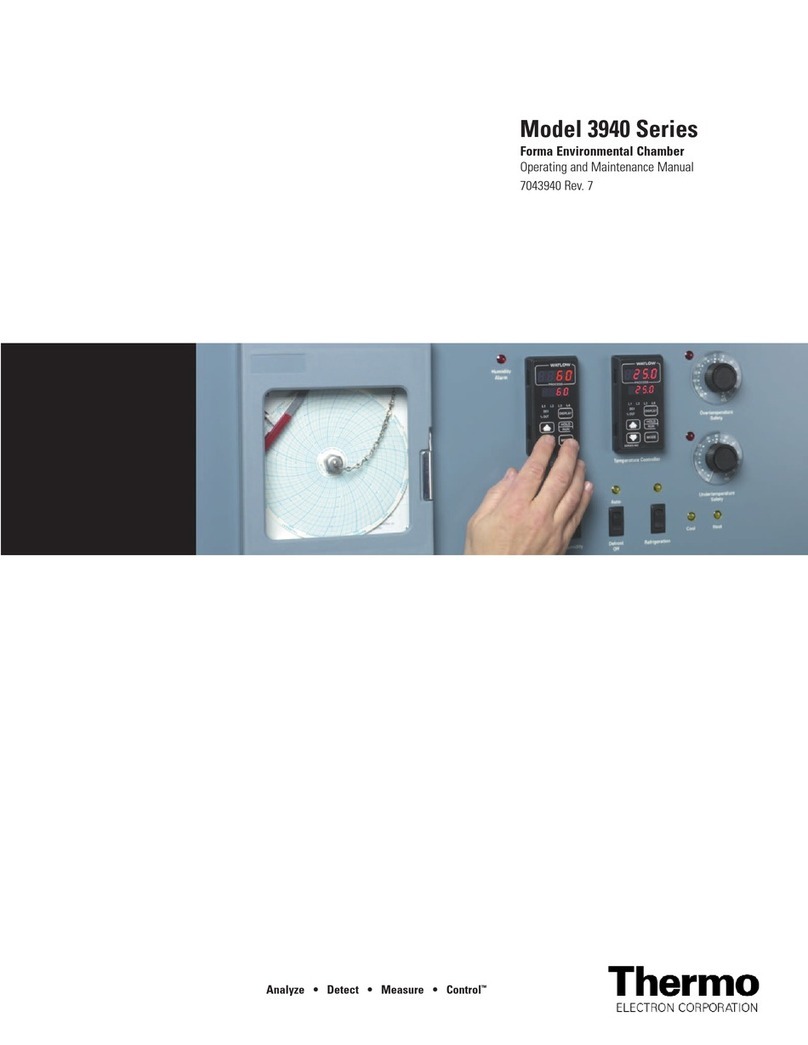

a. Calibrating the Chart Recorder

Place an accurate thermometer(s) in the chamber next to

the recorder’s probe(s). After about three minutes, compare the

thermometer with the chart recorder. For 2 pen operations, also

compare the second thermometer.

Note: For 2 pen operations, first select the

pen you wish to calibrate (Figure 5-9). Hold

down the #1 arrow for the red (#1) pen or the

#2 arrow for the blue (#2) pen, until the light

goes out. Then adjust as necessary.

If an adjustment is necessary, press either

the #1 or #2 button to move the pen left or right. The button

must be held about five seconds before the pen begins to move.

Release the button when the pen matches the thermometer.

5.6 Setting the Door Heater Control

High voltage is present behind control panel.

Servicing must be performed by qualified electrical

service personnel.

The infinite heater control is

located in the right side of the incu-

bator top compartment behind the

control panel door. The heater

varies the amount of door heat from

no heat (zero) to full heat (100) as

indicated by the control dial face. If

the knob is turned past zero, a

“click” will indicate that all power

to the door is shut off. If turned past

100, a similar “click” will indicate

that the heat is set at the maximum.

Initially, the units leave the factory with the dial set at 40.

If desired, the amount of heat can later be reduced until mois-

ture appears on the door, then the heat advanced. However, in

fluctuating ambient conditions, it is recommended that a mini-

mum of 40% door heat be used.

5.7 Cleaning and Adjusting the Humidity Steam

Generator, P/N 505087

Depending upon the quality of water used in the humidifi-

cation system, it may be necessary to clean the humidity gener-

ator and immersion heaters every 2 to 3 months.

Materials Required: 6-foot stepladder, Flat and Phillips

screwdrivers, Clamp-on style Ammeter, Laboratory disinfec-

tant, Siphon, sponge, & cleaning materials

1. Remove all contents from the incubator, shut it off, and

disconnect the power.

2. Turn off the valve supplying the sterile distilled water.

3. From the stepladder, remove the eight Phillips screws

securing the top of the incubator cabinet.

4. When the steam generator has cooled, remove the four

thumbscrews.

The internal temperature of the steam generator

is hot enough to boil water. Make certain suffi-

cient time is given to allow the unit to completely

cool before removing the top.

5. Lift the top off of the steam generator and lay it to the

side taking care to not crimp the copper capillary tube.

6. Siphon all of the water out of the steam generator and

clean it with a good quality laboratory detergent and dis-

infectant. Do not use any type of chloride cleaner. A

bristle brush may be needed for stubborn rust and scale.

Also clean the inside of the standpipe using a test tube

brush. Siphon and sponge the wash water out of the

boiler. Repeat cleaning with soap and water as needed.

7. Carefully pry off the brass top of the float control reser-

voir. Clean and disinfect it and the connecting tube

between the reservoir and the steam generator being

careful to not damage the float assembly.

8. Clean the two heater elements and the part of the copper

capillary tube attached to them.

9. When all surfaces are clean, rinse with sterile distilled

water until all soap and disinfectant are removed.

10. Open the distilled water valve and allow the reservoir to

fill. Measure the water level. The limit is three inches,

plus or minus one-quarter of an inch. The water level is

raised and lowered by carefully bending the float arm.

When set, replace the cover.

11. Replace the top of the steam generator and alternately

tighten the four thumbscrews to evenly compress the

rubber gasket.

Model 3911/3913 _________________________________________________________________________________Service

5 - 4

Figure 5-10 Figure 5-11

Figure 5-9