SMC Sierra Monitor ProtoNode FPC-N54 User guide

Document Revision: 3.C

Web Configurator

Template Revision: 4

ProtoNode FPC-N54

Start-up Guide

For Interfacing ABB Products:

ACS800, ACS880, ACS880-CTDD

To Building Automation Systems:

BACnet MS/TP, BACnet/IP andSMC Cloud

APPLICABILITY & EFFECTIVITY

Explains ProtoNode hardware and installation.

The instructions are effective for the above as of February 2020.

ABB ProtoNode Start-up Guide

Page 2 of 46

Technical Support

Thank you for purchasing the ProtoNode for ABB.

Please call ABB for technical support of the ProtoNode product.

MSA Safety does not provide direct support. If ABB needs to escalate the concern, they will contact MSA

Safety for assistance.

Support Contact Information:

ABB Inc.

16250 W. Glendale Drive

New Berlin, WI 53151

Customer Service:

+49 30 9177 0

Email: contact.center@de.abb.com

Website: www.abb.com

ABB ProtoNode Start-up Guide

Page 3 of 46

Quick Start Guide

WARNING: The brief guide below is generic, please refer to the drive specific instructions in

Appendix B.7 for ACS800, ACS880 or ACS880-CTDD before moving forward.

1. Record the information about the unit. (Section 3.1)

2. Check that the ProtoNode and customer device COM settings match. (Section 3.3)

3. Connect the ProtoNode 3 pin RS-485 R1 port to the RS-485 network connected to the device.

(Section 4.1)

4. If using a serial field protocol:

Connect the ProtoNode 3 pin RS-485 R2 port to the field protocol cabling. (Section 4.2)

5. Connect power to ProtoNode 3 pin power port. (Section 4.5)

6. Connect a PC to the ProtoNode via Ethernet cable. (Section 5)

7. Use a web browser to access the ProtoNode Web Configurator page to select the profile of the

device attached to the ProtoNode and enter any necessary device information. Once the device is

selected, the ProtoNode automatically builds and loads the appropriate configuration. (Section 6)

8. Ethernet Network: If using an Ethernet field protocol, use a web browser to access the ProtoNode Web

Configurator page to change the IP Address. (Section 6.4)

ABB ProtoNode Start-up Guide

Page 4 of 46

TABLE OF CONTENTS

1Certification..........................................................................................................................................7

1.1 BTL Mark –BACnet®Testing Laboratory.......................................................................................7

2Introduction..........................................................................................................................................8

2.1 ProtoNode Gateway .......................................................................................................................8

3ProtoNode Setup..................................................................................................................................9

3.1 Record Identification Data ..............................................................................................................9

3.2 Point Count Capacity and Registers per Device ............................................................................9

3.3 Configuring Modbus Device Communications ...............................................................................9

3.3.1 Confirm the Device and ProtoNode COM Settings Match........................................................9

3.3.2 Set Node-ID for Any Device Attached to the ProtoNode ..........................................................9

4Interfacing ProtoNode to Devices....................................................................................................10

4.1 Device Connections to ProtoNode ...............................................................................................10

4.2 Wiring Field Port to RS-485 Serial Network .................................................................................10

4.3 Bias Resistors...............................................................................................................................11

4.4 Termination Resistor.....................................................................................................................12

4.5 Power-Up ProtoNode....................................................................................................................13

5Connect the PC to the ProtoNode....................................................................................................14

5.1 Connecting to the ProtoNode via Ethernet...................................................................................14

5.1.1 Changing the Subnet of the Connected PC............................................................................14

6Configure the ProtoNode..................................................................................................................15

6.1 Accessing the ProtoNode Web Configurator................................................................................15

6.2 Select Profile and Set Configuration Parameters.........................................................................15

6.3 Verify Device Communications.....................................................................................................16

6.4 Ethernet Network: Setting IP Address for the Field Network .......................................................16

6.5 How to Start the Installation Over: Clearing Profiles ....................................................................18

Appendix A Troubleshooting...................................................................................................................19

Appendix A.1 Lost or Incorrect IP Address .............................................................................................19

Appendix A.2 Viewing Diagnostic Information ........................................................................................20

Appendix A.3 Checking Wiring and Settings...........................................................................................21

Appendix A.4 LED Diagnostics for Communications Between ProtoNode and Devices........................22

Appendix A.5 Take a FieldServer Diagnostic Capture............................................................................23

Appendix A.5.1 Using the FieldServer Toolbox...................................................................................23

Appendix A.5.2 Using FS-GUI.............................................................................................................26

Appendix B Additional Information.........................................................................................................27

Appendix B.1 Updating Firmware............................................................................................................27

Appendix B.2 Securing ProtoNode with Passwords ...............................................................................28

Appendix B.3 Factory Reset Instructions ................................................................................................29

Appendix B.4 Internet Browsers Not Supported .....................................................................................29

Appendix B.5 Mounting ...........................................................................................................................29

Appendix B.6 Physical Dimension Drawing ............................................................................................30

Appendix B.7 Drive Specific QuickStart Guides......................................................................................31

Appendix B.7.1 ACS800 Drive Setup..................................................................................................31

Appendix B.7.1.1 ACS800 Drive Wiring...........................................................................................32

Appendix B.7.1.2 ACS800 Drive Setup Instructions........................................................................33

Appendix B.7.1.3 ACS800 Modbus RTU Mappings to BACnet.......................................................34

Appendix B.7.2 ACS880 Drive Setup..................................................................................................35

Appendix B.7.2.1 ACS880 Drive Wiring...........................................................................................36

Appendix B.7.2.2 ACS880 Drive Setup Instructions........................................................................37

Appendix B.7.2.3 ACS880 Modbus RTU Mapping to BACnet.........................................................39

Appendix B.7.3 ACS880-CTDD Drive Setup.......................................................................................40

Appendix B.7.3.1 ACS880-CTDD Drive Wiring ...............................................................................41

Appendix B.7.3.2 ACS880-CTDD Drive Setup Instructions.............................................................42

Appendix B.7.3.3 ACS880-CTDD Modbus RTU Mappings to BACnet............................................44

ABB ProtoNode Start-up Guide

Page 5 of 46

Appendix C Reference..............................................................................................................................45

Appendix C.1 Specifications....................................................................................................................45

Appendix C.1.1 Compliance with UL Regulations...............................................................................45

Appendix D Limited 2 Year Warranty......................................................................................................46

ABB ProtoNode Start-up Guide

Page 6 of 46

LIST OF FIGURES

Figure 1: ProtoNode Part Numbers ..............................................................................................................9

Figure 2: Supported Point Count Capacity ...................................................................................................9

Figure 3: COM Settings.................................................................................................................................9

Figure 4: RS-485 Connections from Devices to the ProtoNode .................................................................10

Figure 5: Connection from ProtoNode to RS-485 Field Network................................................................10

Figure 6: Bias Resistor DIP Switches .........................................................................................................11

Figure 7: Termination Resistor DIP Switch.................................................................................................12

Figure 8: Required Current Draw for the ProtoNode ..................................................................................13

Figure 9: Power Connections......................................................................................................................13

Figure 10: Ethernet Port Location...............................................................................................................14

Figure 11: Web Configurator Showing Profile Selector Parameter ............................................................15

Figure 12: Web Configurator Screen ..........................................................................................................16

Figure 13: Changing IP Address via FS-GUI..............................................................................................17

Figure 14: Ethernet Port Location...............................................................................................................19

Figure 15: Error Messages Screen.............................................................................................................20

Figure 16: Diagnostic LEDs ........................................................................................................................22

Figure 17: Ethernet Port Location...............................................................................................................23

Figure 18: FS-GUI Passwords Page...........................................................................................................28

Figure 19: Password Recovery Page .........................................................................................................28

Figure 20: DIN Rail......................................................................................................................................29

Figure 21: ProtoNode FPC-N54 Dimensions..............................................................................................30

Figure 22: ACS800 Drive Connections Diagram ........................................................................................32

Figure 23: ACS880 Drive Connections Diagram ........................................................................................36

Figure 24: ACS880-CTDD Drive Connections Diagram.............................................................................41

Figure 25: Specifications.............................................................................................................................45

ABB ProtoNode Start-up Guide

Page 7 of 46

1 CERTIFICATION

1.1 BTL Mark –BACnet®

1

Testing Laboratory

1

BACnet is a registered trademark of ASHRAE

The BTL Mark on ProtoNode is a symbol that indicates that a product has

passed a series of rigorous tests conducted by an independent laboratory

which verifies that the product correctly implements the BACnet features

claimed in the listing. The mark is a symbol of a high-quality BACnet product.

Go to www.BACnetInternational.net for more information about the BACnet

Testing Laboratory. Click here for the BACnet PIC Statement.

ABB ProtoNode Start-up Guide

Page 8 of 46

2 INTRODUCTION

2.1 ProtoNode Gateway

The ProtoNode is an external, high performance building automation multi-protocol gateway that is

preconfigured to automatically communicate between ABB’s devices (hereafter simply called “device”)

connected to the ProtoNode and automatically configures them for BACnet/IP and BACnet MS/TP.

It is not necessary to download any configuration files to support the required applications. The ProtoNode

is pre-loaded with tested profiles/configurations for the supported devices.

FPC-N54 Connectivity Diagram:

The ProtoNode can connect with the SMC Cloud. The SMC Cloud allows technicians, the OEM's support

team and MSA Safety's support team to remotely connect to the ProtoNode. The SMC Cloud provides the

following capabilities for any registered devices in the field:

•Remotely monitor and control devices.

•Collect device data and view it on the SMC Cloud Dashboard and the SMC Smart Phone App.

•Create user defined device notifications (alarm, trouble and warning) via SMS and/or Email.

•Generate diagnostic captures (as needed for troubleshooting) without going to the site.

For more information about the SMC Cloud, refer to the SMC Cloud Start-up Guide.

ABB ProtoNode Start-up Guide

Page 9 of 46

3 PROTONODE SETUP

3.1 Record Identification Data

Each ProtoNode has a unique part number located on the side or the back of the unit. This number should

be recorded, as it may be required for technical support. The numbers are as follows:

Model

Part Number

ProtoNode

FPC-N54-1730

Figure 1: ProtoNode Part Numbers

•FPC-N54 units have the following 3 ports: RS-485 + Ethernet + RS-485/RS-232

3.2 Point Count Capacity and Registers per Device

The total number of registers presented by the device(s) attached to the ProtoNode cannot exceed:

Part number

Total Registers

FPC-N54-1730

1,500

Figure 2: Supported Point Count Capacity

3.3 Configuring Modbus Device Communications

3.3.1 Confirm the Device and ProtoNode COM Settings Match

•Any connected serial devices MUST have the same baud rate, data bits, stop bits, and

parity settings as the ProtoNode.

•Figure 3 specifies the device serial port settings required to communicate with the ProtoNode.

Port Setting

Device

Protocol

Modbus RTU

Baud Rate

19200

Parity

None

Data Bits

8

Stop Bits

1

Figure 3: COM Settings

3.3.2 Set Node-ID for Any Device Attached to the ProtoNode

•Set Node-ID for the device attached to ProtoNode to 1.

ABB ProtoNode Start-up Guide

Page 10 of 46

4 INTERFACING PROTONODE TO DEVICES

NOTE: The information in Section 4.1 and 4.2 is generic. For complete wiring instructions for

connecting to a specific drive go to Appendix B.7.

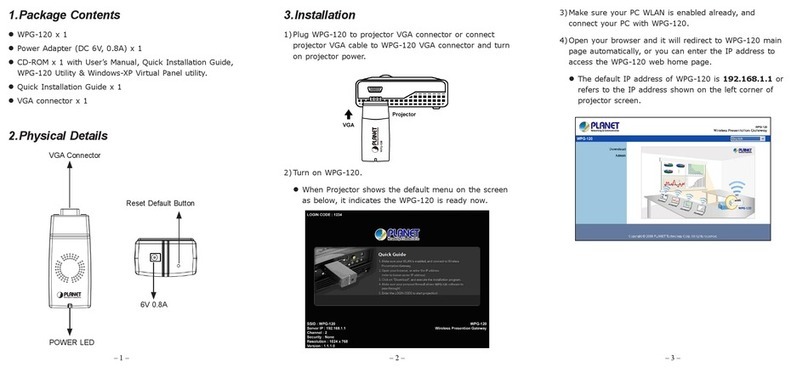

4.1 Device Connections to ProtoNode

The ProtoNode has a 3-pin Phoenix connector for connecting RS-485 devices on the R1 port.

NOTE: Use standard grounding principles for RS-485 GND.

4.2 Wiring Field Port to RS-485 Serial Network

•Connect the RS-485 network wires to the 3-pin RS-485 connector on the R2 port. (Figure 5)

oUse standard grounding principles for RS-485 GND

•See Section 5 for information on connecting to the Ethernet network.

Drive Pins

ProtoNode

Pin Label

Pin

Assignment

B +

TX +

RS-485 +

A -

TX -

RS-485 -

RS-485 GND

GND

RS-485 GND

BMS

Wiring

ProtoNode

Pin Label

Pin

Assignment

RS-485 +

+

RS-485 +

RS-485 -

-

RS-485 -

-

GND

RS-485 GND

Figure 4: RS-485 Connections from Devices to the ProtoNode

Figure 5: Connection from ProtoNode to RS-485 Field Network

G

-

+

G

-

+

ABB ProtoNode Start-up Guide

Page 11 of 46

4.3 Bias Resistors

To enable Bias Resistors, move both the BIAS- and BIAS+ dip switches to the right as shown in

Figure 6.

The ProtoNode bias resistors are used to keep the RS-485 bus to a known state, when there is no

transmission on the line (bus is idling), to help prevent false bits of data from being detected. The bias

resistors typically pull one line high and the other low - far away from the decision point of the logic.

The bias resistor is 510 ohms which is in line with the BACnet spec. It should only be enabled at one

point on the bus (for example, on the field port were there are very weak bias resistors of 100k). Since

there are no jumpers, many gateways can be put on the network without running into the bias resistor

limit which is < 500 ohms.

NOTE: See www.ni.com/support/serial/resinfo.htm for additional pictures and notes.

NOTE: The R1 and R2 DIP Switches apply settings to the respective serial port.

NOTE: If the gateway is already powered on, DIP switch settings will not take effect unless the

unit is power cycled.

R1 Bias Resistor DIP

Switches (2 and 3)

Figure 6: Bias Resistor DIP Switches

R2 Bias Resistor DIP

Switches (2 and 3)

ABB ProtoNode Start-up Guide

Page 12 of 46

4.4 Termination Resistor

If the ProtoNode is the last device on the serial trunk, then the End-Of-Line Termination Switch needs to

be enabled. To enable the Termination Resistor, move the TERM dip switch to the right in the

orientation shown in Figure 7.

Termination resistor is also used to reduce noise. It pulls the two lines of an idle bus together. However,

the resistor would override the effect of any bias resistors if connected.

NOTE: The R1 and R2 DIP Switches apply settings to the respective serial port.

NOTE: If the gateway is already powered on, DIP switch settings will not take effect unless the

unit is power cycled.

R1 Termination

Resistor DIP Switch (1)

Figure 7: Termination Resistor DIP Switch

R2 Termination

Resistor DIP Switch (1)

ABB ProtoNode Start-up Guide

Page 13 of 46

4.5 Power-Up ProtoNode

Check power requirements in the table below:

Power Requirement for ProtoNode External Gateway

Current Draw Type

ProtoNode Family

12VDC

24VDC/AC

FPC –N54 (Typical)

250mA

125mA

NOTE: These values are ‘nominal’ and a safety margin should be added to the power supply of

the host system. A safety margin of 25% is recommended.

Figure 8: Required Current Draw for the ProtoNode

Apply power to the ProtoNode as shown below in Figure 9. Ensure that the power supply used complies

with the specifications provided in Appendix C.1.

•The ProtoNode accepts 9-30VDC or 24VAC on pins L+ and N-.

•Frame GND should be connected.

NOTE: Go to Appendix B.7 for drive specific power setup and wiring instructions.

Power to

ProtoNode

ProtoNode

Pin Label

Pin

Assignment

Power In (+)

L +

V +

Power In (-)

N -

V -

Frame Ground

FG

FRAME GND

Figure 9: Power Connections

ABB ProtoNode Start-up Guide

Page 14 of 46

5 CONNECT THE PC TO THE PROTONODE

5.1 Connecting to the ProtoNode via Ethernet

Connect a Cat-5 Ethernet cable (straight through or cross-over) between the local PC and ProtoNode.

5.1.1 Changing the Subnet of the Connected PC

The default IP Address for the ProtoNode is 192.168.1.24, Subnet Mask is 255.255.255.0. If the PC and

ProtoNode are on different IP networks, assign a static IP Address to the PC on the 192.168.1.xxx network.

For Windows 10:

•Find the search field in the local computer’s taskbar (usually to the right of the windows icon )

and type in “Control Panel”.

•Click “Control Panel”, click “Network and Internet” and then click “Network and Sharing Center”.

•Click “Change adapter settings” on the left side of the window.

•Right-click on “Local Area Connection” and select “Properties” from the dropdown menu.

•Highlight and then click the Properties button.

•Select and enter a static IP Address on the same subnet. For example:

•Click the Okay button to close the Internet Protocol window and the Close button to close the

Ethernet Properties window.

Ethernet Port

Figure 10: Ethernet Port Location

ABB ProtoNode Start-up Guide

Page 15 of 46

6 CONFIGURE THE PROTONODE

6.1 Accessing the ProtoNode Web Configurator

•Navigate to the IP Address of the ProtoNode on the local PC by opening a web browser and

entering the IP Address of the ProtoNode; the default Ethernet address is 192.168.1.24.

NOTE: If the IP Address of the ProtoNode has been changed, the IP Address can be discovered

using the FS Toolbox utility. See Appendix A.1 for instructions.

6.2 Select Profile and Set Configuration Parameters

•On the Web Configurator page, the first configuration parameter is the Profile Selector.

•Select the profile by entering the appropriate number into the Profile Selector Value. Click the

Submit button. Click the System Restart button to save the updated configuration.

•Ensure that all applicable parameters are entered for successful operation of the gateway. Find the

legal value options for each parameter under the Parameter Description in parentheses.

Figure 11: Web Configurator Showing Profile Selector Parameter

ABB ProtoNode Start-up Guide

Page 16 of 46

6.3 Verify Device Communications

•Check that the port R1 TX1 and RX1 LEDs are rapidly flashing. See Appendix A.4 for

additional LED information and images.

•Confirm the software shows good communications without errors (Appendix A.2).

6.4 Ethernet Network: Setting IP Address for the Field Network

•Follow the steps outlined in Section 6.1 to access the ProtoNode Web Configurator.

•To access the FS-GUI, click on the “Diagnostics & Debugging” button in the bottom right corner of

the page.

Figure 12: Web Configurator Screen

ABB ProtoNode Start-up Guide

Page 17 of 46

•From the FS-GUI landing page, click on “Setup” to expand the navigation tree and then select

“Network Settings” to access the IP Settings menu. (Figure 13)

•Modify the IP Address (N1 IP Address field) of the ProtoNode Ethernet port.

•If necessary, change the Netmask (N1 Netmask field).

•If necessary, change the IP Gateway (Default Gateway field).

NOTE: If the ProtoNode is connected to a managed switch/router, the IP Gateway of the

ProtoNode should be set to the IP Address of that managed switch/router.

•Click the “System Restart” button at the bottom of the page to apply changes and restart the

ProtoNode.

•Unplug Ethernet cable from PC and connect it to the network switch or router.

•Record the IP Address assigned to the ProtoNode for future reference.

NOTE: The SMC Cloud button (see Figure 13) allows users to connect to the

SMC Cloud, MSA Safety’s device cloud solution for IIoT. The SMC Cloud enables secure

remote connection to field devices through a FieldServer and its local applications for

configuration, management, maintenance. For more information about the SMC Cloud,

refer to the SMC Cloud Start-up Guide.

Figure 13: Changing IP Address via FS-GUI

ABB ProtoNode Start-up Guide

Page 18 of 46

6.5 How to Start the Installation Over: Clearing Profiles

•Follow the steps outlined in Section 6.1 to access the ProtoNode Web Configurator.

•At the bottom-left of the page, click the “Clear Profiles and Restart” button.

•Once restart is complete, all past profiles discovered and/or added via Web configurator are

deleted. The unit can now be reinstalled.

ABB ProtoNode Start-up Guide

Page 19 of 46

Appendix A Troubleshooting

Appendix A.1 Lost or Incorrect IP Address

•Ensure that FieldServer Toolbox is loaded onto the local PC. Otherwise, download the

FieldServer-Toolbox.zip via the Sierra Monitor website’s Software Downloads.

•Extract the executable file and complete the installation.

•Connect a standard Cat-5 Ethernet cable between the user’s PC and ProtoNode.

•Double click on the FS Toolbox Utility and click Discover Now on the splash page.

•Check for the IP Address of the desired gateway.

•If correcting the IP Address of the gateway: click the settings icon on the same row as the

gateway, then click Network Settings, change the IP Address and click Update IP Settings to save.

Ethernet Port

Figure 14: Ethernet Port Location

ABB ProtoNode Start-up Guide

Page 20 of 46

Appendix A.2 Viewing Diagnostic Information

•Type the IP Address of the ProtoNode into the web browser or use the FieldServer Toolbox to

connect to the ProtoNode.

•Click on Diagnostics Button, then click on view, and then on connections.

•If there are any errors showing on the Connections page, refer to Appendix A.3 to check the

wiring and settings.

Figure 15: Error Messages Screen

Table of contents

Other SMC Sierra Monitor Gateway manuals

SMC Sierra Monitor

SMC Sierra Monitor FieldServer FS-8704-23 Release note

SMC Sierra Monitor

SMC Sierra Monitor FS-IOT-BACX User guide

SMC Sierra Monitor

SMC Sierra Monitor FS-IOT-BAC Series User guide

SMC Sierra Monitor

SMC Sierra Monitor Pure Humidifier ProtoAir FPA-W44 User guide

SMC Sierra Monitor

SMC Sierra Monitor FieldServer FS-QS-2 10 Series User guide

SMC Sierra Monitor

SMC Sierra Monitor FieldServer QuickServer FS-QS-2 0 Series User manual

SMC Sierra Monitor

SMC Sierra Monitor FieldServer ProtoNode User manual

SMC Sierra Monitor

SMC Sierra Monitor ProtoAir FPA-W34 User guide