Sonardyne DPT6 User manual

QUICK START GUIDE

DPT6 C6

BATTERY REPLACEMENT

/ /AMT6 TRANSPONDERS

To access more information

on the transponders battery

change, download a free

QR code app on your

Smartphone and then scan

this code.

QSG-BR-8300-00-A1

04/2013

910-0002

SAFETY

High pressure hazard risk when dismantling sub-sea equipment. Dismantling must only be

carried out by trained personnel.

Electric shock hazard risk when dismantling the equipment. Dismantling must only be carried

out by trained personnel.

Make sure the Pressure Relief Vent Valve is manually operated, in a well ventilated area, to

release any internal pressure before attempting to remove the end-cap.

Risk of burns. Do not change the battery pack if the housing is hot. Lower the transponder

overboard and wait for the housing to cool. Wear Personal Protective Equipment such as gloves.

Risk of impact injury. Do not stand in-line with the end-cap when removing from the

transponder.

Make sure the equipment is dry before dismantling.

Do not fit unauthorised battery pack types into an instrument.

For Lithium and Lithium Ion battery packs, Class D fire extinguishers should be used. Do not use

any other type of extinguisher.

The 8300 series of transponders weigh between 35 and 23 kg. Manual handling Equipment

(MHE) must be used to move the transponders. If MHE is not available, then a manual handling

assessment must be carried out prior to carrying out manual lifting / handling. Personal

Protective Equipment such as protective footwear and gloves must be worn before lifting the

equipment.

WARNINGS

STEP 1

It is recommended the operator complies with the Health and Safety Regulations applicable to the vessel and the

region before operating this equipment.

If the equipment is used in a manner not specified by the manufacturer, the protection provided by the

equipment may be impaired.

Documentation must be consulted whenever the warning symbol is found on the equipment, in order to find

out the nature of the potential hazard and any actions which must be taken.

The batteries used in the 8300 transponders can be lithium based. Due to the high risks associated with these

types of batteries, it is important that the safety instructions in this Quick Start Guide are read and fully

understood.

Only trained and qualified personnel must carry out the battery replacement procedure detailed in this Quick

Start Guide.

Do not expose batteries to extreme temperatures, in excess of 60°C, to prevent reduction in

battery life.

CAUTION

PRODUCT SUPPORT

Email: [email protected]

Tel: +44 (0) 1252 872288

Should you require NON-EMERGENCY product support for your transponder, email and telephone product

support is available during normal UK office hours (08:00-17:00). Alternatively, please contact your nearest

Sonardyne Office. Visit www.sonardyne.com for full details.

In emergency situations, the Sonardyne 24 hour helpline is answered during normal office hours - 08:00-17:00.

Outside these hours, your call is automatically transferred to an agency who will log the details of your

emergency and alert the appropriate Sonardyne personnel. Our aim is to ensure that emergency requests are

dealt with immediately during office hours and are responded to within 30 minutes at all other times.

SONARDYNE 24HR EMERGENCY HELPLINE: UK +44 (0) 1252 877600

STEP 2

PREPARING THE EQUIPMENT

1 Make sure the equipment has been rinsed in clean fresh water.

2 Remove any excess marine growth.

3 Dry the transponder with clean lint free cloth.

4 Inspect the transponder for any signs of damage, temperature.

5 If the transponder body is hot, lower into cold water to cool. When the body has

cooled, dry with clean lint free cloth.

6 Move the transponder to a clean dry environment.

7 Inspect the transponder around the Pressure Relief Vent Valve for deposits. This

would indicate the battery has vented due to water ingress or electronics/battery

malfunction. In these circumstances the battery pack and internal electronics may

have been severely damaged.

Risk of burns. Do not carry out any maintenance if the transponder housing is

hot. Lower the transponder overboard and wait for the housing to cool.

High pressure hazard risk when dismantling sub-sea equipment. Dismantling

must only be carried out by trained personnel.

Heavy Equipment. The type 8300 series of transponders weigh between 35 and

23 kg. Manual handling Equipment (MHE) must be used to move the

transponders. If MHE is not available, then a manual handling assessment must

be carried out prior to carrying out manual lifting / handling. Personal

Protective Equipment such as protective footwear and gloves must be worn

before lifting the equipment.

WARNINGS

This Quick Start Guide gives instructions on how to replace the battery in the 8300 series

transponders.

Before carrying out any activity on the equipment, make sure all Warnings and

Caution labels on the equipment and within this Quick Start Guide are read and

understood. Refer to the equipment manual for further information and assistance.

Before attempting to dismantle the transponder to replace the battery, the transponder

must be cleaned and thoroughly dried.

Use the following procedure to prepare the equipment.

STEP 3

DISMANTLING THE EQUIPMENT

High pressure hazard risk when dismantling the sub-sea equipment, refer to

the Safety Section. Must only be carried out by trained personnel.

Make sure the Pressure Relief Vent Valve is operated in a well vented area, to

remove any risk of internal pressure build up.

Heavy Equipment. The type 8300 series of transponders weigh between 35 and

23 kg. Manual handling Equipment (MHE) must be used to move the

transponders. If MHE is not available, then a manual handling assessment must

be carried out prior to carrying out manual lifting / handling. Personal

Protective Equipment such as protective footwear and gloves must be worn

before lifting the equipment.

WARNINGS

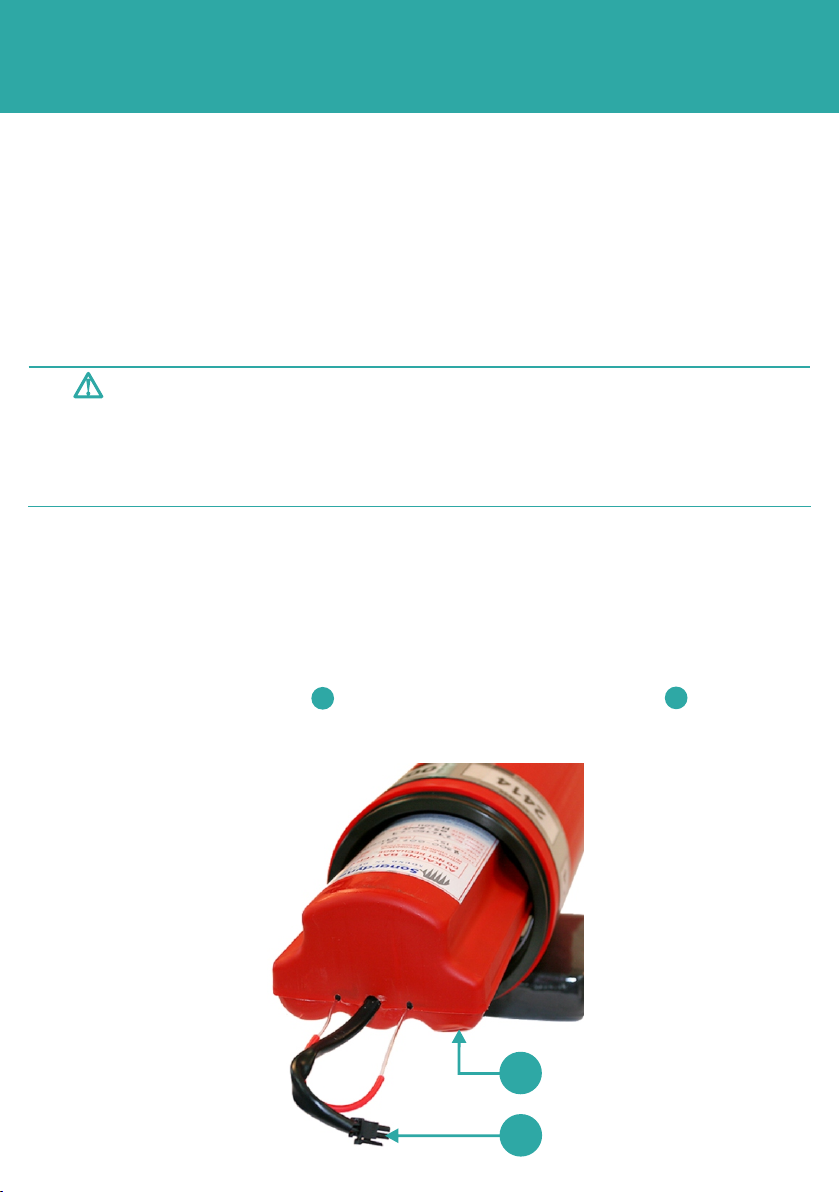

1 Clean the area around the Pressure Relief Vent Valve , make sure any marine

growth is removed.

2 Check the Pressure Relief Vent Valve is flush with the housing.

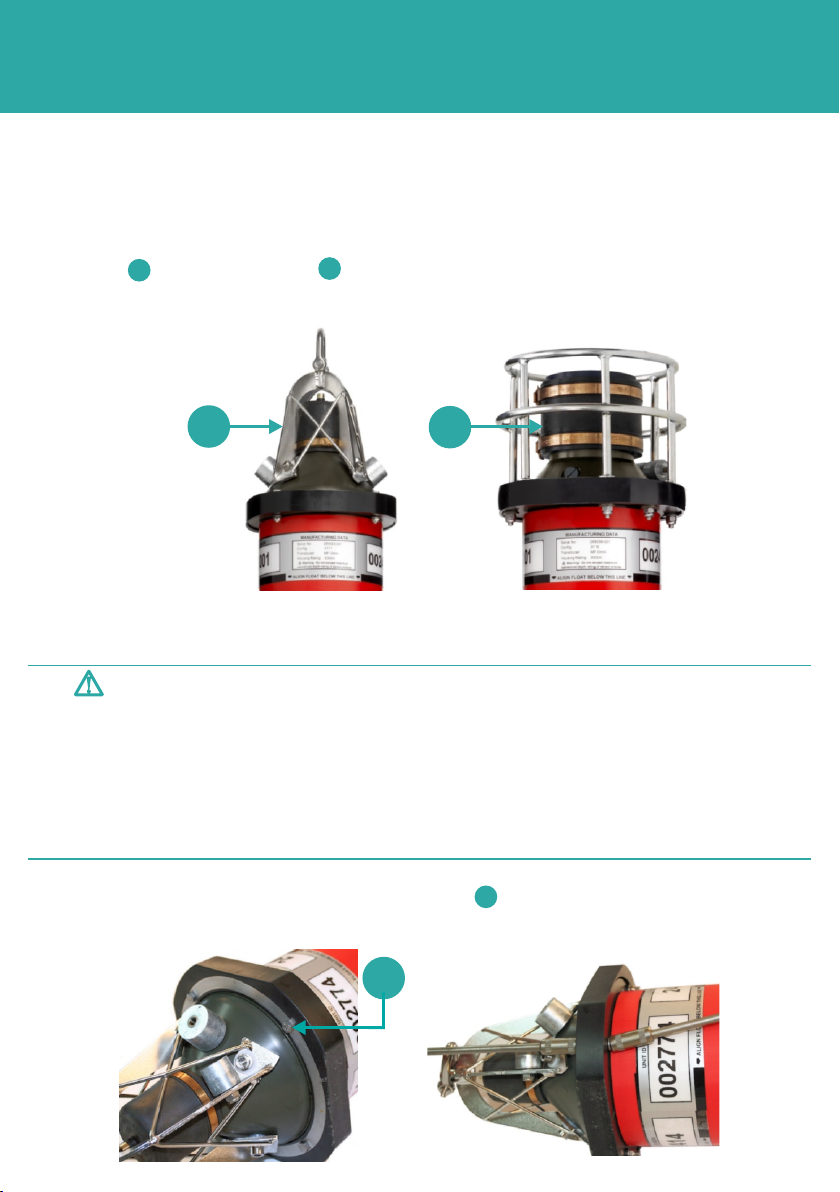

1

1

Use the following procedure to dismantle the equipment and remove the battery.

1

2

3

4

3 Screw an M4 screw ( not supplied) into the Pressure Relief Vent Valve plug.

4 Slowly pull out the Pressure Relief Vent Valve to release any internal pressure,

and reveal the two O-rings . A pair of long nose pliers can be used to assist.

5 Wait for any internal pressure to be fully vented from the housing.

6 Inspect the O-rings , for signs of damage. Apply a light coating of petroleum jelly

to lubricate the O-rings .

7 Release the Pressure Relief Vent Valve and allow it to reseat. Apply a little

pressure to make sure it is flush with the end-cap.

2

3

4

2

4

2

4

STEP 4

DISMANTLING THE EQUIPMENT

There are two types of transducer end-caps that can be fitted to the equipment: an omni-

directional , and a directional . For instructions on removing the directional end-cap

refer to Step 6.

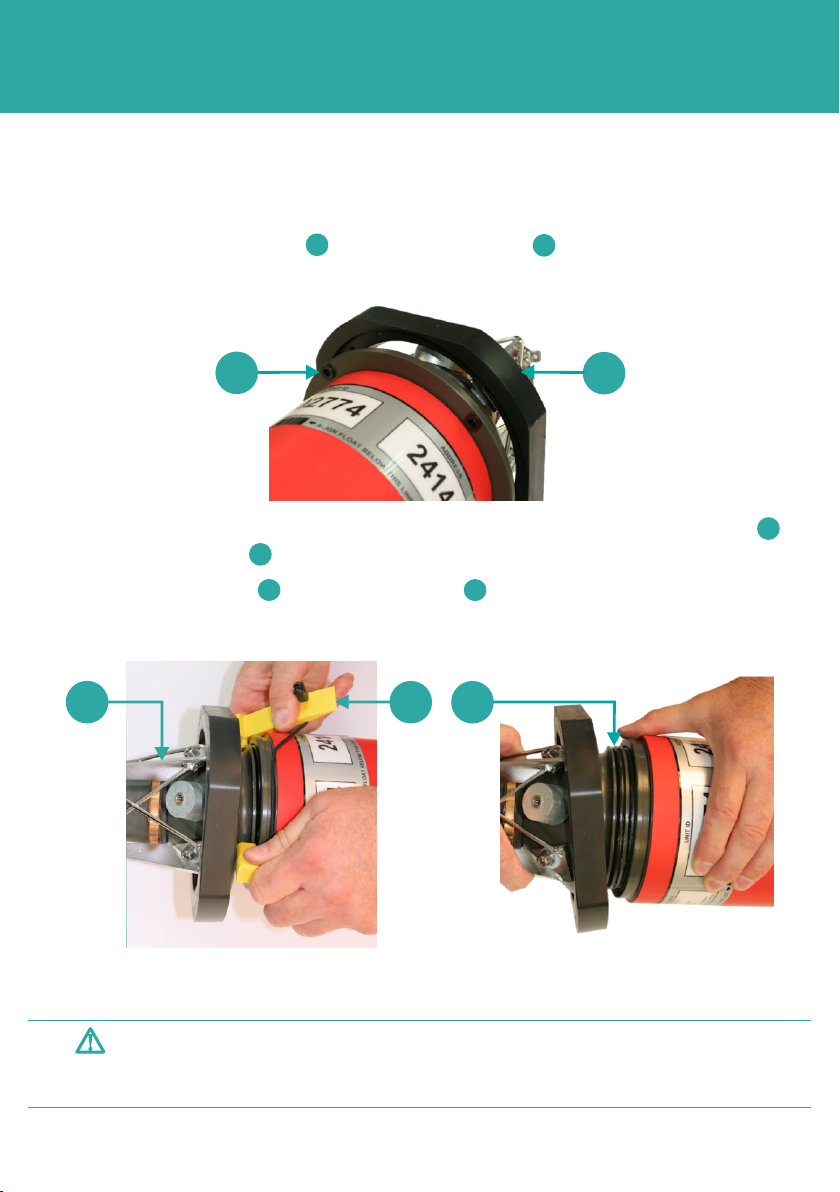

12

1

2

REMOVING THE TRANSCEIVER END-CAPS

REMOVING THE OMNI-DIRECTIONAL TRANSDUCER END-CAP

1 Undo and remove the nuts, washers and bolts securing the clamp rings.

1

1

Do not stand in directly in-line with the end-cap when removing it from the

transponder housing.

Do not remove the end-cap if there is a gap between the end-cap and the

housing body. Refer to the User Manual for instructions.

Do not continue to remove the end-cap if movement is felt during removal

of the clamp rings. Refer to the equipment User Manual for assistance.

WARNINGS

STEP 5

DISMANTLING THE EQUIPMENT

REMOVING THE OMNI-DIRECTIONAL END-CAP

2 Push the rubber bump stop free of the clamp rings and housing.

1

2

4

35

5 Use a lint free cloth to clean around the O-ring seals.

Remove the end-cap slowly to prevent the transducer cable becoming

detached.

CAUTION

6 Remove the end-cap completely.

2

1

3 Remove any dirt or water that may have accumulated between the rubber stop

and the clamp rings .

4 Use the opening tool to lever the end-cap from the housing until the O-ring

seals are exposed.

2

43

1

STEP 6

DISMANTLING THE EQUIPMENT

REMOVING A DIRECTIONAL END-CAP

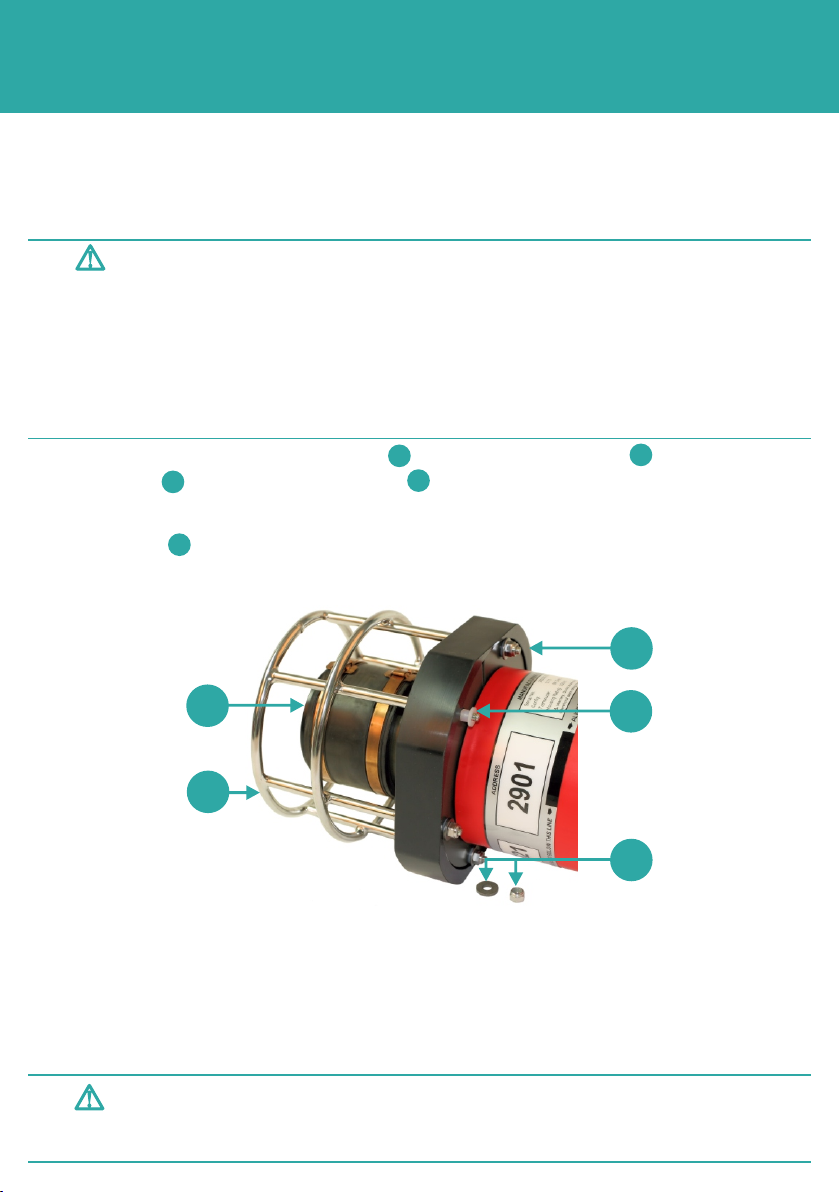

3 With the guard and bump stop removed, remove the clamp rings.

4 Remove any dirt, silt or water that may have accumulated around the end-cap.

5 Using the Opening Tools, lever the transducer end-cap from the housing until the

O-ring seals are exposed. Use a lint free cloth to clean around the O-ring seals.

1

2

3

4

5

1 Undo and remove the nuts, washers and white nylon spacers from the end of

the guard protecting the transducer .

2 Lift the end of the transducer housing sufficiently to allow the protective guard and

bump stop to be removed from the clamp rings.

12

3

4

5

Remove the transducer end-cap slowly to prevent the transducer cable

becoming detached.

CAUTION

Do not stand in directly in-line with the end-cap when removing it from the

transponder.

Do not remove the end-cap if there is a gap between the end-cap and the

housing body. Refer to the User Manual for instructions.

Do not continue to remove the end-cap if movement is felt during removal

of the clamp rings. Refer to the equipment User Manual for assistance.

WARNINGS

STEP 7

DISMANTLING THE EQUIPMENT

REMOVING THE BATTERY

Make sure the transducer is removed from the housing. Proceed with removing the battery

as follows:

Make sure the equipment is dry before dismantling.

Electric shock hazard risk when dismantling the equipment. Dismantling

must only be carried out by trained personnel.

For Lithium and Lithium Ion battery packs, Class D fire extinguishers should

be used. Do not use any other type of extinguishers.

WARNINGS

Do not expose batteries to extreme temperatures, in excess of 60°C, to prevent reduction in

battery life.

CAUTION

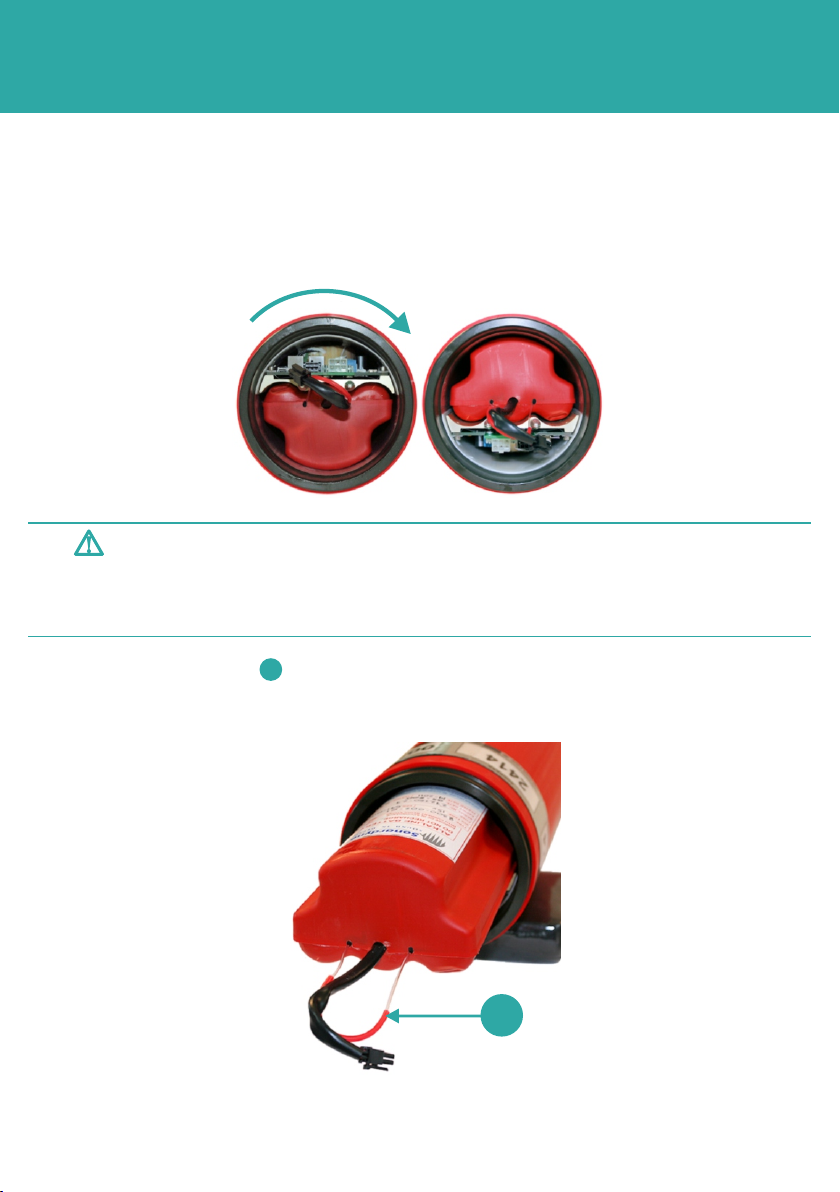

2

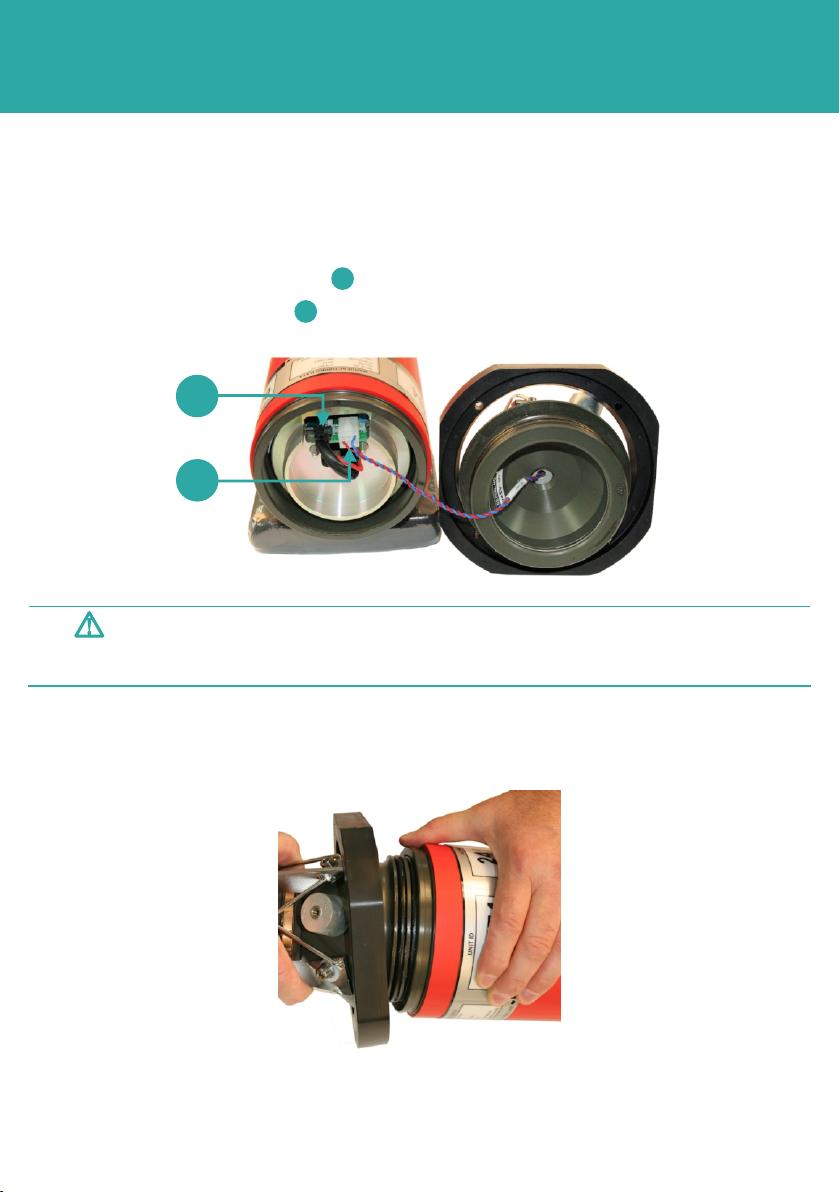

1 Disconnect the battery connector .

2 Disconnect the transducer connector .

1

1

2

3 Pull out the top bulk head .

3

3

STEP 8

DISMANTLING THE EQUIPMENT

6 The battery pack is now fully removed from the transponder.

7 Refer to Step 14 for instructions on disposal or transportation of the batteries.

Risk of burns. If the battery pack has been exposed to flooding, personal

protective equipment, such as gloves, must be worn to handle the battery

pack.

WARNING

4 Rotate the transponder so the battery is upper most in the housing.

5 Using the draw-string , slowly pull and support the battery pack out of the

transponder.

1

1

REMOVING THE BATTERY

STEP 9

CONNECTING THE EQUIPMENT

Electric shock hazard risk when assembling the equipment. Assembly must only

be carried out by trained personnel.

Make sure the equipment is dry before assembly.

Do not fit unauthorised battery pack types into an instrument.

WARNINGS

Before inserting a new battery pack into the transponder housing, inspect the housing for

any signs of damage or corrosion. Refer to the manual for assistance if necessary.

Make sure all Warnings and Cautions in the Safety section have been read and fully

understood.

1 Make sure the correct type of battery is available.

2 If installing a new battery remove any packaging.

3 Make sure the transponder is positioned so the battery pack would be located on

top of the circuitry.

4 Inspect the new battery for any signs of damage.

5 With the battery connector facing outwards, support the battery and slide it

into the transponder housing.

21

1

2

FITTING THE BATTERY

STEP 10

CONNECTING THE EQUIPMENT

7 Position the top bulk head over the two locating pins and firmly push into position.

8 Inspect the end-cap for any signs of damage or corrosion, pay particular attention to

the O-ring groove.

9 Inspect the O-ring seals for signs of damage. Replace if necessary.

10 Lubricate the O-ring seals with petroleum jelly.

1

2

6 Push the battery connector through the top bulk head .

12

FITTING THE BATTERY

STEP 11

CONNECTING THE EQUIPMENT

14 Coil the cable inside the bulk head and push the transducer into the housing. Make

sure the cable does not become trapped.

Observe the position of the transducer cable; be careful not to trap the cable

when inserting the transducer.

CAUTION

11 Position the end-cap next to the transponder housing.

12 Connect the transceiver cable .

13 Connect the battery pack .

2

1

FITTING THE BATTERY

1

2

15 If the transceiver end-cap is an omni-directional type proceed to fitment instructions.

If the transducer end-cap is a directional type, refer to Step 13 for installation

instructions.

STEP 12

CONNECTING THE EQUIPMENT

4 Secure the clamp rings to the bumper stop using the bolts, washers and nuts.

5 Tighten the nuts and bolts.

1 Push the omni-directional transceiver end-cap fully into the housing. Make sure the O-

ring seals do not become damaged.

2 Position the clamp rings in the grooves on the end cap.

3 Slide the rubber bumper stop over the end cap and align with the holes in the

clamp rings .

2

1

FITTING THE OMNI-DIRECTIONAL TRANSDUCER END-CAP

1

4

2

1

STEP 13

CONNECTING THE EQUIPMENT

FITTING THE DIRECTIONAL TRANSDUCER END-CAP

7 The transponder is now ready for operation.

45

6

7

1 Push the directional transducer end-cap fully into the housing. Make sure the O-ring

seals do not become damaged.

2 Position the clamp rings in the grooves on the end cap.

3 Position the guard with the bump stop over the transducer .

4 Rotate the clamp rings, if necessary, to align the holes with the screw ends of the

guard.

12

3

5 Lift the end of the transponder housing enough to locate the guard screws through

the holes in the clamp rings.

6 Secure the guard and bump stop in place with the six nylon spacers ,

washers and nuts .

456

7

1

2

3

DISPOSAL OR TRANSPORTATION

When disposing of all lithium based batteries please refer to the regulations of the local

area. Do not dispose of lithium or lithium ion batteries in a fire or incinerator.

STEP 14

Risk of explosion. Do not dispose of lithium or lithium Ion batteries in a fire.

WARNING

DISPOSAL OF LITHIUM BASED BATTERIES

TRANSPORTATION OF LITHIUM BASED BATTERIES

When transporting lithium based batteries manufacturer’s material safety datasheet must

be read to confirm the amount of lithium per battery pack. These quantities cannot be

verified by Sonardyne International Ltd.

It is the operator’s responsibility to obey local, national and international regulations in

force at the time of transport.

By Road: ADR European Agreement concerning the International Carriage of Dangerous

Goods by Road Regulations.

By Sea: International Maritime Dangerous Goods Code.

By Air: IATA Regulations UN 3090 and UN 3091

Global Headquarters, UK

T. +44 (0) 1252 872288

F. +44 (0) 1252 876100

Houston, USA

T. +1 281 890 2120

F. +1 281 890 7047

24/7 Emergency Hotline

+44 (0) 1252 877600

Email Support

Website

www.sonardyne.com

Twitter

@sonardyne

Aberdeen, UK

T. +44 (0) 1224 707875

F. +44 (0) 1224 707876

Singapore, Asia

T. +65 6542 1911

F. +65 6542 6937

QSG-BR-8300-00-A1

04/2013

910-0002

ACOUSTIC POSITIONING INERTIAL NAVIGATION

llWIRELESS COMMUNICATION lSONAR IMAGING

Rio das Ostras, Brazil

T. +55 22 2123 4950

F. +55 22 2123 4951

Other manuals for DPT6

1

This manual suits for next models

2

Table of contents

Other Sonardyne Marine Equipment manuals