Revision n.1 User Manual B-One Edition: 04/2009 Page 6 of 52

INDEX

1PROPER USE ..............................................................................................9

2TECHNICAL FEATURES...........................................................................10

3INSTALLATION..........................................................................................12

3.1 INSTALLATION AND ELECTRICAL CONNECTION............................12

3.2 SAFETY WARNINGS...........................................................................13

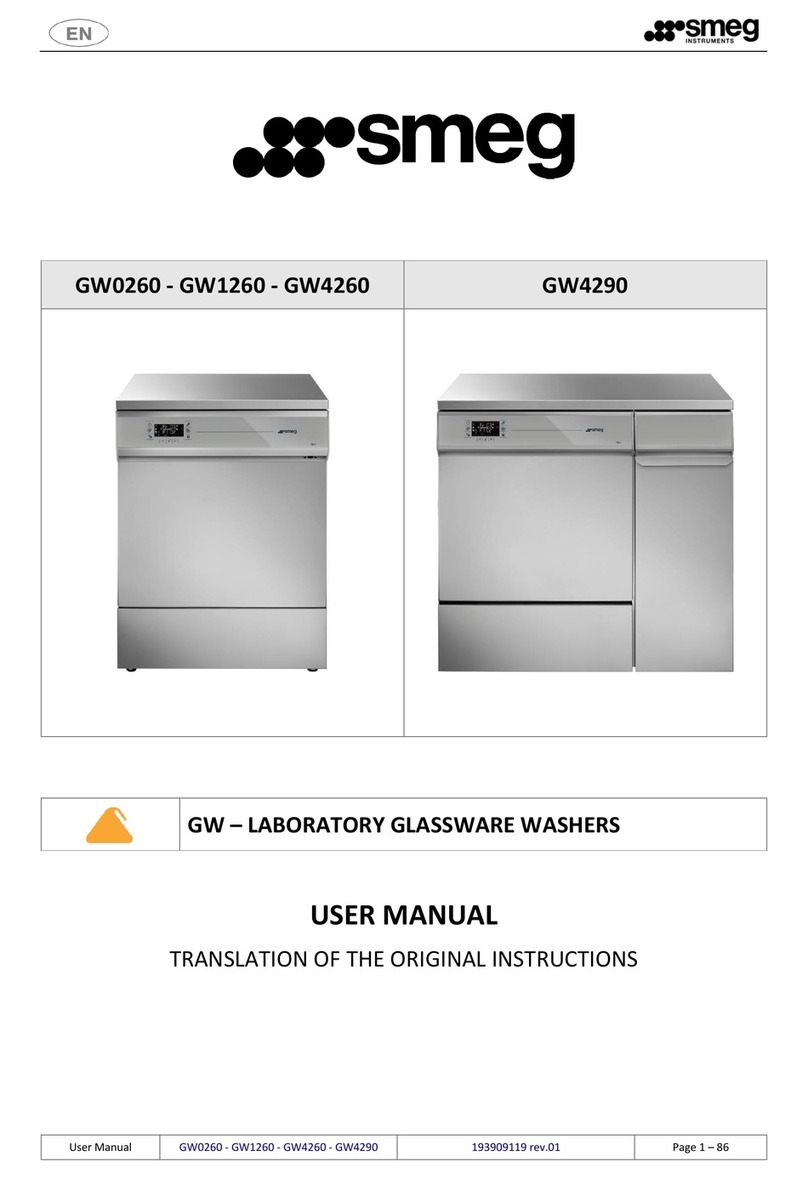

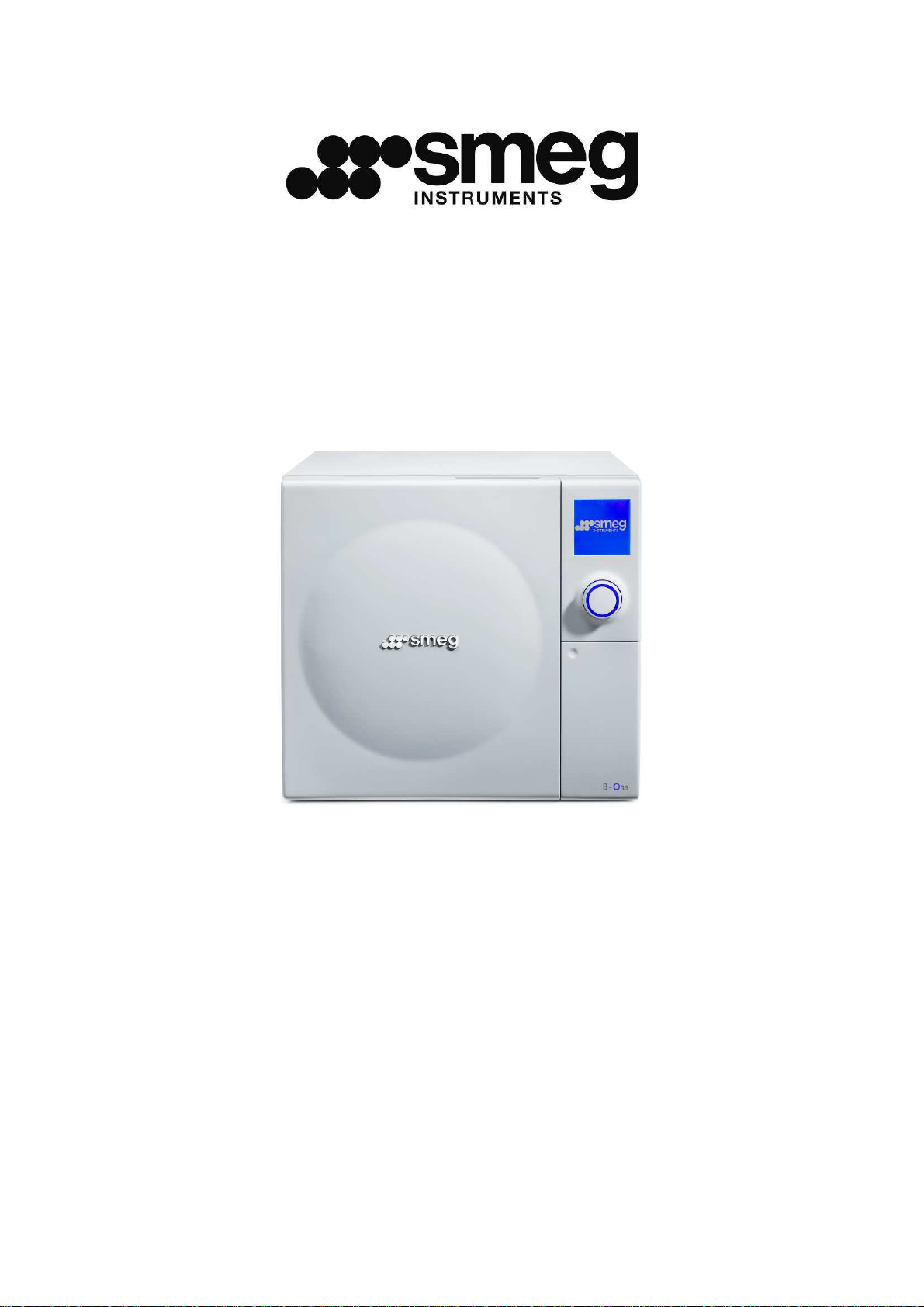

4PRESENTATION........................................................................................14

4.1 FRONT DEVICES – CONTROL PANEL...............................................14

4.2 FRONT HYDRAULIC CONNECTIONS ................................................14

4.3 DEVICES ON THE REAR PANEL........................................................15

5MACHINE OPERATION.............................................................................16

5.1 GENERAL USER INTERFACE.............................................................16

5.2 TURN-ON .............................................................................................17

5.3 STERILIZATION CYCLE SELECTION AND START-UP......................17

5.4 AVAILABLE CYCLES – STERILIZATION AND TESTS........................19

5.5 PREHEATING.......................................................................................20

5.6 SHUTDOWN.........................................................................................21

5.7 RECOVERY AFTER A SUDDEN BLACK-OUT....................................21

5.8 TANK MANAGEMENT..........................................................................21

5.8.1 LOADING TANK FILLING - DEMI...................................................22

5.8.2 DEMINERALISED WATER QUALITY CONTROL..........................24

5.8.3 SUPPLY WATER QUALITY............................................................24

5.8.4 MANUAL DRAINING OF LOADING TANK WATER.......................25

5.8.5 WATER SUPPLY TANK DRAINING...............................................25

5.8.6 AUTOMATIC DRAINING ................................................................26

5.8.7 WATER PURIFIER WATER SUPPLY............................................26

5.8.8 AUTOMATIC SUPPLY FROM AN EXTERNAL CAN......................27

5.9 DOOR CLOSING..................................................................................27

5.10 CYCLE INTERRUPTION...................................................................28

5.11 CYCLE COMPLETED........................................................................29

5.12 PRINTER CONNECTION..................................................................29

5.13 FORCED INTERRUPTION................................................................30

5.14 USER RECOGNITION.......................................................................31

5.15 PASSWORD ENTRY PROCEDURE.................................................31

6SERVICE MENU - SETTINGS ...................................................................32

6.1 CYCLES ARCHIVE - INTERNAL AND MEMORY CARD.....................32

6.2 PREHEATING - WAKE.........................................................................34

6.3 LANGUAGE..........................................................................................34

6.4 DATE AND TIME..................................................................................34

6.5 DATE AND TIME FORMAT..................................................................35

6.6 PASSWORD.........................................................................................35

6.7 DISPLAY...............................................................................................36

6.8 SD MEMORY........................................................................................36

6.9 PRODUCT INFO...................................................................................36

6.10 MAINTENANCE.................................................................................36

6.11 SERVICE...........................................................................................36