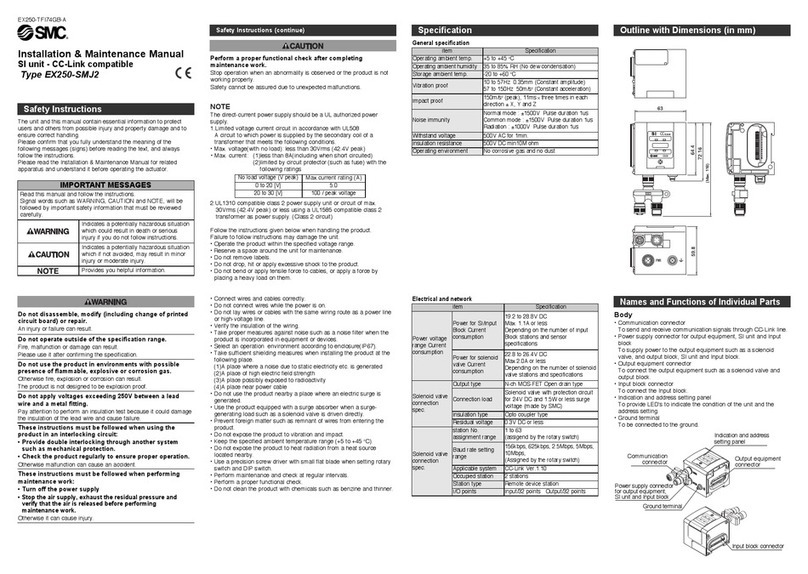

SMC Networks EX250-SMJ2 Instruction Manual

SMC Networks

SMC Networks RS2H Series User manual

SMC Networks

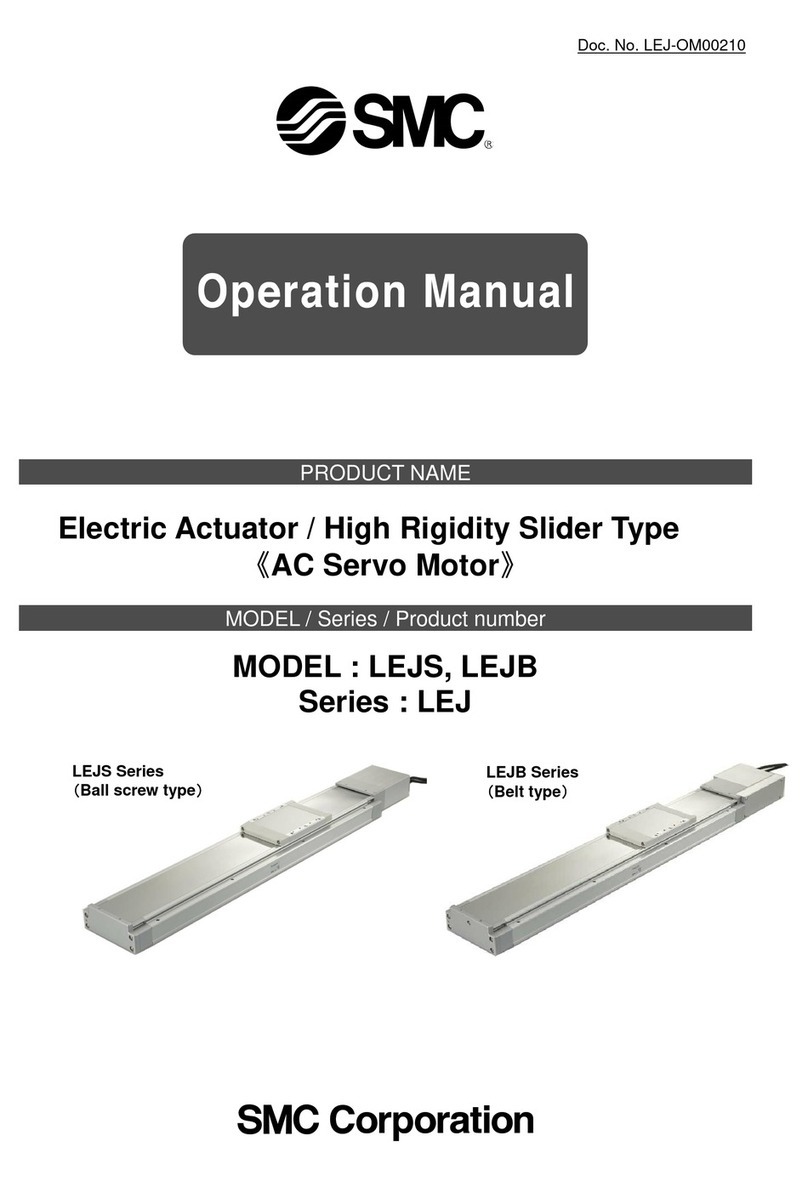

SMC Networks LEJ Series User manual

SMC Networks

SMC Networks ITV1000-DE Series User manual

SMC Networks

SMC Networks AWM20-01 Series User manual

SMC Networks

SMC Networks LECP1 Series User manual

SMC Networks

SMC Networks LEYG User manual

SMC Networks

SMC Networks IN502-44 Series User manual

SMC Networks

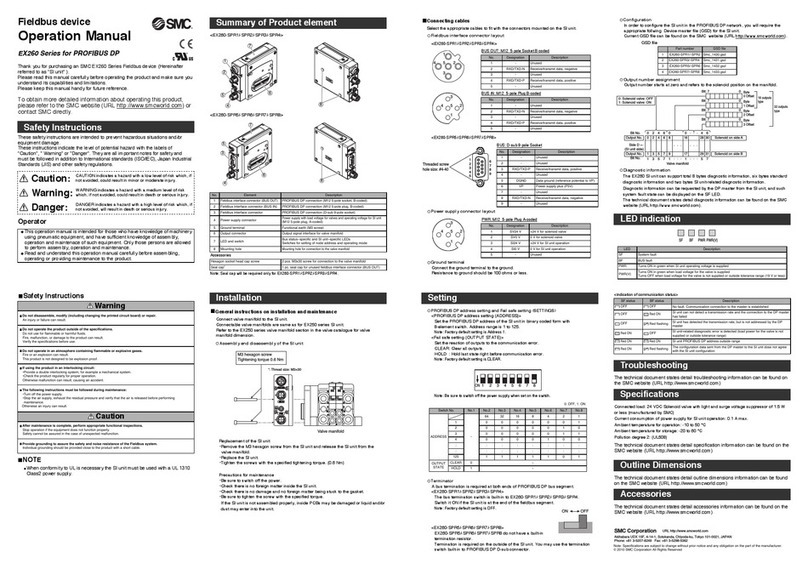

SMC Networks EX260-SPR1 User manual

SMC Networks

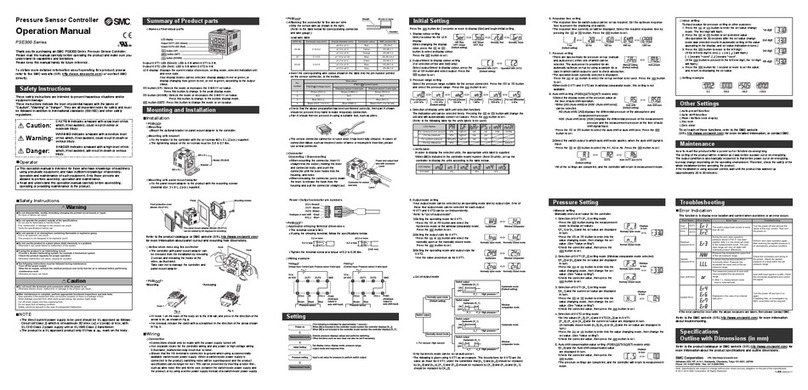

SMC Networks PSE300 Series User manual

SMC Networks

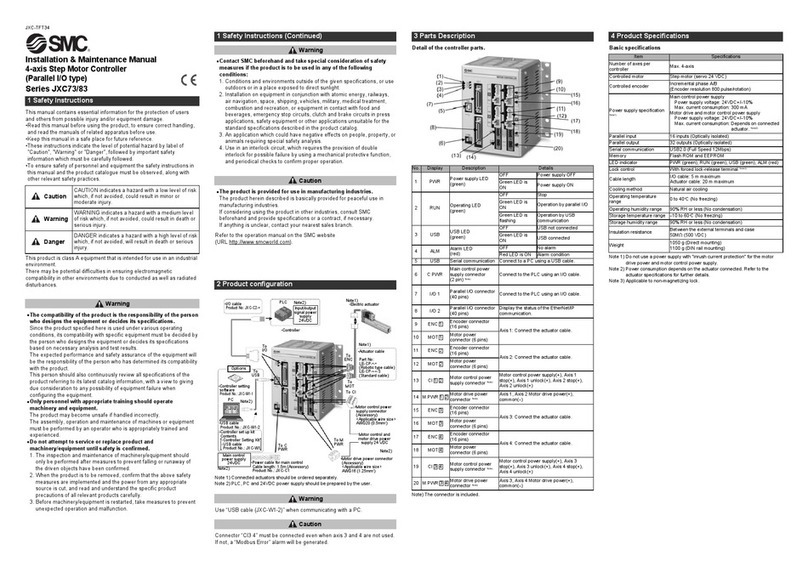

SMC Networks JX73 Series Manual

SMC Networks

SMC Networks PSE300 Series User manual

SMC Networks

SMC Networks JXCM1 User manual

SMC Networks

SMC Networks PFCQ531 Series User manual

SMC Networks

SMC Networks CRA1 Series User manual

SMC Networks

SMC Networks THERMO-CON HEC001 Series Use and care manual

SMC Networks

SMC Networks LEH Series User manual

SMC Networks

SMC Networks EQY Series User manual

SMC Networks

SMC Networks IR2000 Series User manual

Popular Controllers manuals by other brands

Digiplex

Digiplex DGP-848 Programming guide

YASKAWA

YASKAWA SGM series user manual

Sinope

Sinope Calypso RM3500ZB installation guide

Isimet

Isimet DLA Series Style 2 Installation, Operations, Start-up and Maintenance Instructions

LSIS

LSIS sv-ip5a user manual

Airflow

Airflow Uno hab Installation and operating instructions