1 (E)

DXF-20W

Table of Contents

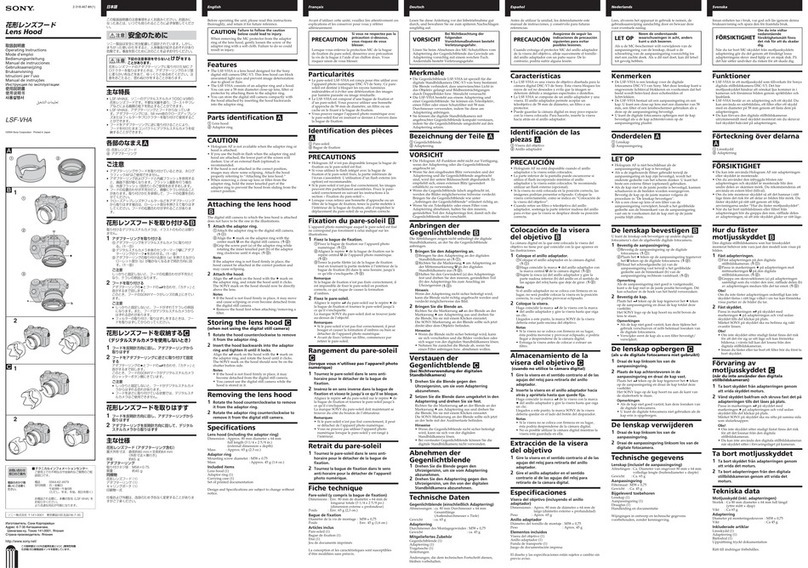

3. Spare Parts

3-1. Exploded Views .............................................................. 3-1

3-2. Electrical Parts List ......................................................... 3-3

3-3. Supplied Accessories ...................................................... 3-3

3-4. Optional Fixtures ............................................................ 3-3

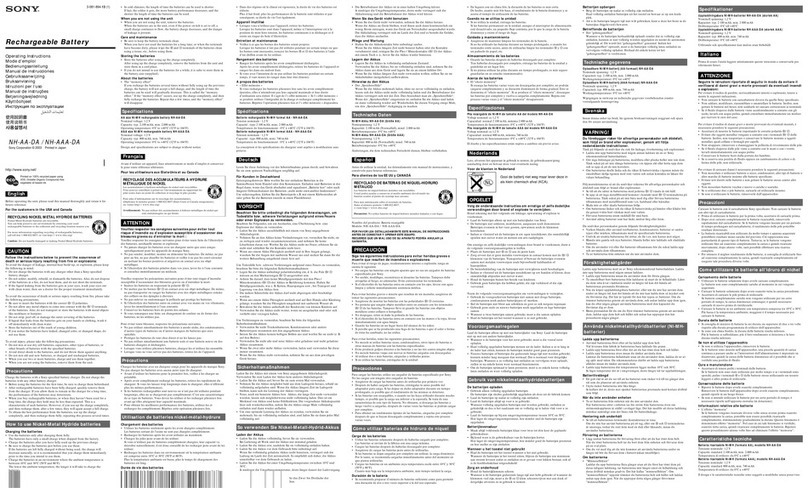

4. Block Diagram

Overall ............................................................................ 4-1

5. Schematic Diagrams

DF-70 .............................................................................. 5-1

VA-229 ........................................................................... 5-2

LE-326 ............................................................................ 5-3

VF-88 .............................................................................. 5-3

6. Board Layouts

DF-70 .............................................................................. 6-1

VA-229 ........................................................................... 6-1

VF-88 .............................................................................. 6-2

Manual Structure

Purpose of this manual ........................................................... 2 (E)

Relative manual ...................................................................... 2 (E)

1. Service Overview

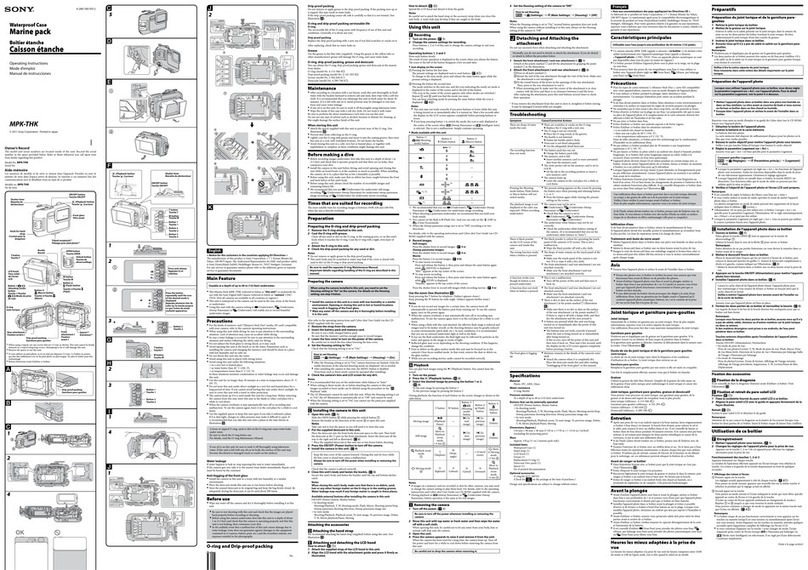

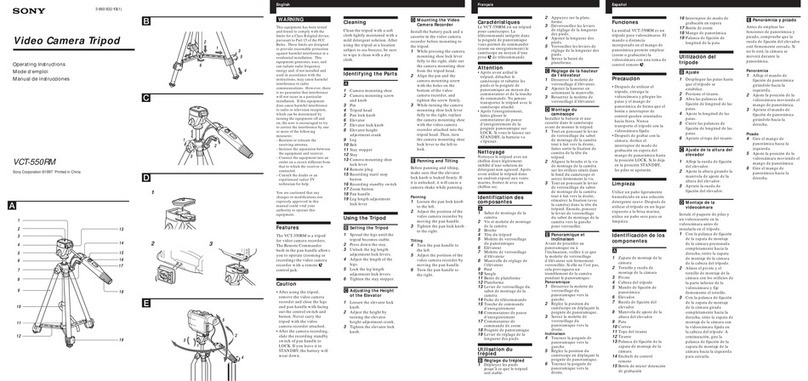

1-1. Location of Printed Circuit Boards .......................... 1-1 (E)

1-2. Recommended Replacement Parts .......................... 1-1 (E)

1-3. Connector Input/Output Signals .............................. 1-1 (E)

1-4. Cleaning ................................................................... 1-2 (E)

1-4-1. Cleaning of Viewfinder .................................. 1-2 (E)

1-4-2. Cares after Using under Special

Environment ................................................... 1-2 (E)

1-5. Replacing CRT/DY Assembly ................................ 1-3 (E)

1-6. Arranging Harness ................................................... 1-4 (E)

1-7. Disconnecting/Connecting Flexible Card Wire ....... 1-5 (E)

1-8. Notes on Spare Parts ................................................ 1-6 (E)

1-9. Unleaded Solder ....................................................... 1-6 (E)

2. Alignment

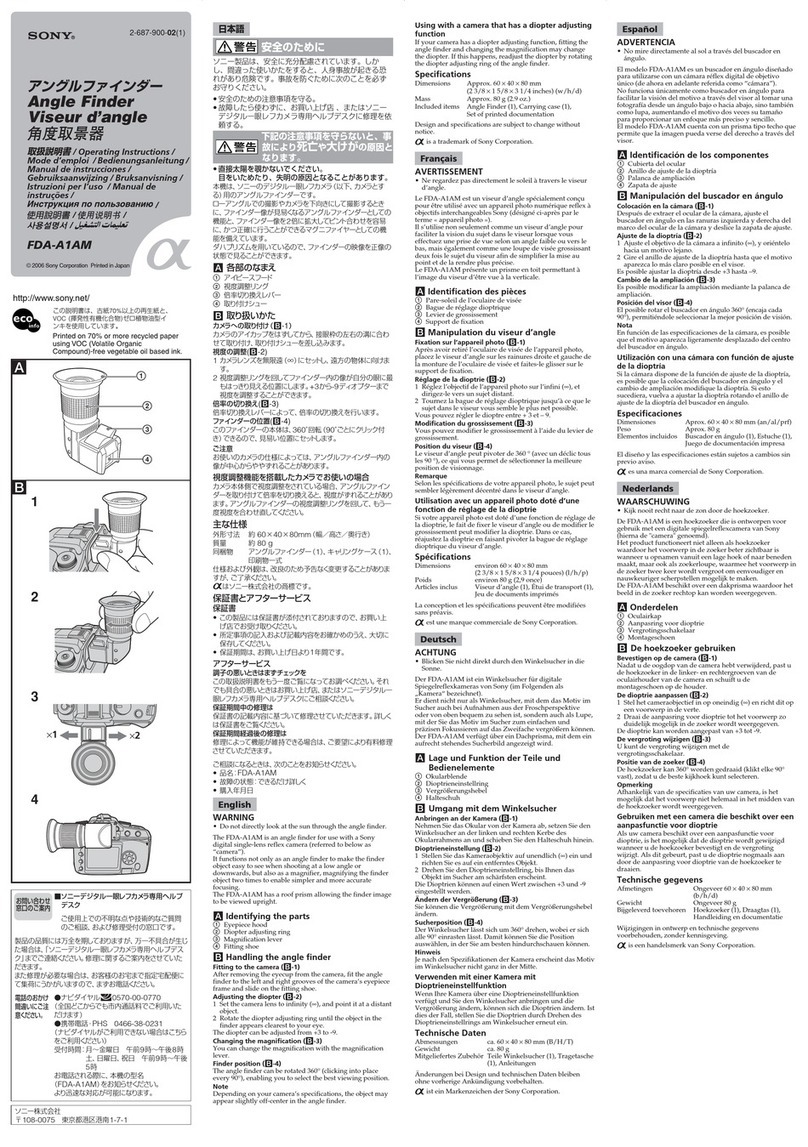

2-1. Preparation ............................................................... 2-1 (E)

2-1-1. Connecting Diagram ...................................... 2-1 (E)

2-1-2. Required Equipment ....................................... 2-1 (E)

2-1-3. Notes on Adjustment ...................................... 2-1 (E)

2-1-4. Initial Setting .................................................. 2-1 (E)

2-2. Viewfinder System Adjustment ............................... 2-2 (E)

2-2-1. Heater Voltage Pre-Adjustment ..................... 2-2 (E)

2-2-2. Focus Adjustment ........................................... 2-2 (E)

2-2-3. Horizontal Frame Adjustment ........................ 2-3 (E)

2-2-4. Heater Voltage Adjustment ............................ 2-4 (E)

2-2-5. Bright Calibration Adjustment ....................... 2-4 (E)

2-2-6. Horizontal Shift Adjustment (For NTSC) ...... 2-5 (E)

2-2-6. Horizontal Shift Adjustment (For PAL) ......... 2-6 (E)

2-2-7. Vertical Frame Adjustment (For NTSC) ........ 2-7 (E)

2-2-7. Vertical Frame Adjustment (For PAL) .......... 2-8 (E)

2-2-8. Screen Centering Check ................................. 2-9 (E)

2-2-9. Vertical Linearity Adjustment ........................ 2-9 (E)