SMT 600REY User manual

Express Service Manual

Central Systems

600REY, 600WCY, 2000REY

You have just purchased the best

spray washer on the market today.

It incorporates the very latest in

technological advances. To assure you

the best and safest performance as

well as longest equipment life, please

read the enclosed information.

After reading the material in this

manual, should you have a service

problem or need help, please call our

toll free number 1-800-548-3373 or

(479) 636-5776.

TERMS: All parts will be shipped with

check in advance or C.O.D. Commercial

accounts are allowed 15 day terms

from date on invoice with approved

credit.

FREIGHT: All freight will be paid by

the customer. Special consideration

will be given to items under warranty

coverage.

NOTE: Specications found in this manual subject to change without notice.

FOR COMMERCIAL USE ONLY

IMPORTANT DOCUMENT - DO NOT DISCARD

Date PurchasedSerial NumberModel Number

SprayMasterTech.com

2

SMT WARRANTY – LIMITED Eective June 23, 2017

Parts – Spray Master Technologies warrants parts for wall mounted and rack mounted 600 series and 2000 series units to be free

from defects in material or workmanship for a period of 2 years from the date of shipment from the factory excluding items listed

below.

Spray Master Technologies warrants parts for all other units (wall mounted 1100 series and all portable units) to be free from

defects in material or workmanship for a period of 1 year from the date of shipment from the factory excluding items listed below.

This warranty is limited to the original purchaser and includes repairing or replacing parts which manufacturer’s investigation

shows to be defective at the time of shipment from the factory. All parts subject to this warranty shall be returned F.O.B. Spray

Master Technologies, Rogers, Arkansas for examination, repair, or replacement.

Excluded Items – The follow items are excluded: spray guns, wands, hoses, nozzles, Hummer Jet Sr & Jr, casters and handles. These

items are covered by the above warranty for 90 days from the date of purchase for defects in materials or workmanship.

Labor and Travel – Labor and travel to repair or replace defective parts shall be covered for a period of 1 year from date of

shipment (90 days on the excluded items).

Items Voiding Warranty – The following voids all warranty claims on Spray Master Technologies products: Accidental breakage;

abuse; misuse; failures caused by incorrect installation (if not factory installed); failure to correctly wire the system at the electrical

source; chemical or mineral buildup in the pumps and water lines caused by untreated or unltered tap, hard, or recaptured

water; excessive hot water temperatures exceeding 120° Fahrenheit (49° Celsius); using bleach as an injected chemical; injecting

harsh or corrosive chemicals in non-compatible equipment.

www.spraymastertech.com

Phone: (479) 636-5776 • Fax: (479) 636-3245 • 115 E. Linden • Rogers, Arkansas 72756 USA

SMT-WARRANTY-Rev 1-170623-EN Specications are subject to change without notice Printed in the U.S.A.

Returned Goods Policy

Any item returned for warranty consideration or for credit must

have a RETURN AUTHORIZATION NUMBER. Call our Customer

Service Department and discuss the nature of your request.

Please note that all items returned must be returned F.O.B. Rogers,

Arkansas. No collect or C.O.D. shipments will be accepted unless

prior arrangements with our Customer Service Department have

been made. A restocking fee may be applied to items for credit that

are not under warranty. To reach our Customer Service Department

call (800) 548-3373 or (479) 636-5776, or write to Spray Master

Technologies, 115 E. Linden Street, Rogers, Arkansas 72756.

Receiving

Damage: Report any damage to the shipping carton or contents

to the freight carrier. File a claim with the carrier within 10 days if

damage is evident. The manufacturer is not responsible for damage

to the equipment caused by the freight carrier.

Package Contents: Carefully check the contents of the shipping

cartons to ensure the contents agree with the packing list. If items

are missing or if you have any questions, please call our customer

service department at (800) 548-3373 or (479) 636-5776.

Table of Contents

Receiving 2

Returned Goods Policy 2

Warranty 2

Service 3

Service Requirements 3

Express Service Program 3

Model Identification 3

Theory of Operation - Mechanical 4

Theory of Operation - Electrical 5-8

Wiring Diagram 7-8

Central System Diagnostic Chart 9-11

600REY / WCY Parts Breakdown / List 12

2000REY Parts Breakdown / List 13

Recess Mount Remote Parts Breakdown / List 14

Surface Remote Parts Breakdown / List 15

Spray Gun Parts Breakdown / List 15

Hummer Jet Jr. Parts Breakdown / List 16

Hummer Jet Sr. Parts Breakdown / List 17

SMT-300HDR Parts Breakdown / List 18

3

If a problem occurs, please refer to the

“Diagnostic and Maintenance Chart” in the

product Service Manual. Also, refer to the

CAT Pumps and General Pumps Service

Manuals provided with your system. If the

problem is not resolved, then please call

our toll free customer service number:

1-800-548-3373 or (479) 636-5776

The complete model number located on the serial

number label identies the series, type, and operating

specications of the system.

Service Requirements

Water:

• Flow: minimum 5 GPM at 30 PSI (3/4”

hose bib connection)

• Temperature: 40° to 120° F (maximum

120° F)

Electric:

• SMT 600 Series:

208-230V/20Amp (single phase) Dedi-

cated Circuit with Ground Fault breaker.

(NEMA 6-15R) Rated for wet location at

the unit.

• SMT 2000 Series:

208-230V/30Amp (single phase) dedi-

cated circuit with ground fault breaker.

(Nema L630R) rated for wet locations at

the unit.

• International:

See Serial Number Plate on machine

Model IdenticationService

Express Service Program

If you have a problem, we can solve it QUICKLY and EFFICIENTLY.

Your Spray Master Technologies pressure cleaning system has

been designed for rapid and easy repairs. Some, you can do,

others we will do.

With the“EXPRESS SERVICE” program, your machine has been

divided into six major component groups. These groups consist of:

Group #1: Pump, Unloader, Injector, In/out hoses

Group #2: Motor, Switch, and Cord Set

Group #3: Float Tank Assembly

Group #4: High Pressure Hose

Group #5: Spray Gun Assembly

Group #6: Accessories and Miscellaneous Parts

Like circuit boards on a computer, these groups can be

exchanged as a complete unit. The advantage is your savings in

time and money.

With a toll free call to experienced service technicians at Spray

Master Technologies, the problem can usually be diagnosed to

one of the six component groups by answering a few questions.

The person doing the parts replacement doesn’t need to have

any equipment knowledge. He/she need only be able to loosen

and tighten a few bolts. The“Express Service” exchange program

eliminates having an inexperienced person trying to repair a

complicated part.

If you do your own“GROUP” exchange, you won’t be paying for

those high labor rates and expensive service calls. With a few

basic tools, the defective component group can be removed and

replaced or sent to the factory for repair by a qualied technician

with minimum downtime. To further expedite the repair, either

you or your dealer can stock spare components“groups”. However,

with express mail services, rarely does it take more than 48 hours to

receive a component. This is usually faster and less expensive than

many service companies can make a service call.

The enclosed information shows all components groups and

accessories. Our trained personnel are ready to help. If you need

service, try our “EXPRESS SERVICE” plan. It will save you time and

money.

Model #: SMT 600 RE Y 22 20 04 0850

Series

SMT 600

SMT 2000

Type

-RE = Rack Mount System

-WC = Wall Mount System

Chemical Injection

Y = Before the Pump

X = After Pump

Pump Flow Rate (gallons per minute)

22 = 2.2 GPM 36 = 3.6 GPM

29 = 2.9 GPM 40 = 4.0 GPM

Motor Horsepower

20 = 2 HP Motor5 0 = 5 HP Motor

Nozzle Size

04 = #4 Nozzle 05= # 5.0 75 = # 7.5 Nozzle0 8 = #8 Nozzle

Max Operating Pressure

0850 = 850 PSI 1100 = 1100 PSI2 000 = 2000 PSI

4

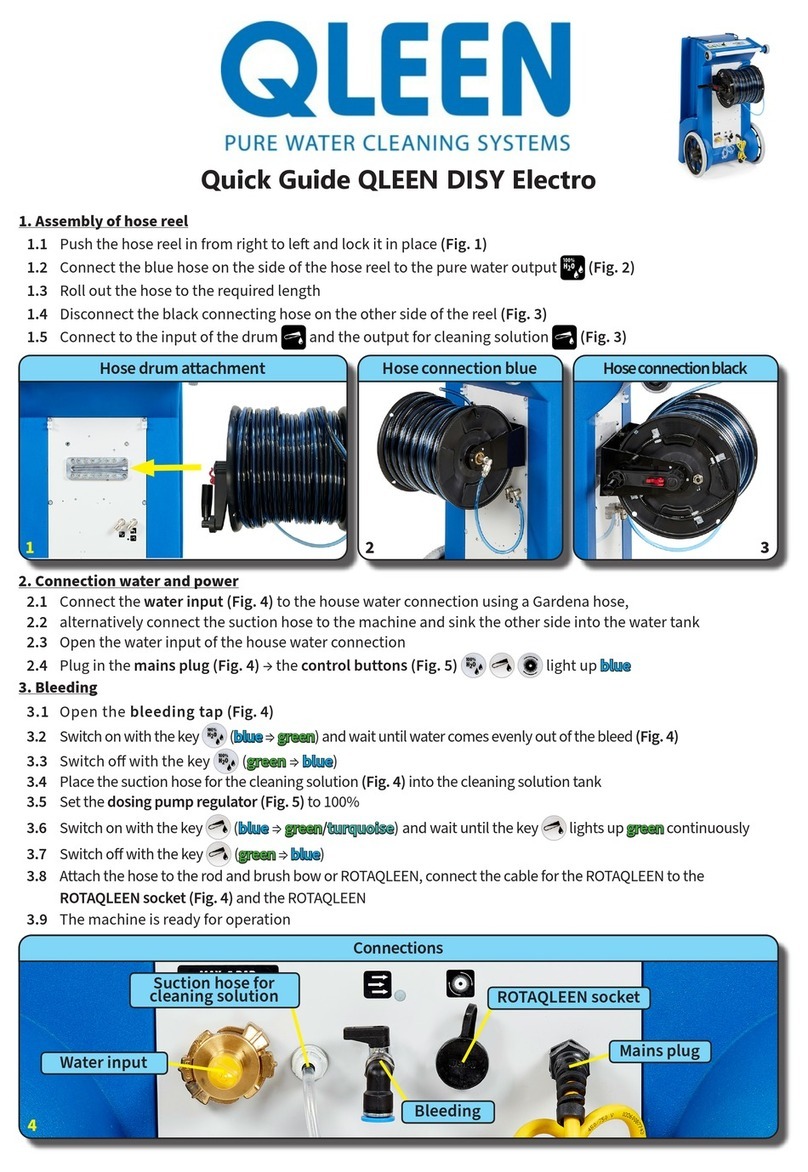

General Principle of Pressure Washers.

Pressure in Spray Master Technologies and most other pressure

washers is produced by forcing a xed gallons per minute

(GPM) volume of water through an orice. The xed volume of

water is provided by a positive displacement pump, which will

produce a specic GPM of water ow regardless of the operating

pressure. The orice is a part of the nozzle on the end of the

Theory of Operation - Mechanical

Figure 1. Simplied SMT Central Pressure Cleaning System

The water supply source to the system must provide a minimum

ow of ve gallons per minute at 30 PSI, and should be ltered

through a high quality lter to eliminate contaminates that will

cause wear and shorten the life of the pump. The output from the

lter enters the oat tank through one or two oat valves within

the tank. The oat tank maintains a minimum water source for

the pump and is monitored by the oat switch. If the water level

falls below the oat switch, the system is disabled to prevent

damage that would occur from running the pump dry.

When the pump is in operation, it draws water from the oat

tank and pumps it out to the unloader assembly. The unloader

assembly directs the water through the system to the spray gun

if the spray gun is open, or it diverts the water back to the oat

tank, through the re-circulate path, if the spray gun is closed. In

addition, the unloader is used to set the maximum operating

pressure of the system.

From the high-pressure output of the unloader, the water ows

through the chemical inhibit ow-switch, past the bleeder valve

assembly to the interconnecting high-pressure tubing and out to

all the remote stations. The pump can service up to ten remote

stations. Each remote station is equipped with a quick-connect

port for connection of a high-pressure hose.

spray gun. The volume of water and the orice size can be varied,

resulting in a corresponding change in the operating pressure

of the system. The following paragraphs explain the function of

system components and ow sequence in SMT pressure cleaning

systems. This brief theory of operation will provide a service tech

with information necessary to quickly diagnose and correct any

malfunction of the system.

Water Flow

Refer to Figure 1, Simplied SMT Central Pressure Cleaning

System, for the following discussion. The key plumbing

components of a basic SMT Central Pressure Wash System

consists of 1) water lter, 2) water supply oat tank, 3) oat

switch, 4) pump, 5) unloader valve, 6) chemical inhibit ow

switch, 7) bleeder valve, 8) interconnecting hi-pressure tubing, 9)

remote stations, 10) hi-pressure hose, 11) spray gun/nozzle, 12)

line pressure release valve and 13) thermal limit switch.

From the remote station, the water ows through the hose to

the spray gun. The water passes through the spray gun when

the gun-trigger is activated and ows to the nozzle at the end of

the lance. As the water is forced through the orice in the nozzle,

pressure builds within the system. The size of the orice in the

nozzle determines the maximum pressure that can be achieved

with the ow rate provided by the pump. The smaller the orice,

the higher the pressure. Most SMT systems are equipped with a

dual nozzle selector and two nozzles. The nozzle with the small

orice will produce high pressure, while the nozzle with the large

orice produces low pressure.

Note: Selecting the correct nozzle size

for the system is critical to the correct

operation and cleaning eectiveness.

A nozzle with too small an orice will

result in less water ow and reduced

cleaning eectiveness and may result

in too high pressure, overloading the

motor. A nozzle too large will result in

lower pressure and reduced cleaning

eectiveness.

During operation, when the spray gun trigger is released,

pressure builds in the system until it overcomes the tension on

the unloader spring and activates the unloader assembly. When

the unloader assembly is activated, it locks pressure into the

output line to the spray gun and redirects the ow of water, at

low pressure, through the recirculate line back to the system oat

tank. Recirculation will continue until the line pressure is reduced

by reactivating the trigger on the spray gun. This unloading

feature prolongs the life of the pump and motor by removing the

strain on the pump and motor during periods when the spray

gun is inactive.

5

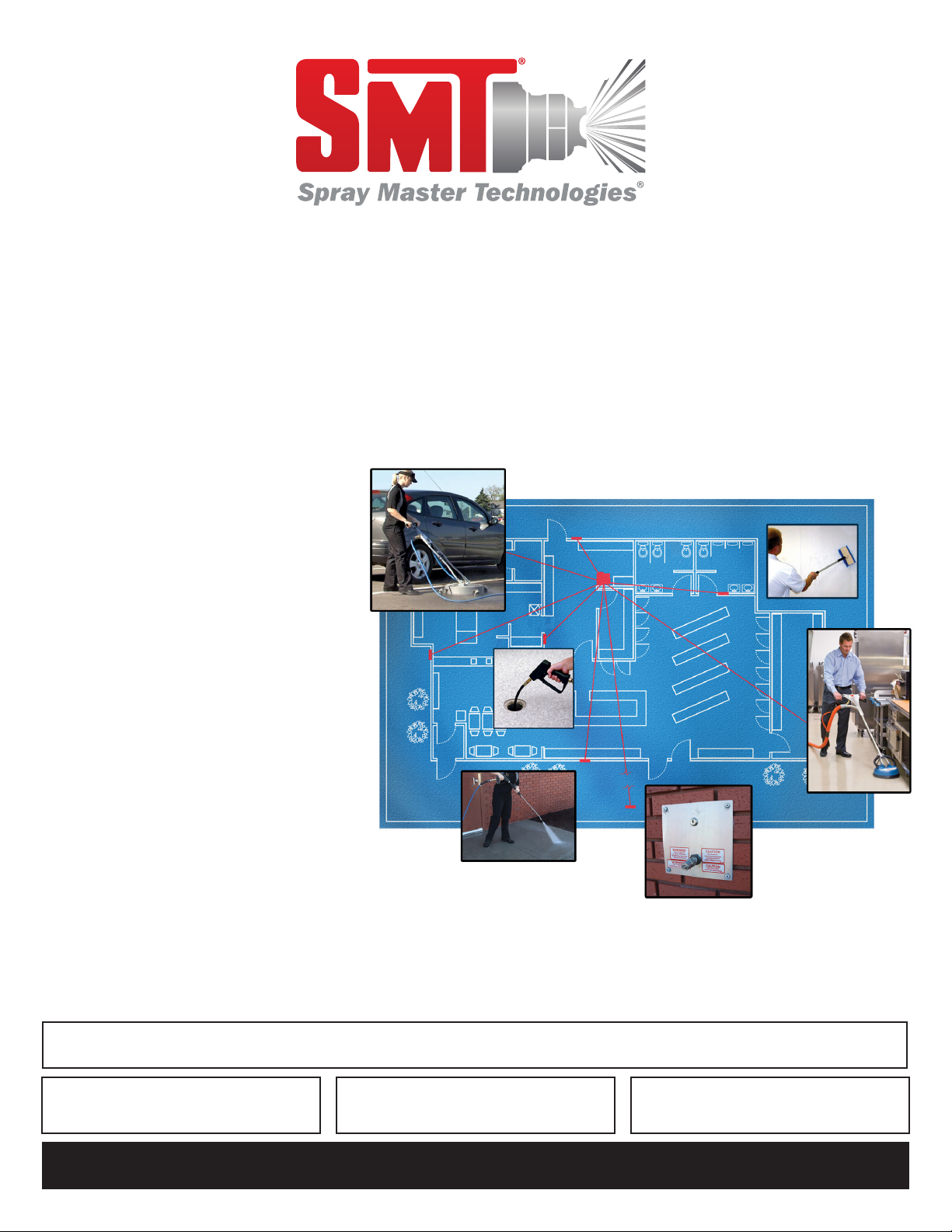

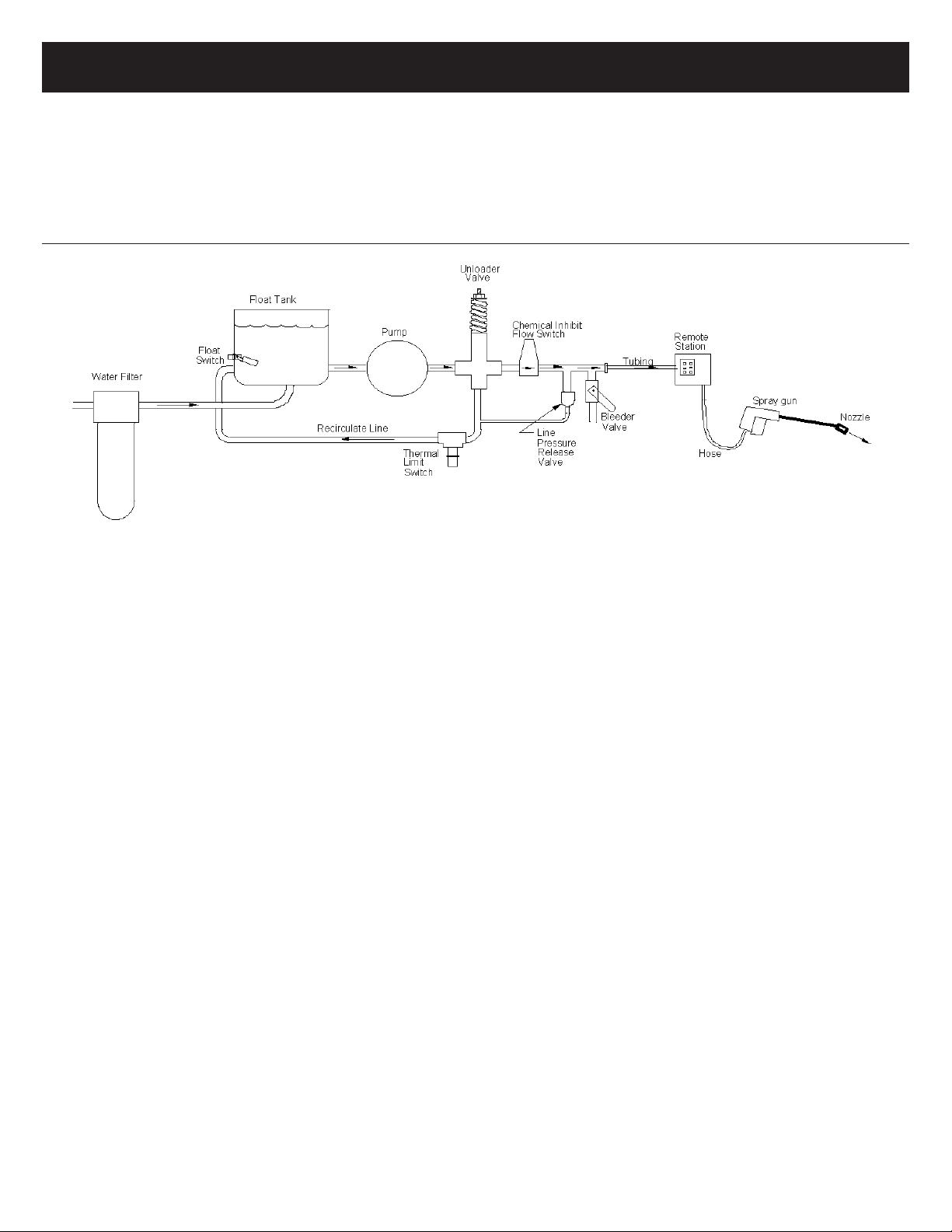

Theory of Operation - Electrical

Electrical Requirements

The electrical requirements for the SMT Central Pressure Cleaning

system depends on the SMT model installed. Regardless of model,

all central systems must be powered by a dedicated circuit with a

Ground Fault Circuit Interrupter (GFCI) breaker in the main breaker

panel. Electrical service requirements are:

2000REY: (Nema L630R) 208/230 Volt, 30 Amp rated for wet locations

at the unit.

600REY/WCY: (NEMA 6-15R) 208/230 Volt, 20 Amp Rated for wet

location at the unit.

Line voltage to the system is supplied from the dedicated outlet

through power cord into the SMT Master Control Panel (MCP) to

the input side of contactor K3.

Motor Drive Circuit

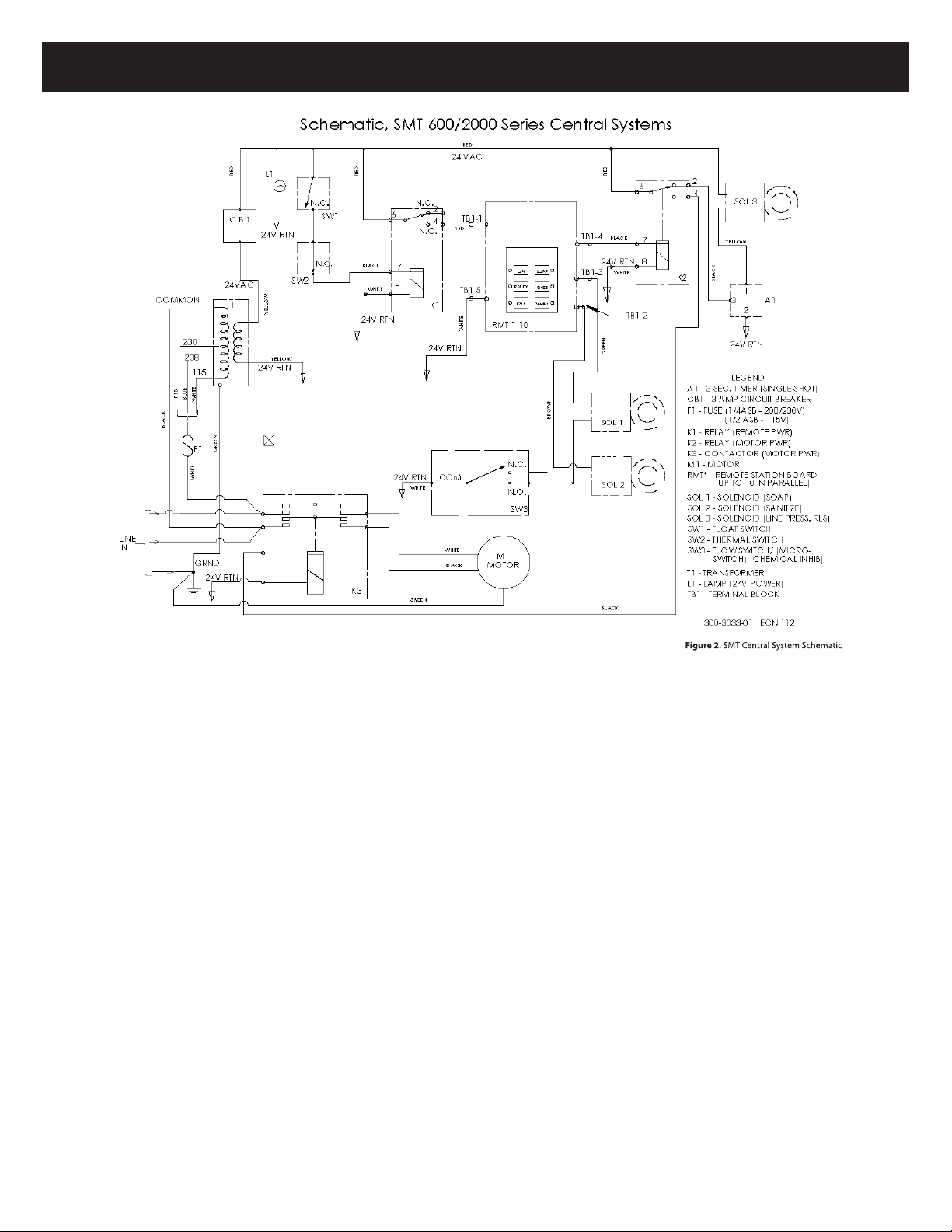

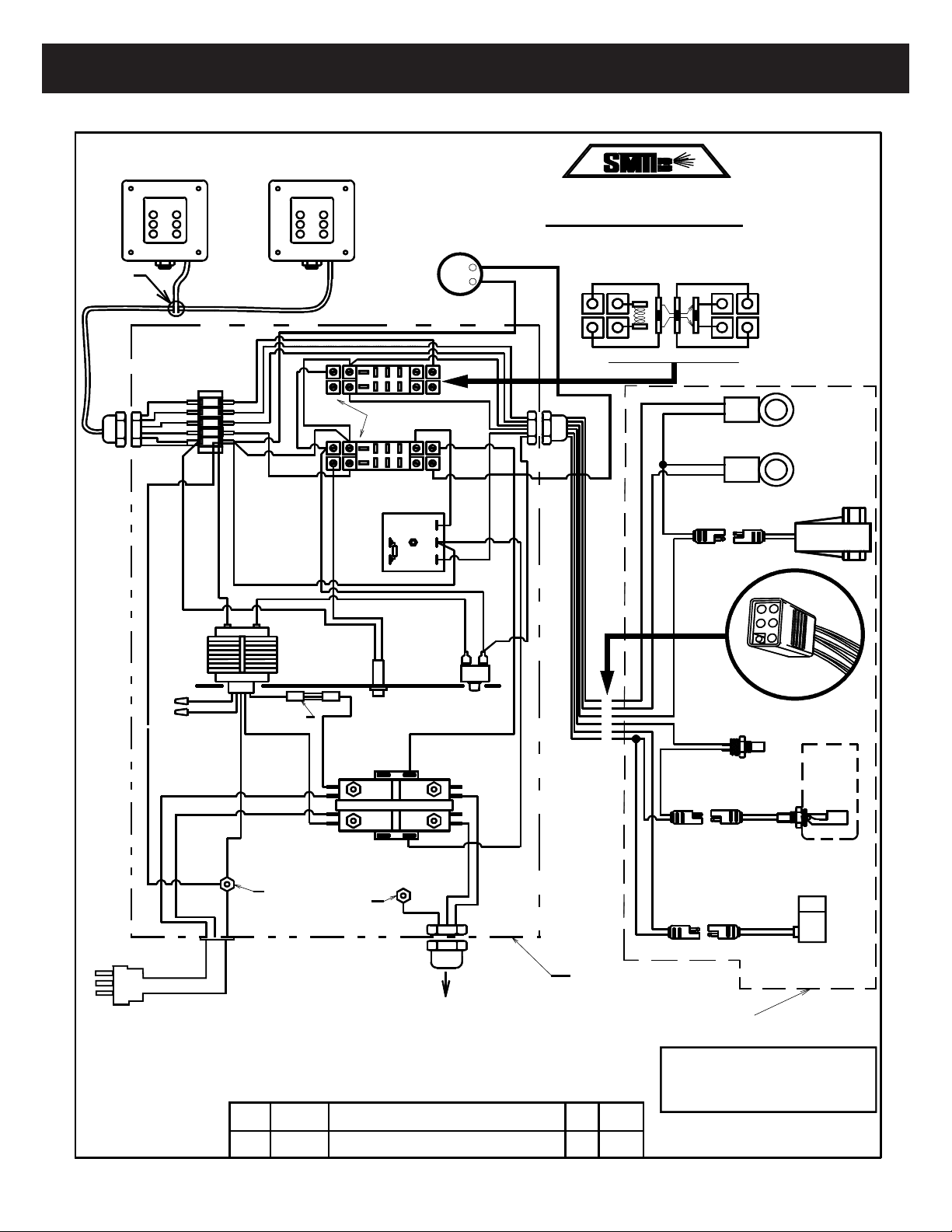

Refer to Figures 2 and 4 (schematic and wiring diagram of the SMT

electrical circuits). When contactor K3 is energized by the control

circuit, the line voltage is applied through the contactor to the

motor. The motor starts up, drives the pump and produces water

ow.

Control Circuits

Control circuits within SMT central systems are 24 Volt AC low

voltage. The control circuits include the 24V AC power circuit,

water condition sensors circuit, remote stations circuit, motor

control circuit, chemical control circuits and the line pressure

release circuit.

24V AC power circuit provides low voltage AC for all control

circuits. Line voltage to the system is picked o of the contactor

line terminals and applied through fuse (FI) to the multi-tap input

of the 24V transformer (T1). F1 requires a ¼ amp slow-blow fuse

for 208 and 230 volt inputs. Voltage is applied to Transformer (T1)

through one of three leads of the primary winding. The multi-tap

primary leads permit system operation on 208 or 230 volts AC.

The 24V output is routed through 3 amp circuit breaker (CB1)

to the 24V AC Power indicator (LI) and the rest of the control

circuits. Current ow through all circuits returns to the transformer

through the 24V AC return line. The 24V AC is connected to Float

Switch (SW1), Remote Station Power Relay (K1), Motor Drive Relay

(K2), and to the Line Pressure Release Solenoid (SOL 3).

Water condition sensor circuits provide protection to the pump

when adverse water conditions exist. The sensors will remove

power from the remote stations when the water supply level is

too low or water temperature exceeds 120° F. Float Switch (SW1)

is closed when the water level in the oat tank is above the

minimum operating level for the pump, completing the circuit

through Thermal Limit Switch (SW2) which will energize Relay (K1)

and apply power to all Remote Stations (RMT-*). Thermal Limit

Switch (SW2) is normally closed. When water temperature within

the system exceeds 120°F, Thermal Limit Switch (SW2) will open

and remove power from the remote stations.

(continued on next page)

6

Theory of Operation - Electrical (cont.)

Remote station control circuits facilitate remote operation of

the pump and consists of up to ten remote stations (TB1 – TB10),

ve conductor shielded cable and 5-pole Terminal Block (TB1). All

signals to and from the remote stations enter and exit the Master

Control Panel through terminal block (TB1). Signal lines to/from

the remote are:

Red wire – 24V AC power (out to remote station)

White wire – 24V AC return (out to remote station)

Black wire – 24V AC motor control signal (in from remote

station)

Green wire – 24V AC soap control signal (in from remote

station)

Brown wire – 24V AC sanitizer control signal (in from

remote station)

All remote stations are connected in parallel through the 5

conductor shielded cable. Each remote is spliced into the main

trunk of the control cable by color matching and connecting the

wires at each splice.

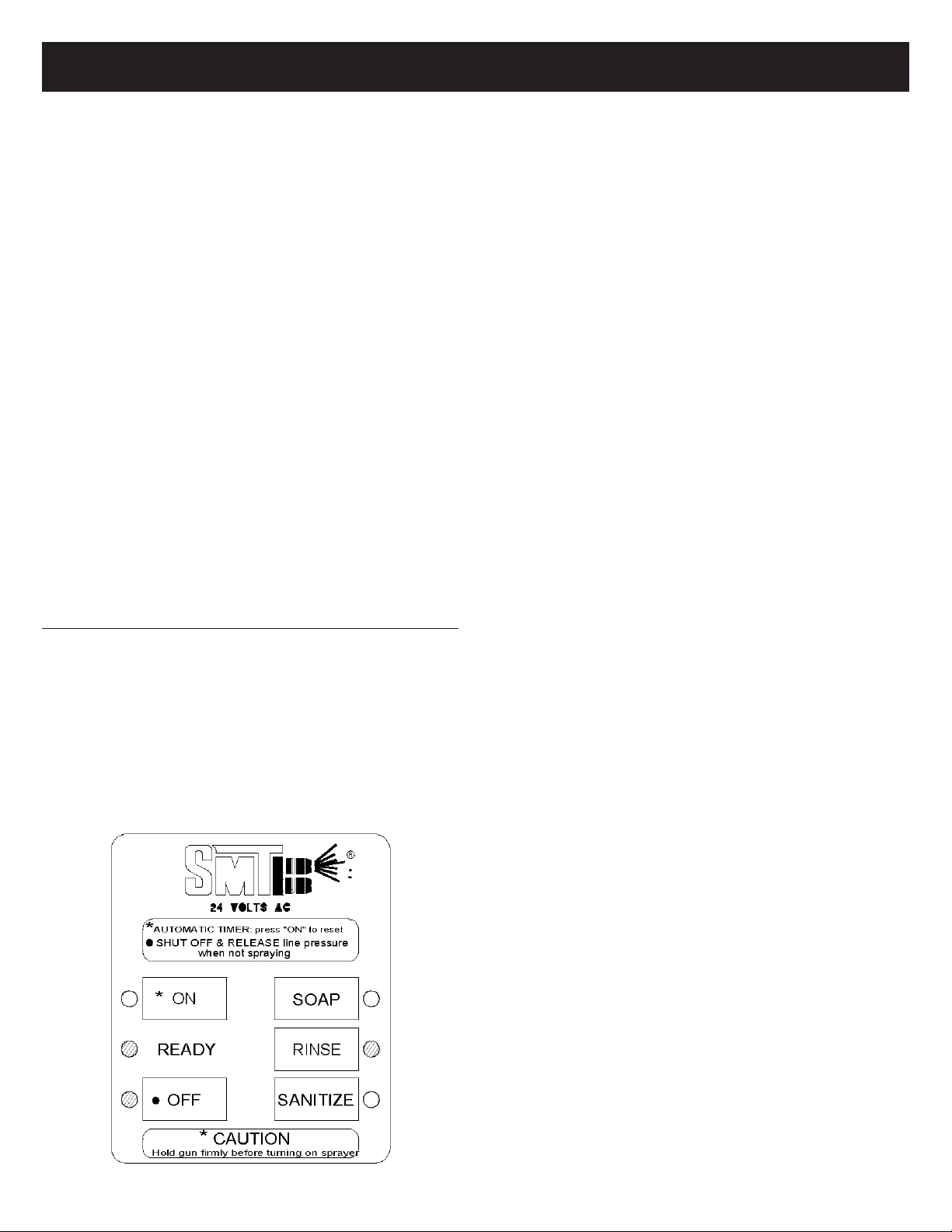

Refer to Figure 3, Remote Station Control Panel. When power

is initially applied to each remote station, the Remote Station

Control Panel will power-up in the “READY” state with the

indications and outputs as shown.

Touch pad Control Lead/ Output

Button Lamp Signal Wire Signal

ON o Motor control Black 0 volt

READY on n/a

OFF on n/a

SOAP o Soap control Green 0 volt

RINSE on n/a

SANITIZE o Sanitizer control Brown 0 volt

The remote stations will remain in the “READY” state until it is

operated with the touch-pad buttons on its control panel or

another remote is operated. When the “ON”button is pressed,

the “ON”lamp illuminates, the“READY” lamp and “OFF”lamp will

extinguish, and 24V AC will be present at the motor control signal

output (black wire). The motor control output must be active for

either the soap or sanitize controls to be active regardless of what

the soap or sanitize lamps may indicate.

Note: The motor control lead (black) is both an output and input

for the remote station. When any remote station is turned to “ON”

the 24V AC out from that remote station is applied to the motor

control circuit and to the Motor Control lead (black) of all other

remote stations. The 24V AC applied by the active remote station

to all other remote stations becomes an “inhibit” input signal. The

inhibit signal will force the remotes out of the “READY” state and

disable them.

The Motor control circuit is the signal control path from the

remote station to turn on the pump. When the ON button is

pressed on the remote station, the motor control signal (24V AC) is

sent through the 5-conductor control cable black wire to Terminal

Block (TB1) pin 4 in the Master Control Panel. From TB1-4, 24V

AC is sent to the coil of Motor Control Relay (K2). When K2 closes,

24VAC power is applied through its contacts to the coil of Motor

Contactor (K3) to turn on the pump motor (M1).

Chemical Control Circuits are driven by the remote station

circuit boards and control the ow of chemical in the system.

The chemical control circuits become functional only when the

pump is ON. While the pump is running, the operator may select

either Soap or Sanitizer using the Remote Station Control Panel.

The Soap circuitry and the Sanitize circuitry operation is identical.

When the operator selects Soap, the remote station Control Panel

will send 24V AC out the green lead through the 5-conductor

cable to Terminal Block (TB1) pin 3 of the Master Control Panel.

From TB1-3 the 24V AC is routed to the coil of Soap Solenoid

(SOL 1). SOL1 is connected in series with Chemical Inhibit Switch

(SW3) to the 24V AC return. If SW3 is closed, indicating that water

is owing out to the spray gun, the Solenoid is activated and

chemical is injected into the owing water. If the spray gun is

closed and the water is re-circulated to the oat tank rather than

through the ow switch, the ow switch SW3 is open and the

chemical solenoids are disabled. Only one chemical control circuit

can be enabled at a time.

The Line Pressure Release Circuit controls the Line Pressure

Release Valve (SOL3) to automatically release pressure from the

system, upon turning the pump o. The line pressure release

circuit is driven by the normally closed output of Motor Control

Relay (K2). When the pump is turned “OFF” by the control panel,

Relay K2 is de-energized, sending 24V AC from the relay to solid

state 3-Second Timer (A1) pin 3. Upon receiving the 24V AC signal,

A1 energizes SOL3 for three seconds to open the solenoid and

release any pressure that may remain in the pressurized output

lines. SOL3 is de-energized and closes the Line Pressure Release

Valve at the end of three seconds, or immediately upon turning

the pump back “ON

Figure 3. SMT Remote Station Panel

7

Figure 4. SMT Central System Wiring Diagram

Theory of Operation - Electrical (cont.) Wiring Diagram

1

2

34

56

3-AMP

MANUAL

RESET

BREAKER

LINE (L1)

LINE (L2) OR NEUTRAL

GREEN

GREEN

WHITE

BLACK

CONTACTOR

LEAD (TO MOTOR)

WARNING:

GFCI REQUIRED IN SUPPLY CIRCUIT.

ALL CONNECTIONS MUST BE RATED

FOR WET LOCATIONS, MUST

COM-

PLY WITH ELECTRICAL CODES.

WIRING DIAGRAM, CENTRAL SYSTEMS

ROGERS,ARK. 72756

SPRAY MASTER TECHNOLOGIES

MASTER CONTROL PANEL

30 AMP

CAUTION: HIGH VOLTAGE

WARNING: DISCONNECT POWER BEFORE SERVICING

208, 230, VOLT SYSTEMS

N.C.

GROUND

LUG

208/230 VAC

200-1025

1

2

34

56

LUG

RED

BRO WN

GREEN

BLACK

WHITE

BRO WN

RED

GREEN

BLACK

WHITE

WHITE

BLACK

BLACK

BLACK

RELAY,

TIME DELAY

RED

RED

YELLOW

BLACK

BLACK

FUSE,

1/4 AMP, SB

N.O.

N.C.

RED

300-2849

300-2887 SOCKET, WITH

300-2888 RELAY, SPDT

5 POLE

BARRIER STRIP

300-2837

REMOTE STATION BOX

24 VOLT, 5/6 CONDUCTOR SHIELDED CABLE

REMOTE STATION BOX

SPLICE -

ISOLATE COLORS

TO COLORS:

RED TO RED ETC.

24 VAC 24 VAC

GREEN

YELLOW

COMMON

BLUE WIRE

NOT USED

AC+

AC-

LOAD

YELLOW

WHITE

WHITE

300-2885

GROUND

(OPTIONAL 20 AMP

FOR SMT 600)

WHITE

SEE VOLTAGE

WIRING LABLE ON

TRANSFORMER

N.C.

5

6

1

3

4

2

N.C.

1

2

3

MULTI-

CONNECTOR

WIRE ROUTING

FROM CONNECTOR

300-2888/300-2887 SOCKET/RELAY DETAIL

6

5

4

BROWN

WHITE

WHITE

GREEN

BLACK

BLACK

SALES & SERVICE - 1-800-548-3373

TRANSFORMER

300-2861

300-2482

RED

BLACK OR WHITE

LED (24V)

N.O.

33

111

77

WHITE

RMT-1 RMT-2

TB1

K1

K2

F1

L1

SOL 3

SW1

SW2

M1

K3

T1

CB1

SW3

SOL 1

SOL 2

A1

1

2

3

4

5

HOUR

ME T ER

(OPTIONAL)

+

-

BLACK

WHITE

12

Add Powr Cord to Master Control Panel

Tom

6/28/18

SMT 600REY,600WCY

SHIEL DE D DRAIN WIRE

GREEN

Pump Assembly

Incoming Power Cord

208V / 15A Nema 6-15R

SOLENOID

FLOAT TANK

SWITCH

THERMAL SWITCH

SOLENOID

SOAP

SANITIZE

PRESSURE RELIEF

SOLENOID

SWITCH

FLOW

CHG

ECN#

DESCRIPTION OF CHG

DATE

BY

8

Figure 5. SMT Central System Wiring Diagram

Theory of Operation - Electrical (cont.) Wiring Diagram

1

2

34

56

3-AMP

MANUAL

RESET

BREAKER

LINE (L1)

LINE (L2) OR NEUTRAL

GREEN

GREEN

WHITE

BLACK

CONTACTOR

LEAD (TO MOTOR)

WARNING:

GFCI REQUIRED IN SUPPLY CIRCUIT.

ALL CONNECTIONS MUST BE RATED

FOR WET LOCATIONS, MUST

COM-

PLY WITH ELECTRICAL CODES.

WIRING DIAGRAM, CENTRAL SYSTEMS

ROGERS,ARK. 72756

SPRAY MASTER TECHNOLOGIES

MASTER CONTROL PANEL

30 AMP

CAUTION: HIGH VOLTAGE

WARNING: DISCONNECT POWER BEFORE SERVICING

208, 230, VOLT SYSTEMS

N.C.

GROUND

LUG

208/230 VAC

200-1025

1

2

34

56

LUG

RED

BRO WN

GREEN

BLACK

WHITE

BRO WN

RED

GREEN

BLACK

WHITE

WHITE

BLACK

BLACK

BLACK

RELAY,

TIME DELAY

RED

RED

YELLOW

BLACK

BLACK

FUSE,

1/4 AMP, SB

N.O.

N.C.

RED

300-2849

300-2887 SOCKET, WITH

300-2888 RELAY, SPDT

5 POLE

BARRIER STRIP

300-2837

REMOTE STATION BOX

24 VOLT, 5/6 CONDUCTOR SHIELDED CABLE

REMOTE STATION BOX

SPLICE -

ISOLATE COLORS

TO COLORS:

RED TO RED ETC.

24 VAC 24 VAC

GREEN

YELLOW

COMMON

BLUE WIRE

NOT USED

AC+

AC-

LOAD

YELLOW

WHITE

WHITE

300-2885

GROUND

(OPTIONAL 20 AMP

FOR SMT 600)

WHITE

SEE VOLTAGE

WIRING LABLE ON

TRANSFORMER

N.C.

5

6

1

3

4

2

N.C.

1

2

3

MULTI-

CONNECTOR

WIRE ROUTING

FROM CONNECTOR

300-2888/300-2887 SOCKET/RELAY DETAIL

6

5

4

BROWN

WHITE

WHITE

GREEN

BLACK

BLACK

SALES & SERVICE - 1-800-548-3373

TRANSFORMER

300-2861

300-2482

RED

BLACK OR WHITE

LED (24V)

N.O.

33

111

77

WHITE

RMT-1 RMT-2

TB1

K1

K2

F1

L1

SOL 3

SW1

SW2

M1

K3

T1

CB1

SW3

SOL 1

SOL 2

A1

1

2

3

4

5

HOUR

ME T ER

(OPTIONAL)

+

-

BLACK

WHITE

12

Add Powr Cord to Master Control Panel

Tom

6/28/18

SMT 2000REY

SHIEL DE D DRAIN WIRE

GREEN

Pump Assembly

Incoming Power Cord

208V-230V / 30A Nema L630R

SOLENOID

FLOAT TANK

SWITCH

THERMAL SWITCH

SOLENOID

SOAP

SANITIZE

PRESSURE RELIEF

SOLENOID

SWITCH

FLOW

CHG

ECN#

DESCRIPTION OF CHG

DATE

BY

9

(continued on next page)

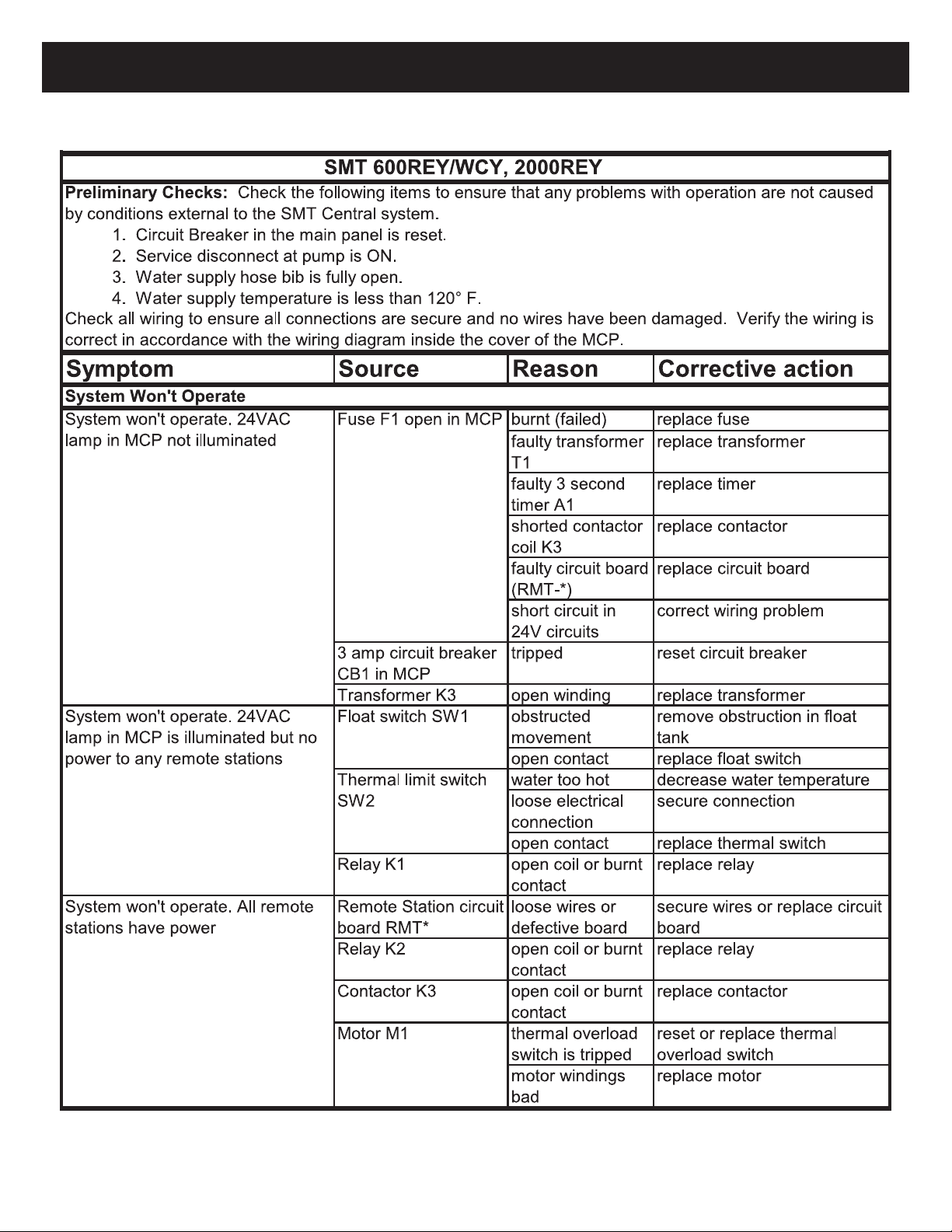

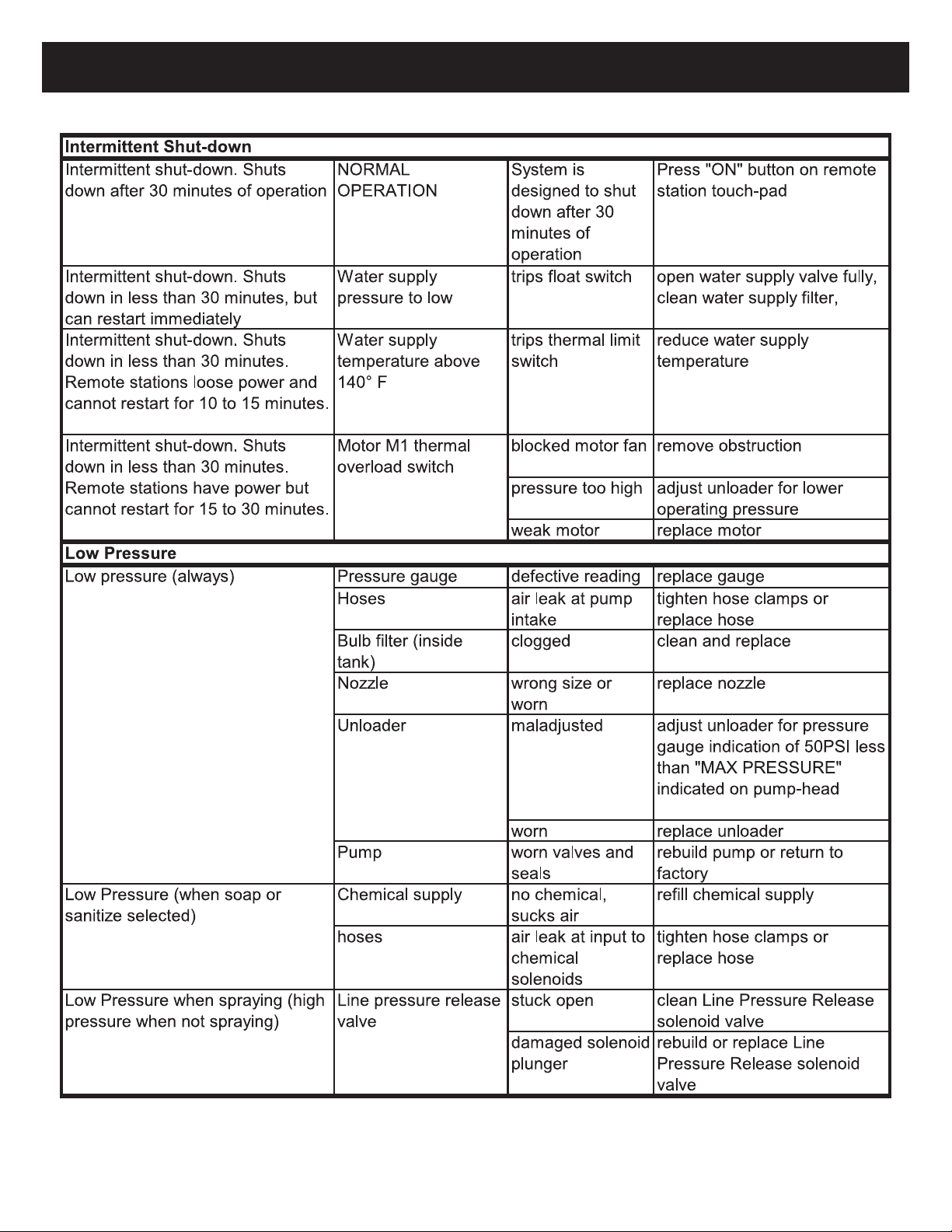

Central System Diagnostic Chart

10

Central System Diagnostic Chart (cont.)

(continued on next page)

11

Central System Diagnostic Chart (cont.)

12

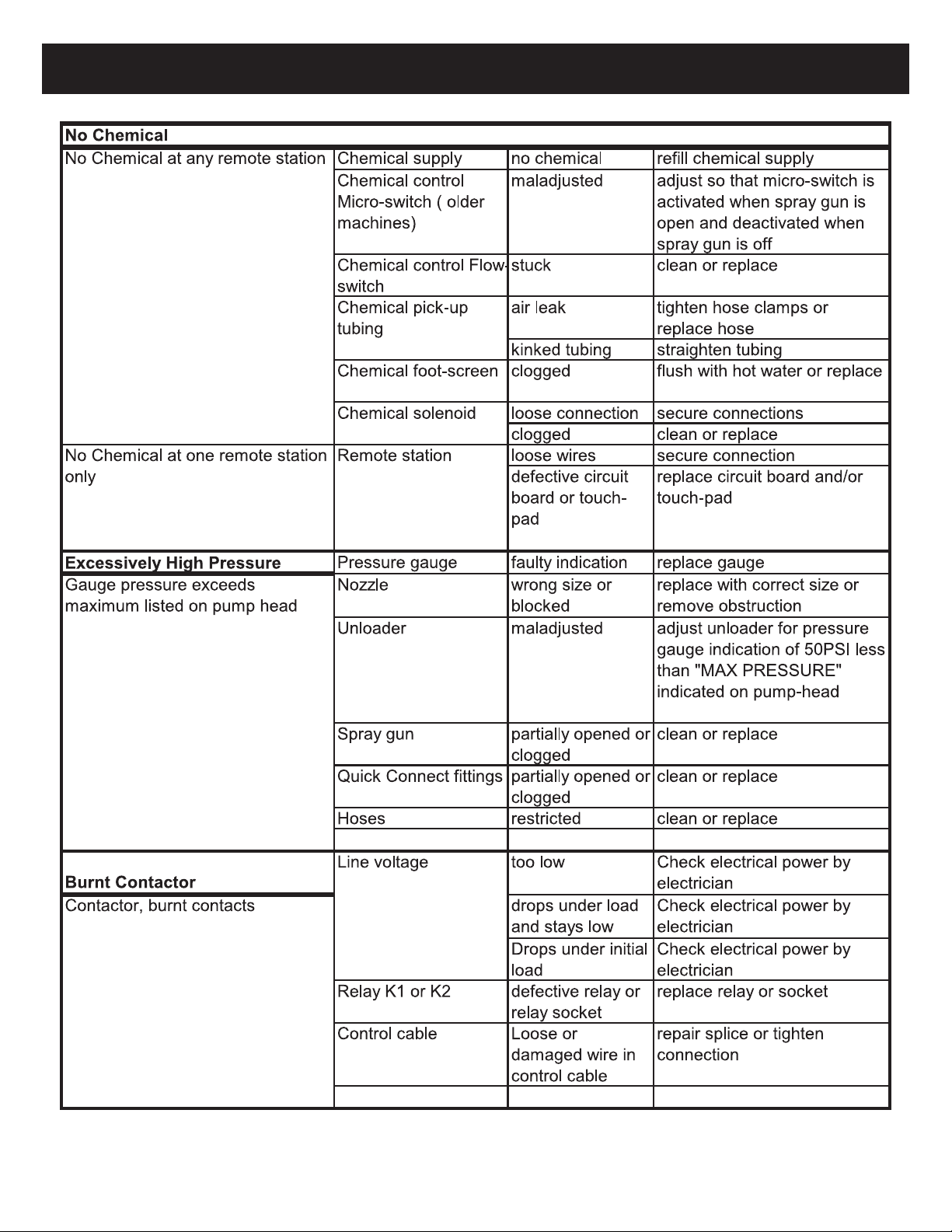

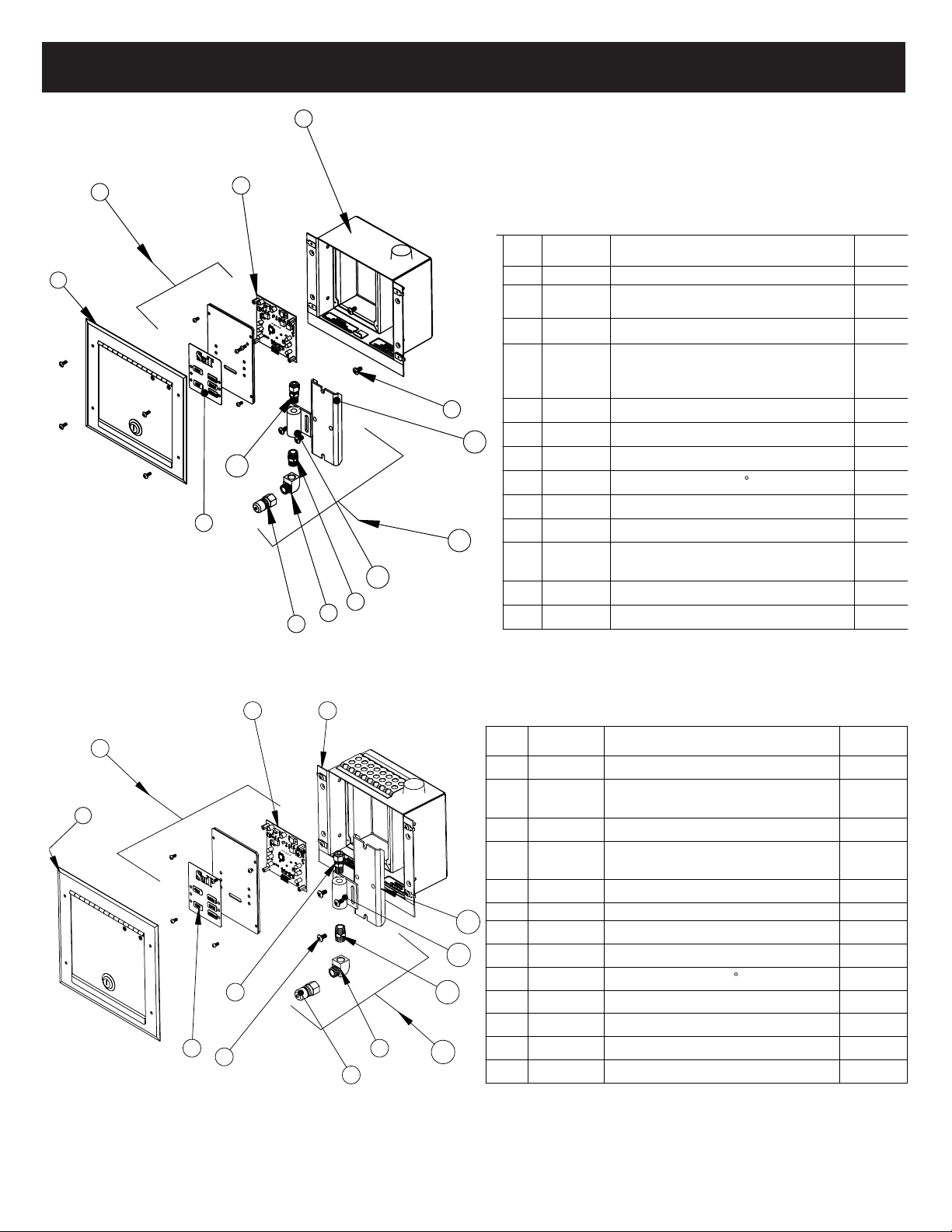

600REY / WCY Parts Breakdown / List

Figure 6.

600REY/WCY Exploded View

7

8

18

1

6

4

511

12

14

13

15

16

10

9

2

3

17

Item 5. 300-0838 is the

item changing for ETL.

ITEM

PART No.

DESCRIPTION

QTY.

Length

U/M

1

300-1733

Unloader, 600REY/WCY w/Flow Switch

1

Ea

Unloader Assy, 600REY/WCY, Hi-Temp

2

300-2756

Frame, Plt, 600W, SS, 600 Wlmnt Series

1

Ea

3

300-0494

Hardware: 600REY, Working Assy, Phan

1

Ea

4

300-1885

Panel Master Control, 600 Control Sys

1

Ea

5

300-0838

Pwr Cord, 6', 240V, 15A, Nema 6-15

1

Ea

6

300-0403

Tank, 600WD/REY/WCY w/Float Switch

1

Ea

7

300-0041

Motor Assy, 600REY/WCY, 208-230V, Prwrd

1

Ea

300-0040

Motor Assy, 600REY/WCY, 115V, Prewired

300-0642

Motor Assy, 600REY/WCY, 220V, HZ, Prwrd

8

300-2582

Pump, 600WCY, 2.2G w/Oil, Ga & Ftngs

1

Ea

300-2583

Pump, 600WCY, 2.9G w/Oil, Ga & Ftngs

9

300-1518

Tubing, 1/4" ID, Clear Nylex Reinforced

1

Ea

10

300-0477

Solenoid Chemical Assy, 600REY/WCY

1

Ea

11

300-2840

Harness, Pump Assy, Branched 6 Pin

1

Ea

12

300-3120

Tubing, Vinyl, 1/4 ID x 3/8 OD, Clear

2 8

�

13

300-3808

Hose, Water Supply 6' FM Ballcock

1

Ea

14

300-2693

Filter Assy, Water Supply

1

Ea

15

300-3543

Oil,16oz Btls, General Pmp, 100216

1

Ea

16

300-3623

Replacement Filter, 5 Micron, 2.5x10

1

Ea

17

300-0495

Hardware: 600REY, Final Assy, Phan

1

Ea

18

300-1967

Valve, Bleeder 3/8 Tube, Central System

1

Ea

600REY, Unit

01

DO NOT SCALE DRAWING

SHEET 1 OF 1

07/05/18

Thomas Schwirian

UNLESS OTHERWISE SPECIFIED:

SCALE: 1:50

WEIGHT:

REV

A

SIZE

Description:

NAME

DATE

COMMENTS:

ENG APPR.

CHECKED

DRAWN

FINISH

MATERIAL

INTERPRET GEOMETRIC

TOLERANCING PER:

DIMENSIONS ARE IN INCHES

TOLERANCES:

FRACTIONAL

ANGULAR: MACH

BEND

TWO PLACE DECIMAL

THREE PLACE DECIMAL

PROPRIETARY AND CONFIDENTIAL

THE INFORMATION CONTAINED IN THIS

DRAWING IS THE SOLE PROPERTY OF

ASSEMBLED PRODUCTS CORP. ANY

REPRODUCTION IN PART OR AS A WHOLE

WITHOUT THE WRITTEN PERMISSION OF

ASSEMBLED PRODUCTS CORP. IS

PROHIBITED.

Assembled Products Corp.

300-5286

DWG. NO.

7

8

18

1

6

4

511

12

14

13

15

16

10

9

2

3

17

Item 5. 300-0838 is the

item changing for ETL.

ITEM

PART No.

DESCRIPTION

QTY.

Length

U/M

1

300-1733

Unloader, 600REY/WCY w/Flow Switch

1

Ea

Unloader Assy, 600REY/WCY, Hi-Temp

2

300-2756

Frame, Plt, 600W, SS, 600 Wlmnt Series

1

Ea

3

300-0494

Hardware: 600REY, Working Assy, Phan

1

Ea

4

300-1885

Panel Master Control, 600 Control Sys

1

Ea

5

300-0838

Pwr Cord, 6', 240V, 15A, Nema 6-15

1

Ea

6

300-0403

Tank, 600WD/REY/WCY w/Float Switch

1

Ea

7

300-0041

Motor Assy, 600REY/WCY, 208-230V, Prwrd

1

Ea

300-0040

Motor Assy, 600REY/WCY, 115V, Prewired

300-0642

Motor Assy, 600REY/WCY, 220V, HZ, Prwrd

8

300-2582

Pump, 600WCY, 2.2G w/Oil, Ga & Ftngs

1

Ea

300-2583

Pump, 600WCY, 2.9G w/Oil, Ga & Ftngs

9

300-1518

Tubing, 1/4" ID, Clear Nylex Reinforced

1

Ea

10

300-0477

Solenoid Chemical Assy, 600REY/WCY

1

Ea

11

300-2840

Harness, Pump Assy, Branched 6 Pin

1

Ea

12

300-3120

Tubing, Vinyl, 1/4 ID x 3/8 OD, Clear

2 8

�

13

300-3808

Hose, Water Supply 6' FM Ballcock

1

Ea

14

300-2693

Filter Assy, Water Supply

1

Ea

15

300-3543

Oil,16oz Btls, General Pmp, 100216

1

Ea

16

300-3623

Replacement Filter, 5 Micron, 2.5x10

1

Ea

17

300-0495

Hardware: 600REY, Final Assy, Phan

1

Ea

18

300-1967

Valve, Bleeder 3/8 Tube, Central System

1

Ea

600REY, Unit

01

DO NOT SCALE DRAWING

SHEET 1 OF 1

07/05/18

Thomas Schwirian

UNLESS OTHERWISE SPECIFIED:

SCALE: 1:50

WEIGHT:

REV

A

SIZE

Description:

NAME

DATE

COMMENTS:

ENG APPR.

CHECKED

DRAWN

FINISH

MATERIAL

INTERPRET GEOMETRIC

TOLERANCING PER:

DIMENSIONS ARE IN INCHES

TOLERANCES:

FRACTIONAL

ANGULAR: MACH

BEND

TWO PLACE DECIMAL

THREE PLACE DECIMAL

PROPRIETARY AND CONFIDENTIAL

THE INFORMATION CONTAINED IN THIS

DRAWING IS THE SOLE PROPERTY OF

ASSEMBLED PRODUCTS CORP. ANY

REPRODUCTION IN PART OR AS A WHOLE

WITHOUT THE WRITTEN PERMISSION OF

ASSEMBLED PRODUCTS CORP. IS

PROHIBITED.

Assembled Products Corp.

300-5286

DWG. NO.

13

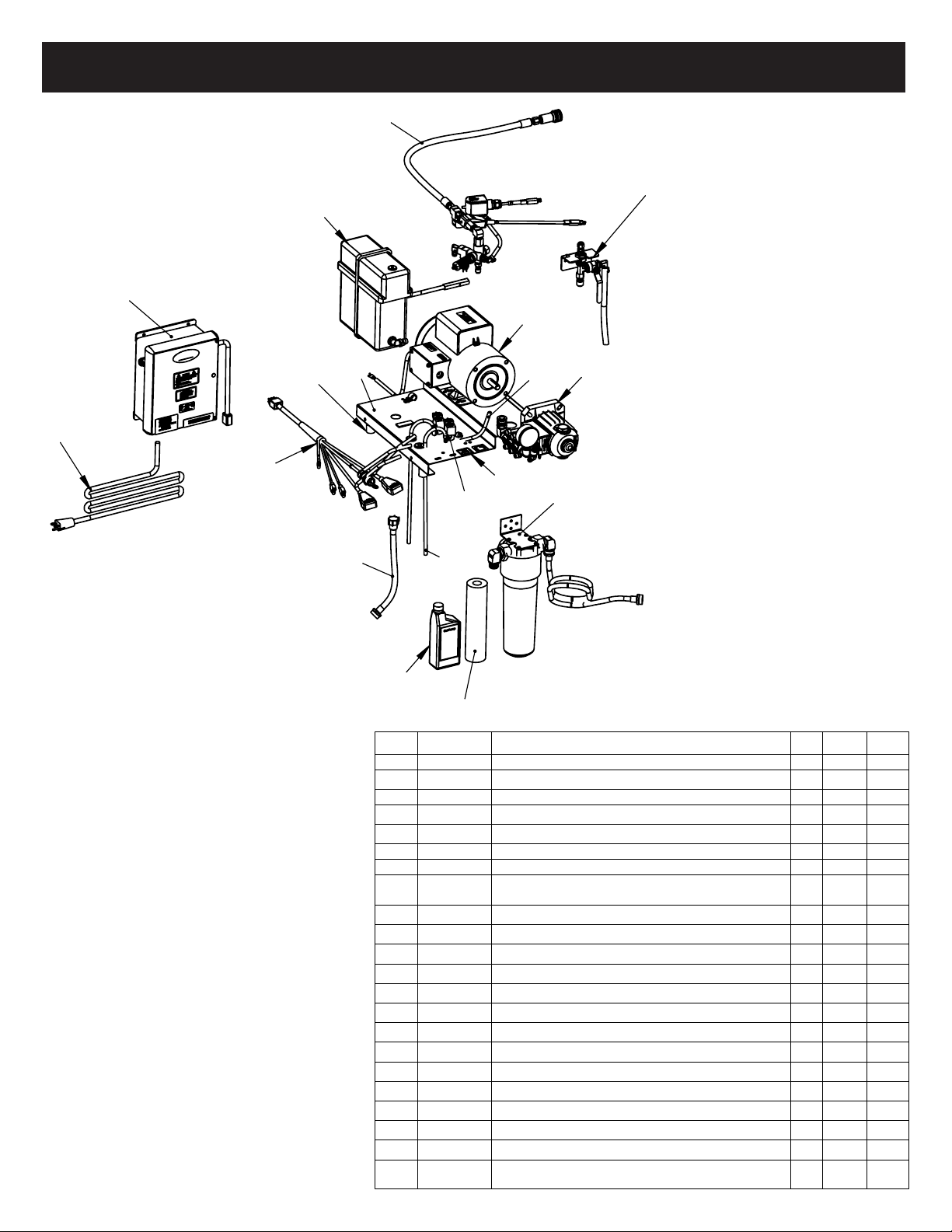

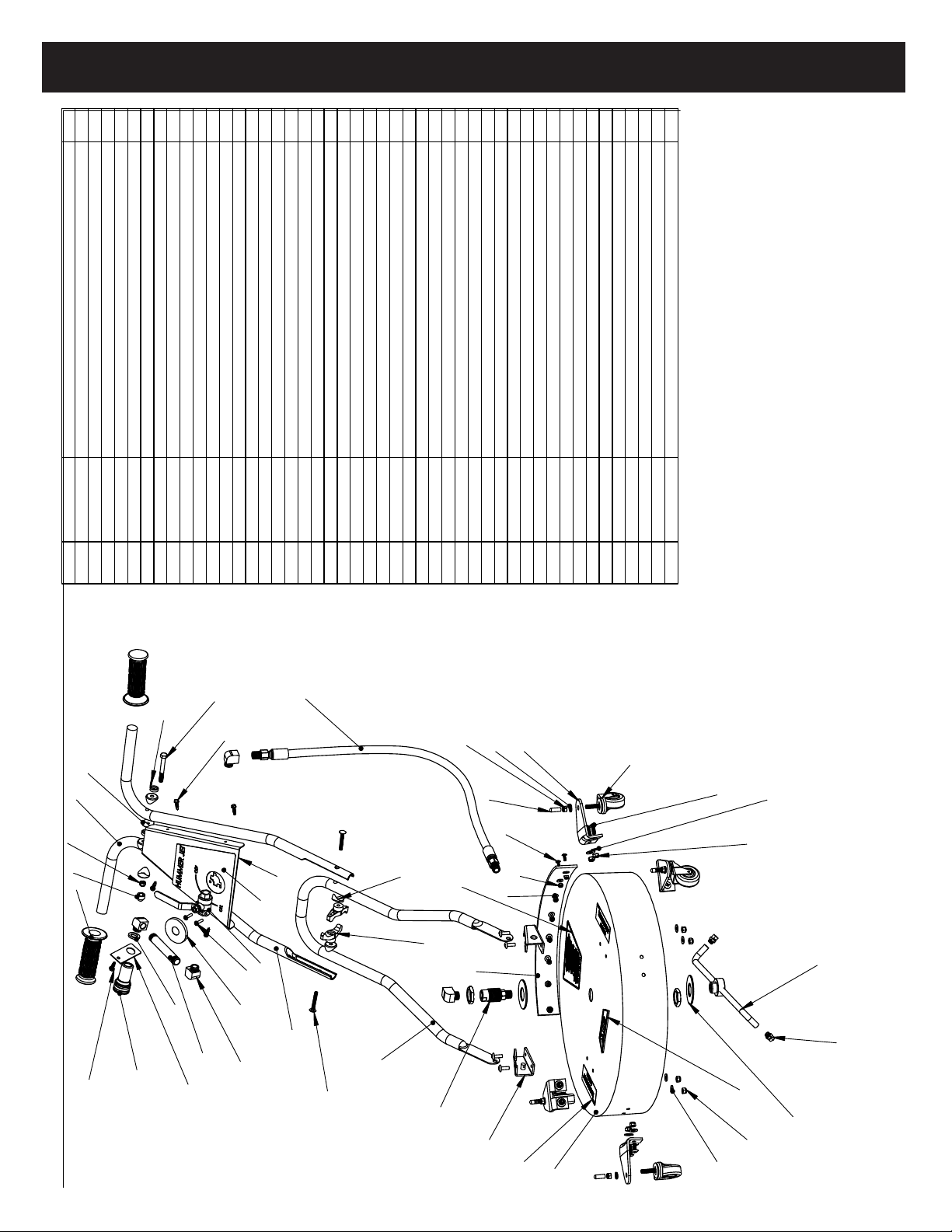

2000REY Parts Breakdown / List

Figure 7.

2000REY Exploded View

6

8

9

1

2

5

7

3

10

1

4

14

12

13

11

Item 9. 300-0840 is the

item changing for ETL

ITEM

PART No.

DESCRIPTION

QTY.

Length

U/M

1

300-1732

Unloader, 2000REY/WCY w/Flow Switch

1

2

300-1831

Frame Plate, 2000REY, SS

1

3

300-2584

Pump, 2000REY/WCY, 3.6G, Oil, Ga & Ftngs Price/Roll

1

4

300-2665

Cover, 5HP Motor, 16Ga, SS, 2000PE/REY

1

5

300-0442

Solenoid, Chemical Assy w/Fi�ngs

1

6

300-1671

Tank, 2000REY w/Float Switch

1

7

300-2840

Harness, Pump Assy, Branched 6 Pin

1

8

300-1883

Panel Master Control, 2000 Control Sys

1

9

300-0840

Pwr Cord, 6', 20V, 30A, Nema L630

1

10

300-1967

Valve, Bleeder 3/8 Tube, Central System

1

11

300-2700

Filter Assy, Water Supply, 2000 REY

1

12

300-3623

Replacement Filter, 5 Micron, 2.5x10

1

13

300-7605

Oil,16oz Btls, General Pmp, 100216

2

14

300-3120

Tubing, Vinyl, 1/4 ID x 3/8 OD, Clear

1 8

Ft

2000REY, Unit

SHEET 1 OF 1

01/03/18

SCALE: 1:50

WEIGHT:

REV

A

SIZE

Description:

DATE

Assembled Products Corp.

300-5074

DWG. NO.

6

8

9

1

2

5

7

3

10

1

4

14

12

13

11

Item 9. 300-0840 is the

item changing for ETL

ITEM

PART No.

DESCRIPTION

QTY.

Length

U/M

1

300-1732

Unloader, 2000REY/WCY w/Flow Switch

1

2

300-1831

Frame Plate, 2000REY, SS

1

3

300-2584

Pump, 2000REY/WCY, 3.6G, Oil, Ga & Ftngs Price/Roll

1

4

300-2665

Cover, 5HP Motor, 16Ga, SS, 2000PE/REY

1

5

300-0442

Solenoid, Chemical Assy w/Fi�ngs

1

6

300-1671

Tank, 2000REY w/Float Switch

1

7

300-2840

Harness, Pump Assy, Branched 6 Pin

1

8

300-1883

Panel Master Control, 2000 Control Sys

1

9

300-0840

Pwr Cord, 6', 20V, 30A, Nema L630

1

10

300-1967

Valve, Bleeder 3/8 Tube, Central System

1

11

300-2700

Filter Assy, Water Supply, 2000 REY

1

12

300-3623

Replacement Filter, 5 Micron, 2.5x10

1

13

300-7605

Oil,16oz Btls, General Pmp, 100216

2

14

300-3120

Tubing, Vinyl, 1/4 ID x 3/8 OD, Clear

1 8

Ft

2000REY, Unit

SHEET 1 OF 1

01/03/18

SCALE: 1:50

WEIGHT:

REV

A

SIZE

Description:

DATE

Assembled Products Corp.

300-5074

DWG. NO.

14

Recess Mount Remote Parts Breakdown / List

1

1

Figure 9.

Recess Remote

Exploded View

Figure 10.

Recess Remote

With Gripper

Exploded View

15

ENCLOSURE, REMOTE, LOW PROFILE

REDUCER, 3/8"MPT X 1/4"FPT,HEX BRASS

ADAPTER, STRAIGHT 3/8" TUBE X 1/4" MPT

BULKHEAD FITTING, 3/8" NPT

NIPPLE, HEX, 3/8", BRASS

COUPLER, Q.C., SHUTOFF, MALE PLUG, 3/8" FP

SCREW, #6-32 X 3/8"

PANEL, CONTROL, REMOTE STATION, SS, LOW PROFILE

ENCLOSURE, REMOTE, LOW PROFILE

REDUCER, 3/8"MPT X 1/4"FPT,HEX BRASS

ADAPTER, STRAIGHT 3/8" TUBE X 1/4" MPT

BULKHEAD FITTING, 3/8" NPT

NIPPLE, HEX, 3/8", BRASS

COUPLER, Q.C., SHUTOFF, MALE PLUG, 3/8" FP

SCREW, #6-32 X 3/8"

PANEL, CONTROL, REMOTE STATION, SS, LOW PROFILE

Surface Remote Parts Breakdown / List

ENCLOSURE, REMOTE, LOW PROFILE

REDUCER, 3/8"MPT X 1/4"FPT,HEX BRASS

ADAPTER, STRAIGHT 3/8" TUBE X 1/4" MPT

BULKHEAD FITTING, 3/8" NPT

NIPPLE, HEX, 3/8", BRASS

COUPLER, Q.C., SHUTOFF, MALE PLUG, 3/8" FP

SCREW, #6-32 X 3/8"

PANEL, CONTROL, REMOTE STATION, SS, LOW PROFILE

Figure 8.

Surface Remote

Exploded View

Spray Gun Parts Breakdown / List

Figure 11.

Spray Gun

Exploded View

16

HJJR Parts Breakdown / List

Figure 12.

HJJR

Exploded View

17

Hummer Jet Sr. Parts Breakdown / List

MODEL-HUMMER JET SR #2.5 NOZ

ITEM P ART# DES CR IPTIO N Q TY.

1 300-2939 GRIP, 7/8" X 5", WITH FLANGE BLACK

2

2 300-1644 BRACKET, M OUN T, QUICK CONNECT FOR HUMM ER JET S R

1

3 000-0041 CONNECT, QUIUCK S-O SOCKET 3/8" FPT, BRASS

1

4 300-1110 ELBOW, STREET, 3/8"M X F, 90° BRASS

4

5 300-1360 NIPPLE, 3/8"" X 4"" BRASS

1

6 300-1400

VALVE, BALL, 3/8"FPT X 3/8"FPT 3/16-24 THREAD MOUNT H O LES

1

7 3 0 0- 4 1 1 6 D E C A L, H U M M E R J ET, V A LVE P LATE 1

8 3 0 0 -3 8 5 1 P LA TE , V ALV E M O U N T F O R HU M M ER JET S R

1

9 300-4120 HAN DLE, U PPER ASSEM BLY HU M M ER JET SR., FO R M E D TU B E

2

10 300-0283

H O S E, H I- P RES , 3 /8 " X 2 8 " , B LU 3 /8 " M P T S W IV EL F ITTIN G (X 2 )

1

11 300-4117

SW IVEL, HI SPEED, HI PRESSU RE BU LKHEAD FITTING, 3/8" N P T

1

12 300-3909 T-HANDLE ONLY, HUMMER BOLT

1

13 300-4115

HAN DLE, LOW ER ASSEM BLY HUM M ER JET SR., FO RM ED TU BE

1

14 300-3896 DECAL, "WARNING: DO NOT USE ..

1

15 300-3899 BRACKET SET, HANDLE MOUNT, SET OF 2 (LEFT & R IG H T)

1

16 300-4130 DECK, HUMMER JET SR, ROUND STAINLESS,

1

17 300-3895 DECAL, "WARNING, KEEP HANDS.."

2

18 300-4118 WAND, ROTARY, T-BAR 18" HUMMER JET, 86-812

1

19 300-3893 NOZZLE, 1/8 M EG, #15O25, SS 15 DEG, #2.5 O RIFICE

2

20 300-4030 DECAL, LOGO, "SMT" RAISED PLASTIC, TRAPEZO ID 1

21 300-2818 BRACKET, CASTER, HUMMER JET SR 1/8" SS.,90 DEG.

4

22 300-2772

CASTER, SWIVEL, 3"DIA X1 1/4"W STEM 3/8-16 X 1". HUMMER

4

23 020-0058 WASHER,3/8X11/16X.094,LOCK,SS 4

24 021-0049 NUT,.375-18,HN,SS

4

25 300-1940 CAP BLK.313X.5 VINYL ROUND END

4

26 022-0005 BOLT,.25-20X.75,PHTS,SS 16

27 021-0038 NUT,.25-20.HN,NYLON LOCK,SS

12

28 020-0085 WASHER,1/4X9/16X.04,FLAT,SS

12

29 020-0053 WASHER,1 1/8X2 1/2X.1,FLAT,SS

2

30 300-3711 SKIRT, SPLASH,

1

31 300-3927 SPACER, COVED 5/16""

4

32 023-0137 SCREW,10-24X.375,BHCS,CZ

2

33 025-0014 BOLT,.25-2X 3,HH,CZ,5 1

34 023-0132 SCREW,#12X.75,HHFS,TEK,CZ

1

35 022-0023 SCREW,8-32X.5,PHTS,SS

9

36 020-0082 WASHER,.75X1X.125,RUBBER 1

37 300-1922 CAP, 2", VINYL, BLACK

1

38 020-0059 WASHER,#10X7/16X.061,FLAT,SS

9

39 021-0039 NUT,8-32,HN,NYLON LOCK,SS 9

40 023-0170 BOLT,.3125-18x2.25,SADDLE BOLT CZ

2

41 023-0105 SCREW,#8X.5,HHFS,TEK,CZ

4

42 029-0007 SCREW COVER,HINGED

2

43 000-0025 SPACER, ROUND TO FLAT,PLASTIC

4

44 300-3276 BOX, SHIPPING, HUM MER JETSR. 28"X24"X14"

1

45 021-0038 NUT,.25-20,HN,NYLON LOCK,SS

1

46 300-1911 COVER, PROTECTOR, NUT 1

Figure 13.

HJSR

Exploded View

18

IT EM P A R T # D E S C R IP T IO N Q TY.

1 300-2395 REEL, HEAVY DUTY, BLACK 1

2 000-1312 CLAM P, HOSE, 5/8", W /VINYL COAT 1

3 020-0061 W ASHER, FLAT, 2" O D X .88" ID,ZINC 1

4 300-1768 ASSY- SW IVEL, HOSE REEL 1

5 3 0 0-0 3 4 4 H A N D LE, H O SE R EEL, 4 " B LAC K P LASTIC 1

6 3 0 0 -1 6 47 D ECAL, "FO R SALES AND SERVICE" 1

7 022-0004 BO LT, HEX, 5/16-18 X1 4

8 300-1111 ELBOW , STREET, 1/2" M PT X 1/2" FPT 1

9 000-0039 CO UPLER, 1/2" X 3/8" FPT, BRASS 1

10 021-0034 NUT, 5/16-18 4

11 021-0018 NUT, .25-20, HN X .5 PHTS 3

12 022-0037 BOLT, .25-20 X .5 PHTS 3

13 300-0604 B R A K E, R E E L, A D JU S T A B LE F O R H EA V Y D U TY H O S E R EEL 1

NOT SHOWN 300-1845 DECAL, " SM T HD REEL" 1

14 300-0100 GRIP, HANDLE, HO SE REEL 1

15 300-2394 FRAME, HOSE REEL, HS, SQUARE 1

16 020-0085 W ASHER, 1/4 X9/16 X .04, FLAT, SS 1

17 021-0018 NUT, .25-20 HN NYLON LOCK 1

18 300-1911 CAP, PLASTIC PROTECTOR BLACK 1

19 000-1182 DECAL "PROTECT FROM FREEZING" 1

20 300-4063 DECAL " STO RE INDOO RS" 1

21 300-0091 BUM PER/FO OT RUBBER, HOSE REEL 2

22 300-0099 PLUG, SQUARE TUBING, PLASTIC 2

23 020-0028 W ASHER, 1/4 X 3/4 X .075 FLAT, CZ 2

24 023-0077 #10 X 1" TEK SCRW 2

25 300-1387 W HEEL, 10.5" DIAM ., 5/8" HUB 2

26 000-1123 C A P , R O U N D , LP E -B LK 1 1 /8 2

27 000-0014 CO LLAR, 5/8", #2 X 569 2

28

020-0050

W ASH E R , 3 /8 X 1 1 /2 X .1 , F LA T C Z 2

29 300-0175 HANGER, SPRAYGUN 1

30 022-0020 BOLT, .25-20 X 1.74=5 2

31 300-0147 HO SE, 12' , UM BILICAL 1

SMT-300HDR Parts Breakdown / List

Figure 14.

300 HDR

Exploded View

19

SMT-CSYSEXPRESS-SM-Rev 1-180719-EN Price and specifications are subject to change without notice . Printed in the USA.

115 E. Linden • Rogers, Arkansas 72756 USA

(479) 636-5776 • Fax: (479) 636-3245

www.SprayMasterTech.com

800-548-3373

Other manuals for 600REY

1

This manual suits for next models

2

Table of contents

Popular Cleaning Equipment manuals by other brands

HERKULES

HERKULES G550 owner's manual

Kärcher

Kärcher BRC 40/22 C instructions

IBS Scherer

IBS Scherer BK-50 Translation of the original instructions

THERMA-KLEEN

THERMA-KLEEN Ultra Propane 600 Operator's manual

Lincoln Electric

Lincoln Electric WELDLINE OPTICLEAN II Use and maintenance instructions

Getinge

Getinge Castle 7900 installation instructions