HERKULES G550 User manual

Part# 1003108-12

9/14/2020

Made in USA

This manual contains important information concerning the

installation and operation of the gun washers listed above.

Read manual thoroughly and keep for future reference

OWNERS MANUAL INSTRUCTIONS

Toll Free: 800-444-4351

Phone: 248-960-7100

Fax: 248 960-7109

Website: www.herkules.us

E-mail: info@herkules.us Herkules Equipment Corporation

2760 Ridgeway Court

Walled Lake, MI 48390-1662 USA

Page 1 of 16

Warranty ……………………………………………………………………………………………………………….................... 3

Model Information ……………………………………………………………………………………………………………. 4

Warnings ……………………………………………………………………………………………………………………… 5-6

Installation ………………………………………………………………………………………………………………….. 7

Operation ……………………………………………………………………………………………………………………. 7 - 9

Preventive Maintenance ………………………………………………………………………………………………………. 10

Troubleshooting ……………………………………………………………………………………………………………… 10

Drawings with Part Lists …………………………………………………………………………………………………… 11 - 15

G550 Schematic ………………………………………………………………………………………………………................... 16

Herkules Equipment Corporation

A U.S.-based manufacturer, Herkules Equipment Corporation offers a diverse line of products that support multiple

industries by improving efficiency, productivity, ergonomics, comfort, and safety in the work environment. The

company consists of the three product lines: Herkules, Enkon and BossLifts.

Since 1985, Herkules has designed, engineered and manufactured quality products at our Walled Lake,

Michigan facility. Our company supports our products after delivery, with U.S. based customer service, and

replacement parts, enabling our customers to proceed with confidence.

To learn more about Herkules, visit http://herkules.us. Contact us at info@herkules.us with any

questions or concerns.

Thank you for purchasing a Herkules product!

Table of Contents

Page 2 of 16

Warranty

At Herkules we take great pride in the construction of our American-made products, and we stand behind their reliability.

Our limited liability warranty coverage for Paint Gun Washers warranties the unit for a period of 12 months. Washer pumps

have a separate warranty; the Herkules 338 pump is protected for a period of 2 years from the date of purchase. All other

pumps, including rinse pumps, are warrantied for 12 months.

This warranty does not apply to equipment damaged from accident, abuse, overload, misuse, negligence, improper

installation, abrasive or corrosive materials, or shipping damage.

In the event of product failure, the defective item must be returned, freight prepaid, to the Herkules manufacturing plant for

repair or replacement. If repairs are required, Herkules will not be liable for these repairs to take place in the field regardless

of the application. Proof of purchase and date of purchase must be confirmed. An RGA* (Returned Goods Authorization) and

written approval from Herkules must be obtained before any goods can be shipped to Herkules. We reserve the right to

Determine whether failure is due to defective material, normal wear, and / or other causes.

There are no warranties which extend beyond the description on the face hereof. Herkules

disclaims any warranty of merchantability or fitness for a particular purpose in connection with

the Buyer's purchase of any Product under this agreement. Damages are limited to the sales

price of the Herkules system. The terms and conditions herein represent the entire agreement

between Herkules and the Buyer. Any prior / future representations do not apply.

*To obtain a RGA, contact Herkules at 1-800-444-4351 and have the item model, serial numbers, and invoice number if applicable.

Upon receipt of your equipment, please write your purchase information below. Please retain this manual for your records.

Serial Number Model Number

Purchase Date Distributor (if applicable)

IMPORTANT NOTICE: if you have a problem with your Herkules product,

DO NOT RETURN TO PLACE OF PURCHASE

Contact Herkules: by phone 1-800-444-4351; by email, info@herkules.us; or on the web at herkules.us/contact-us.

Page 3 of 16

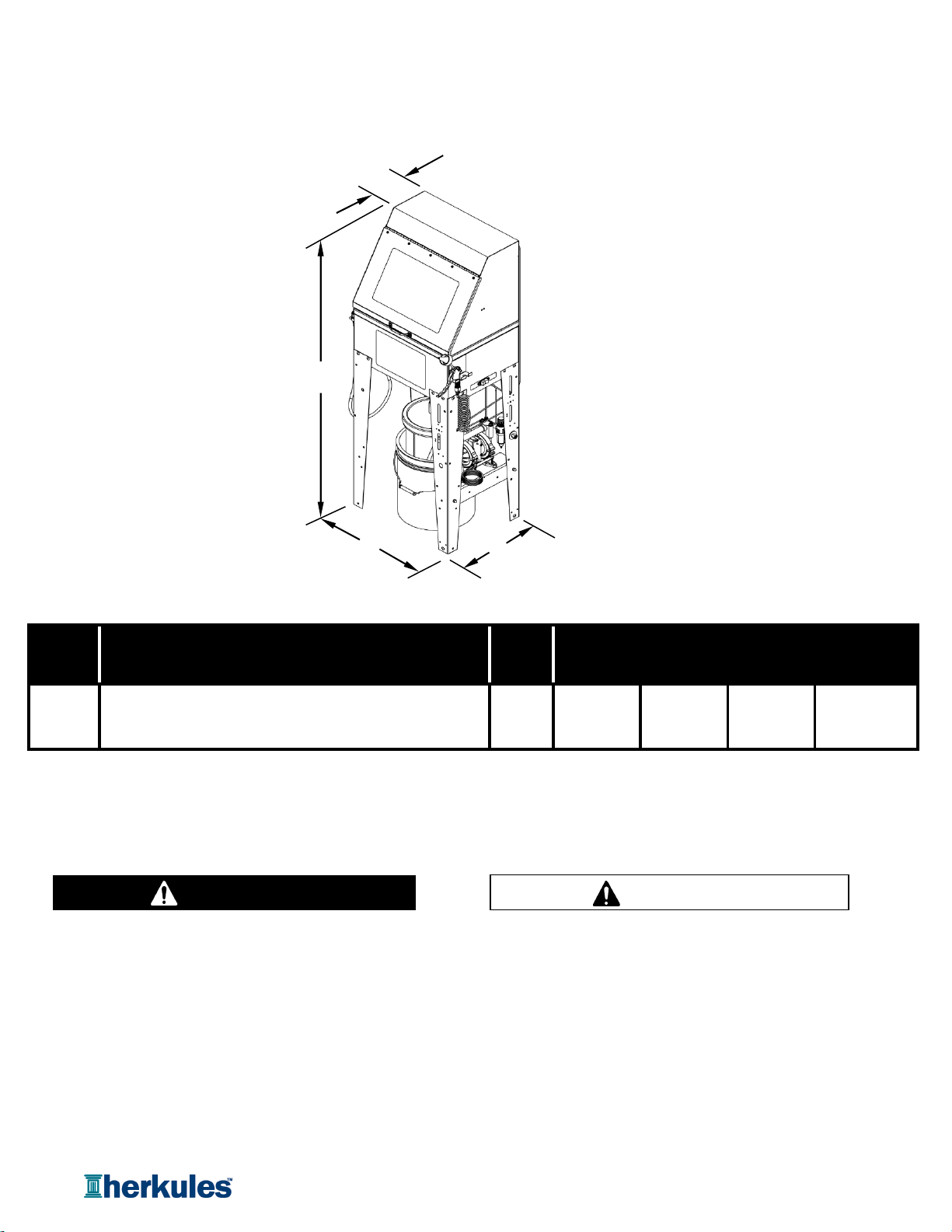

Model Information

`

Dimensions in./(mm)

A

B

C

D

Manual cleaning waterborne Gun Washer includes 56 15.5 6.5 20.38

pressure cleaning nozzle, clean rinse nozzle, flow thru (1422) (394) (165) (518)

brush and agitator / accelerator.

NOTE: Dimensions listed are overall measurements.

Model Description Weight

lbs/(kg)

69

G550 (31.3)

Warning Symbol Caution Symbol

A

B

C

D

CAUTION

WARNING

This symbol alerts you to the possibility of serious

injury or death if you do not follow the instructions. This symbol alerts you to the possibility of damage to

or destruction of equipment if you do not follow the

instructions.

Page 4 of 16

EQUIPMENT MISUSE HAZARD

Equipment misuse can cause the equipment to rupture, malfunction, or start unexpectedly

and result in serious injury.

•

This equipment is for professional use only.

•

Read all instruction manuals, tags, and labels before operating the equipment.

•

Use the equipment only for its intended use.

•

Do not alter or modify this equipment.

•

Do not exceed the maximum working pressure of the lowest rated system component.

•

Do not operate the gun washer at a pressure above the maximum working pressure rating of the

gun(s) being cleaned.

•

Route the hoses away from traffic areas, sharp edges, moving parts, and hot surfaces.

•

Do not use the hoses to pull the equipment.

•

Do not move pressurized equipment.

•

Comply with all applicable local, state and national fire, electrical and other safety regulations.

PRESSURIZED EQUIPMENT HAZARD

Spray from hose leaks, ruptured components, or from operating the gun washer with an open lid

can splash fluid in the eyes or on the skin and cause serious injury.

•

Do not stop or deflect fluid leaks with your hand, body, glove, or rag.

•

Tighten all fluid connections before operating the equipment.

•

Replace worn, damaged, or loose parts immediately.

WARNING

Page 5 of 16

Other manuals for G550

1

Table of contents

Other HERKULES Cleaning Equipment manuals

Popular Cleaning Equipment manuals by other brands

Suevia

Suevia 130.5011 EASYCLEANER Mounting instructions

i-MO

i-MO Öko 2000 user guide

unGer

unGer Hydro Power Ultra UNP01 operating instructions

Black & Decker

Black & Decker BHPC130 Original instructions

Uni-ram

Uni-ram UG5000E operating manual

Axi

Axi MTC HC-300 Installation, operating and maintenance manual