SolarEdge SPV 60MMJ Series User manual

Installation Guide

Smart Modules

Version 1.3

Disclaimers 1

Disclaimers

Important Notice

Copyright © SolarEdge Inc. All rights reserved.

No part of this document may be reproduced, stored in a retrieval system or

transmitted, in any form or by any means, electronic, mechanical, photographic,

magnetic or otherwise, without the prior written permission of SolarEdge Inc.

The material furnished in this document is believed to be accurate and reliable.

However, SolarEdge assumes no responsibility for the use of this material. SolarEdge

reserves the right to make changes to the material at any time and without notice. You

may refer to the SolarEdge web site (www.solaredge.com) for the most updated version.

All company and brand products and service names are trademarks or registered

trademarks of their respective holders.

Patent marking notice: see http://www.solaredge.com/patent

The general terms and conditions of delivery of SolarEdge shall apply.

The content of these documents is continually reviewed and amended, where

necessary. However, discrepancies cannot be excluded. No guarantee is made for the

completeness of these documents.

Please note: This product is intended to provide remote shutdown of the SolarEdge PV

harvesting system, to enable safer access to a building in the event of fire. This product

DOES NOT reduce the risk of fire or protect firefighters or others accessing a building in

the event of a fire.

The images contained in this document are for illustrative purposes only and may vary

depending on product models.

Emission Compliance

This equipment has been tested and found to comply with the limits applied by the

local regulations.

These limits are designed to provide reasonable protection against harmful interference

in a residential installation. This equipment generates, uses and can radiate radio

frequency energy and, if not installed and used in accordance with the instructions,

may cause harmful interference to radio communications. However, there is no

guarantee that interference will not occur in a particular installation. If this equipment

does cause harmful interference to radio or television reception, which can be

determined by turning the equipment off and on, you are encouraged to try to correct

the interference by one or more of the following measures:

Smart

Modules

Installation

Guide

MAN-01-00520-1.3

Reorient or relocate the receiving antenna.

Increase the separation between the equipment and the receiver.

Connect the equipment into an outlet on a circuit different from that to which the

receiver is connected.

Consult the dealer or an experienced radio/TV technician for help.

Changes or modifications not expressly approved by the party responsible for

compliance may void the user’s authority to operate the equipment.

Smart

Modules

Installation

Guide

MAN-01-00520-1.3

2Emission Compliance

Contents

Disclaimers 1

Important Notice 1

Emission Compliance 1

Important Safety Instructions 4

General Safety 4

Installation Safety 5

Chapter 1: Introduction 7

Limitation of Liability 7

Chapter 2: Mechanical Installation 8

Installation Considerations and Environmental Conditions 8

Installation Method 9

Chapter 3: Electrical Installation 16

Chapter 4: Reporting and Monitoring Installation Data

Creating Logical and Physical Layout using Installation Information

1

1

8

9

Chapter 5: Maintenance and Disposal 21

Support Contact Information 22

Version History

Version 1.3 - (March 2020)

Modified Chapter 3 Mechanical Installation

Add Chapter 4 - Reporting and Monitoring Installation Data

Version 1.2 - (March 2020)

Modified Chapter 1 Mechanical Installation - Adding Smart Module Half-cut

Cell Mono PERC Module with Integrated Power Optimizer

Modified Technical Specifications - Adding Smart Module Half-cut Cell Mono

PERC Module with Integrated Power Optimizer

Version 1.1 - (September 2019)

Added Appendix A - Module Mechanical and Electrical Rating is STC

Modified Technical Specifications for Europe

Version 1.0 - (November 2018) initial release

3

Smart

Modules

Installation

Guide

MAN-01-00520-1.3

Important Safety Instructions

SAVETHESEINSTRUCTIONS

General Safety

NOTE

Consult and follow local codes and other applicable laws concerning

required permitting as well as installation & inspection requirements,

rules, and regulations.

Modules and PV systems should be installed by authorized and qualified

personnel.

Follow all safety precautions of all components used in the system.

Long periods of shading on the modules surface from the sun can result

in cell power dissipation and overheating.

Do not clean the glass surface with chemicals.

Do not drop the PV module or drop objects onto the module.

Do not attempt to disassemble the modules, and do not remove any

attached components from the modules.

Do not scratch or otherwise harm the back sheet ,the glass or the

junction box. Do not pull or twist the cables or touch them with bare

hands.

Do not drill holes in the frame or scratch the insulating coating of the

frame.

Keep the module packed in the package until installation.

Do not use modules near equipment or in places where gases, liquids or

other flammable materials may be generated.

External or otherwise artificially concentrated sunlight shall not be

directed onto the front or back face of the module.

Smart

Modules

Installation

Guide

MAN-01-00520-1.3

4Important Safety Instructions

Installation Safety

NOTE

Wear protective head gear, insulating gloves, safety shoes, and insulated

tools when installing the modules.

Do not install the modules in rain, snow, or otherwise wet or windy

conditions.

Modules may be covered with an opaque material during module

installation and wiring to reduce risk of charge buildup and electrical

shocks or burns.

When mating connectors, make sure they are firmly connected.

Due to the risk of electrical shock, do not perform any work if the

junction box is wet.

Do not touch the junction box and the end of output connectors with

bare hands.

Do not unplug the connectors under laod.

It is recommended not to work alone.

Wear a safety belt if working far above the ground.

Do not wear metallic jewelry, which can cause electric shock, while

installing or troubleshooting the PV system.

Follow the safety regulations for any and all other system components,

including wires, connectors, charging regulators, batteries, inverters, etc.

The cables must be protected from direct sunlight and away from areas

of water collection.

Do not damage the surrounding modules or mounting structure when

replacing a module.

Do not change any module components (diode, junction box, plug

connectors, etc.).

Important Safety Instructions 5

Smart

Modules

Installation

Guide

MAN-01-00520-1.3

NOTE

A module's maximum reverse current is 15A. Using a blocking diode and

maximum series overcurrent protective device in the combiner box are

recommended for reverse current protection when more than four strings

are connected in parallel. When used with a SolarEdge optimizer, it’s not

needed because the optimizer has reverse current protection.

When installing the modules on a roof, it is recommended to install over

a fireproof and insulating roof covering.

Do not touch terminals, connectors and modules while the system is on.

Do not stand, walk, drop or put objects on the module.

Damaged modules (broken glass, torn back sheet, broken junction box,

broken connectors, etc.) can be electrical hazards as well as laceration

hazards. Contact with damaged module surfaces or module frame can

cause electric shock. In such cases, removethe damaged module from

array and contact the supplier for disposal instructions.

Do not block draining holes.When working above ground level, wear a

safety belt.

Avoid use of sharp objects and tools that might damage the module.

Smart

Modules

Installation

Guide

MAN-01-00520-1.3

6Installation Safety

Chapter 1: Introduction

This document provides detailed instructions and safety information regarding the

installation, electrical connection and maintenance of following SolarEdge smart

modules:

Smart 60-cell Mono PERC Module

Integrated with power optimizers, these high-performance modules are based on

Passivated Emitter Rear Cells (PERC) technology. The module is powered by high-

efficiency cells providing an effective solution for lowering the cost of the power

produced over time in large and small PV systems.

Smart Half-cut Cell Mono PERC Module

Chapter 1: Introduction 7

Integrated with power optimizers, these high-performance modules are based on Smart

Half-cut Cell Mono PERC Module. Half-cell solar modules, are solar cells that are cut in

half during manufacturing. This technology increases the power output of a module by

lowering resistance of the module.

All instructions, mechanical and electrical requirements should be read and understood

before attempting installation.

When installing the module, installers must conform to all safety precautions detailed in

this guide .

Limitation of Liability

Because the use of this manual and the conditions or methods of installation,

operation, use and maintenance of photovoltaic (PV) products are beyond SolarEdge

control, SolarEdge does not accept responsibility and expressly disclaims liability for

loss, damage, or expense arising out of or in any way connected with such installation,

operation, use or maintenance. SolarEdge reserves the right to change the manual

without prior notice.

Modules rated for use in this application class may be used in systems operating at

greater than 50V DC or 240W, where general contact access is anticipated. Modules

qualified for safety through IEC 61730-1 and this part of IEC 61730 within this

application class are considered to meet the requirements for safety

class II.

Where common grounding hardware (nuts, bolts, star washers, spilt-ring lock washers,

flat washers, etc.) is used to attach a listed grounding/bonding device, the attachment

must be made in conformance with the grounding device manufacturer’s instructions.

Smart

Modules

Installation

Guide

MAN-01-00520-1.3

Chapter 2: Mechanical Installation

Installation Considerations and Environmental

Conditions

Install smart modules at sites that meet the following requirements:

Ambient temperature: -40 to 85 °C

Operating temperature: -40 to 85 °C

Maximum altitude: 2000 m

Mechanical load on modules (e.g., from wind or snow):

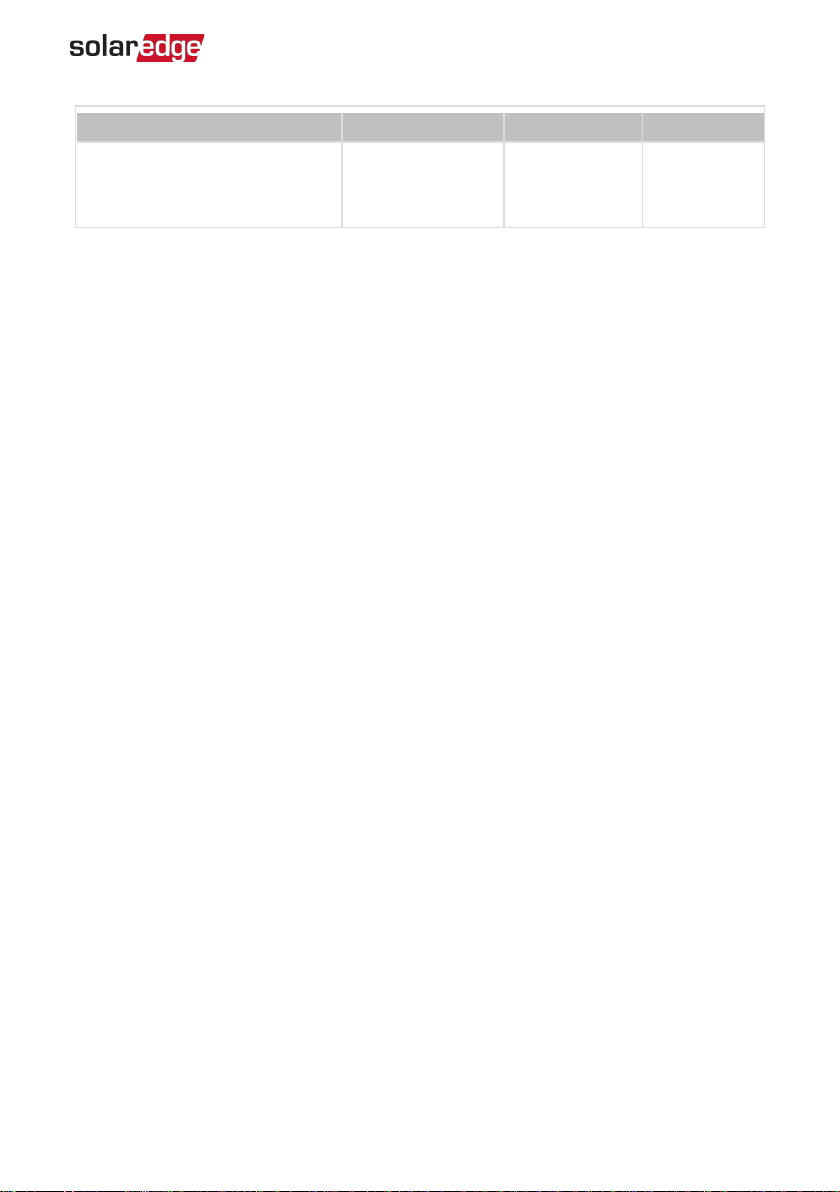

Smart 60-cell Mono PERC Module Front Load Rear Load

Design Load 3600 Pa 2400 Pa

Test load (safety factor of 1.5) 5400 Pa 3600 Pa

Smart Half-cut Cell Mono PERC

Module Front Load Rear Load

Mechanical Load 5400 Pa 2400 Pa

Table 1: Mechanical load on modules

To maintain the modules’ Class C fire rating, the fire class of the roof and building

materials should be higher than Class C. The fire safety rating of this module is

valid only when mounted in the manner specified in the mechanical mounting

instructions.

Do not install modules at locations that come with direct contact of water

collections, salt water or any aggressive environmental condition.

Do not install the modules near flames or flammable materials or locations with

hazardous materials.

Do not make any modifications to the module frame.

Top or bottom clamping methods will vary and are dependent on the mounting

structures. Follow the mounting guidelines recommended by the mounting system

supplier.

Clamp material should be anodized aluminum alloy or stainless steel

Each module must be securely fastened at a minimum of four points on two

opposite sides. The clamps should be positioned symmetrically.

Smart

Modules

Installation

Guide

MAN-01-00520-1.3

8Chapter 2: Mechanical Installation

Installation Method

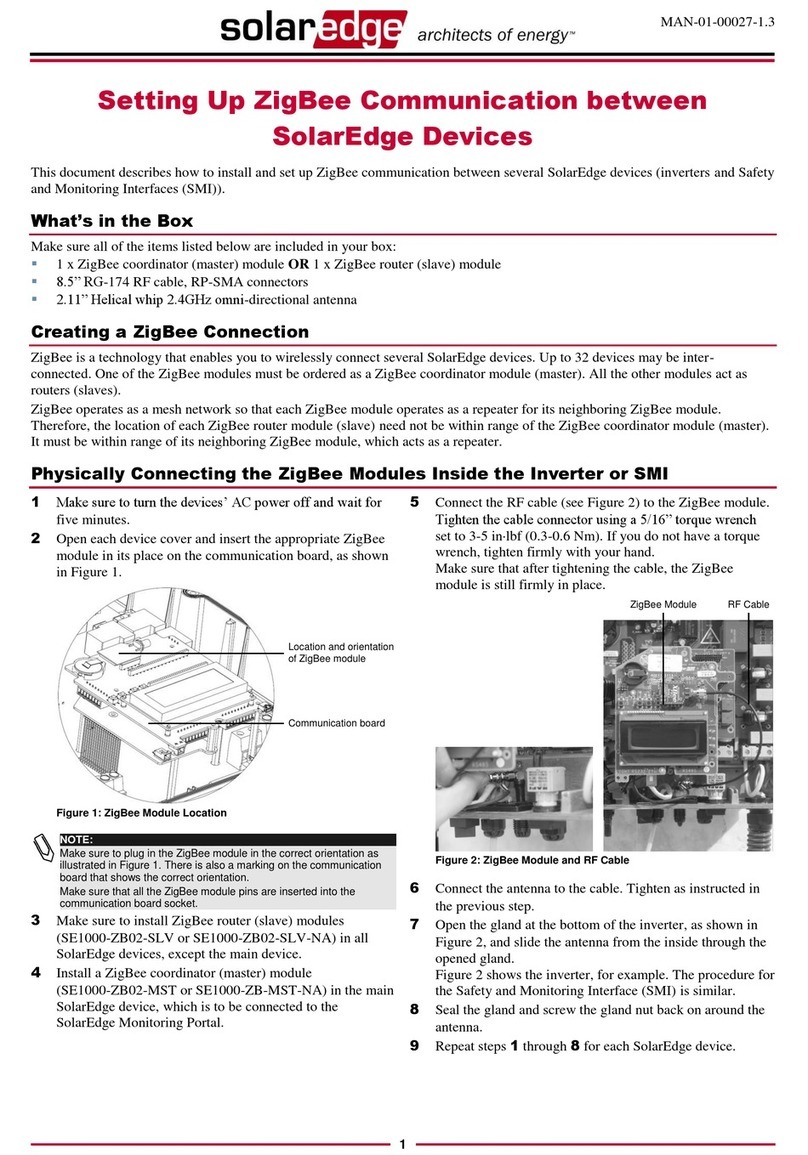

Clamping the Smart 60-cell Mono PERC Module

Modules can be laid on rails, either on the long side of the frame (

Figure 1

) or on the

short side of the frame.

Figure 1: Connecting modules by clamps on long side of frame

Attach each aluminum mounting clamp with an M8 bolt, a plain washer, a spring

washer, and an M8 nut. At least 4 clamps should be used to fasten the modules on the

supporting rails.

NOTE

Make sure to use clamps with the following properties:

The dimensions for the middle clamps are: a ≥ 40 mm, b ≥ 26 mm, c = 8 mm,

d ≥ 28 mm, and Ø = 9 mm (See

Figure

2

)

The recommended torque for tightening the bolts and nuts is 28 N*m when

the bolts and nuts have property is Class 8.8.

To fasten the module:

1. Place the module on two supporting rails (not provided). The rails should be made

from stainless material or treated with an anti-corrosion process (e.g.,anodic

oxidation treatment).

2. If the rail does not have grooves compatible with M8 bolts, suitable holes should be

drilled for securing the module frame.

3. Secure each clamp by attaching a plain washer, spring washer, and nut, in that order.

Chapter 2: Mechanical Installation 9

Smart

Modules

Installation

Guide

MAN-01-00520-1.3

4. Close -ups of the middle clamps and the side clamps are indicated in

Figure 2

and

Figure 3

.

Figure 2: Middle clamps (left) and side clamps (right)

Middle clamp installation End clamp installation

Figure 3: End clamp and middle clamp installation

6. For mounting the supporting rails on the long side of the frame, slide bolts through

the rail grooves next to the 4 clamp locations. The module may be clamped only in

the permitted clamping range.

For exact frame clamping locations refer to area C in

Figure 4

and

Table 2

.

Smart

Modules

Installation

Guide

MAN-01-00520-1.3

10 Installation Method

Figure 4: Long side clamping range

Module Type Series Dimension A B C Clamping

Range

SPVxxx-60MMJ 1650*992*40 mm 1650 mm 200 mm 210 mm

Table 2: Module dimensions for mounting rails on the long side of the frame

7. For mounting the supporting rails on the short side of the frame , slide bolts

through the rail grooves next to the 4 clamps locations. The module may be

clamped only in the permitted clamping range . For the exact locations refer to area

F in

Figure 5

and

Table 3

.

Chapter 2: Mechanical Installation 11

Smart

Modules

Installation

Guide

MAN-01-00520-1.3

Figure 5: Short side clamping range

Module Type Series Dimension D E F Clamping Range

SPVxxx-60MMJ 1650*992*40 mm 992 mm 50 mm 150 mm

Table 3: Modules dimensions for mounting rails on the short side of the frame

Smart

Modules

Installation

Guide

MAN-01-00520-1.3

12 Installation Method

Clamping the Smart Half-cut Cell Mono PERC Module

Modules can be laid on rails, either on the long side of the frame (See

Figure

6

).

Figure 6: Connecting the SPVxxx-R60LWMG/SPVxxx-R60LBMG Modules by clamps to a frame

Attach each aluminum mounting clamp with an M8 (5/16") bolt, nut. Tightening

torque should be within 17~23 Nm (12.5~17.0 ft-lbs) coarse thread bolts. Secure

each clamp by attaching a plain washer, spring washer, and nut, in that order.

Figure 7: Attaching mounting clamp

Ensure the clamps overlap the module frame by at least 5 mm (0.2 in)

Ensure the clamps overlap length is at least 40 mm (1.57 in)

Ensure the clamp’s thickness is at least 3 mm (0.12 in)

NOTE

For configurations where the mounting rails run parallel to the frame,

precautions should be taken to ensure the bottom flange of the module frame

overlaps the rail by 15 mm (0.59 in) or more.

Chapter 2: Mechanical Installation 13

Smart

Modules

Installation

Guide

MAN-01-00520-1.3

To fasten the module:

1. Place the module on two supporting rails (not provided). The rails should be made

from stainless material or treated with an anti-corrosion process (e.g.,anodic

oxidation treatment).

2. If the rail does not have grooves compatible with M8 bolts, suitable holes should be

drilled for securing the module frame.

3. Secure each clamp by attaching a plain washer, spring washer, and nut, in that order.

Figure 8: Clamping the SPVxxx-R60LWMG/SPVxxx-R60LBMG Modules

6. For mounting the supporting rails on the frame, slide bolts through the rail grooves

next to the four clamp locations. Clamp positions are of crucial importance for the

reliability of the installation. The clamp center lines must only be positioned within

the ranges indicated in

Figure

9 and Table4

, depending on the configuration and

load.

Figure 9: Side Clamping Ranges of the SPVxxx-R60LWMG/SPVxxx-R60LBMG Modules

Smart

Modules

Installation

Guide

MAN-01-00520-1.3

14 Installation Method

Module Series Dimension A1 Range A2 Range

SPVxxx-R60LWMG/

SPVxxx-R60LBMG 1776*1052*40 mm 340 – 550 mm 410 – 490 mm

Table 4: Mounting dimensions for rails on the Monocrystalline PERC module with half-cut cell

technology and integrated power optimizer

Chapter 2: Mechanical Installation 15

Smart

Modules

Installation

Guide

MAN-01-00520-1.3

Chapter 3: Electrical Installation

Details for electrical installation in accordance with the IEC61730-1.

Installation

The maximum system voltage of the Smart Module 60-cell Mono PERC with

Integrated Power Optimizer (module SPVxxx-60MMJ) is 1000 V.

The maximum system voltage of the Smart Module Half-cut Cell Mono PERC with

Integrated Power Optimizer is 1500 V (module SPVxxx-R60LWMG) and 1000V

(module SPVxxx-R60LBMG).

The power optimizers regulate the string voltage at a constant level, regardless of

string length and environmental conditions.

Under normal conditions, a module might produce more current and/or voltage than

reported at standard test conditions(1). The requirements of the National Electrical

Code (NEC) in Article 690 shall be followed to address these increased outputs. In

installations not under the requirements of the NEC, the values of Isc and Voc marked

on this module should be multiplied by a factor of 1.25 when determining component

voltage ratings, conductor capacities, over current device ratings, and size of controls

connected to the PV output.

Each series-connected string of modules shall be provided with the maximum series

overcurrent protective device, specified as 15A for the Smart Module 60-cell Mono

PERC module with Integrated Power Optimizer series and 20A for the Smart Module

Half-cut Cell Mono PERC Module with Integrated Power Optimizer series.

Use a cable with a cross section of 4 mm2 (12AWG) that can withstand the maximum

possible system open-circuit voltage and make sure that all connections are safe and

tight.

The cable minimum bending radius should be 43 mm.

Bypass diodes are included in module junction boxes to avoid decreased module

performance. Check the relevant specifications for the specific diodes of the junction

box.

For the smart module electrical data and temperature coefficients , refer to the

technical specification sections in this manual.

(1)Standard Test Conditions (STC): 1000 W/m², cell temperature 25°C, air mass AM 1.5

Smart

Modules

Installation

Guide

MAN-01-00520-1.3

16 Chapter 3: Electrical Installation

Grounding

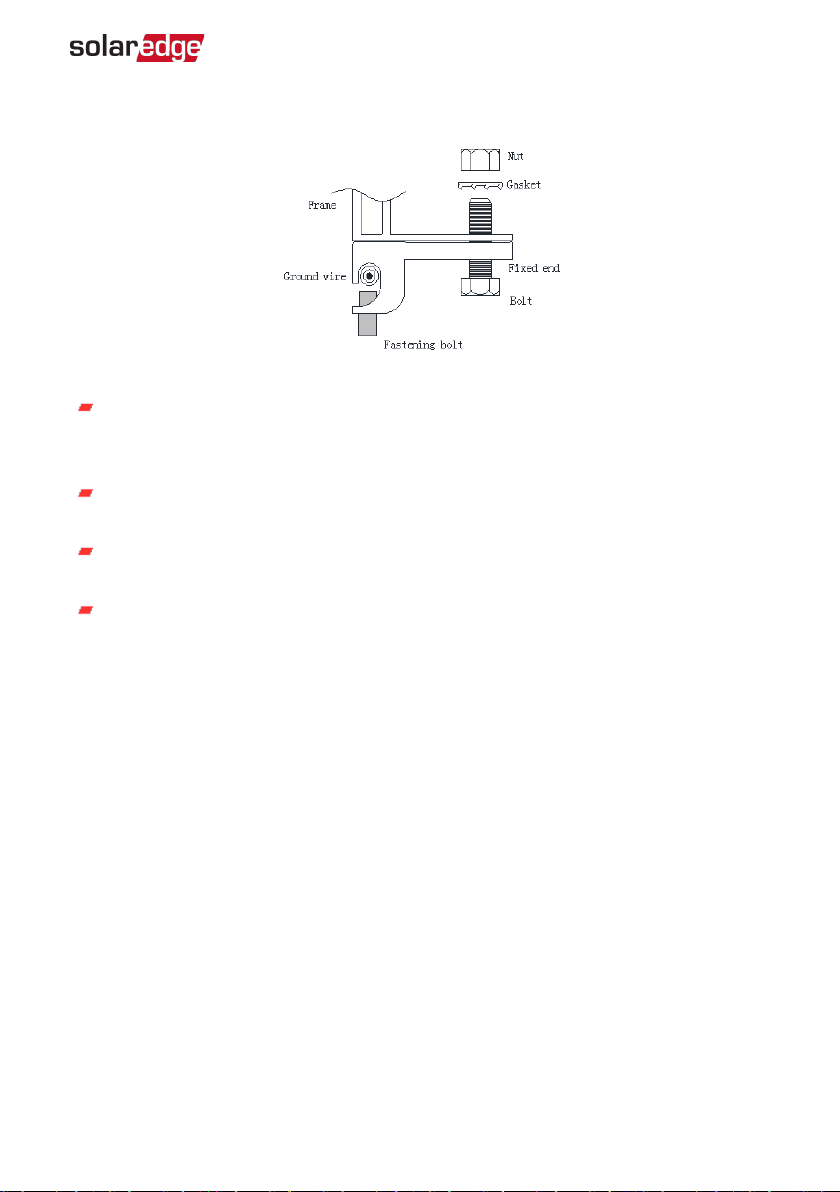

Figure 10: Grounding the aluminum frame with a copper wire

Use the marked 5.5 mm grounding holes to ground the anodized aluminum frame.

Use an M5 nut, an M5 gasket, and an M5 bolt, fastening bolt and a ground wire.

All nuts, bolts, and gasket should be made of stainless steel. See

Figure 10

.

Secure the ground wire on fixed end through fastening bolt (note that the copper

wire cannot be attached directly to the aluminum).

Insert the bolt through the fixed end and then through the hole in the aluminum

frame.

Add the gasket and nut on the other side of the bolt and tighten to secure all parts.

The tightening torque should be 2.1±0.1 N*m.

Chapter 3: Electrical Installation 17

Smart

Modules

Installation

Guide

MAN-01-00520-1.3

Chapter 4: Reporting and Monitoring

Installation Data

The Monitoring Platform

The monitoring platform provides enhanced PV performance monitoring and yield

assurance through immediate fault detection and alerts at the module, string and

system level.

Using the platform, you can:

View the latest performance of specific components.

Find under-performing components, such as modules, by comparing their

performance to that of other components of the same type.

Pinpoint the location of alerted components using the physical layout.

The monitoring platform enables accessing site information, including up-to-date

information viewed in a physical or logical view:

Logical Layout: Shows a schematic tree-layout of the components in the system,

such as: inverters, strings, modules, meters and sensors, as well as their electrical

connectivity. This view enables you to see which modules are connected in each

string, which strings are connected to each inverter, and so on.

Physical Layout: Provides a bird's eye view of the actual placement of modules in

the site, and allows pinpoint issues to the exact location of each module on a

virtual site map.

18 Chapter

4:

Reporting

and

Monitoring

Installation

Data

If you do not report the mapping of the installed power optimizers, the monitoring

platform will show the logical layout indicating which power optimizers are connected

to which inverter, but will not show strings or the physical location of power optimizers.

The monitoring platform includes a built-in help system, that guides you

through the monitoring functionality.

For more information, refer to https://www.solaredge.com/products/pv-

monitoring#/.

Smart

Modules

Installation

Guide

MAN-01-00520-1.3

To display a physical layout, you need to map the locations of the installed modules or

power optimizers. To map the locations, use one of the methods described in the next

sections.

Designer

Designer recommends inverter and power optimizer selection per site size and enables

report generation. You can create a project in Designer and export the site design with

the string layout to the monitoring platform.

For more information, refer to

https://www.solaredge.com/products/installer-tools/designer#/.

Mapper Application

Use the Mapper smart phone application to create a virtual map of a PV

site for enhanced monitoring and easier maintenance using one of the

two scanning options:

Scan the smart module's 2D bar-code located on the front of the module

Scan the power optimizer 2D bar-code

The Mapper application is integrated with the monitoring platform and enables:

Simple on-site registration of new systems.

Creating, editing and verifying system physical layout.

Scanning and assigning the module and power optimizer serial numbers in the

system physical layout.

For detailed information, refer to the

Mapper

demo movies:

Scanning a smart panel using the SolarEdge Mapper App

Upon scanning the smart module or the power optimizer, the Mapper activates a

dedicated mapping process to ensure that the power optimizer inputs are assigned to

their module(s). You can approve each input assignment separately.

Smart

Modules

Installation

Guide

MAN-01-00520-1.3

Creating

Logical

and

Physical

Layout

using

Installation

Information 19

I

C

n

r

s

e

t

a

a

t

l

i

la

n

t

g

io

L

n

o

I

g

n

ic

fo

al

r

a

m

n

at

d

io

P

n

hysical Layout using

To display a logical layout after the inverter was installed, insert the inverter serial

number in the new site created in the monitoring platform. When the communication

between the inverter and the monitoring server is established, the logical layout is

displayed.

This manual suits for next models

5

Table of contents

Other SolarEdge Control Unit manuals

Popular Control Unit manuals by other brands

GatesAir

GatesAir Intraplex VF-25 Installation and operation manual

Mitsubishi Electric

Mitsubishi Electric A1SJ71AP23Q user manual

wattwatchers

wattwatchers FBC-HC Installation and operating instruction

Lucent

Lucent Stinger Guide

Festo

Festo HMPL-20 Series operating instructions

CYG

CYG PRS-7395 instruction manual