Instructions for the installer

6

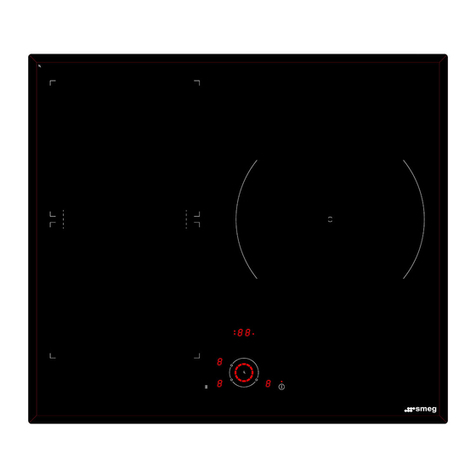

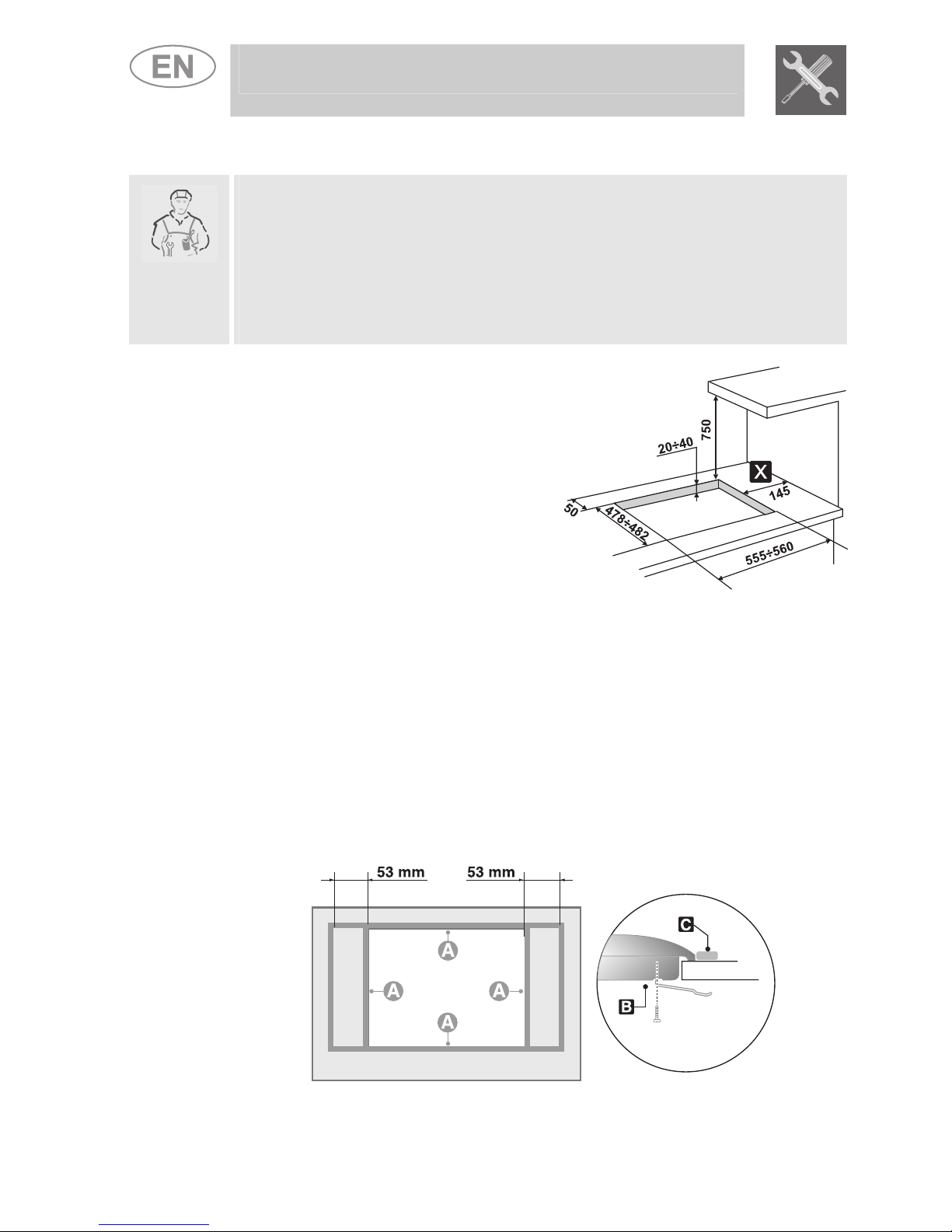

2. POSITIONING THE COOKTOP

The following operation requires building and/or carpentry work that must

be carried out by a skilled tradesman.

The cooktop may be installed on various materials, such as masonry,

metal, solid wood, plastic laminated wood etc. as long as they are heat

resistant (T = 90°C - 194° F).

Never use silicone or other insulating products when installing the

appliance; only use the rubber gasket provided.

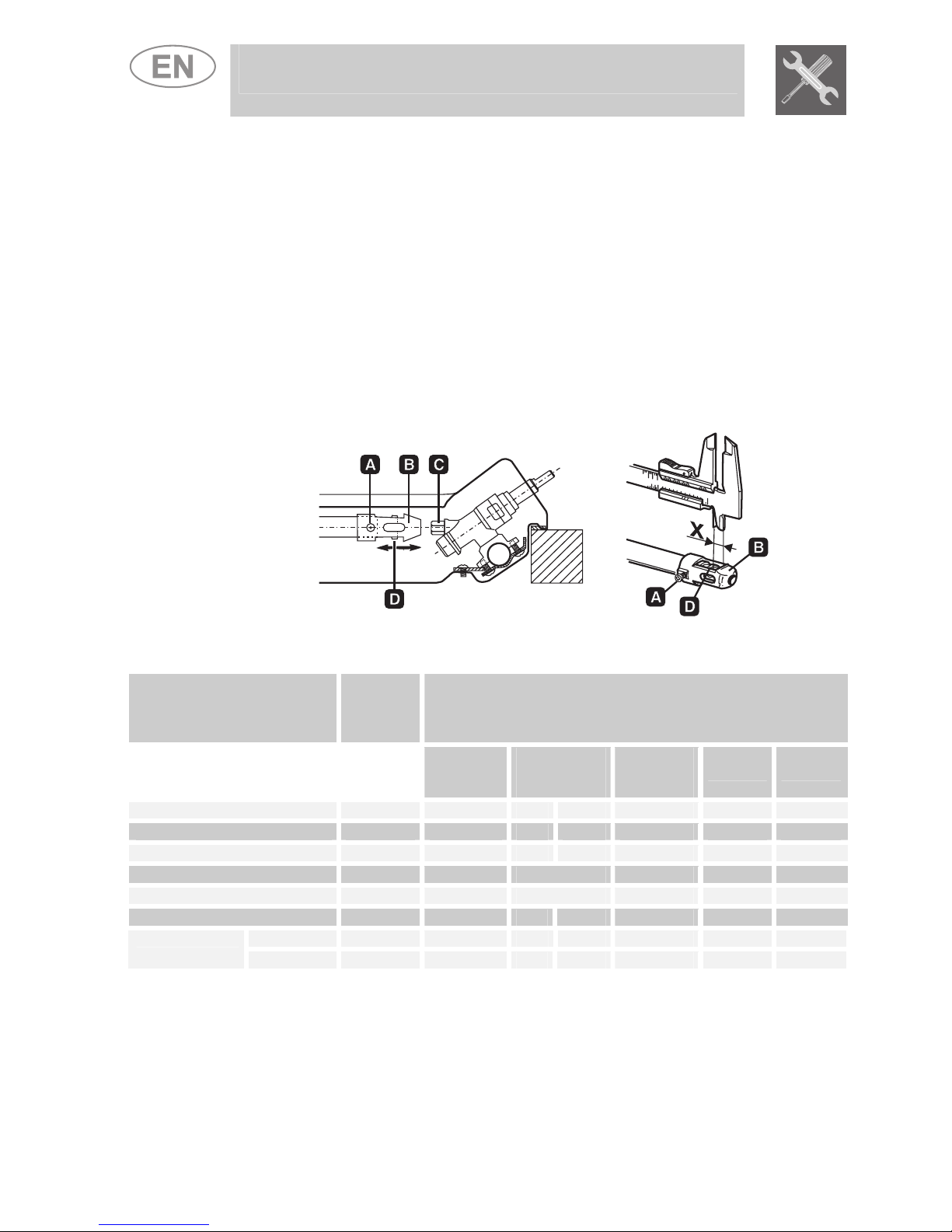

2.1.1 Attachment to the support structure

Create an opening in the top surface

of the counter with the dimensions

shown in the figure, keeping a

minimum distance of 50 mm (2

inches) from the rear edge.

This appliance is classified "type Y"

with regard to risks against fire and

can be positioned adjacent to walls

that are higher than the work

surface, provided that a distance of

145 mm (5.7 in) is respected (as

shown in the figure) in order to

prevent damage due to overheating.

Make sure there is a minimum of 750 mm (30 in) between the burner

flames and any shelf that may be installed directly above them.

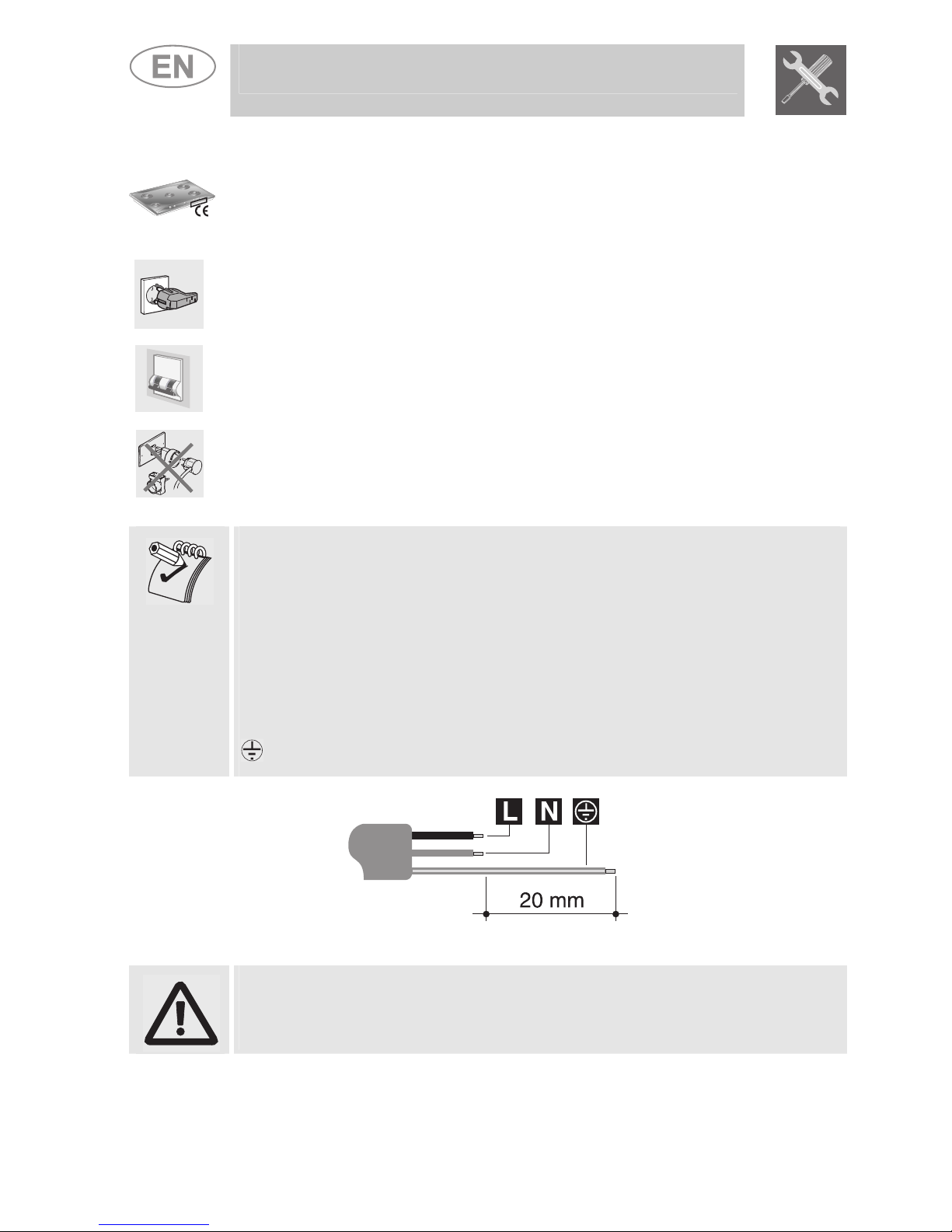

Carefully position the insulation gasket (supplied) on the external

perimeter of the hole made in the top surface (see figures below) and try

to make it stick to the entire surface by applying light pressure with your

hands. Refer to the coordinates shown in the figure, keeping in mind that

sides Ashould be adjacent to the hole. Secure the cooktop to the counter

with brackets B(supplied). Carefully trim any excess from border Cof the

gasket. The distances in the following drawing refer to the hole on the

inner side of the gasket.