Note 1) Refer to “Applicable Fluids List” on page 379.

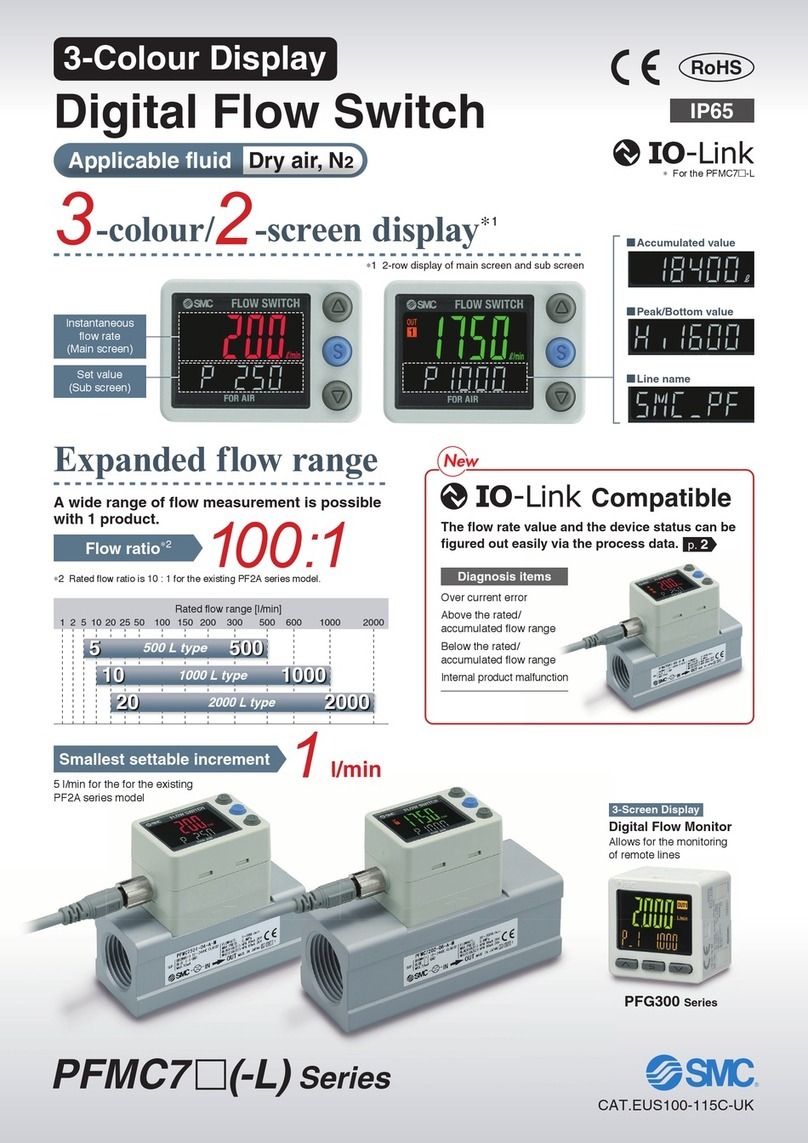

Note 2) 0 L/min is displayed when the flow is less than zero-cut flow.

Note 3)

When fluids with high temperature are used, the operating pressure range and proof pressure will be reduced. (For details, refer to “Operating Pressure Range” on page 365.)

Note 4)

Cleared when the power supply is turned off. Hold function can be selected. (Interval of 2 or 5 minutes can be selected.) If the 5 minutes interval is selected,

the life of the memory element (electronic parts) is limited to 1 million cycles. (If energized for 24 hours, life is calculated as 5 minutes x 1 million = 5 million

minutes = about 9.5 years.) Therefore, if using the hold function, calculate the memory life for your operating conditions, and use within this life.

Note 5) The response time when the set value is 63% in relation to the step input.

Note 6) The response time until the set value reaches 63% in relation to the step input. There might be a 0.05 seconds delay at response time of 0.25 s or

0.5 s due to the timing of internal processing.

Note 7) The stability of display and analog output is improved by increasing the response time setting. (For details, refer to “Stability” on page 365.)

Note 8) When options are used, add the weight of the optional parts.

Note 9) Enclosure is for digital flow switch with lead wire and M12 connector.

Note 10) Piping port is grounded to DC(–)/blue line. Power supply with positive ground cannot be used. (Refer to Figure 1.)

Please consult SMC if the product is used for positive ground environment.

Note 11) The rated flow range is a flow range in which the product specifications (accuracy and repeatability) of the sensor are satisfied. The correct flow

value may not be indicated outside the flow range.

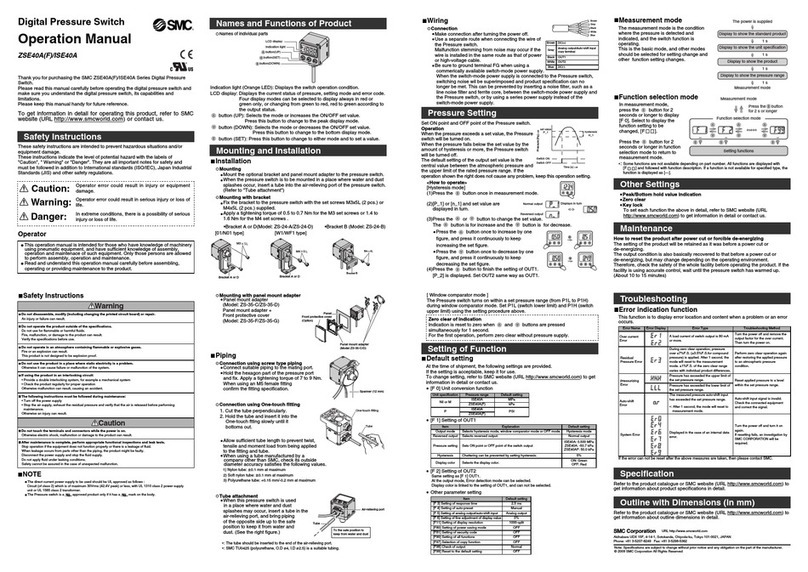

Model LFE1 LFE2 LFE3

Applicable fluid Note 1)

Applicable fluid conductivity Note 1)

Detection method

Ground Note 10)

Rated flow range Note 11)

Display flow range

Set flow range

Zero-cut flow Note 2)

Minimum setting unit

Accumulated volume per pulse (Pulse width: 50 ms)

Operating fluid temperature Note 3)

Display units

Repeatability

Operating pressure range Note 3)

Proof pressure Note 3)

Accumulated flow range Note 4)

Switch output

Analog output

Hysteresis

Display method

Status LED’s

Power supply voltage

Current consumption

Standards and regulations

Parts material in contact with fluid

Port size

Weight (Body) Note 8)

Maximum load current

Maximum applied voltage

Internal voltage drop

Response time Note 5) 7)

Output protection

Output mode

Response time Note 6) 7)

Voltage output

Current output

Enclosure Note 9)

Operating temperature range

Operating humidity range

Ambient temperature

Fluid temperature

Temperature

characteristics

Environmental

resistance

Water, Conductive fluids which do not corrode the fluid contact materials. Note 1)

5 µS/cm or more (micro siemens)

Electrostatic capacity type

Negative ground

0 to 85°C (with no freezing and condensation)

Instantaneous flow rate L/min, Accumulated flow L

Displayed values: ±2% F.S. Analog output: ±1.5% F.S.

±5% F.S. (25°C reference)

±5% F.S. (25°C reference)

0 to 1 MPa

2 MPa

NPN or PNP open collector output

80 mA

28 VDC

NPN: 1 V or less (at load current 80 mA) PNP: 1.5 V or less (at load current 80 mA)

0.25 s/0.5 s/1 s/2 s/5 s

Short-circuit protection

Select from hysteresis mode, window comparator mode, accumulated output mode, or accumulated pulse output mode.

0.25 s/0.5 s/1 s/2 s/5 s

Output voltage: 1 to 5 V Output impedance: 1 kΩ

Output current: 4 to 20 mA Max. load impedance: 600 Ω

Variable

2-screen (Main screen: 4-digit, 7-segment, 2-color, Red/Green; Sub screen: 6-digit, 11-segment, White)

Display values updated 5 times per second

Output 1, Output 2: (Orange)

24 VDC ±10%

45 mA or less (Load current is not included.)

IP65

0 to 50°C(with no freezing and condensation)

Operating, Storage: 35 to 85% R.H. (with no condensation)

CE marking, RoHS

PPS, FKM, Brass

2.5 to 100 L/min

2.0 to 120.0 L/min

2.0 to 120.0 L/min

2.0 L/min

0.5 L/min

0.5 L/pulse

5 to 200 L/min

4 to 240 L/min

4 to 240 L/min

4 L/min

1 L/min

1 L/pulse

0.5 to 20 L/min

0.4 to 24.0 L/min

0.4 to 24.0 L/min

0.4 L/min

0.1 L/min

0.1 L/pulse

999999999 L

by 1 L

99999999.9 L

by 0.1 L

3/8 (10A)

Approx. 340 g

3/4 (20A)

Approx. 520 g

1 (25A)

Approx. 680 g

1/2 (15A)

Approx. 400 g

Specifications (Integrated Display Type)

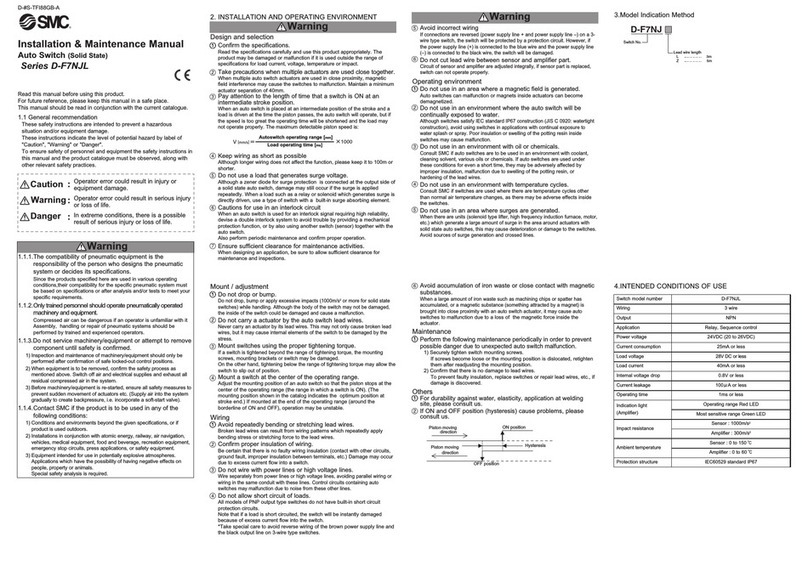

DC (+)

DC (−) DC (+)

DC (+)

DC (−) DC (−) part is connected to DC (–).part is connected to DC (–).

If used with power supply with positive ground,

the metal part shorts.

Piping Piping

Figure 1

363

Electromagnetic Type Digital Flow Switch LFE Series

3-color display