LEF#-TF2Y013EN-A

Page 2 of 3

2 Specifications (continued)

Series LEFS, Motor: High performance [Step 24VDC]

2 Specifications (continued)

Series LEFS

Motor: Battery-less absolute High performance [Step 24VDC]

2 Specifications (continued)

note1) Please consult with SMC for non-standard strokes produced to special order.

note2) Speed changes according to the work load. Check “Speed-Work Load Graph

(Guide)” in the catalogue. Furthermore, if the cable length exceeds 5m, then it

will decrease by up to 10% for each 5m.

note3) A reference value for correcting an error in reciprocal operation.

note4) Impact resistance: No malfunction occurred when the actuator was tested

with a drop tester in both axial and perpendicular direction to the lead screw

(the test was performed with the actuator in the initialized state).

Vibration resistance: No malfunction occurred in a test ranging between 45 to

2000 Hz, when the actuator was tested in both an axial and perpendicular

direction to the lead screw. (The test was performed with the actuator in the

initialized state).

note5) Static allowable moment is static moment when the actuator is stopped.

When impact is applied or repeated load is applied, please use the actuator

with sufficient safety.

note6) It is max.power consumption (including the controller) when the actuator is

operating. This value can be used for the power supply selection.

note7) For models including lock only.

note8) For an actuator with lock, add the power consumption for the lock.

note9) Maximum work load at 3000 mm/s

2

acceleration and deceleration speed.

(Values with * indicate the maximum work load at 1000 mm/s

2

acceleration and

deceleration speed). The work load varies depending on the speed and

acceleration. Check the “Speed-Work Load Graph (Guide)” in the catalogue.

Furthermore, if the cable length exceeds 5 m then the speed and work load

may decrease by up to 10% for each 5 m (at 15 m it is reduced by up to 20%).

Actuator weight

Series LEF

(without Series LEFS Motor: High performance [Step 24VDC],

Battery-less absolute High performance [Step 24VDC])

Series LEFS Motor: High performance [Step 24VDC],

Battery-less absolute High performance [Step 24VDC]

Warning

For special products, which include a suffix of “-X#”, “-D#”, then please

refer to the customer drawing of that specific product.

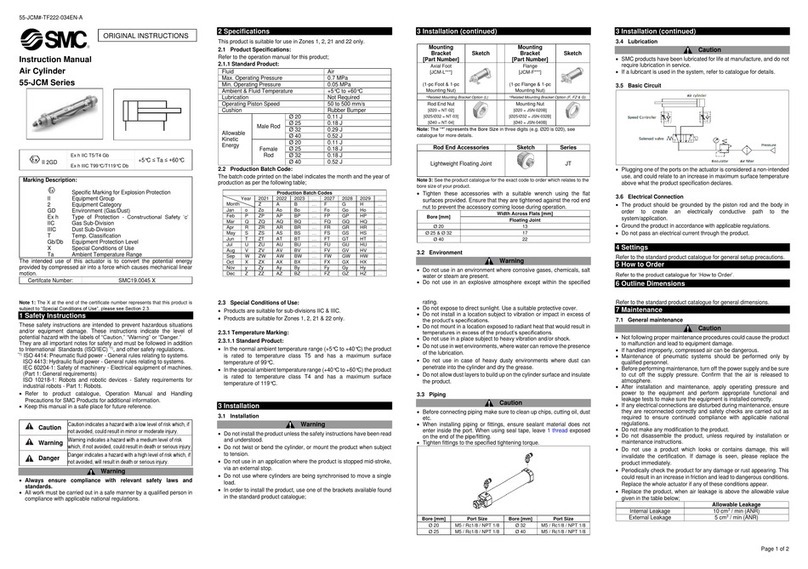

3 Installation

3.1 Installation

Warning

•Do not install the product unless the safety instructions have been read

and understood.

•Do not use the product in excess of its allowable specification.

•When installing, inspecting or performing maintenance on the product,

be sure to turn off the power supplies. Then, lock it so it cannot be

tampered with while work is happening.

Keep the flatness of the mounting surface to 0.1 mm maximum per

500mm. Insufficient flatness of a work piece or actuator mounting

surface can cause play in the guide and increased sliding resistance.

In the case of overhang mounting (including cantilever), use a support

plate or support guide to avoid deflection of the actuator body.

•When mounting the actuator, use all mounting holes.

If all mounting holes are not used, this will not maintain the specified

performance. e.g. the amount of displacement of the table will increase.

•When mounting the actuator leave a space of 40 mm or more to allow

for bending of the actuator cable.

•When mounting the actuator, use screws with adequate length and

tighten them with adequate torque.

Tightening the screws with a torque higher than recommended may

cause malfunction, whilst tightening with a torque lower than

recommended can cause displacement of the mounting position, or the

actuator could become detached from its mounting position.

Model Screw

size

Max. tightening

torque [N・m] ∅A [mm] L [mm]

LEF□16

M3 0.6 3.5 20

LEF□25 M4 1.5 4.5 24

LEF□32 M5 3.0 5.5 30

LEF□40

M6 5.2 6.6 31

Work piece Mounting

•In order to prevent the work piece fixing screws from damaging the

table, use screws at least 0.5 mm shorter than the maximum thread

depth. Longer screws can hit the body and cause operation failure.

Actuator Mounting

Model Screw

size

Max. tightening

torque [N・m]

L Max. thread

depth[mm]

LEF□16

M4 x 0.7 1.5 6

LEF□25 M5 x 0.8 3.0 8

LEF□32 M6 x 1.0 5.2 9

LEF□40 M8 x 1.25 12.5 14

Horizontal 14 20 16 28 * 40

Vertical 3 6 3 7.5 15

Up to 400 10 to 800 5 to 400 20 to 1500 12 to 900 6 to 500

401 to 500 10 to 700 5 to 360 20 to 1100 12 to 750 6 to 400

501 to 600 - - 20 to 900 12 to 540 6 to 270

601 to 700 - - 20 to 630 12 to 420 6 to 230

701 to 800 - - 20 to 550 12 to 330 6 to 180

801 to 900 - - - - -

901 to 1000 - - - - -

1001 to 1100 - - - - -

1101 to 1200 - - - - -

Horizontal

Vertical

Basic type

High precision

Basic type

High precision

10 5 20 12 6

Mep(Pitching)

Mey(Yawing)

Mer(Rolling)

20 39 47 78 157

Rated Voltage [V]

Actuator specificationsElectrical

allowable

moment

note5)

10

10

20

Max. 102

Motor size

0.1 or less

0.05 or less

50 / 20

Motor type

Encoder

□28

Max. 132

Lock nut

Type

note7)

Holding force [N]

Power consumption [W]

note8)

2.9

Non magnetizing lock

5

Rated voltage [V] 24VDC ±10%

□42

Ball screw

Linear guide

5 to 40

90 or less(No condensation)

Step motor(Servo 24VDC)

24VDC ±10%

Incremental

acceleration/

deceleration

2

10000

5000

±0.02

±0.015(Lead H:±0.02)

Operating temperature range

27

27

52

Lead [mm]

Impact/Vibration resistance

[m/s

2

]

note4)

Actuation type

Model LEFS16 LEFS25

Stroke [mm]

note1)

50 to 500 50 to 800

Guide type

Positioning

repeatability

[mm]

Lost motion

[mm]

note3)

Work load

[kg]

note9)

Speed

[mm/s

]

Strok

e

range

Horizontal 40 50 68 26 60 * 75

Vertical 4 12 18 4.5 4.5 25

Up to 400 24 to 1300 16 to 1000 8 to 520 30 to 1200 20 to 1000 10 to 500

401 to 500 24 to 1300 16 to 950 8 to 520 30 to 1200 20 to 1000 10 to 500

501 to 600 24 to 1200 16 to 800 8 to 400 30 to 1200 20 to 1000 10 to 500

601 to 700 24 to 930 16 to 620 8 to 310 30 to 1200 20 to 900 10 to 440

701 to 800 24 to 750 16 to 500 8 to 250 30 to 1140 20 to 760 10 to 350

801 to 900 24 to 610 16 to 410 8 to 200 30 to 930 20 to 620 10 to 280

901 to 1000 24 to 500 16 to 340 8 to 170 30 to 780 20 to 520 10 to 250

1001 to 1100 - - - 30 to 660 20 to 440 10 to 220

1101 to 1200 - - - 30 to 570 20 to 380 10 to 190

Horizontal

Vertical

Basic type

High precision

Basic type

High precision

24 16 8 30 20 10

Mep(Pitching)

Mey(Yawing)

Mer(Rolling)

72 108 216 75 113 225

Step motor(Servo 24VDC)

46

46

101

110

110

207

Ball screw

Linear guide

5 to 40

90 or less(No condensation)

□56.4

±0.02

±0.015(Lead H:±0.02)

0.1 or less

0.05 or less

50 / 20

24VDC ±10%

Lock nut

Type

note7)

Holding force [N]

Power consumption [W]

note8)

5 5

Rated voltage [V]

Non magnetizing lock

Guide type

Actuator specifications

note8)

Max. 158 Max. 202

Strok

e

range

Rated Voltage [V]

Operating temperature range

[℃]

[%RH]

Motor size

Motor type

Encoder Incremental

24VDC ±10%

10000

5000

Electrical

LEFS32 LEFS40

Stroke [mm]

note1)

Lead [mm]

Impact/Vibration resistance

2

note4)

Positioning

repeatability

[mm]

Lost motion

[mm]

note3)

50 to 1000 150 to 1200

Work load

[kg]

note9)

Speed

[mm/s

]

Static

allowable

moment

[Nm]

note5)

Max.

acceleration/

deceleration

[mm/s

2

]

Model

Actuation type

Model

Stroke(mm)

50 100 150 200 250 300 350 400 450 500

Weight(kg)

0.83 0.9 0.98 1.05 1.13 1.2 1.28 1 .35 1.43 1.5

Additional w eight f or lock(kg)

Model

Stroke(mm)

50 100 15 0 200 250 30 0 350 400 45 0 500 550 60 0 650 700 750 800

Weight(kg)

1.70 1.84 1.98 2.12 2.26 2.40 2.54 2.68 2.82 2.96 3.10 3.24 3.38 3.52 3.66 3.80

Additional w eight f or lock(kg)

Model

Stroke(mm)

50 100 15 0 200 250 30 0 350 400 45 0 500 550 60 0 650 700 750 800 850 900 950 1000

Weight(kg)

3.15 3.35 3.55 3.75 3.95 4.15 4.35 4.55 4.75 4.95 5.15 5.35 5.55 5.75 5.95 6.15 6.35 6.55 6.75 6.95

Additional w eight f or lock(kg)

Model

Stroke(mm)

150 200 25 0 300 350 40 0 450 500 55 0 600 650 70 0 750 800 850 900 950 1000 1100 1200

Weight(kg)

5.37 5.65 5.93 6.21 6.49 6.77 7.15 7.33 7.61 7.89 8.17 8.45 8.73 9.01 9.29 9.57 9.85 10.13 10.69 11.25

Additional w eight f or lock(kg)

LEFS40

0.53

LEFS16

0.12

LEFS32

0.53

LEFS25

0.26

Model

Stroke(mm) 300 500 600 700 800 900 1000

Weight(kg) 1.19 1.45 1.58 1.71 1.84 1.97 2 .10

Additional weight for lock(kg)

Model

Stroke(mm) 300 500 600 700 800 900 1000 1200 1500 1800 2000

Weight(kg) 2.39 2.85 3.08 3.31 3.54 3.77 4 .00 4.46 5.15 5.84 6.30

Additional weight for lock(kg)

Model

Stroke(mm) 300 500 600 700 800 900 1000 1200 1500 1800 2000

Weight(kg) 4.12 4.80 5.14 5.48 5.82 6.16 6 .50 7.18 8.20 9.22 9.90

Additional weight for lock(kg)

LEFB16

0.12

LEFB25

0.26

LEFB32

0.53

Model

Stroke(mm)

50 100 150 200 250 300 350 400 450 500

Weight(kg)

0.85 0.92 1 1.07 1 .15 1.22 1.3 1.37 1.45 1.52

Additional w eight f or lock(kg)

Model

Stroke(mm)

50 100 15 0 200 250 30 0 350 400 450 500 550 600 650 700 750 800

Weight(kg)

1.70 1.8 4 1.98 2.12 2.26 2.40 2.54 2.68 2.82 2.96 3.10 3.24 3.38 3.52 3.66 3.80

Additional w eight f or lock(kg)

Model

Stroke(mm)

50 100 15 0 200 250 30 0 350 400 450 500 550 600 650 700 750 800 850 900 950 1000

Weight(kg)

3.15 3.3 5 3.55 3.75 3.95 4.15 4.35 4.55 4.75 4.95 5.15 5.35 5.55 5.75 5.95 6.15 6.35 6.55 6.75 6.95

Additional w eight f or lock(kg)

Model

Stroke(mm)

150 200 250 300 350 400 450 500 550 600 650 700 750 800 850 900 950 1000 1100 1200

Weight(kg)

5.37 5.6 5 5.93 6.21 6.49 6.77 7.15 7.33 7.61 7.89 8.17 8.45 8.73 9.01 9.29 9.57 9.85 10.13 10.69 11.25

Additional w eight f or lock(kg)

LEFS40

0.53

LEFS16

0.12

LEFS25

0.26

LEFS32

0.53

Horizontal 6 15 15 28 40

Vertical 3 6 3 7.5 15

Up to 400 10 to 800 5 to 400 20 to 1500 12 to 900 6 to 500

401 to 450 10 to 700 5 to 360 20 to 1100 12 to 750 6 to 400

451 to 500 10 to 600 5 to 300 20 to 1100 12 to 750 6 to 400

501 to 600 - - 20 to 900 12 to 540 6 to 270

601 to 700 - - 20 to 630 12 to 420 6 to 230

701 to 800 - - 20 to 550 12 to 330 6 to 180

801 to 900 - - - - -

901 to 1000 - - - - -

1001 to 1100 - - - - -

1101 to 1200 - - - - -

Horizontal

Vertical

Basic type

Basic type

High precision

type

10 5 20 12 6

Mep(Pitching)

Mey(Yawing)

Mer(Rolling)

20 39 47 78 157

Rated Voltage [V]

Actuator specificationsElectrical

allowable

moment

note5)

10

10

20

note8)

Max. 116

Motor size

0.1 or less

0.05 or less

50 / 20

Motor type

Encoder

□28

Max. 126

Lock nut

Type

note7)

Holding force [N]

Power consumption [W]

note8)

2.9

Non magnetizing lock

5

Rated voltage [V] 24VDC ±10%

□42

Ball screw(LEFS□), Ball screw+Belt(LEFS□L/R)

Linear guide

5 to 40

90 or less(No condensation)

Battery-less absolute(Step 24VDC)

24VDC ±10%

Battery-less absolute

acceleration/

deceleration

2

10000

5000

±0.02

±0.015(Lead H:±0.02)

Operating temperature range

27

27

52

Lead [mm]

Impact/Vibration resistance

[m/s

2

]

note4)

Actuation type

Model LEFS16 LEFS25

Stroke [mm]

note1)

50 to 500 50 to 800

Guide type

Positioning

repeatability

[mm]

Lost motion

[mm]

note3)

Work load

[kg]

note9)

Speed

[mm/s

]

Strok

e

range

Horizontal 40 50 68 26 60 75

Vertical 4 10 18 4.5 4.5 25

Up to 400 24 to 1300 16 to 1000 8 to 500 30 to 1200 20 to 1000 10 to 500

401 to 500 24 to 1300 16 to 950 8 to 500 30 to 1200 20 to 1000 10 to 500

501 to 600 24 to 1200 16 to 800 8 to 400 30 to 1200 20 to 1000 10 to 500

601 to 700 24 to 930 16 to 620 8 to 310 30 to 1200 20 to 900 10 to 440

701 to 800 24 to 750 16 to 500 8 to 250 30 to 1140 20 to 760 10 to 350

801 to 900 24 to 610 16 to 410 8 to 200 30 to 930 20 to 620 10 to 280

901 to 1000 24 to 500 16 to 340 8 to 170 30 to 780 20 to 520 10 to 250

1001 to 1100 - - - 30 to 660 20 to 440 10 to 220

1101 to 1200 - - - 30 to 570 20 to 380 10 to 190

Horizontal

Vertical

Basic type

High precision

Basic type

High precision

24 16 8 30 20 10

Mep(Pitching)

Mey(Yawing)

Mer(Rolling)

72 108 216 75 113 245

Electrical

LEFS32 LEFS40

Stroke [mm] note1)

Lead [mm]

Impact/Vibration resistance

[m/s2]note4)

Positioning

repeatability

[mm]

Lost motion

[mm] note3)

50 to 1000 150 to 1200

Work load

[kg] note9)

Speed

[mm/s

]

allowable

moment

note5)

acceleration/

deceleration

2

Model

Actuation type

Guide type

Actuator specifications

Max. 222 Max. 222

Strok

e

range

Rated Voltage [V]

Operating temperature range

Motor size

Motor type

Encoder Battery-less absolute

24VDC ±10%

10000

5000

24VDC ±10%

Lock nut

Type note7)

Holding force [N]

Power consumption [W] note8) 5 5

Rated voltage [V]

Non magnetizing lock

±0.02

±0.015(Lead H:±0.02)

0.1 or less

0.05 or less

50 / 20

Ball screw(LEFS□), Ball screw+Belt(LEFS□L/R)

Linear guide

5 to 40

90 or less(No condensation)

□56.4

Battery-less absolute(Step 24VDC)

46

46

101

110

110

207