— 2 —

Parts No.

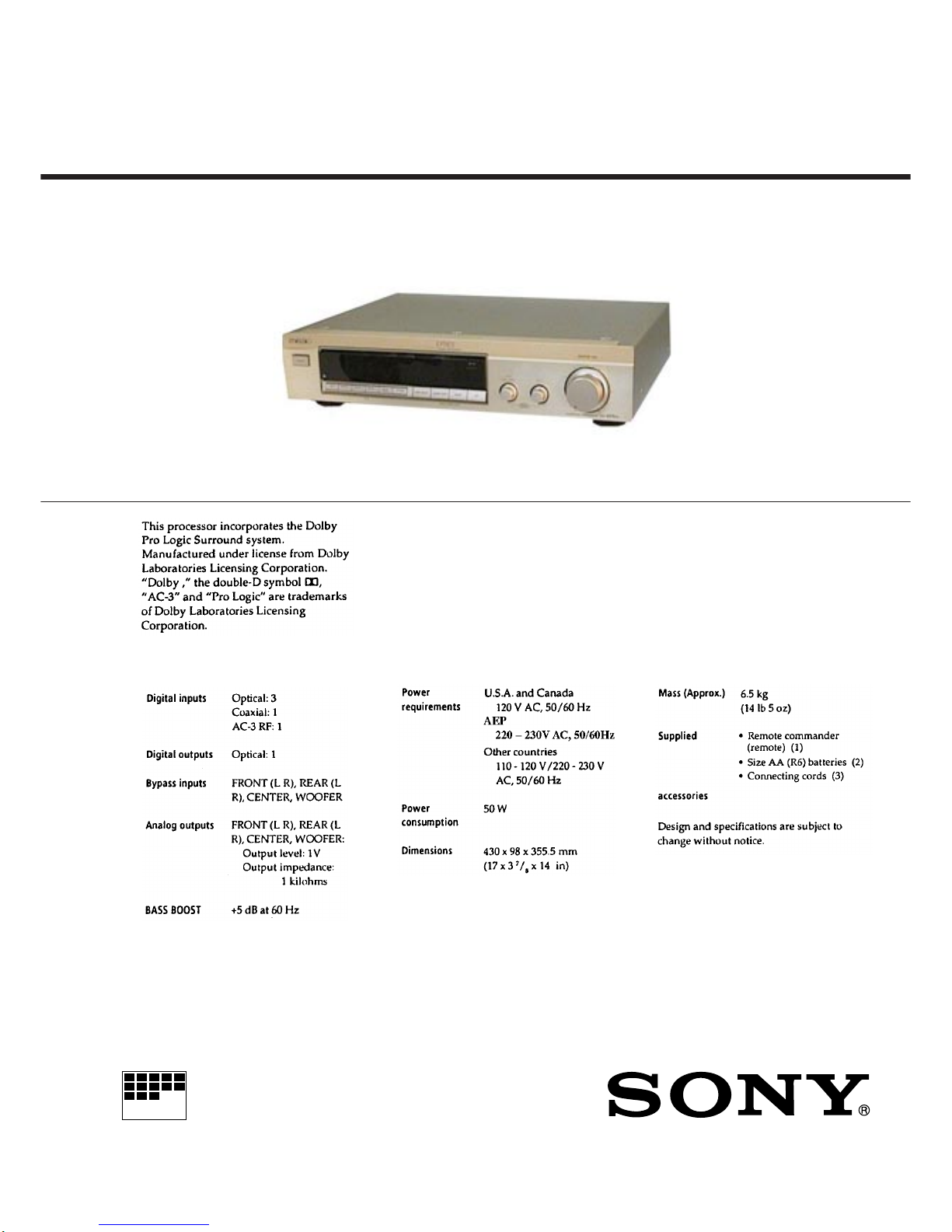

MODEL IDENTIFICATION

— BACK PANEL —

US model

CND model

AEP model

E, MY, SP, CH model

4-987-861-1

4-987-861-2

4-987-861-3

4-987-861-4

MODEL PARTS No.

ATTENTION AU COMPOSANT AYANT RAPPORT

À LA SÉCURITÉ!!

LESCOMPOSANTSIDENTIFIÉSPAR UNE MARQUE!SUR

LES DIAGRAMMES SCHÉMATIQUES ET LA LISTE DES

PIÈCES SONT CRITIQUES POUR LA SÉCURITÉ DE

FONCTIONNEMENT. NE REMPLACER CES COMPOSANTS

QUE PAR DES PIÈCES SONY DONT LES NUMÉROS

SONT DONNÉS DANS CE MANUEL OU DANS LES

SUPPLÉMENTS PUBLIÉS PAR SONY.

SAFETY-RELATED COMPONENT WARNING !!

COMPONENTS IDENTIFIED BY MARK !OR DOTTED LINE

WITH MARK !ON THE SCHEMATIC DIAGRAMS AND IN

THE PARTS LIST ARE CRITICAL TO SAFE OPERATION.

REPLACE THESE COMPONENTS WITH SONY PARTS

WHOSE PART NUMBERS APPEAR AS SHOWN IN THIS

MANUAL OR IN SUPPLEMENTS PUBLISHED BY SONY.

TABLE OF CONTENTS

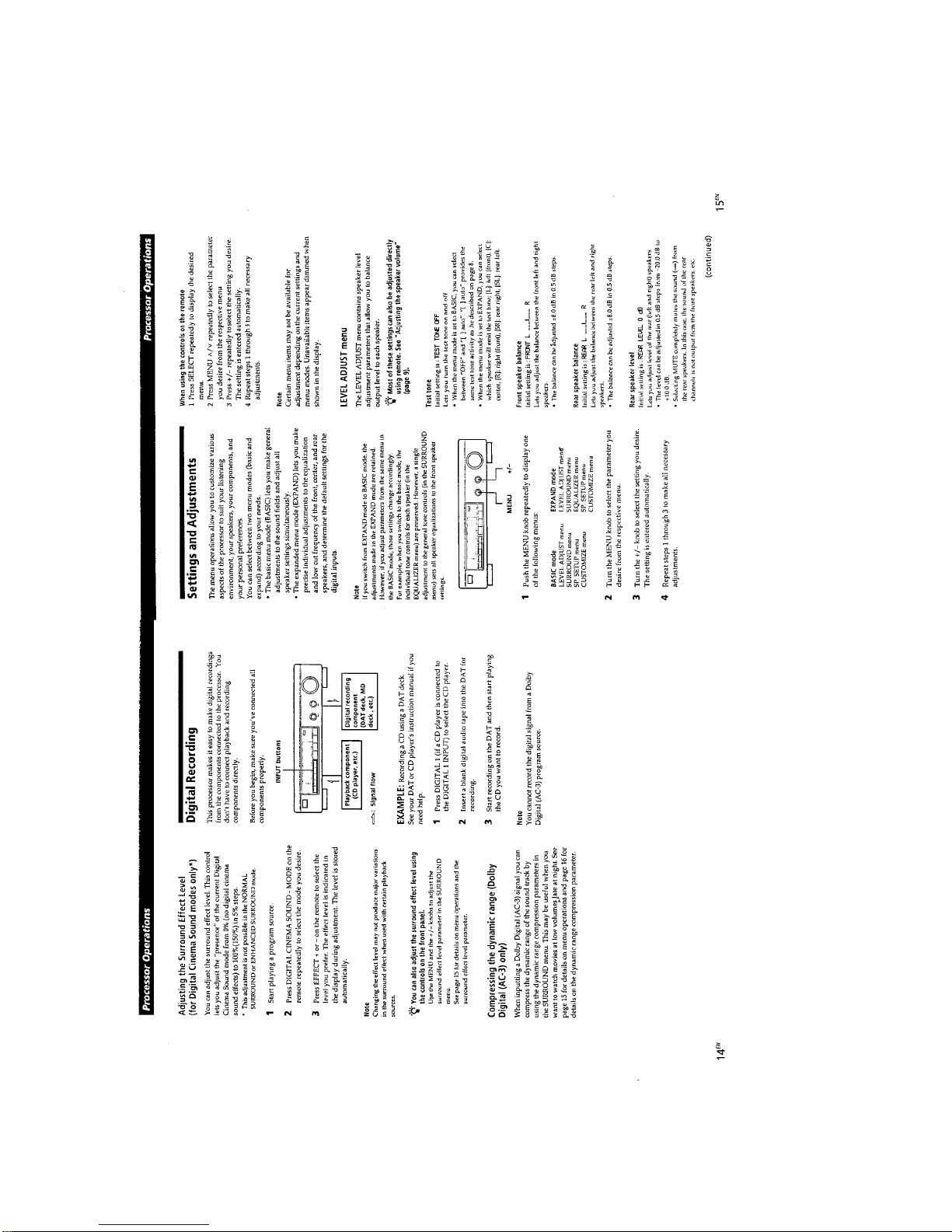

1. SERVICING NOTE ........................................................... 3

2. GENERAL ............................................................................ 4

3.TEST MODE ...................................................................... 12

4. ELECTRICAL ADJUSTMENTS ................................ 15

5. DIAGRAMS

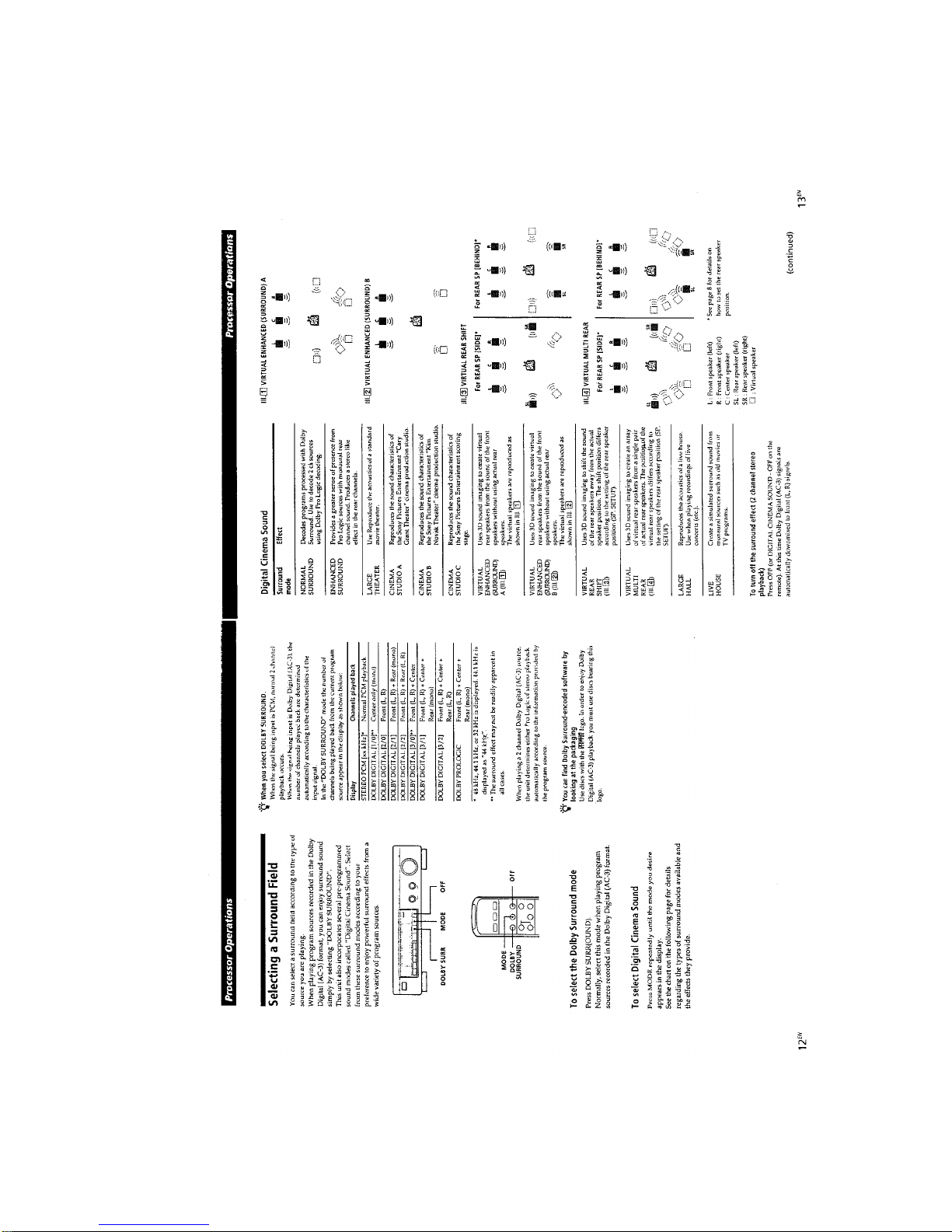

5-1. Circuit Boards Location .................................................... 16

5-2. Block Diagrams

• D/A Section .................................................................... 17

• AC-3 (RF) Section ......................................................... 19

• Control Section............................................................... 21

• Power Section................................................................. 23

5-3. Printed Wiring Board — Main Section — ........................ 25

5-4. Schematic Diagram — Control Section — ....................... 29

5-5. Schematic Diagram — Dolby AC-3 Section —................ 32

5-6. Schematic Diagram — D/A Section —............................. 35

5-7. Printed Wiring Board — Display Section — .................... 39

5-8. Schematic Diagram — Display Section — ....................... 43

5-9. Printed Wiring Board — Power Section — ...................... 46

5-10. Schematic Diagram — Power Section — ......................... 49

5-11. IC Pin Functions

• IC201 System Controller (HD6433397A13F) ............... 51

• IC301 Digital Audio Interface Receiver (LC8905V)..... 53

• IC401, 402, 403 Sampling Rate Converter

(CXD8517Q) .................................................................. 54

• IC423 Digital Signal Processor (SSP424923)................ 55

• IC424 Digital Signal Processor (DSP56009) ................. 57

• IC901 Digital Signal Processor (AC-3 RF Demodulator)

(PD4606A) ..................................................................... 59

5-12. IC Block Diagrams ............................................................ 62

6. EXPLODED VIEWS

6-1. Front Panel Section............................................................ 67

6-2. Chassis Section .................................................................. 68

7. ELECTRICAL PARTS LIST ......................................... 69

• Abbreviation

CND : Canadian model.

MY : Malaysia model.

SP : Singapore model.

CH : Chinese model.

Notes on chip component replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be

damaged by heat.