Smiths Graseby MS16A Operating manual

Smiths Medical Publications

This publication has been compiled and approved by Smiths

Medical for use with their respective products. It is supplied in

this format to permit users to access the text and illustrations

for their own use e.g. training and educational purposes.

Users of the equipment must ensure that they have read and

understood the contents of the complete manual including the

warnings and cautions and have been trained in the correct use

of the product.

Smiths Medical cannot be held responsible for the accuracy and

any resulting incident arising from information that has been

extracted from this publication and compiled into the users

documentation.

This publication maybe subject to revision and it is the users

responsibility to ensure that the correct version of manual/

text/illustration is used in conjunction with the equipment.

Technical Service

Manual

Part Number 00SM-0105-6

Issue 6 (February 2005)

© 2005 Smiths Medical family of companies. All rights reserved.

Graseby®MS16A

Syringe Driver

SM0105-COV-6.PMD 2/23/2005, 12:12 PM1

MS16A Syringe Driver

Technical Ser vice Manual Issue 6 (February 2005) Page i

Smiths Medical

Published by Smiths Medical.

All possible care has been taken in the preparation of this

publication, but Smiths Medical, accepts no liability for any

inaccuracies that may be found.

Smiths Medical reserves the right to make changes without notice

both to this publication and to the product which it describes.

Copyright © 2005 Smiths Medical family of companies. All rights

reserved.

No part of this publication may be reproduced, transmitted,

transcribed, or stored in a retrieval system or translated into any

human or computer language in any form or by any means without

the prior permission of Smiths Medical.

Smiths Medical MD, Inc.

1265 Grey Fox Road, St. Paul, MN 55112, U.S.A.

European Representative:

Smiths Medical International Limited

Watford, Hertfordshire,

United Kingdom, WD24 4LG

http://www.smiths-medical.com

Registered in England. Company number 362847

Trademarks and acknowledgements:

“Graseby” and “Smiths” are trademarks of the Smiths Medical family

of companies.

All other trademarks are acknowledged as the property of their

respective owners.

SM0105-CON-6.PMD 2/23/2005, 12:12 PM1

MS16A Syringe Driver

Page ii Issue 6 (February 2005) Technical Service Manual

Smiths Medical

DROCEREUSSI

eussI

.oN egnahcrofnosaeR segaP

detceffe etaD

5launaMfoeussi-eRllA0002yaM

6etaroproC.deddastnairavSUdnaxobkcoL

.egnahc.d.i llA5002yraurbeF

SM0105-CON-6.PMD 2/23/2005, 12:12 PM2

MS16A Syringe Driver

Technical Ser vice Manual Issue 6 (February 2005) Page iii

Smiths Medical

Scope of this manual

This manual enables service personnel to service and repair the

MS16A Syringe Driver. It has been updated to incorporate Lockbox

information and the US variant.

Related manuals

Refer to the following Instruction Manual when more detailed

operating information is required. The Service Manual contains basic

driver operation information only.

zMS16A Syringe Driver, MS26 Syringe Driver Instruction

Manual, part number 0105-0549-A

Smiths Medical service contacts

In the event of any queries or problems that cannot be resolved by

this manual, please contact the appropriate Service/ Repair Centre.

UK address

SMITHS MEDICAL INTERNATIONAL LIMITED

Repair Centre

WATFORD

WD24 4LG

ENGLAND

TEL: (+44) (0) 1923 246434 FAX: (+44) (0) 1923 447773

Web: www.smiths-medical.co.uk

USA service address

MARCAL MEDICAL INC.

1114 BENFIELD BLVD, SUITE H

MILLERSVILLE

MARYLAND

21108-2540

TEL: (410) 987 4001 FAX: (410) 987 4004

Web: www.marcalmedical.com

email: [email protected]

SM0105-CON-6.PMD 2/23/2005, 12:12 PM3

MS16A Syringe Driver

Page iv Issue 6 (February 2005) Technical Service Manual

Smiths Medical

Contents

Chapter 1 - Product Overview

Description ............................................................................................................. 1 - 3

Controls ................................................................................................................. 1 - 4

Operation ............................................................................................................... 1 - 4

Packed set ............................................................................................................. 1 - 5

Accessories and consumables ............................................................................. 1 - 6

Chapter 2 - Specification and Standards

Specification .......................................................................................................... 2 - 3

Type ....................................................................................................................... 2 - 3

Infusion time ........................................................................................................... 2 - 3

Rate range .............................................................................................................. 2 - 3

Motor operating interval .......................................................................................... 2 - 3

Drive accuracy ....................................................................................................... 2 - 3

Drive force .............................................................................................................. 2 - 3

Actuator movement ................................................................................................ 2 - 3

Actuator stroke ....................................................................................................... 2 - 3

Syringe sizes.......................................................................................................... 2 - 3

Occlusion pressure ................................................................................................. 2 - 3

Controls .................................................................................................................. 2 - 3

Alarm ...................................................................................................................... 2 - 3

Indicator ................................................................................................................. 2 - 4

Battery type ............................................................................................................ 2 - 4

Battery life .............................................................................................................. 2 - 4

Accuracy of delivery ............................................................................................... 2 - 4

Dimensions ............................................................................................................ 2 - 4

Weight .................................................................................................................... 2 - 4

Operating conditions ............................................................................................... 2 - 4

Transport and storage ............................................................................................. 2 - 4

Materials ................................................................................................................ 2 - 4

Standards .............................................................................................................. 2 - 5

Electrical safety...................................................................................................... 2 - 5

EMC ....................................................................................................................... 2 - 5

Biological evaluation ............................................................................................... 2 - 5

Packaging ............................................................................................................... 2 - 5

Medical device directive 93/42/EEC ....................................................................... 2 - 5

Quality system standards used .............................................................................. 2 - 5

Symbols ................................................................................................................. 2 - 5

Disposal ................................................................................................................. 2 - 6

Chapter 3 - Circuit Descriptions

Circuit descriptions ................................................................................................ 3 - 3

Logic ...................................................................................................................... 3 - 3

Start ....................................................................................................................... 3 - 3

Motor drive ............................................................................................................. 3 - 3

Primary guard ......................................................................................................... 3 - 4

Secondary guard .................................................................................................... 3 - 4

Switch-off alarm...................................................................................................... 3 - 4

Test circuit .............................................................................................................. 3 - 5

Safety features ....................................................................................................... 3 - 5

Low battery indication ............................................................................................. 3 - 5

MS16A Circuit diagram ........................................................................................... 3 - 6

MS16A Printed circuit board layout......................................................................... 3 - 7

SM0105-CON-6.PMD 2/23/2005, 12:12 PM4

MS16A Syringe Driver

Technical Ser vice Manual Issue 6 (February 2005) Page v

Smiths Medical

Chapter 4 - Disassembly and Assembly

General .................................................................................................................. 4 - 3

Tools, equipment and materials required ................................................................ 4 - 3

Removal and dismantling procedures .................................................................... 4 - 5

Case separation...................................................................................................... 4 - 5

Leadscrew and bearing assembly removal .............................................................. 4 - 5

Actuator and back bearing disassembly ................................................................. 4 - 5

PCB removal .......................................................................................................... 4 - 5

Motor and gearbox disassembly ............................................................................. 4 - 6

Assembly procedures ............................................................................................ 4 - 7

Motor and gearbox assembly .................................................................................. 4 - 7

PCB assembly ....................................................................................................... 4 - 7

Actuator and bearing ............................................................................................... 4 - 9

Leadscrew and bearing assembly ........................................................................... 4 - 9

Case assembly ...................................................................................................... 4 - 10

Lockbox ............................................................................................................... 4 - 12

Chapter 5 - Service Test Procedures

Service Test Procedures........................................................................................ 5 - 3

Tools and equipment ............................................................................................... 5 - 3

Adjustments potentiometers ................................................................................... 5 - 4

Service Testing....................................................................................................... 5 - 5

Cam follower adjustment ........................................................................................ 5 - 5

9 Volt thrust test ..................................................................................................... 5 - 7

7 Volt thrust test ..................................................................................................... 5 - 7

Guard test .............................................................................................................. 5 - 8

Flash frequency ...................................................................................................... 5 - 8

Timer and feed rate tests ........................................................................................ 5 - 8

Cam alignment ....................................................................................................... 5 - 9

Half nut slip ............................................................................................................ 5 - 9

Rate switch test...................................................................................................... 5 - 9

Current tests ........................................................................................................... 5 - 9

Sounder check ...................................................................................................... 5 - 10

General .................................................................................................................. 5 - 10

Test Checklist - MS16A ........................................................................................ 5 - 11

Chapter 6 - Maintenance

Maintenance.......................................................................................................... 6 - 3

Cleaning ................................................................................................................ 6 - 3

Annual performance check ................................................................................... 6 - 3

Battery replacement .............................................................................................. 6 - 4

Continuous alarm conversion ............................................................................... 6 - 5

Basic troubleshooting ........................................................................................... 6 - 6

Chapter 7 - Parts List

General assembly of the MS16A ........................................................................... 7 - 3

MS16A PCB assembly .......................................................................................... 7 - 7

SM0105-CON-6.PMD 2/23/2005, 12:12 PM5

MS16A Syringe Driver

Page vi Issue 6 (February 2005) Technical Service Manual

Smiths Medical

Figures

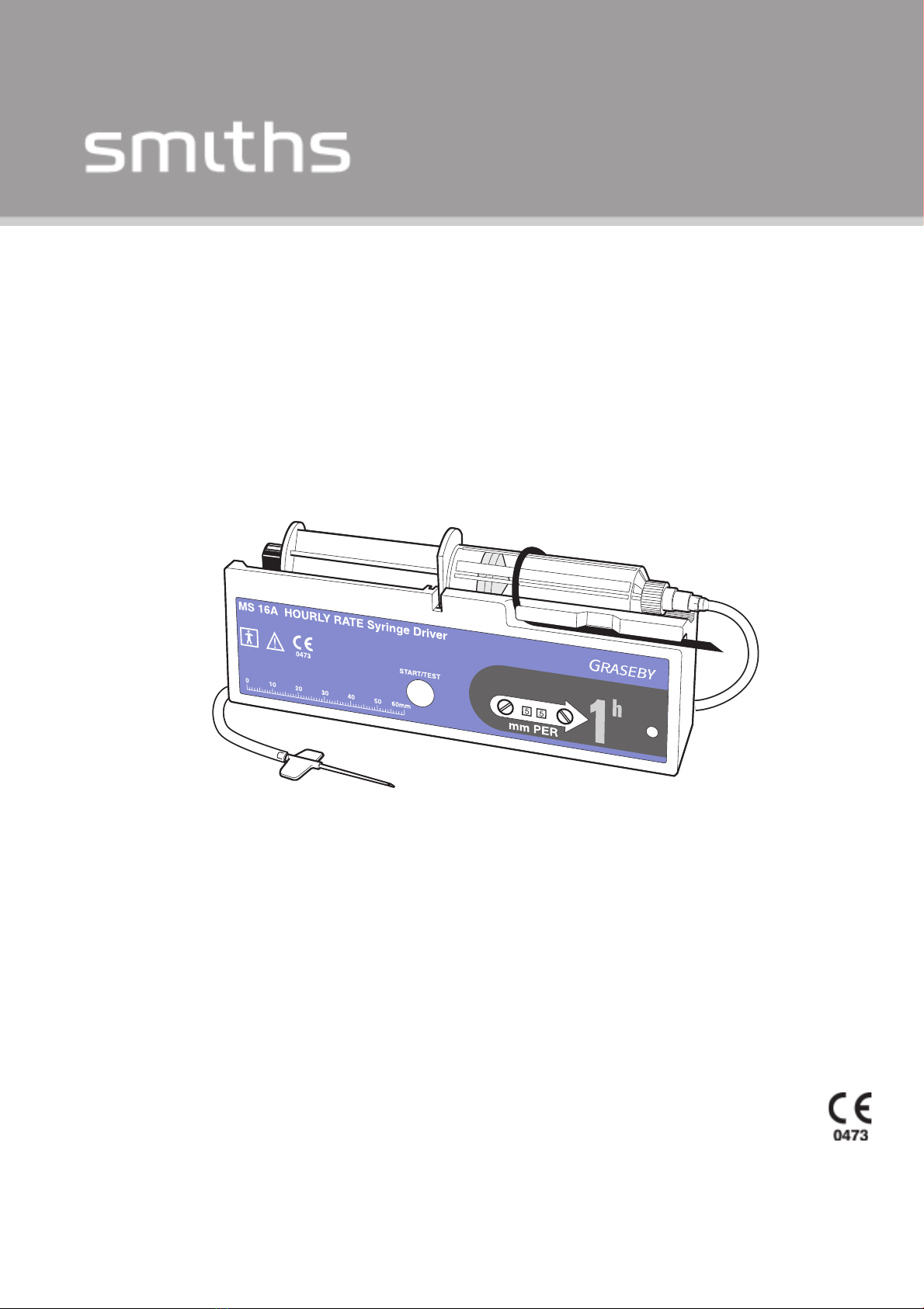

1 - 1 MS16A Hourly rate syringe driver .................................................................. 1 - 3

1 - 2 Lockbox ......................................................................................................... 1 - 3

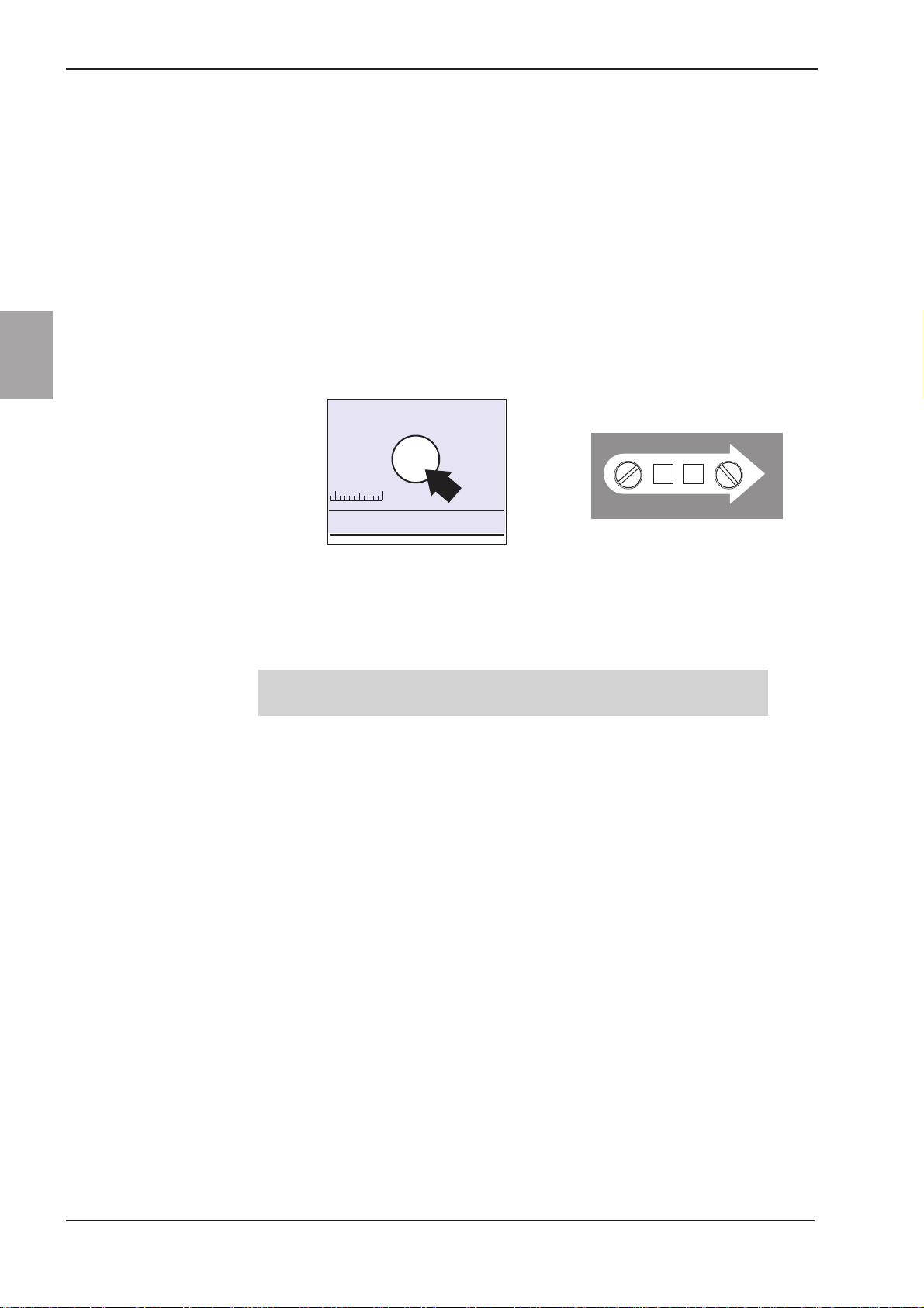

1 - 3 MS16A Controls ............................................................................................ 1 - 4

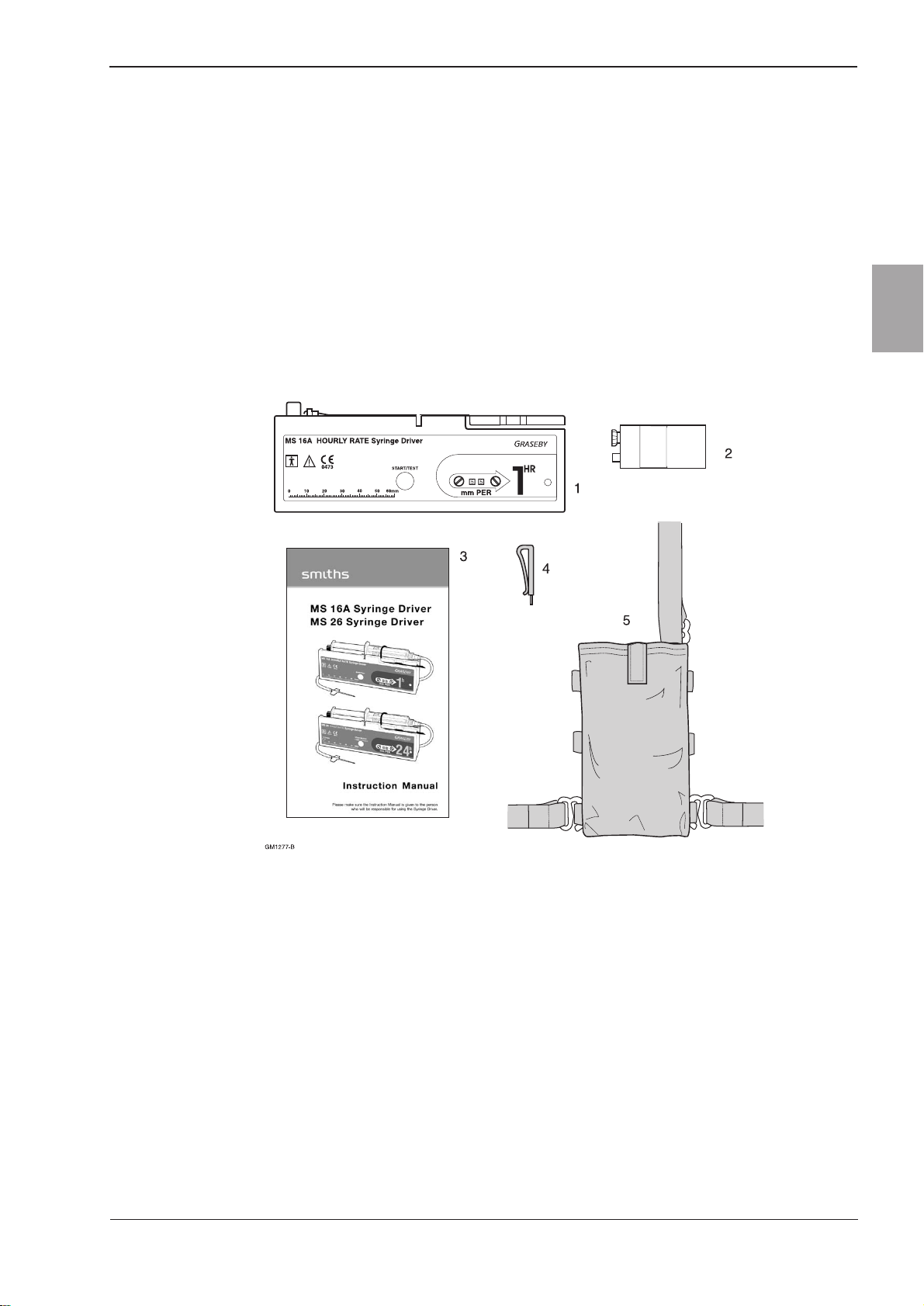

1 - 4 Package contents .......................................................................................... 1 - 5

3 - 1 MS16A Circuit diagram .................................................................................. 3 - 6

3 - 2 MS16A Printed circuit board layout ................................................................ 3 - 7

4 - 1 MS16A exploded view ................................................................................... 4 - 4

4 - 2 Release piezo-transducer assembly .............................................................. 4 - 6

4 - 3 Orientation of dials and rate switches ............................................................ 4 - 7

4 - 4 Foam pad position ......................................................................................... 4 - 8

4 - 5 Piezo-transducer wiring.................................................................................. 4 - 9

4 - 6 Sealant application ....................................................................................... 4 - 10

4 - 7 Lockbox ........................................................................................................ 4 - 12

5 - 1 Cam and cam follower ................................................................................... 5 - 5

5 - 2 Camswitch operating timing ........................................................................... 5 - 5

5 - 3 Typical waveform for one pulse ...................................................................... 5 - 6

5 - 4 Using the cam adjustment tool ...................................................................... 5 - 7

5 - 5 Thrust rig set-up ............................................................................................. 5 - 7

6 - 1 Battery replacement ...................................................................................... 6 - 4

6 - 2 Continuous alarm conversion ......................................................................... 6 - 5

7 - 1 Exploded view of the MS16A Syringe Driver .................................................. 7 - 4

7 - 2 MS16A PCB assembly .................................................................................. 7 - 7

SM0105-CON-6.PMD 2/23/2005, 12:12 PM6

MS16A Syringe Driver

Technical Ser vice Manual Issue 6 (February 2005) Page vii

Smiths Medical

Warnings

Warnings tell you about dangerous conditions that may occur, and

which could lead to death or serious injury to the user or patient if

you do not obey all of the instructions in this manual.

1. Remember the rate is set in milliMETRES

NOT

milliLITRES. The correct rate is essential to

prevent serious injury or death to the patient.

2. Any damaged pumps must be thoroughly tested by a competent person in accordance with the

procedures in this service manual before re-use with a patient. Failure to observe this may result

in patient injury or death.

2. Completely prime the administration set, and remove all air from both the administration set and

the syringe before measuring the mm of fluid length, otherwise the rate calculation will be

incorrect.

3. The driver must only be used with the syringe rubber securing strap fixed firmly in place, thus

preventing an uncontrolled infusion to the patient that could result in serious injury or death.

4. Never take a syringe that is not empty off the driver if it is still connected to the patient.

The infusion line must first be clamped or disconnected to prevent serious injury or death to the

patient.

5. The use of spare parts other than those recommended is not advised, and may affect the correct

operation of the driver, resulting in injury or death.

6. The syringe driver must not be used for infusing medication where pulsatile delivery action is

unacceptable.

7. The syringe driver must not be used in environments with flammable gas mixtures or with oxygen-

enriched atmospheres.

8. If the syringe driver is used in the lockbox, the alarm volume will be reduced.

SM0105-CON-6.PMD 2/23/2005, 12:12 PM7

MS16A Syringe Driver

Page viii Issue 6 (February 2005) Technical Service Manual

Smiths Medical

Cautions

Cautions tell you about dangerous conditions that can occur which

may cause damage to the pump if you do not obey all of the

instructions in this manual.

A damaged pump must never be put into active service, as it

may be a hazard to patients through under- or over-infusing.

1. To prevent serious damage to the driver it must

not

be immersed in any liquids or exposed to

strong organic solvents. If immersion occurs or the driver is subject to a serious spillage or

wetting incident, it must be thoroughly tested by a competent person in accordance with the

procedures in this service manual before re-use with a patient.

2. Wipe off spills immediately. Do not allow fluid or residues to remain on the pump.

3. The pump is not designed to be autoclaved, steam-sterilised, ETO sterilised or subjected to

temperatures in excess of 45° C (113° F). Failure to observe this caution may cause serious damage

to the pump.

4. To avoid possible malfunction of the pump, do not expose the pump to X- rays, gamma rays or

other ionizing radiation, or to the RF interference or strong electric / magnetic fields emitted (for

example) by arc welding equipment or mobile transmitting equipment.

5. Moving parts of the driver do not require lubrication during their lifetime. Worn or stiff parts

should be replaced.

6. Handling the printed circuit board is required during disassembly/ assembly. A static controlled

work station including a conductive mat and grounded wrist strap should be used to provide

protection against electrostatic discharge (ESD) or circuit board damage could result.

Take care to avoid contamination of the exposed switches, circuit tracks and components, e.g. by

the entry of solder particles.

7. Refer all service, repair, testing and calibrations to suitably qualified technical personnel.

Unauthorised modifications to the driver must not be carried out.

8. Federal law restricts these Syringe Drivers for use by or on the order of a physician. This applies to

drivers distributed

only

within the United States.

SM0105-CON-6.PMD 2/23/2005, 12:12 PM8

MS16A Syringe Driver

Technical Ser vice Manual Issue 6 (February 2005) Page ix

Smiths Medical

Glossary

Abbreviations

The following abbreviations are used in this Manual.

Abbreviation Meaning

ABS Acrylonitrile Butadiene Styrene

C Centigrade or capacitor

cNm Centinewton metre

DC Direct Current

gm grams

h/hr hour

hPa Hectopascal (=100 pascals)

IC Integrated Circuit

Kg Kilogram

Kgf Kilogram force

KHz Kilohertz

LED Light Emitting Diode

ml Millilitre

mm Millimetre

N Newton

PCB Printed Circuit Board

R Resistor

RH Relative Humidity

Sec Second

SW Switch

TR Transistor

V Volts

SM0105-CON-6.PMD 2/23/2005, 12:12 PM9

MS16A Syringe Driver

Page x Issue 6 (February 2005) Technical Service Manual

Smiths Medical

SM0105-CON-6.PMD 2/23/2005, 12:12 PM10

1

Graseby®MS16A

Syringe Driver

Chapter 1

Product Overview

SM0105-1-6.PMD 2/23/2005, 2:54 PM1

Technical Service Manual Issue 6 (February 2005) 1 — 3

Smiths Medical MS16A Syringe Driver

1

Chapter 1 - Product Overview

Figure 1-1 MS16A Hourly rate syringe driver

Description

The MS16A Syringe Driver (Figure 1-1) is a portable, battery-

operated device, designed for the continuous infusion of small

volumes of liquid from commercially available disposable syringes.

The driver operates over time spans ranging from less than 30

minutes to 60 hours.

The syringe plunger is operated by a linear actuator, at rates ranging

from 1 to 99 mm/hour (mm PER). The rate required is set by

adjusting two digital rotary switches.

Most brands of syringe can be fitted to the driver, and the volumetric

delivery depends on the size of the syringe being used. A millimetre

scale is provided on the front of the driver to measure the stroke

length of the syringe, so that the rate in mm/hour may be calculated.

For added security, the syringe driver can be secured in a

transparent plastic, lockable box (see Figure 1-2).

When fitted, the box minimises the risk of tampering with the

infusion.

Figure 1-2 Lockbox

SM0105-1-6.PMD 2/23/2005, 2:54 PM3

Issue 6 (February 2005) Technical Service Manual

Smiths Medical

1 — 4

MS16A Syringe Driver

1

The clear plastic lockbox is hinged at the back and features a lock at

the front. The syringe is held in place on the driver by the securing

strap and the infusion line passed through the slot at the front of the

box. When the mm PER setting has been selected and the START/

TEST pushbutton pressed, the loaded driver is located in the box

which is then locked. The patient controls (Figure 1-3) may be viewed

through the clear window at the side of the lockbox.

Controls

Patient controls (Figure 1-3) consist of two rotary set rate mm PER

slotted switches, and a START/TEST pushbutton.

START/TEST

50 60mm

GM0418-A

mm PER

9

GM0307-A

0

Figure 1-3 MS16A Controls

Operation

Note: For detailed operating information, refer to the MS16A, MS26

Instruction Manual, part number 0105-0549.

To start an infusion, fit a primed syringe and press the START/TEST

pushbutton.

When held down, the START/TEST pushbutton tests a safety cut-out

circuit. When released, it starts the drive circuit. Once started, the

front panel LED flashes approximately every second.

When the plunger reaches the end of travel (syringe empty) or is

occluded, the driver switches off, the LED stops flashing and an

audible alarm sounds.

If the START/TEST pushbutton is held down for more than 3 seconds,

the alarm sounds, the driver stops and the LED stops flashing.

If required, the driver can be modified to sound a continuous tone

when the driver stops. See Chapter 6, Maintenance for modification

instructions.

For additional protection, the syringe driver can be secured in a

Lockbox.

SM0105-1-6.PMD 2/23/2005, 2:54 PM4

Technical Service Manual Issue 6 (February 2005) 1 — 5

Smiths Medical MS16A Syringe Driver

1

Packed set

The MS16A packed set (part number 0105-0504) is supplied with the

following items:-

1. MS16ASyringe Driver.

2. Battery, type IEC 6LR61.

3. Instruction manual.

4. Rate adjuster.

5. Shoulder holster (not US version).

6. Clear cover (not shown).

Figure 1-4 Package contents

SM0105-1-6.PMD 2/23/2005, 2:54 PM5

Issue 6 (February 2005) Technical Service Manual

Smiths Medical

1 — 6

MS16A Syringe Driver

1

Accessories and consumables

Item Description Part number

100 cm infusion set PVC line with 25 gauge needle. 0105-0029

Subcutaneous BD 10 ml syringe, Tegaderm dressing 0105-0117

infusionpack alcohol wipe, transfer needle,

100 cm infusion set.

Syringe driver Provides a secure base to stand the 0105-0108

non-slip base syringe drive on a flat surface.

Cover Clear rigid plastic to protect the syringe 0105-0529

driver and syringe.

Holster Washable, soft fabric holster with cover 0105-0027

Instruction manual Instructions for use. Guide to subcutaneous 0105-0549

analgesia, technical and performance

specifications.

Rate adjuster Tool to turn slotted rate switches. 0105-0023

Training pack A full package of presentation, instruction TPF-00130

and testing materials.

Lockbox A transparent plastic, lockable security 0105-0640

container (includes two keys). See page 1-3.

SM0105-1-6.PMD 2/23/2005, 2:54 PM6

2

Graseby®MS16A

Syringe Driver

Chapter 2

Specification and Standards

SM0105-2-6.PMD 2/23/2005, 2:55 PM1

Technical Service Manual Issue 6 (February 2005) 2 — 3

Smiths Medical MS16A Syringe Driver

2

Chapter 2 - Specification and Standards

Type:

Syringe driver with motor driven linear actuator, pulsed motion. Internal 9V

alkaline battery power source. Digital electronic rate control.

Automatic switch off when the syringe is empty.

Infusion time:

< 30 min. - 60 hours

Rate range:

Variable delivery rate of 0 - 99 mm/h in steps of 1 mm/h.

Motor operating interval:

420 ÷ rate = seconds

Drive accuracy:

The accuracy of the linear drive mechanism that pushes the syringe plunger

forward: ± 5%

Drive force:

The force the linear drive mechanism that pushes the syringe plunger forward can

produce: >3 Kg

Actuator movement:

0.12 mm every time motor turns.

Actuator stroke:

60 mm available (depends on syringe).

Syringe sizes:

2 ml to 35 ml

The holster supplied will enclose most types of syringe up to 20 ml capacity.

Occlusion pressure:

3 - 5 Kg

Maximum actuator force 50 N (5 Kgf) @ 9 V

Controls:

START/TEST and mm PER rate adjusters (tens and units digit controls).

Alarm:

Audiblefrequency: 3 kHz ± 0.5 kHz (end of travel: occlusion).

Duration: 5 - 20 secs.

Volume: Audible at 1m with normal or corrected hearing

SM0105-2-6.PMD 2/23/2005, 2:55 PM3

Issue 6 (February 2005) Technical Service Manual

Smiths Medical

2 — 4

MS16A Syringe Driver

2

Indicator:

Low battery level: 7.0 V to 5.5 V (LED stops flashing)

Flashperiod:1.05 secs ± 2%

Yellow solid state LED

Green solid state LED (US)

Battery type:

PP3 size. 9 V, primary alkaline, IEC 6LR61 (or 6LF22) type.

(Duracell MN1604 recommended)

Battery life:

50 full deliveries depending on the operating conditions and battery condition.

Automatic switch off at end of plunger travel.

Accuracy of delivery:

The rate of the actuator is accurate to within plus or minus 5% of the rate set on

the rotary switches.

Dimensions (without syringe):

Height: 53.0 ± 0.5 mm

Width: 166.0 ± 1.0 mm

Depth: 23.0 ± 1.0 mm

Weight (including battery):

190 gm.

Operating conditions:

+10° C to +40° C. 30% to 75% RH (non-condensing).

700 hPa to 1060 hPa

Transport and storage conditions:

-40° C to +70° C. 10% to 100% RH (non-condensing).

500 hPa to 1060 hPa

Materials:

Case and battery cover - ABS RTA50 injection moulding.

Labels - 125 micron fine matt Lexan.

Other materials - nitrile rubber, small plastic parts -Acetal (25% glass filled

Kemetal) and PA-GF (glass-filled nylon).

Metal parts - stainless steel, mild steel.

Circuit board - epoxy glass fabric.

Holster - elasticated soft-backed fabric.

Note:All materials used in this product are latex free.

SM0105-2-6.PMD 2/23/2005, 2:55 PM4

Table of contents

Other Smiths Medical Equipment manuals

Popular Medical Equipment manuals by other brands

Otto Bock

Otto Bock E-MAG Active 17B203-L Instructions for use

ROHO

ROHO ADAPTOR PAD Operation manual

BeautyRelax

BeautyRelax BR-2610 user manual

Pressalit

Pressalit MCT 3 Operation and maintenance manual

MPS

MPS M.C. Rexx QD2000 Series Use Care and Service Parts Manual

Hospira

Hospira Plum 360 Technical & service manual