ENGLISH 6

9. Fuel information

A high performance two-stroke engine operated

with a petrol:oil mixture (petrol + oil = fuel mixture)

or with a special fuel mixture for two-stroke

engines available from specialists powers this

machine.

We recommend the proprietary “Aspen 2-takt”

special fuel mixture. Please observe the special

fuel manufacturer’s instructions.

Information on individual mixing of the fuel mixture

The fuel mix must be formed from the following

components:

Lead-free regular petrol or lead-free super petrol

with a minimum octane number of 92 RON.

Branded 2-stroke engine oil corresponding to

the standard ISO-L-EGD or JASO FD

Recommendation:

Use the "SOLO Profi 2-stroke engine oil" at a

mixing ratio of oil:petrol of 1:50 (2 %).

Store the fuel mix no longer than 3 weeks.

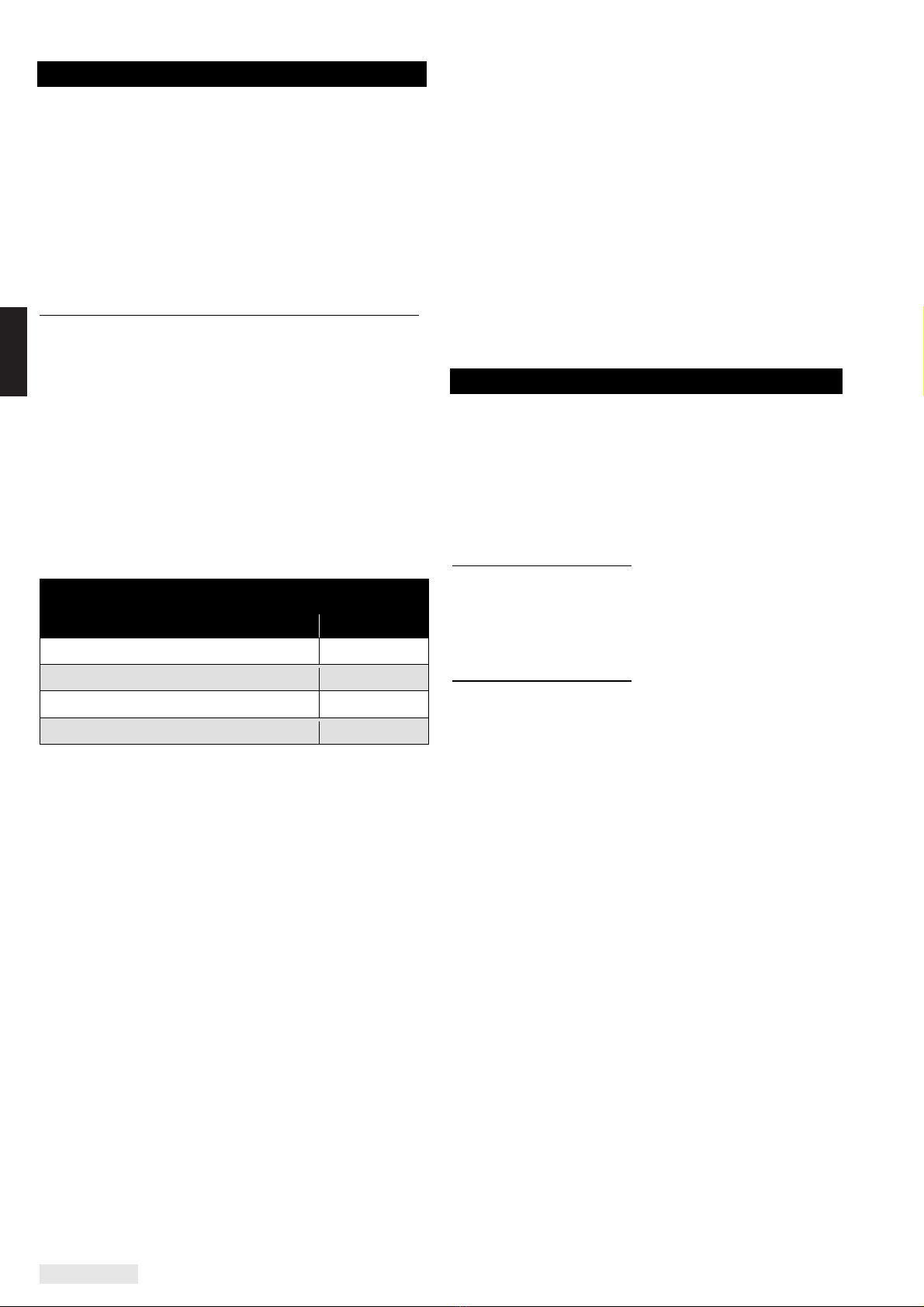

Mix table for fuel mix:

Unsuitable petrol or deviations in the mixing ratio

may lead to serious engine damage!

Smoking or open flame is prohibited

Allow engine to cool before re-fuelling

Fuel may contain solvent-like substances.

Avoid skin and eye contact with mineral

products. Wear gloves while refueling.

Frequently change and clean protective

clothing. Do not inhale fuel vapors.

Do not spill fuel or oil. In case of spillage,

immediately wipe off mistblower. Do not allow

fuel mix to contact clothing. If fuel mix is spilled

on clothing, change clothing immediately.

Ensure fuel or oil do not contaminate soil

(environmental protection). Always use a

suitable protective soil cover.

Do not re-fuel in unventilated rooms. Fuel

vapors collect at ground level (danger of

explosion).

Transport and store fuel and oil only in

approved and clearly marked containers.

Children should have no access to fuel or oil.

Ensure you do not inhale exhaust fumes while

using the machine. The use of the motorized

mistblower is prohibited in closed rooms.

The handling of fuel requires caution and

consideration. It is imperative that all safety

instructions are observed! Only refuel when the

engine has been stopped!

Clean the area around filler inlet before

refueling.

Remove tank lid and fill fuel mix up to the lower

edge of the filler neck. Do not overfill. If

possible, always use a fuel funnel with filter.

Fill in card fully to avoid spilling of fuel or oil.

Replace and secure fuel tank lid.

10. Filling

When handling the spraying agents, always follow

the safety instructions of these operating

instructions (pay special attention to section 5.6)

and the information provided by the manufacturer

of the particular spraying agent.

Spraying agent volume:

Mix the spraying agents according to the

instructions provided by the manufacturer of the

spraying agent. Choose the appropriate volume

according to requirements.

Mixing spraying agents:

Only mix spraying agents out in the open. Never do

this inside living spaces, stables or in storage

spaces that are used for food or animal feed.

Never mix the spraying agent directly in the

spraying agent tank.

When using spraying agents that have been mixed

from herbal preparations, the liquid needs to be

pre-filtered.

For filling the equipment, always use the strainer

inside the filler neck and observe the filler area

through the filling process.

The strainer has a mesh size of 0.5 mm. Only use

original SOLO strainers, part no.: 15137 with

standard mesh size.

Avoid any direct contact of the filling hose and the

contents of the spraying agent tank.

Fill level markings are applied to the backside of

the spraying agent tank .

When filling up the tank, ensure that you do not fill

above the top marking (maximum fill volume).

Never allow the spraying agent tank to overflow or

public bodies of water, rainwater drains or sewage

drains to become contaminated.

Immediately wipe up any spilled spraying agent.

Oil:petrol ratio = 1:50 (2 %)

Branded 2-stroke engine oil Petrol

20 ml 1 l

40 ml 2 l

100 ml 5 l

200 ml 10 l