Z/ SE3-TFK26GB-A

Installation & Maintenance Manual

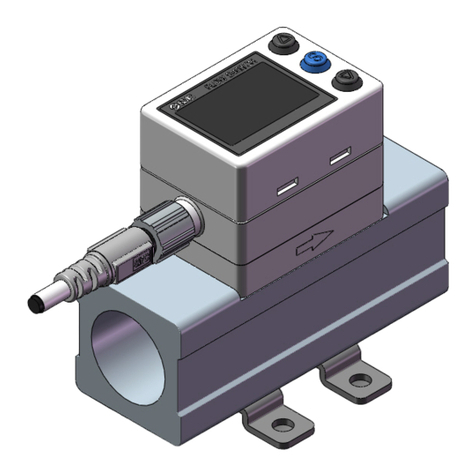

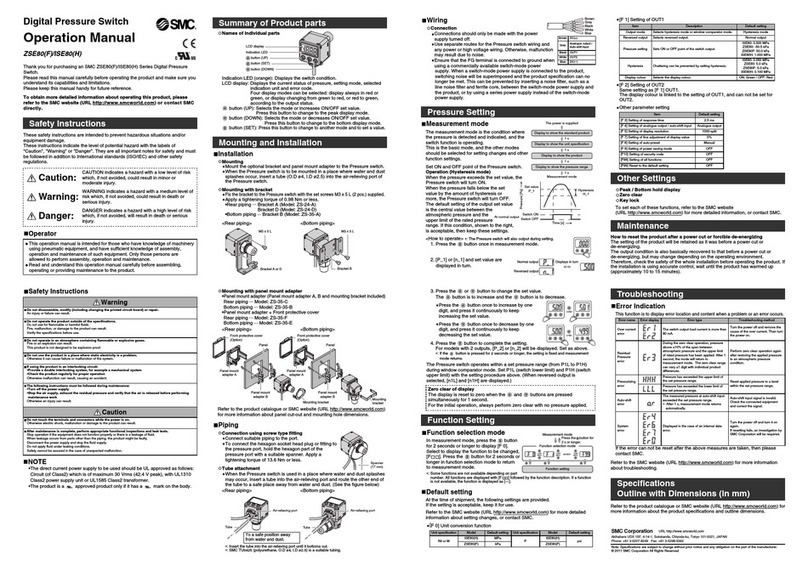

Digital Pressure Switch

Series ZSE3 / ISE3

1. Safety Instructions

f instructions are not followed there is a

possibility of serious injury or loss of life.

f instructions are not followed there is a

possibility of injury or equipment damage.

1. Safety Instructions (continued)

n extreme conditions, there is a possible result

of serious injury or loss of life.

DA GER

WAR I G

CAUTIO

•This manual contains essential information for the protection of users

and others from possible injury and/or equipment damage.

• Read this manual before using the product, to ensure correct handling,

and read the manuals of related apparatus before use.

• Keep this manual in a safe place for future reference.

• These instructions indicate the level of potential hazard by label of

DANGER , WARN NG or CAUT ON , followed by important

safety information which must be carefully followed.

•To ensure safety of personnel and equipment the safety instructions in

this manual and the product catalogue must be observed, along with

other relevant safety practices.

WAR I G

CAUTIO

3. How to Order

•Do not disassemble, modify (including change of printed circuit

board) or repair the product.

An injury or product failure may result.

•Do not operate the product beyond the specification range.

Fire, malfunction or equipment damage may result. Use the product

only after confirming the specifications.

•Do not use the product in the presence of flammable, explosive

or corrosive gas.

Fire, explosion or corrosion may result. This product does not have an

explosion proof construction.

•When using the product as part of an interlocking system:

1) Provide a double interlocking system, for example a mechanical

system.

2) Check the product regularly to ensure proper operation.

•Before performing maintenance, be sure of the following:

1) Turn off the power supply.

2) Stop the air supply, exhaust the residual pressure and verify the

release of air from the system.

•Always perform a system check after maintenance.

Do not use the product if any error occurs.

Safety cannot be assured if caused by un-intentional malfunction.

•Provide grounding to ensure correct operation and to improve

noise resistance of the product.

This product should be individually grounded using a short cable.

•Follow the instructions given below when handling the product.

Failing to do so may result in product damage.

•Maintenance space should always be provided around the product.

•Do not remove labels from the product.

•Do not drop, hit or apply excessive shock to the product.

•Follow all specified tightening torques.

•Do not bend, apply tensile force, or apply force by placing heavy

loads, on the cables.

•Connect wires and cables correctly, and do not connect while the

power is ON.

•Do not route wires and cables together with power or high-voltage

cables.

•Check the insulation of wires and cables.

•Take proper measures against noise, such as noise filters, when the

product is incorporated in equipment or devices.

•Select the required protection ( P) rating according to the environment

of operation.

•Take sufficient shielding measures when the product is to be used in

the following conditions:

(1) where noise due to static electricity is generated.

(2) where electro-magnetic field strength is high.

(3) where radioactivity is present.

(4) where power lines are located.

•Do not use the product in a place where electric surges are generated.

•Use suitable surge protection when a surge generating load such as a

solenoid valve are to be directly driven.

•Prevent any foreign matter from entering this product.

•Do not expose the product to vibration or impact.

•Use the product within the specified ambient temperature range.

•Do not expose the product to any heat radiation.

•Do not clean the product with chemicals such as benzene or thinners.

Follow the instructions given below when handling your digital pressure

switch. Otherwise, the switch may be damaged or may fail, thereby

resulting in malfunction.

• Do not pull the lead wire with force nor lift the switch by holding the lead

wire. (Tensile strength: less than 49N.)

• Connect the terminal FG to ground when using a switching regulator

obtained on the commercial market.

• nsert a noise filter (line noise filter and ferrite core or other elements)

between the switching regulator and this digital pressure switch when ana-

logue output is used.

• Do not use with corrosive or flammable gas or liquid.

• Do not press the setting buttons with a sharp pointed object.

• Do not rub the LCD indicator during operation (the display may change due

to static electricity.)

•

When performing piping, tighten the pipe by using a spanner on the hexagon

section of the attachment of the

digital pressure switch

(Do not apply force on

the switch body).

• Do not use this digital pressure switch in areas that are exposed to water,

oil or chemicals (open-type specification).

When the 0X or 0XY type (with filter) is used

• f the filter element (ZX1-FE) is clogged, stop operation and replace the ele-

ment.

ISE3

ZSE3

Piping specifications

Piping specifications

Wiring specifications

nput specifications

Output specifications

Pressure setting range

For posi-

tive

pressure

For vacuum

2. Specifications

Note 1) When vacuum is used, there is no influence on the switch even if 0.5 MPa of pressure is supplied

instantaneously.

Note 2) Only for the pressure switch with analogue output selected.

Note 3) n case of ZSE3- -23 or 24, failure predictive output: Red.

Environmental

Vacuum

ZSE3

0to -101 kPa

1kPa

Air, non-corrosive gas

200 kPa (Note 1)

12 to 24 Vdc (Ripple 10 % or less)

25 mA or less

NPN open collector output

80 mA

30 Vdc

5ms.

1 %F.S. or less

Voltage output: 1 to 5 V 5 %, Output impedance: Approx. 1 k

Variable (0 digits or more)

Fixed ( 3 digits)

3 1/2 digits LCD (character height 5 mm).

Lit when ON (OUT1: Green OUT2: Red)

Detection of overcurrent, overpressure, data error, and pressure during 0 clear

Indicator: Red LED flashes. Error code displayed on LCD.

3 %F.S. or less

IP40

0 to 60 (No condensation or freezing)

Between external terminal and case: 1000 Vac 50/60 Hz for 1 min.

Between external terminal and case: 2 M (by 500 Vdc M)

10 to 500 Hz 2 hours each in X, Y,and Z directions, at 10 to 500 Hz

with amplitude of 1.5 mm or acceleration 98m/s2, whichever smaller.

980m/s2, 3 times each in X, Y,and Z directions

CE marked

Heat resistant vinyl wire 1.55 0.31 mm24-wire

Oil resistant vinyl heavy-duty cable

-21,-23: 3.5 0.14 mm24-core

-22,-24: 3.5 0.15 mm25-core

40 g (including lead wire 0.6 m)

Rc1/8, M5 x 0.8, NPT F1/8, M5 x 0.8,

M5 x 0.8 with suction filter,

M6 x 1 (made to order)

Rated Pressure Range

Minimum Setting Unit

Fluid

Maximum Operating Pressure

Power Supply Voltage

Current Consumption

Switch Output

Model

Response Time

Repeatability

Analogue Output (Note 2)

Hysteresis

(Note 4)

Display Method

Indicator Light (Note 3)

Self-diagnosis Function

Error Indication

Temperature Characteristic

Standard

Port Size

Lead Wire

Maximum Load Current

MaximumApplied Voltage

Hysteresis Mode

Window Comparator Mode

Connector type

Grommet type

Weight

Enclosure

Ambient Temperature Range

Withstand Voltage

Insulation Resistance

Vibration Proof

Impact Proof

Rated Pressure Range

Minimum Setting Unit

Fluid

Maximum Operating Pressure

Power Supply Voltage

Current Consumption

Switch Output

Model

12 to 24 Vdc (Ripple 10 % or less)

25 mA or less

NPN open collector output

80 mA

30 Vdc

5ms.

1 %F.S. or less

Voltage output: 1 to 5 V 5 %, Output impedance: Approx. 1 k

Variable (0 digits or more)

Fixed ( 3 digits)

31/2 digits LCD (character height 5 mm).

Lit when ON (OUT1: Green OUT2: Red)

Detection of overcurrent, overpressure, data error, and pressure during 0 clear

Indicator: Red LED flashes. Error code displayed on LCD.

3 %F.S. or less

IP40

0 to 60 (No condensation or freezing)

Between external terminal and case: 1000 Vac 50/60 Hz for 1 min.

Between external terminal and case: 2 M (by 500 Vdc M)

Air, non-corrosive gas

Positive Pressure 100kPa

ISE3L

0to 98 kPa

1kPa

Positive Pressure 1MPa

ISE3

0 to 0.98 MPa

0.01 MPa

200 kPa (Note 1) 1MPa

10 to 500 Hz 2 hours each in X, Y,and Z directions, at 10 to 500 Hz

with amplitude of 1.5 mm or acceleration 98m/s2,whichever smaller.

980m/s2,3 times each in X, Y,and Z directions

CE marked

Rc1/8, M5 x 0.8, NPTF 1/8, M5 x 0.8

Heat resistant vinyl wire 1.55 0.31 mm24-wire

Oil resistant vinyl heavy-duty cable

-21: 3.5 0.14 mm24-core

-22: 3.5 0.15 mm25-core

40 g (including lead wire 0.6 m)

Response Time

Repeatability

Analogue Output (Note 2)

Hysteresis

(Note 4)

Display Method

Indicator Light (Note 3)

Self-diagnosis Function

Error Indication

Temperature Characteristic

Standard

Port Size

Lead Wire

Maximum Load Current

MaximumApplied Voltage

Hysteresis Mode

Window Comparator Mode

Connector type

Grommet type

Weight

Enclosure

Ambient Temperature Range

Withstand Voltage

Insulation Resistance

Vibration Proof

Impact Proof

Environmental

Wiring connection

• Be sure to turn off the power supply before performing connection

work.

• ncorrect wiring will lead to digital pressure switch breakdown, failure

or malfunction. Be sure to confirm the wire colour and terminal number

before wiring.

Note) The symbol shown in [ ] means the pin assignment of connec-

tor connection type.

N L 0 to 0.98 MPa

L 0 to 98 kPa

01

Single-installation type Rc 1/8

T1

Single-installation type NPTF 1/8

Note) M 5 x 0 . 8 female t h r ead is p r o v ided o n t h e inte r na l s i de of th e p i ping .

21 NPN open collector 2 outputs

Without analogue output

22 NPN open collector 2 outputs

With analogue output (1 to 5V)

N L Grommet type lead wire (length: 0.6 m)

L Grommet type lead wire (length: 3 m)

C Connector type lead wire (Length: 0.6 m)

CL Connector type lead wire (length: 3 m)

CN Without connector

Note) Analogue output is available only for grommet type.

21 NPN open collector 2 outputs

Without analogue output

22 NPN open collector 2 outputs

With analogue output (1 to 5V)

23 NPN open collector 1 output and failure predictive output

Without analogue output

24 NPN open collector 1 output and failure predictive output

With analogue output (1 to 5V)

01 Single-installation type Rc 1/8

T1 Single-installation type NPTF 1/8

0X With suction filter M5 x 0.8

0XY With suction filter M6 x 1(made-to-order)

Note) An M5 x 0.8 female thread is provided on the internal side of the single-installation type piping.