55-C55*-SMX55EN

Page 1 of 2

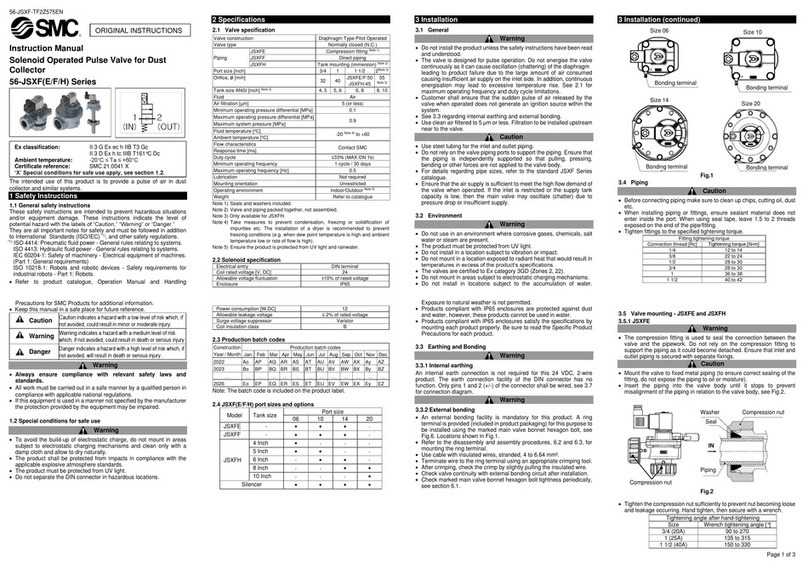

Instruction Manual

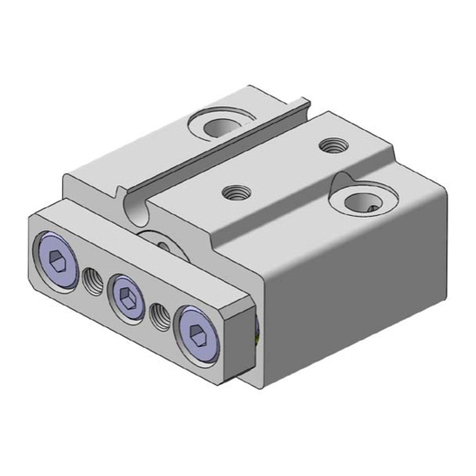

Compact Cylinder ISO Standard

55-C55 Series

Ex h IIIC T84°C/T104°C Db

Product marking shown above is for the standard product.

ATEX Marking Description:

Specific Marking for Explosion Protection

II Equipment Group

2 Equipment Category

GD Environment (Gas/Dust)

Ex h General Protection Level Symbols

IIC Gas Sub-Division

IIIC Dust Sub-Division

T Temp. Classification

Gb/Db Equipment Protection Level

X Special Conditions of Use

Ta Ambient Temperature Range

The intended use of an actuator is to convert the potential energy

provided by compressed air into a force which causes mechanical linear

motion.

Note 1: The X at the end of the certificate number represents that this

product is subject to “Special Conditions of Use”, please see Section 2.3.

1 Safety Instructions

These safety instructions are intended to prevent hazardous situations

and/or equipment damage. These instructions indicate the level of

potential hazard with the labels of “Caution,” “Warning” or “Danger.”

They are all important notes for safety and must be followed in addition

to International Standards (ISO/IEC)*1), and other safety regulations.

*1) ISO 4414: Pneumatic fluid power - General rules relating to systems.

ISO 4413: Hydraulic fluid power - General rules relating to systems.

IEC 60204-1: Safety of machinery - Electrical equipment of machines.

(Part 1: General requirements)

ISO 10218-1: Manipulating industrial robots -Safety. etc.

•Refer to product catalogue, Operation Manual and Handling

Precautions for SMC Products for additional information.

•Keep this manual in a safe place for future reference.

Caution indicates a hazard with a low level of risk which, if

not avoided, could result in minor or moderate injury.

Warning indicates a hazard with a medium level of risk

which, if not avoided, could result in death or serious injury.

Danger indicates a hazard with a high level of risk which, if

not avoided, will result in death or serious injury.

Warning

•Always ensure compliance with relevant safety laws and

standards.

•All work must be carried out in a safe manner by a qualified person in

compliance with applicable national regulations.

2 Specifications

This product is certified to ATEX Category 2GD and therefore is

suitable for use in Zones 1, 2, 21 and 22 only.

2.1 Product Specifications:

Refer to the operation manual for this product;

2.1.1 Standard Product:

Ambient & Fluid Temperature

2.2 Production Batch Code:

The batch code printed on the label indicates the month and the year of

production as per the following table;

2.3 Special Conditions of Use:

•Products are suitable for sub-divisions IIC & IIIC.

•Products are suitable for Zones 1, 2, 21 & 22 only.

2.3.1 Temperature Marking:

2.3.1.1 Standard Product:

•In the normal ambient temperature range (-10°C to +40°C)the product

is rated to temperature class T6 and has a maximum surface

temperature of 84°C.

•In the special ambient temperaturerange (+40°C to +60°C) the product

is rated to temperature class T4 and has a maximum surface

temperature of 104°C.

3 Installation

3.1 Installation Warning

•Do not install the product unless the safety instructions have been read

and understood.

•Do not twist or bend the cylinder, or mount the product when subject

to tension.

•Do not use in an application where the product is stopped mid-stroke,

via an external stop.

•Do not use where cylinders are being synchronised to move a single

load.

•In order to install the product, use one of the brackets available found

in the standard product catalogue;

Mounting

Bracket

[Part Number]

Mounting

Bracket

[Part Number]

Rod Side Flange

[C55-Fxxx]

Head Side Flange

[C55-Fxxx]

Note 2: The “xxx” represents the Bore Size (e.g. Ø40 is 040), see catalogue for

more details.

•When replacing brackets use the hexagon wrench and torques shown

below;

Note 3: “*” is dependent on the stroke of the product, see catalogue for details.

3.2 Environment Warning

•Do not use in an environment where corrosive gases, chemicals,

water, salt water or steam are present.

•Do not use in an explosive atmosphere except within the specified

rating.

•Do not expose to direct sunlight. Use a suitable protective cover.

•Do not install in a location subject to vibration or impact in excess of

the product’s specifications.

•Do not use in a place subject to heavy vibration and/or shock.

•Do not usein wet environments, where water can remove thepresence

of the lubrication.

•Do not use in case of heavy dusty environments where dust can

penetrate into the cylinder and dry the grease.

•Do not allow dust layers to build up on the cylinder surface and insulate

the product.

3.3 Piping Caution

•Before connecting piping make sure to clean up chips, cutting oil, dust

etc.

•When installing piping or fittings, ensure sealant material does not

enter inside the port. When using seal tape, leave 1 thread exposed

on the end of the pipe/fitting.

•Tighten fittings to the specified tightening torque.

3.4 Lubrication Caution

•SMC products have been lubricated for life at manufacture, and do not

require lubrication in service.

•If a lubricant is used in the system, refer to catalogue for details.

3.5 Basic Circuit

•Plugging one of the ports on the actuator is considered a non-intended

use, and could relate to an increase in maximum surface temperature

above what the product specification declares.

3.6 Electrical Connection

•The product should be grounded by the piston rod and the body in

order to create an electrically conductive path to the

system/application.

•Ground the product in accordance with applicable regulations.

•Do not pass an electrical current through the product.

4 Settings

•Refer to the operation manual of the C55 series products.

5 How to Order

Refer to the standard product catalogue for ‘How to Order’.

6 Outline Dimensions (mm)

Refer to the standard product catalogue for general dimensions.

7 Maintenance

7.1 General Maintenance

Caution

•Not following proper maintenance procedures could cause the product

to malfunction and lead to equipment damage.

•If handled improperly, compressed air can be dangerous.

•Maintenance of pneumatic systems should be performed only by

qualified personnel.

•Before performing maintenance, turn off the power supply and be sure

to cut off the supply pressure. Confirm that the air is released to

atmosphere.

•After installation and maintenance, apply operating pressure and

power to the equipment and perform appropriate functional and

leakage tests to make sure the equipment is installed correctly.

•If any electricalconnections are disturbed during maintenance, ensure

they are reconnected correctly and safety checks are carried out as

required to ensure continued compliance with applicable national

regulations.

•Do not make any modification to the product.

•Do not disassemble the product, unless required by installation or

maintenance instructions.

•Do not use a product which looks or contains damage, this will

invalidate the certification. If damage is seen, please replace the

product immediately.

•Periodically check the product for any damage or rust appearing. This

could result in an increase in friction and lead to dangerous conditions.

Replace the whole actuator if any of these conditions appear.

•Periodically check the condition of the rod seal and forthe presence of

lubrication, where possible. If these areas appear to be dry, please

follow the lubrication procedure.

•Replace theseals, when air leakage is above the allowable value given

in the table below;

Refer to Declaration of

Conformity for relevant

Directives