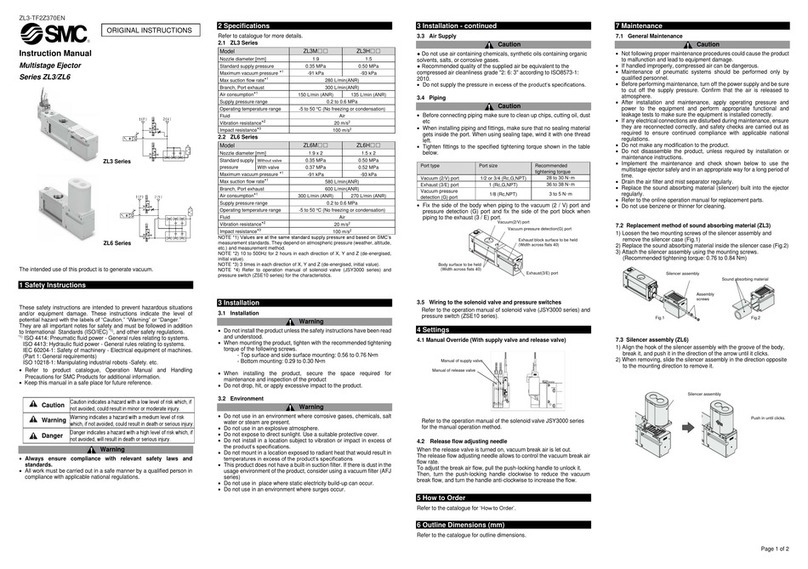

Mounting

Noise Counter Measures

Caution

Sensor Unit

Handling of Technical Material

Effects of Noise

23 m∗

Operating Environment

Use in an environment where liquid (water, oil, coolant, etc.)

splashes on the product may result in a malfunction; therefore, if

using in such an environment, be sure to take measures such as

installing a waterproof, dust-proof cover, etc. (CE1)

ø12

ø20 to ø32

ø40 to ø63

Bore size

Allowable

rotational torque

10 N· m

20 N· m

30 N· m

1. When screwing a nut or fitting, etc. onto the threaded section at

the end of the piston rod, return the piston rod to its fully

retracted position, and grasp the exposed portion of the rod

across two parallel sides with a wrench. In the case of the high

precision stroke reading cylinder, there are no parallel sides.

Secure the workpiece with a double nut.

Note) Do not apply rotational torque to the piston rod.

2. Operate the cylinder in such a way that the load is always

applied in the axial direction.

• In case the load is applied in a direction other than the axial

direction of the cylinder, provide a guide to constrain the load

itself.

• When mounting a cylinder, centering should be done carefully.

3. Avoid using the air cylinder in such a way that rotational torque

would be applied to the piston rod.

4. Be careful to avoid scratches or dents, etc. on the sliding

sections of the piston rod.

1.

The sensor unit is adjusted to an appropriate position at the time of

shipment. Therefore, never detach the sensor unit from the body.

2. The sensor cable should not be pulled with a strong force.

3. Since the sensor for stroke reading cylinder adopts the magnetic

method, it may result in malfunction if there is a strong magnetic

field around the sensor. Use it under the external magnetic field

with 14.5 mT or less.

This is equivalent to a magnetic field of approximately 18 cm in radius from a

welding area using a welding amperage of almost 15,000 amperes. To use

the system in a magnetic field that exceeds this value, use a magnetic

material to shield the sensor unit.

4. Switches or relays, etc. should not be installed in the power

supply line (12 to 24 VDC).

∗When using SMC extension cable and counter.

Stroke reading cylinder

Multi counter CEU5

When the stroke reading cylinder is used near a motor, welding

machine or other source of noise generation, there is a possibility of

miscounting. In this case, noise should be suppressed as much as

possible and the following countermeasure should be taken.

1. Connect the shield wire to FG (flame ground).

2. The maximum transmission distance for the stroke reading

cylinder is 23 m, but since the output signal is a pulse output, the

sensor cable should be wired separately from other power lines.

1. Connect only the shield wire to FG (frame ground).

2. Use a power source separate from large motors and AC valves,

etc.

3. Run the stroke reading cylinder’s cable away from other power

lines.

4. Install a noise filter in the 100 VAC power line, a varistor in the

DC power supply of the sensor cable and a ferritic core in the

signal line (sensor cable).

Methods of dealing with noise are given below.

Earth ground

White

Blue

Yellow

Brown

Red

Black

F.G.

Reference

Varistor: ERZV10D220

(Made by Panasonic Corporation)

Noise filter: RSEL-2003W, etc.

(Made by TDK-Lambda Corporation)

Ferritic core: GRFC-10, etc.

(Manufactured by KITAGAWA

INDUSTRIES CO., LTD.)

If sources of noise generation

(motors, AC type valves,

relays, etc.) are connected on

the secondary side of the

noise filter, the filter will have

no effect.

<Counting speed of counter>

When the speed of the stroke reading cylinder is greater than the

counting speed of the counter, the counter will miscount.

For CE1 (when measuring to 0.1 mm), a counter should be used

with a counting speed of 10 kHz (kcps) or more.

And for CEP1 (when measuring to 0.01 mm), use a counter with a

counting speed of 50 kHz (kcps) or more when 4 times

multiplication is input.

<Malfunction due to lurching and bounding>

When lurching or bounding occurs at the beginning or end of stroke

reading cylinder, or due to other causes, the cylinder speed

momentarily increases, and there is a possibility of exceeding the

counting speed of the counter or the response speed of the sensor,

thereby causing a miscount.

The operation manuals should be read before using the CEP1 series

high precision stroke reading cylinder, CEU5 multi counter, CE1

scale cylinder and CEU1 3 point preset counter.

CE Series

Specific Product Precautions

Be sure to read this before handling the products.

Refer to back page 50 for Safety Instructions and pages 3 to 12 for Actuator

and Auto Switch Precautions.

Ferritic core

MULTI COUNTER:CEU5

ACOM COM COM

B

DC12V

GND F.G. R.S.

HOLD

BANK1 BANK2

COM

S.STOP

OUT1 OUT2 OUT3 OUT4 OUT5

AC100~240V

COUNT

PRESET

FUNC.

SD SGRD

RS-232C

UP

LEFT

RIGHT

DOWN

SEL. SET

MODE

Varister

Noise filter

Caution

646