Software House PSX Series User manual

www.swhouse.com

.

PSX RACKMOUNT

INSTALLATION AND OPERATION

PSX-ISU-RD

PSX-ISUSE-RD

PSX-GCM-RB

P03-032 revAO7

ii

PSX Rackmount Power Supply - Installation and Operation Manual

Table of Contents ........................................ii

Notes and Warnings ........................................................... iii

Symbol Definitions ............................................................ iii

Warnings.................................................................... iii

Regulatory Information ......................................................... iii

Conventions Used Within this Manual.............................................. iii

Introduction............................................iv

Section 1 – Installation ....................................1

1.1 Mounting the Rack Mount Supply into a Standard 19" Rack ...........................1

1.2 PSX Rackmount Power Supply Overview .........................................2

1.3 Internal Pre-Configuration.....................................................4

1.4 Making the Wiring Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

1.5 FAI Connections ............................................................7

Section 2 – Power and Network Connections .....................8

2.1 Main AC Power Connection....................................................8

2.2 Remote Access via Ethernet ...................................................8

Section 3 – Configuration and Usage........................... 9

3.1 Removing the Faceplate of the Enclosure.........................................9

3.2 Configuring the Zones - PSX-ISUSE.............................................9

3.3 Configuring the Zones - PSX-ISU..............................................10

3.4 Disabling Faults - PSX-ISU...................................................10

3.5 Status LEDs - PSX-ISUSE ...................................................11

3.6 Status LED - PSX-ISU ......................................................11

3.7 Remote Access via Ethernet (All models)........................................11

Section 4 – Specifications ................................. 12

4.1 Electrical Specifications .....................................................12

4.2 Temperature Specifications ..................................................14

4.3 Mechanical Specifications ...................................................14

Table of Contents

iii

Notes and Warnings

Symbol Definitions

The following symbols are used throughout this manual

hThis symbol is intended to alert the installer of shock

hazards within the enclosure. Service should only be

performed by qualified service personnel

iThis symbol is intended to alert the installer of im-

portant information intended to help the installer

avoid personal injury or property damage

Warnings

hInstallation and service should be performed only by

qualified service personnel and should conform to

all local codes

h

To reduce the risk of electric shock or fire, do not

expose this equipment to rain or moisture

i

This equipment shall be installed in a manner which

prevents unintentional operation by employees,

cleaning personnel, or others working in the prem-

ises, by falling objects, customers, building vibra-

tion, or similar causes

i

This equipment is not intended for use within the pa-

tient care areas of a Health Care Facility

h

Replace fuses only with the same type and rating as

indicated in the specifications section of this manual.

i

To prevent impaired operation, ensure that all wiring

is routed and secured to prevent accidental open or

short circuit conditions

i

The system and any batteries (if used) should be test-

ed at least once per year to ensure proper operation.

Regulatory Information

The equipment discussed within this manual has been test-

ed to the following standards:

• UL294, UL603, UL864, UL1076, UL1481,

UL2044, UL2572

• ULC S318, ULC S319, ULC S527

• CSA C22.2 #107.1, CSA C22.2 #60950

FCC Information

Note: This equipment has been tested and found to comply

with the limits for a Class A digital device, pursuant to Part

15 of the FCC Rules. These limits are designed to provide

reasonable protection against harmful interference when

the equipment is operated in a commercial environment.

This equipment generates, uses, and can radiate radio fre-

quency energy and, if not installed and used in accordance

with the instruction manual, may cause harmful interfer-

ence to radio communications. Operation of this equipment

in a residential area is likely to cause harmful interference in

which case the user will be required to correct the interfer-

ence at his own expense

Conventions Used Within this Manual

Positional information (e.g. top, bottom, up, down, left,

right, etc.) is referenced with the board or enclosure in the

orientation shown in the illustrations in this manual

iv

PSX Rackmount Power Supply - Installation and Operation Manual

Introduction

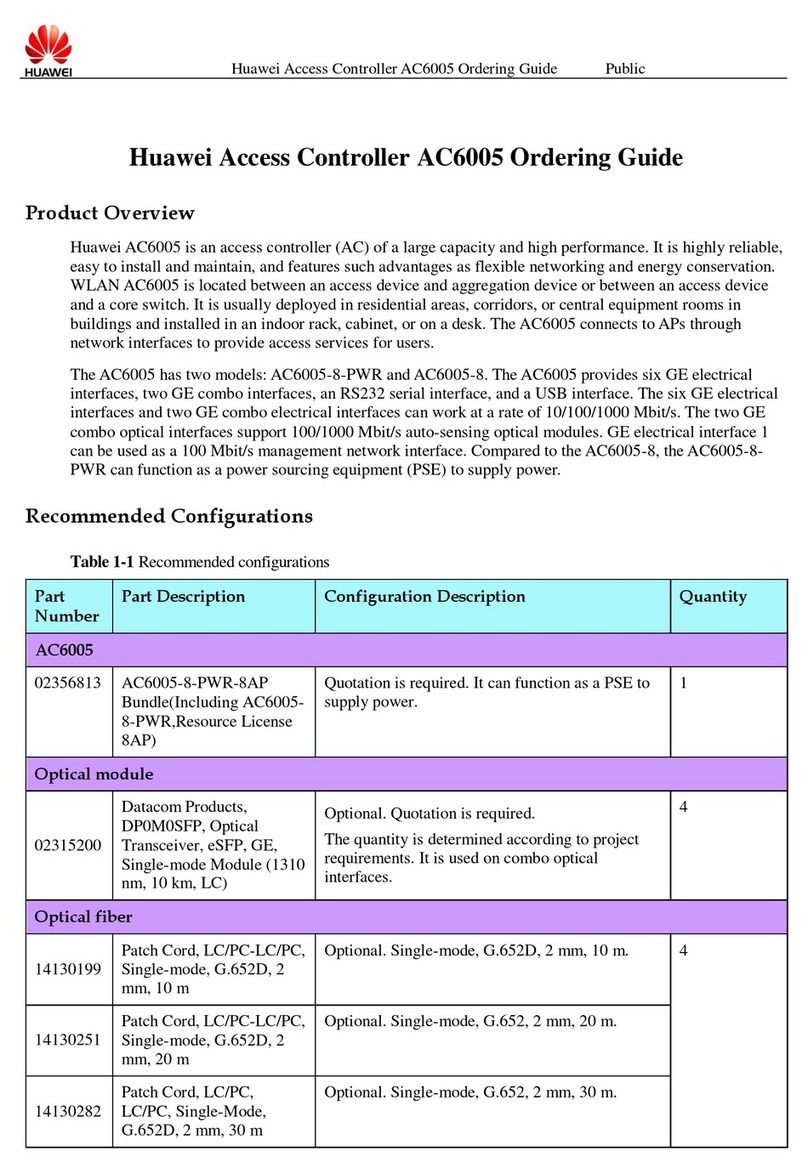

PSX Models Power Outputs Description

PSX-GSM-RB 75W 2 Single Voltage 6A @ 12VDC (SYSTEM)

PSX-ISU-RD 400W 2 Dual Voltage 12A @ 12VDC (SYSTEM) 10A @ 24VDC (LOCK)

PSX-ISU-RDN 400W 2 Dual Voltage 12A @ 12VDC (SYSTEM) 10A @ 24VDC (LOCK) NETWORK

PSX-ISUSE Power Outputs Description

PSX-ISUSE-RD 400W 16 Dual Voltage 12A @ 12VDC (SYSTEM) 10A @ 24VDC, 16 LOCK OUTPUTS

PSX-ISUSE-RDN 400W 16 Dual Voltage 12A @ 12VDC (SYSTEM) 10A @ 24VDC, 16 LOCK OUTPUTS, NETWORK

The PSX rackmount series of power supplies provide DC

power for lifesafety applications. Designed to fit neatly into

standard 19" equipment racks, the streamlined cabinetry

and exceptional features combine to significantly reduce

installation and service costs. Features include removable

terminal strips for field wiring, input and output surge sup-

pression, automotive blade fuses for improved reliability,

and is enclosed in a 16 gauge steel 2U rack mount chassis.

Product Description

The PSX-ISUSE rackmount series for iSTAR ULTRA SE

provides 12 and/or 24 VDC power at 400W of total power with

16 individual lock control outputs. PSX-ISUSE is available

with optional network monitoring: PSX-ISUSE-RDN model.

1

Installation and Operation

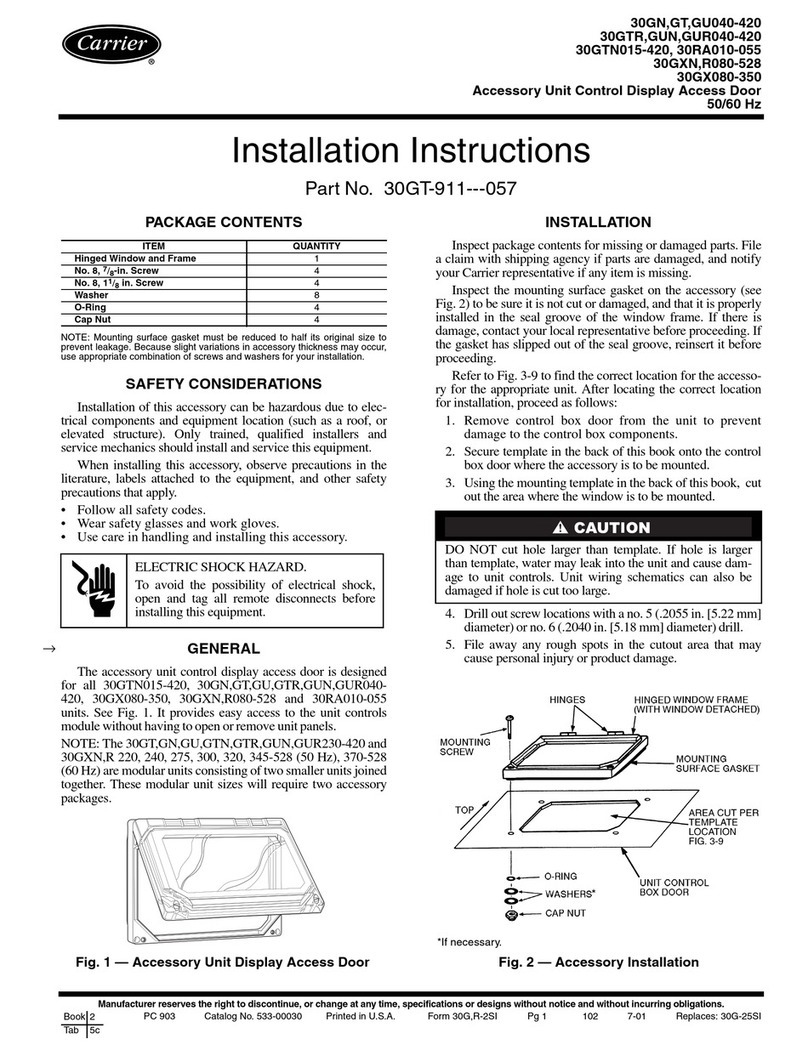

Use the following procedure when mounting an PSX series

supply into a standard EIA 19" equipment rack.

1. Ensure any internal configuration (voltage selection, fault

detection settings, etc) are complete before mounting.

See Section 1.3 of this manual for more information.

2. Securely mount the included ears to the enclosure sides

using the eight included 6-32 countersunk screws (four

per ear).

3. Locate the rack-mounting holes in the ears of the en-

closure. (Figure 1)

4. Slide the enclosure into an open 2U location in the rack

5. Center the enclosure in the rack and secure with the

four 10-32 x 3/4" screws provided.

NOTE: Use rails or other appropriate support for heavy

enclosures. Keep heavier components near the bottom of

the rack to reduce the risk of toppling of a top-heavy rack.

NOTE: For UL864 Installations, the Rack Mount Supply

must be mounted in an ENCLOSED rack where the field

wiring will be protected.

1.1 Mounting the Rack Mount Supply into a Standard 19" Rack

The following pages cover the installation of the PSX Series rack-mountable power supplies.

Section 1 – Installation

Figure 1 - The Enclosure Mounting Holes

2

PSX Rackmount Power Supply - Installation and Operation Manual

1.2 PSX Rackmount Power Supply Overview

AC Power

10-100

Base-T

9

A B

10

A B

11

A B

12

A B

13

A B

14

A B

15

A B

16

A B

9

A B

10

A B

11

A B

12

A B

13

A B

14

A B

15

A B

16

A B

MAIN OUTPUT 1

BAT+

BAT-

DC1 +

DC1 -

DC2 +

DC2 -

ACF

ACF

V +

V -

I -

I -

V -

I -

SF

SF

MAIN OUTPUT 2

BAT+

BAT-

DC1 +

DC1 -

DC2 +

DC2 -

ACF

ACF

V +

V -

I -

I -

V -

I -

SF

SF

1

A B

2

A B

3

A B

4

A B

CONTROLLED OUTPUTS 1 CONTROLLED OUTPUTS 2

CONTROL INPUTS 1 CONTROL INPUTS 2

5

A B

6

A B

7

A B

8

A B

9

A B

10

A B

11

A B

12

A B

13

A B

14

A B

15

A B

16

A B

CH1 CH2 CH3 CH4 CH5 CH6 CH7 CH8

FLT

3

3

3

3

3

3

3

3

3

CH1 CH2 CH3 CH4 CH5 CH6 CH7 CH8

FLT

3

3

3

3

3

3

3

3

3

CH1 CH2 CH3 CH4 CH5 CH6 CH7 CH8

FLT

3

—

3

3

3

3

3

3

3

3

CH1 CH2 CH3

VOLTAGE SELECT JUMPERS

DC1

DC2

CH4 CH5 CH6 CH7 CH8

FLT

3

3

3

3

3

3

3

3

1

ON

23 4 5 6 87

CH1 CH2 CH3 CH4 CH5 CH6 CH7 CH8

FLT

3

3

3

3

3

3

3

3

1

ON

23 4 5 6 87

CH1 CH2 CH3 CH4 CH5 CH6 CH7 CH8

FLT

3

3

3

3

3

3

3

3

1

ON

23 4 5 6 87

A B

CONTROLLED OUTPUTS

CONTROL INPUTS

1

+

2 3 4

-+-+-+-

5

+

6 7 8

1 2 3 4 5 6 7 8

-+-+-+-

A B A B A B A B A B A B

A B

1

ON

23 4 5 6 871

ON

ON ON ON ON

23 4 5 6 87

N.O. INPUT

N.C. INPUT

Enable FAI

Disable FAI

Fail-Safe OUTPUT

Fail-Secure

OUTPUT

AC Power

10-100

Base-T

ACF

ACF

DC2 –

DC2 +

BAT –

SF

SF

L

L

V –

I –

I +

V +BAT +

DC1 –

DC1 +

MAIN OUTPUT 2

SF

SF ACF

ACF

DC2 –

DC2 +

BAT –

L

L

V –

I –

I +

V +BAT +

DC1 –

DC1 +

MAIN OUTPUT 1

PSX-ISUSE

PSX-GCM / PSX-ISU

CH1 CH2 CH3 CH4 CH5 CH6 CH7 CH8 CH1 CH2 CH3 CH4 CH5 CH6 CH7 CH8

CH1 CH2 CH3 CH4 CH5 CH6 CH7 CH8

FLT

1

2

3

4

5

6

7

8

3

3

3

3

3

3

3

3

—

1

B1 B2

JP1

2 3

CH1 CH2 CH3 CH4 CH5 CH6 CH7 CH8

FLT

1

2

3

4

5

6

7

8

3

3

3

3

3

3

3

3

—

1

B1 B2

JP1

2 3

CH1 CH2 CH3 CH4 CH5 CH6 CH7 CH8

FLT

1

2

3

4

5

6

7

8

3

3

3

3

3

3

3

3

—

1

B1 B2

JP1

2 3

CH1 CH2 CH3 CH4 CH5 CH6 CH7 CH8

FLT

1

2

3

4

5

6

7

8

3

3

3

3

3

3

3

3

—

1

B1 B2

JP1

2 3

3

Installation and Operation

1Main AC Power Switch / Circuit Breaker

This is the main AC power switch for the enclosure. This switch

lights when power is on and also has a built-in circuit breaker rated

at 8A. If the circuit breaker trips, reset it by cycling the switch to off

then back to on.

2AC Line Input

This is the connector for the AC line cord. Plug the included computer-

style line cord into this connector. Connect the other end of the cord to

the power strip inside the rack or another suitable AC power receptacle.

iThe PSX Series is preconfigured for a 120VAC input. See sec-

tion 1.3.2 to set for a 230VAC input.

3Ethernet Connection

This is the RJ45 jack for the network connection for the internal NetLink

board (if present). The ethernet cable is plugged into this jack. This jack

is only present on PSX series power supplies with a model number end-

ing in "N". See Section 2.2 and the corresponding NetLink manual for

more information.

4Field Wiring

These terminals provide the field wiring connections. Terminal

quantity and function varies based on configuration and the func-

tion is marked adjacent to each terminal. All rear terminal blocks

may be secured with the screw on either end of the block. These

terminals all accept AWG 12-22.

• (PSX-ISUSE only) Controlled Outputs 1&2 — These are the

zone outputs. The PSX-ISUSE has 16 outputs. The output num-

bers correspond with the output zone numbers on the front panel.

See Section 1.4.1 for more information.

• (PSX-ISUSE only) Control Inputs 1&2 — These terminals are

the inputs which control the corresponding outputs. These in-

puts accept a NO or NC dry contact, voltage, or open collector

(transistor) input. See #10 for configuring input type.

• Bat(±) — This is where the battery connection is made. The

voltage of the battery set must match the voltage of the associ-

ated power supply. Dual power supply models will have two

independent battery connections. See Section 1.41 for more

information.

• DC1(±) —This is a bulk power output with the full power of

the associated power supply available on these terminals. Dual

power supply models will have two DC1 outputs. See Section

1.4.1 for more information.

• DC2(±) —This is an FAI-controllable bulk power output with

the full power of the associated power supply available on these

terminals. Dual power supply models will have two DC2 outputs.

See Section 1.4.1 for more information.

• ACF & SF — These terminals accept the optional FAI input for

controlling the DC2 outputs and any controlled output which has

FAI control enabled. See Section 1.4.1 for more information.

• V+, I+, I–, V–, L, L —These terminals accept the optional FAI

input for controlling the DC2 outputs. See Section 1.4.1 for

more information.

5Bus Selection

These jumpers select the output voltage for each output in dual voltage

systems. Single voltage systems should leave these jumpers in the DC1

(UP) Position. For dual voltage systems, selection is as follows:

• DC1 (UP) - Power Supply 1

• DC2 (DOWN) - Power Supply 2

6Output Fuses

These are the fuses for each zone output. Each fuse corresponds to

the zone LED below it.

7Fault Status LED (YELLOW)

This LED lights when the front board detects a fault condition. Fault

conditions reported by this LED include ruptured output fuse(s) or

improperly configured jumpers or switches. This LED does not in-

dicate problems with the internal power supply. See Section 3.3 for

more information.

8

Output Status LEDs (GREEN)

These LEDs indicate the status of the zone’s output.

PSX-ISUSE When Powering Lock Devices:

•OnSteady-DoorLocked(FuseorPTCIntact)

•Off-Fuserupturedorjumpermissing

•Flashing-DoorunlockedduetoinputorFAI

PSX-ISU

•OnSteady-VoltageAvailableatOutput

•Off-Fuserupturedorjumpermissing

9Fault Disable Switches (PSX-ISU only)

These switches disable fault detection by individual zone. This

allows removal of the fuse for unused zones without causing a

fault condition. See Section 2.3 for more information.

bk Output Selection (Front Board) PSX-ISUSE only

These switches are used to select a fail-safe or fail-secure output for

each zone. Switch 1 sets zone 1, switch 2 sets zone 2, and so on.

Set this switch so that the door is UNLOCKED when the zone output

LED is flashing (Zone Active).

• ON (FAIL SECURE Output) By setting this switch to ON, the

zone's output terminals will output a voltage when the zone

input is activated.

• OFF (FAIL SAFE Output) By setting this switch to OFF, the

zone's output terminals will output a voltage when the zone in-

put is NOT active. This position is typically used for Mag Locks.

bl Input Selection (Rear Board) PSX-ISUSE only

These switches are used to select a normally open or normally

closed input for each zone. Switch 1 sets zone 1, switch 2 sets zone

2, and so on. Adjust this switch so that the zone's output LED is

FLASHING when the door is unlocked.

• OFF (NC/Fail Safe) Set this switch to OFF for a NC contact input

(contact OPENS to unlock door) or for a voltage input where the

voltage is REMOVED to unlock the door.

• ON (NO/Fail Secure) Set this switch to ON for a NO contact

input (contact CLOSES to unlock door) or for a voltage input

where the voltage is APPLIED to unlock the door.

bm FAI Selection (Rear Board) PSX-ISUSE only

These switches enable or disable FAI for the selected zone. Switch

1 sets zone 1, switch 2 sets zone 2, and so on.

• ON (FAI Enabled) When this switch is set to ON, the zone's

output will invert when the FAI input is active. This is typically

used to drop power to maglocks on a fire alarm condition.

• OFF (FAI Disabled) When this is set to OFF, FAI will have no

effect on the zone's output.

The following are basic descriptions. Refer to the appropriate section for more detailed information. Note that the front and

back panels may appear different based on the configuration of your system.

4

PSX Rackmount Power Supply - Installation and Operation Manual

Configuration internal to the rack mount enclosure is re-

quired on PSX series power supplies prior to installation

into a rack.

1.3.1 Removing the Top Cover of the Enclosure

Use the following steps to remove the top cover of the rack-

mount enclosure and gain access to the configurable settings.

(Figure 2)

1. Lay the enclosure flat on its bottom surface

2. Remove and retain the six philips head screws from

the top cover

3. Remove the top cover and set it aside in a safe location

When configuration is complete, reverse the removal pro-

cedure to replace the cover.

Figure 2 - The Top Cover Mounting Screws

1.3.2 Configuring for a 230VAC Input Voltage

The PSX series is factory set for a 120VAC input. If the PSX

is to be used with a 230VAC input, jumper JP1 must be cut on

ALL PSX power supplies internal to the PSX. (Figures 3 and 4).

See the PSX manual for more information.

i Failure to cut JP1 on both supplies when connecting to a

230VAC input will damage the system and void the warranty.

1.3.3 Setting the Output Voltages

The PSX series will contain one or two internal power sup-

plies, depending on model. The voltage may be set on each

PSX power supply for 12 or 24VDC .

After removing the top cover, set the output voltage of the

PSX power supplies by moving SW1 to either 12V or 24V

(See #3 in Figure 3).

See the PSX manual for more information on setting the

output voltage.

1.3.4 Enabling or Disabling Battery Presence Detection

Each PSX power supply may be set to detect a missing

battery set. To enable battery presence detection, place the

BATDET jumper ON. To disable battery presence detection,

remove the BATDET jumper, or place it on only one pin.

(See #2 in Figure 3)

1.3.5 Enabling or Disabling Earth Ground Detection

Each PSX power supply is able to detect earth ground

faults. To enable earth ground fault detection, place the

EARTH GND DET jumper ON. To disable earth ground fault

detection, remove the EARTH GND DET jumper or place it

on only one pin. (See #1 in Figure 3)

NOTE: Only one device in a system should have earth

ground fault detection enabled or conflicts may occur. In

addition, only ONE PSX power supply in a dual-supply PSX

system should have earth ground fault detection enabled or

a conflict may occur.

1.3.6 Changing the Operation of the Fault Contact Output

From the factory, PSX series supplies are shipped with a

normally open fault contact operation (relay contact closed

until a fault occurs).

This operation may be switched to a normally closed con-

tact (relay contact open until a fault occurs) by moving a

wire on each fault contact.

To switch from the default NO fault contact to a NC contact,

locate the fault output terminal strip on the PSX power sup-

ply. Identify the contact you want to change (SYS FLT or AC

FLT), loosen the terminal, remove the wire from the NO ter-

minal, move it to the NC terminal, and tighten the terminal.

NOTE: This must be done on BOTH power supplies in dual-

supply models.

1.3.7 Changing the FAI Operation

The DC2 output may be set to either power up when an FAI

is received or to drop power when an FAI is received by

changing the position of the DC2 fuse on the PSX board.

• DC2 NO Position - DC2 output has no voltage until a

valid FAI input signal is received.

• DC2 NC Position - DC2 output has voltage present in

the normal state. This voltage goes away when a valid

FAI input signal is received.

1.3 Internal Pre-Configuration

5

Installation and Operation

PSX-150

PSX-250

PSX-75

Earth GND

Battery DETECT

Voltage SELECT

230VAC jumper

Figure 3 - Configuring the Internal PSX Power Supplies in a Rackmount System

Figure 4 - PSX 230VAC jumper location

AC Input

cut jumper

for 230VAC

cut jumper

for 230VAC

AC ON

AC Input

AC ON

PSX-150, 250

PSX-75

6

PSX Rackmount Power Supply - Installation and Operation Manual

Field wiring connections are made on the rear panel after installing

the PSX enclosure into the rack. Field wiring connections are made

to the removable terminal strips, which accept AWG 12-22 wire. The

back panel is also where the main AC power and optional ethernet

connections are made.

1.4.1 Field Wiring

The PSX Rackmount series has terminals for various inputs

and outputs as follows:

Controlled Outputs - PSX-ISUSE only

These terminals provide the distributed, controlled outputs

to the load devices. Depending on model, there will be ei-

ther 8 or 16 output zones. The output zone numbers will

correspond with the numbering of the zones on the front

panel. Polarity is indicated adjacent to each terminal. The

output is configured by setting the front and rear panel

jumpers and switches.

Control Inputs - PSX-ISUSE only

These are the zone input terminal strips. The terminals are

labeled on the back panel near the terminal strip.

•Whenusingadrycontactinput,thecontactisconnected

across the A and B terminals. When configured for a dry

contact input, it is normal to measure a voltage across

these two terminals. This voltage is current limited and will

not damage the activation contact.

•Whenusingavoltageinput,thevoltageisconnectedto

the B terminal. The activation voltage must be common

grounded with the system voltage. The activation voltage

must be between 12 and 24VDC nominal. Do not connect

anything to the A terminal of the input.

•Whenusinganopencollector(transistor)input,placea

jumper across the A and B terminals and connect the open

collector to the B terminal. Note that the input source must

be common grounded with the enclosure power source.

Battery (Bat+, Bat–)

This pair of terminals is for connection to a backup battery set, if

required for the installation. Polarity is noted adjacent to the termi-

nals. These terminals also charge the battery set.

NOTE: Observe polarity or damage to the system will occur.

Ensure the voltage of the battery set matches the voltage of

the power supply.

NOTE: It is the installer's responsibility to determine the prop-

er battery size for the installation. See the Specifications sec-

tion for battery standby current requirements.

DC1+, DC1–

The main DC output of the PSX power supply. The full cur-

rent of the PSX is available on these terminals at all times

and is unaffected by the FAI input.

DC2+, DC2–

The DC2 output may optionally be controlled by the FAI in-

put. The full current of the PSX is available on these termi-

nals. The DC2 output may be set to power up when an FAI

signal is received or to drop power when an FAI signal is

received by changing the position of the DC2 fuse on the

PSX before installing the PSX into the rack.

AC Fault (ACF)

These terminals provide the AC Fault relay output from the

PSX power supply. This relay signals when the internal PSX

power supply detects a low or missing AC input voltage.

From the factory this output is set to provide a CLOSED

connection when there is no fault. During a fault condition,

the connection between these terminals will OPEN.

To reverse this operation, see Section 1.3.6 of this manual.

System Fault (SF)

These terminals provide the System Fault relay output

from the PSX power supply. This relay signals when any

of the following conditions occur:

• Missing Battery (If BAT DET jumper is ON)

• Earth Ground Fault (If EARTH GND DET jumper is ON)

• Battery voltage out of range

• DC output voltage out of range

• Ruptured fuse

• Accessory Board Fault

• Internal Fault

From the factory this output is set to provide a CLOSED

connection when there is no fault. During a fault condition,

the connection between these terminals will OPEN.

To reverse this operation, see Section 1.3.6 of this manual.

FAI Input (V+, I+, I–, V–, L, L)

These terminals accept the optional FAI / Access Control

input for controlling the outputs. See FAI Input Usage dia-

grams on next page for more information.

Connections are as follows:

• L Terminals Latch Reset contact input. If a latching FAI In-

put is desired, a normally closed contact is placed across

these terminals. When the FAI Input is activated, it will

latch in the activated state until this contact is momentarily

opened. If the latching feature is not desired, leave these

terminals open.

• V+ & V– Terminals These terminals are a low-current aux-

iliary voltage output to be used with a dry contact or open

collector for activating the FAI Input.

• I+ & I– Terminals These terminals are the input terminals

for the FAI Input. The FAI input is activated when a voltage

between 9 and 30 volts is applied across these terminals in

the correct polarity.

1.4 Making the Wiring Connections

7

Installation and Operation

1.5 FAI Connections

This section provides more detailed information on the connection and usage of the FAI input.

Activation with a Normally Open Relay Contact

FAI Activates when the

NO contact CLOSES.

FAI Deactivates when the

NO contact OPENS.

Activation with a Normally Closed Relay Contact

FAI Activates when the

NC contact OPENS.

FAI Deactivates when the

NC contact CLOSES.

Note: FAI with a NC contact

cannot be tested by removing

the terminal strip, as this will

remove the jumper wires from

V+ and V- as well. To test,

remove one wire going to the

NC Contact.

Activation with a Voltage Input

FAI Activates when voltage is

APPLIED in the correct polarity.

FAI Deactivates when voltage is

REMOVED or the polarity of the

voltage is REVERSED. Polarity

shown in the ACTIVATED state

Latching the FAI Input

Latching of the FAI Input

is achieved by placing a

NC contact across the

two ‘L’ terminals. The FAI

may be activated by any

of the methods listed.

FAI Deactivates when the

input is deactivated AND

the NC Latching contact is

momentarily OPENED.

Example – NO Contact

activation with latching

FAI Activates when the NO contact CLOSES. FAI Deactivates

when the NO contact OPENS AND the NC contact momentarily

OPENS.

FAI Activation with a Normally Open Relay Contact

and PSX AC Fault Lock Over Ride

FAI Activates either, when the Fire Alarm NO contact CLOSES,

or when the AC Fault NC contact CLOSES

FAI Deactivates either, when the Fire Alarm NO contact OPENS,

or when the PSX AC Fault NC contact OPENS

SYS ACSYS AC

FAULTSFAULTS

FAI

INPUT

CC NCNC NONO CC NCNC NONO

FAI INPUTFAI INPUT

LL LL V–V– I–I– I+I+ V+V+

FAI INPUTFAI INPUT

LL LL V–V– I–I– I+I+ V+V+

NO

Contact

NC

Contact

FAI INPUTFAI INPUT

LL LL V–V– I–I– I+I+ V+V+

9-30 VDC

–

+

FAI INPUTFAI INPUT

LL LL V–V– I–I– I+I+ V+V+

NO

Contact

NC

Contact

FAI INPUTFAI INPUT

LL LL V–V– I–I– I+I+ V+V+

8

PSX Rackmount Power Supply - Installation and Operation Manual

Section 2 – Power and Network Connections

2.2 Remote Access via Ethernet

PSX Series power supplies with model numbers ending in

"N" may be accessed over the internet or local intranet via

the ethernet port on the back of the enclosure (Figures 5

and 6). Functionality varies by model type. This section only

gives basic information. See the PSX-NL manual for more

information.

Features available with the PSX-NL in a PSX rackmount

include monitoring and email reporting of voltage, bat-

tery status, AC and System Fault status and other pa-

rameters. Additionally, a periodic status report can be

emailed.

i The internal Netlink communication module must be

configured before connecting to a network.

See the PSX Netlink manual for more information.

Figure 5 - PSX-GCM, PSX-ISU AC Connection and Ethernet Network Connection

Figure 6 - PSX-ISUSE AC Connection and Ethernet Network Connection

AC Power

10-100

Base-T

9

+ –

10

+ –

11

+ –

12

+ –

13

+ –

14

+ –

15

+ –

16

+ –

9

A B

10

A B

11

A B

12

A B

13

A B

14

A B

15

A B

16

A B

MAIN OUTPUT 1

BAT+

BAT-

DC1 +

DC1 -

DC2 +

DC2 -

ACF

ACF

V +

V -

I -

I -

V -

I -

SF

SF

MAIN OUTPUT 2

BAT+

BAT-

DC1 +

DC1 -

DC2 +

DC2 -

ACF

ACF

V +

V -

I -

I -

V -

I -

SF

SF

1

+ –

2

+ –

3

+ –

4

+ –

CONTROLLED OUTPUTS 1 CONTROLLED OUTPUTS 2

CONTROL INPUTS 1 CONTROL INPUTS 2

5

+ –

6

+ –

7

+ –

8

+ –

1

A B

2

A B

3

A B

4

A B

5

A B

6

A B

7

A B

8

A B

2.1 Main AC Power Connection

To connect the PSX Series to the main AC power source, plug

one end of the included computer-style AC cord into the AC

Power connector on the back of the enclosure. See Figures 5, 6.

Connect the other end of the AC cord into a suitable AC

power outlet.

iThe PSX Series is preconfigured for a 120VAC input.

See section 1.3.2 to set for a 230VAC input.

9

Installation and Operation

This section describes the final configuration as well as operation details for the PSX series power supplies.

3.1 Removing the Faceplate of the Enclosure

Use the following steps to remove the faceplate of the rack-

mount enclosure and gain access to the front boards.

1. Remove and retain the five philips head 6-32 screws

from the faceplate. DO NOT remove the four 10-32

screws securing the enclosure to the rack.

2. Carefully remove the faceplate and set it aside in a

safe location

When configuration is complete, reverse the removal pro-

cedure to replace the cover, taking care to align the LEDs

with the holes in the faceplate (See figure 7).

3.2 Configuring the Zones - PSX-ISUSE

Input Selection (see Figure 8)

These switches are used to select a normally open or normally

closed input for each zone. Switch 1 sets zone 1, switch 2 sets

zone 2, and so on. Adjust this switch so that the zone's output

LED is FLASHING when the door is unlocked.

•OFF(NC/FailSafe) Set this switch to OFF for a NC contact

input (contact OPENS to unlock door) or for a voltage input

where the voltage is REMOVED to unlock the door.

•ON(NO/FailSecure) Set this switch to ON for a NO contact

input (contact CLOSES to unlock door) or for a voltage input

where the voltage is APPLIED to unlock the door.

FAI Selection (see Figure 8)

These switches enable or disable FAI for the selected zone.

Switch 1 sets zone 1, switch 2 sets zone 2, and so on.

•ON(FAIEnabled)When this switch is set to ON, the zone's

output will invert when the FAI input is active. This is typically

used to drop power to maglocks on a fire alarm condition.

•OFF(FAIDisabled) When this is set to OFF, FAI will have no

effect on the zone's output.

Output Selection (see Figure 9)

These switches are used to select a fail-safe or fail-secure out-

put for each zone. Switch 1 sets zone 1, switch 2 sets zone 2,

and so on. Set this switch so that the door is UNLOCKED when

the zone output LED is flashing (Zone Active).

•ON(FailSecureOutput) By setting this switch to ON, the

zone's output terminals will output a voltage when the zone in-

put is activated.

• OFF (Fail Safe Output) By setting this switch to OFF, the

zone's output terminals will not output a voltage when the zone

input is activated. This position is typically used for Mag Locks.

Section 3 – Configuration and Usage

A B

CONTROLLED OUTPUTS

CONTROL INPUTS

1

+

2 3 4

-+-+-+-

5

+

6 7 8

1 2 3 4 5 6 7 8

-+-+-+-

A B A B A B A B A B A B A B

1

ON

23 4 5 6 871

ON

23 4 5 6 87

N.O. INPUT

N.C. INPUT

Enable FAI

Disable FAI

2 3 4 5 6 7 8 F F1 10 11 12 13 14 15 169

Figure 8 - PSX-ISUSE Back Board

Figure 9 - PSX-ISUSE Front Board

Figure 7 - Faceplate

CH1 CH2 CH3 CH4 CH5 CH6 CH7 CH8

FLT

3

—

3

3

3

3

3

3

3

3

CH1 CH2 CH3

VOLTAGE SELECT JUMPERS

DC1

DC2

Fail-Safe

OUTPUT

Fail-Secure

OUTPUT

CH4 CH5 CH6 CH7 CH8

FLT

3

3

3

3

3

3

3

3

1

ON

23 4 5 6 87

10

PSX Rackmount Power Supply - Installation and Operation Manual

3.3 Configuring the Zones - PSX-ISU

Each output zone is configurable for one of two selections

which vary by model type. Selections are made by moving the

zone's corresponding jumper (marked as B1 and B2 on the PC

Board). See Figure 10

Single Supply Models

Each output is configurable for continuous or FAI con-

trolled. To set the operation of the FAI controlled outputs,

see Section 1.3.6.

• B1 (Left) Continuous Output (No FAI control)

• B2 (Right) FAI Controlled Output

Dual Supply Models

Each output is configurable for either internal power supply.

PSX#1 is the power supply on the left when looking from

the front and PSX#2 is the power supply on the right.

FAI control is provided on any distributed outputs set for

PSX#2 and the DC2 terminals of both PSX power sup-

plies.

• B1 (Left) PSX PS #1

• B2 (Right) PSX PS #2

3.4 Disabling Faults - PSX-ISU

Sometimes it is desirable to disable fuse fault detection for

individual zones. This allows removal of the fuse for spe-

cific unused zones or zones with unfinished wiring.

Faults can be disabled via the block of switches on the top

right of each front board (See Figure 2.2). Note that the

color of this switch block may vary. Switch numbers cor-

respond with zone numbers of the board (Switch 1 disables

faults for Zone 1, etc.). Switch settings are as follows:

• ON Fault Detection Enabled

• OFF Fault Detection Disabled

Figure 10 - PSX-ISU Front Board

CH1 CH2 CH3 CH4 CH5 CH6 CH7 CH8

FLT

1

2

3

4

5

6

7

8

3

3

3

3

3

3

3

3

—

1

B1 B2

JP1

2 3

11

Installation and Operation

ACF

ACF

DC2 –

DC2 +

BAT –

SF

SF

L

L

V –

I –

I +

V +BAT +

DC1 –

DC1 +

MAIN OUTPUT 2

9

+

10 11 12

-+-+-+-

13

+

14 15 16

-+-+-+-

9 10 11 12 13 14 15 16

A B

SF

SF ACF

ACF

DC2 –

DC2 +

BAT –

L

L

V –

I –

I +

V +BAT +

DC1 –

DC1 +

MAIN OUTPUT 1

CONTROLLED OUTPUTS

CONTROL INPUTS

1

+

2 3 4

-+-+-+-

5

+

6 7 8

1 2 3 4 5 6 7 8

-+-+-+-

A B A B A B A B A B A B A B A B A B A B A B A B A B A B A B

CONTROLLED OUTPUTS

CONTROL INPUTS

Figure 13 - Ethernet Network Connection

Figure 11 - PSX-ISUSE Front Board

Figure 12 - PSX-ISU Front Board

CH1 CH2 CH3 CH4 CH5 CH6 CH7 CH8

FLT

3

—

3

3

3

3

3

3

3

3

CH1 CH2 CH3

VOLTAGE SELECT JUMPERS

DC1

DC2

Fail-Safe

OUTPUT

Fail-Secure OUTPUT

CH4 CH5 CH6 CH7 CH8

FLT

3

3

3

3

3

3

3

3

1

ON

23 4 5 6 87

CH1 CH2 CH3 CH4 CH5 CH6 CH7 CH8

FLT

1

2

3

4

5

6

7

8

3

3

3

3

3

3

3

3

—

1

B1 B2

JP1

2 3

3.5 Status LEDs - PSX-ISUSE

Each front board has nine LEDs (see figure 11).

The eight green LEDs indicate the status of the zone’s output.

•OnSteady–Door Locked (Fuse or PTC Intact)

•Flashing–Door Unlocked (either due to Zone Input or FAI)

•Off–Fuse open or jumper missing

The yellow LED will light if a fault condition is detected by the

RC front board.

3.6 Status LED - PSX-ISU

Each front board has nine LEDs (see Figure 12). The eight

green LEDs give the voltage availability of the associated

zone. The yellow LED will light if a fault condition is detected.

3.7 Remote Access via Ethernet (All models)

PSX-N Series Rackmount power supplies use the optional Net-

Link board to allow access over the internet or local intranet via

the ethernet port on the back of the enclosure (see figure 13).

See the PSX NetLink manual for more information.

12

PSX Rackmount Power Supply - Installation and Operation Manual

Section 4 – Specifications

4.1 Electrical Specifications

Specifications PSX-GCM-RB PSX-ISU 150W PSX-ISU 250W

AC Input Voltage 120/230VAC

±15% at 50-60Hz

120/230VAC

±15% at 50-60Hz

120/230VAC

±15% at 50-60Hz

Power 100 Watts 200 Watts 300 Watts

Standby Current 100mA 100mA 100mA

Rated Current for UL603 Proprietary

Alarm Installations

Current 1.25A maximum from

all circuits in system

2.5A maximum from

all circuits in system

2.5A maximum from

all circuits in system

DC Output at 12V Setting Voltage 12.5V ±0.5V nominal 12.5V ±0.5V nominal 12.5V ±0.5V nominal

Max Current 6A 12A 20A

Ripple 120mV 120mV 120mV

Regulation ±2% ±2% ±2%

Efficiency 85% (120VAC

60Hz In, Full Load,

No Batt)

88% (120VAC

60Hz In, Full Load,

No Batt)

89% (120VAC

60Hz In, Full Load,

No Batt)

DC Output at 24V Setting Voltage 25.0V ±0.5V nominal 25.0V ±0.5V nominal 25.0V ±0.5V nominal

Max Current 3A 6A 10A

Ripple 120mV 120mV 120mV

Regulation ±2% ±2% ±2%

Efficiency 85% (120VAC

60Hz In, Full Load,

No Batt)

88% (120VAC

60Hz In, Full Load,

No Batt)

89% (120VAC

60Hz In, Full Load,

No Batt)

Battery Size & Type 4-40AH Lead Acid

or Gel Cell

4-80AH Lead Acid

or Gel Cell

4-80AH Lead Acid

or Gel Cell

Charge Current 1A (±10%) Maximum

(Adjustable via

PowerCom Software)

2A (±10%) Maximum

(Adjustable via

PowerCom Software)

2A (±10%) Maximum

(Adjustable via

PowerCom Software)

Fuse Ratings DC1 (Internal) ATM 7.5A ATM 15A ATM 30A

DC2 (Internal) ATM 7.5A ATM 15A ATM 30A

Battery (Internal) ATM 7.5A ATM 15A ATM 30A

BTU Output BTU 33 66 109

Fault Setpoints Low AC 95V (±6%) 95V (±6%) 95V (±6%)

Earth GND 2000 Ohms 2000 Ohms 2000 Ohms

Output Voltage ±10% of nominal ±10% of Nominal ±10% of Nominal

Batt Voltage ±10% of nominal ±10% of Nominal ±10% of Nominal

Batt Presence 6–15V (12V Setting),

11–29V (24V Setting)

6–15V (12V Setting),

11–29V (24V Setting)

6–15V (12V Setting),

11–29V (24V Setting)

Fault Relay Contacts AC FLT 1A at 24VDC 1A at 24VDC 1A at 24VDC

SYS FLT 1A at 24VDC 1A at 24VDC 1A at 24VDC

13

Specifications

Section 4 – Specifications

4.1 Electrical Specifications - continued

Specifications PSX-ISUSE 150W PSX-ISUSE 250W

AC Input Voltage 120/230VAC

±15% at 50-60Hz

120/230VAC

±15% at 50-60Hz

Power 200 Watts 300 Watts

Standby Current 100mA 100mA

Rated Current for UL603 Proprietary

Alarm Installations

Current 2.5A maximum from

all circuits in system

2.5A maximum from

all circuits in system

DC Output at 12V Setting Voltage 12.5V ±0.5V nominal 12.5V ±0.5V nominal

Max Current 12A 20A

Ripple 120mV 120mV

Regulation ±2% ±2%

Efficiency 88% (120VAC

60Hz In, Full Load,

No Batt)

89% (120VAC

60Hz In, Full Load,

No Batt)

DC Output at 24V Setting Voltage 25.0V ±0.5V nominal 25.0V ±0.5V nominal

Max Current 6A 10A

Ripple 120mV 120mV

Regulation ±2% ±2%

Efficiency 88% (120VAC

60Hz In, Full Load,

No Batt)

89% (120VAC

60Hz In, Full Load,

No Batt)

Battery Size & Type 4-80AH Lead Acid

or Gel Cell

4-80AH Lead Acid

or Gel Cell

Charge Current 2A (±10%) Maximum

(Adjustable via

PowerCom Software)

2A (±10%) Maximum

(Adjustable via

PowerCom Software)

Fuse Ratings DC1 (Internal) ATM 15A ATM 30A

DC2 (Internal) ATM 15A ATM 30A

Battery (Internal) ATM 15A ATM 30A

BTU Output BTU 66 109

Fault Setpoints Low AC 95V (±6%) 95V (±6%)

Earth GND 2000 Ohms 2000 Ohms

Output Voltage ±10% of Nominal ±10% of Nominal

Batt Voltage ±10% of Nominal ±10% of Nominal

Batt Presence 6–15V (12V Setting),

11–29V (24V Setting)

6–15V (12V Setting),

11–29V (24V Setting)

Fault Relay Contacts AC FLT 1A at 24VDC 1A at 24VDC

SYS FLT 1A at 24VDC 1A at 24VDC

Distributed Outputs

Count 16

Current Fused 3A

Current PTC 2.5A

14

PSX Rackmount Power Supply - Installation and Operation Manual

Section 4 – Specifications

4.2 Temperature Specifications

All Models

Ambient Temperature 0°C to 49°C (32°F to 120°F)

Ambient Humidity 93% at 32°C (90°F) maximum

Storage Temperature –30°C to 70°C (–22°F to 158°F)

4.3 Mechanical Specifications

Size (Without Ears)

Approximate Weight

17.5" W x 3.8" H x 14.0" D (445mm W x 97mm H x 356mm D)

Varies, based on configuration

co International Compan y

www.swhouse.com

The trademarks, logos, and service marks displayed on this document are registered in the United States [or other countries]. Any misuse of the trademarks is strictly prohibited and Tyco International Ltd. will aggressively

enforce its intellectual property rights to the fullest extent of the law, including pursuit of criminal prosecution wherever necessary. All trademarks not owned by Tyco International Ltd. are the property of their respective owners,

and are used with permission or allowed under applicable laws.

Product oerings and specications are subject to change without notice. Actual products may vary from photos. Not all products include all features. Availability varies by region; contact your sales representative.

© 2015 Tyco International Ltd. and its respective companies. All rights reserved.

15

User Certificate

co International Compan y

www.swhouse.com

The trademarks, logos, and service marks displayed on this document are registered in the United States [or other countries]. Any misuse of the trademarks is strictly prohibited and Tyco International Ltd. will aggressively

enforce its intellectual property rights to the fullest extent of the law, including pursuit of criminal prosecution wherever necessary. All trademarks not owned by Tyco International Ltd. are the property of their respective owners,

and are used with permission or allowed under applicable laws.

Product oerings and specications are subject to change without notice. Actual products may vary from photos. Not all products include all features. Availability varies by region; contact your sales representative.

© 2015 Tyco International Ltd. and its respective companies. All rights reserved.

This manual suits for next models

4

Table of contents

Other Software House IP Access Controllers manuals