55

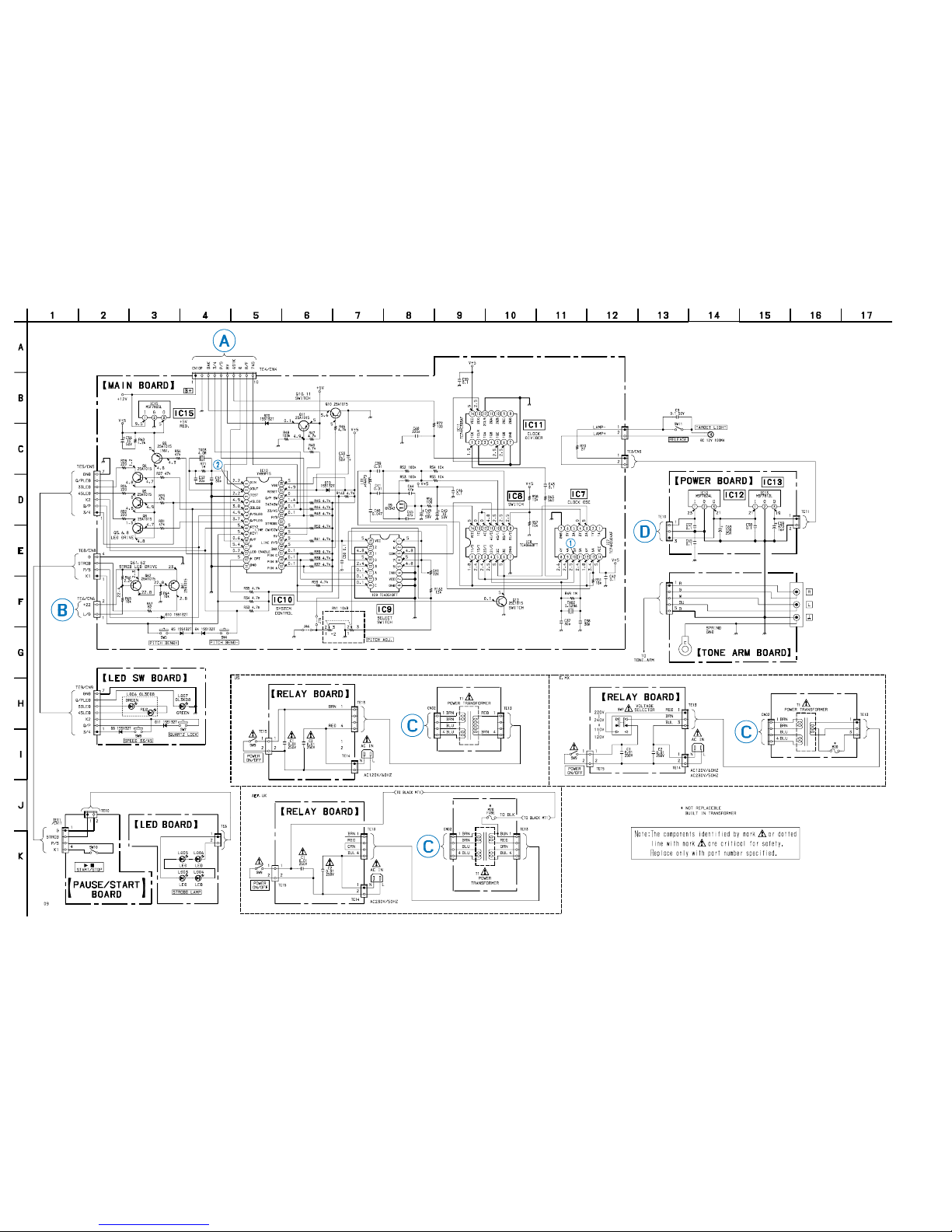

SECTION 2

DIAGRAMS

Note on PrintedWiring Board:

•X: parts extracted from the component side.

•Y: parts extracted from the conductor side.

•b: Pattern from the side which enables seeing.

Note on Schematic Diagram:

• All capacitors are in µF unless otherwise noted. pF: µµF

50 WV or less are not indicated except for electrolytics

and tantalums.

• All resistors are in Ωand 1/4W or less unless otherwise

specified.

•C: panel designation.

•U: B+ Line.

•V: B– Line.

• Voltages are dc with respect to ground under no-signal

conditions.

no mark : Power on

• Voltages are taken withaVOM (Input impedance 10MΩ).

Voltage variations may be noted due to normal produc-

tion tolerances.

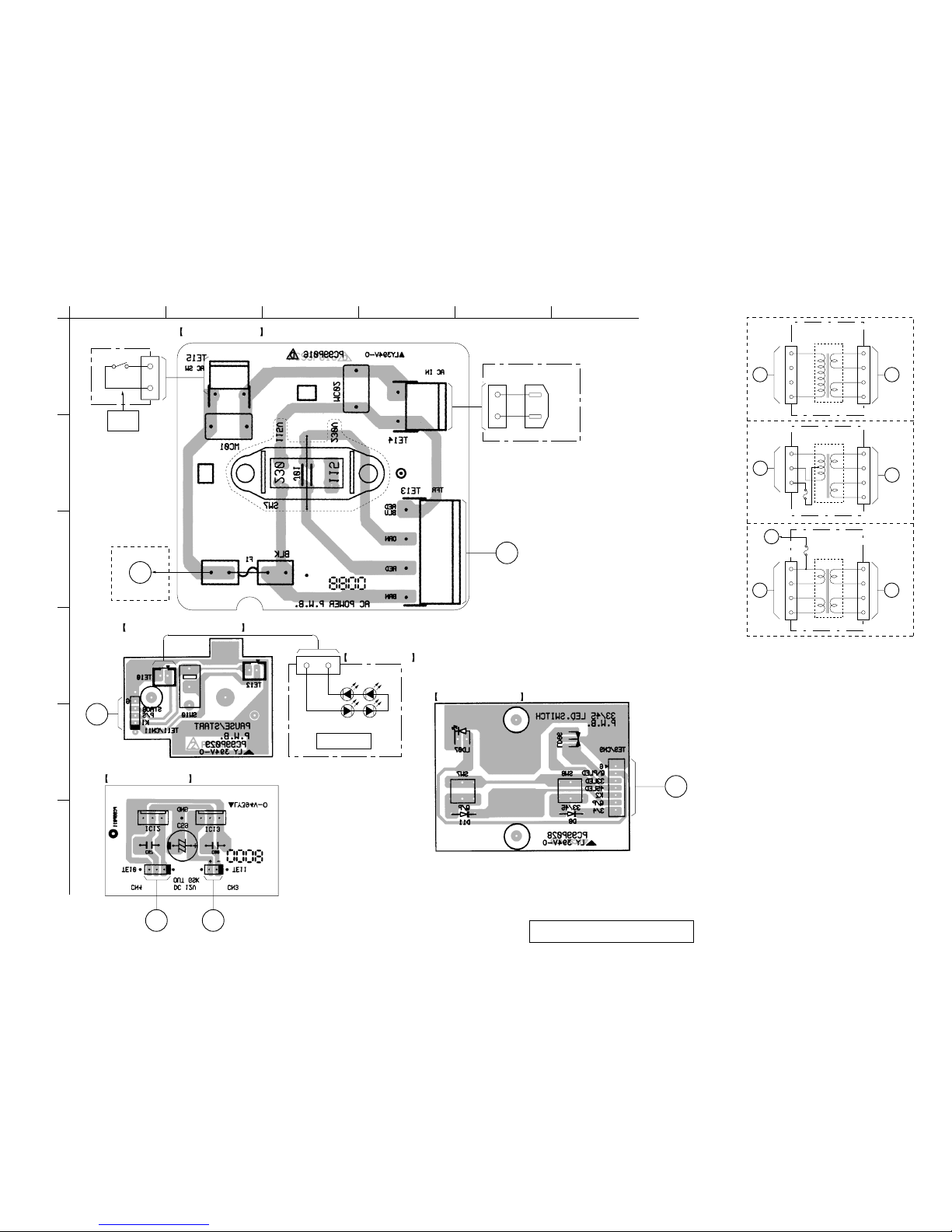

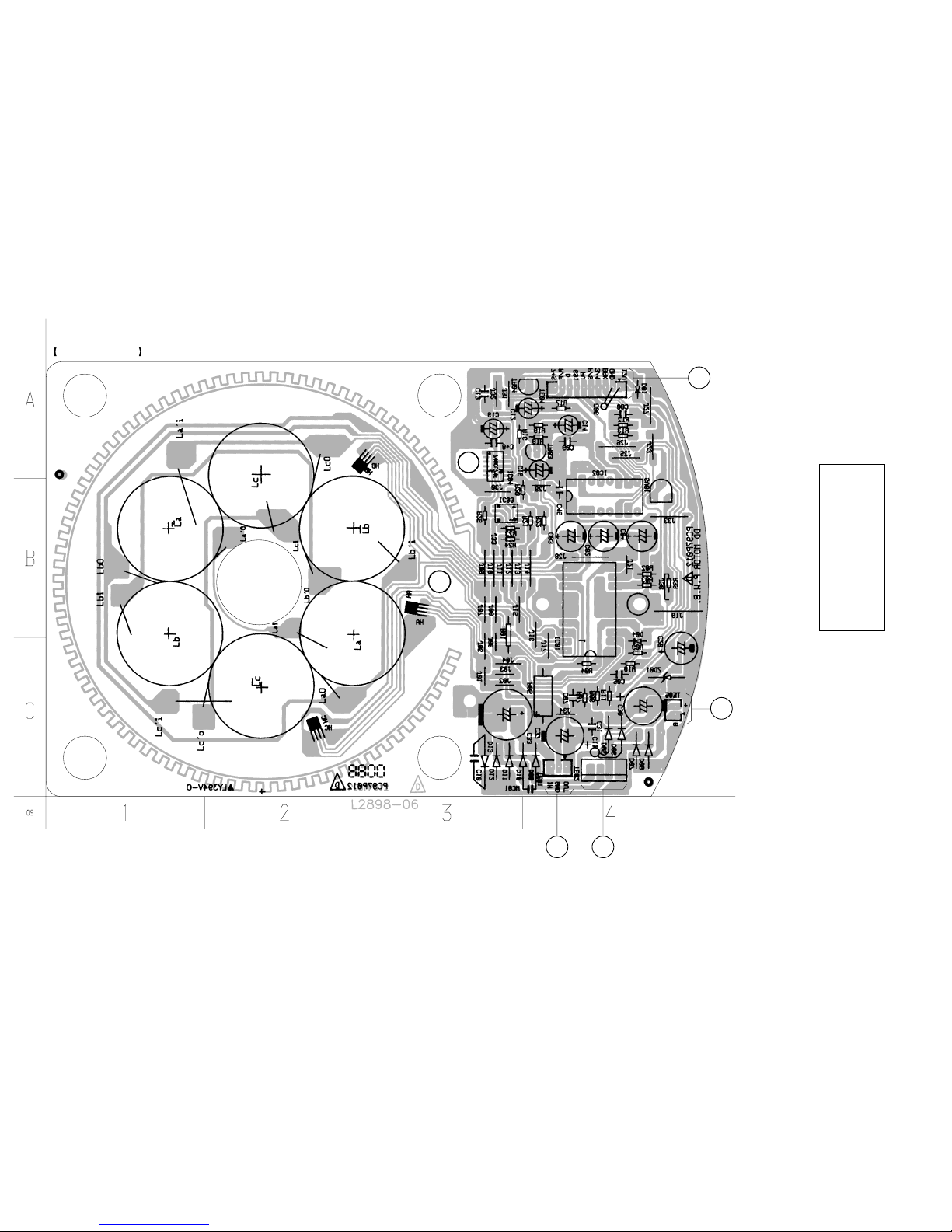

2-1. Circuit Boards Location

Note: The components identified by mark 0or dotted line

with mark 0are critical for safety.

Replace only with part number specified.

NOTE FOR PRINTED WIRING BOARD AND SCHEMATIC DIAGRAM

7

OperationsOperations

5

Remove the protective cover from the cartridge

and release the arm stopper.

6

Set the cueing lever in the up position.

Move the tonearm to the desired point on the

record.

7

Set the cueing lever to the down position.

The tonearm will descend slowly to the record and

play will begin.

8

If you want to change the pitch, press the

QUARTZ lock button (the QUARTZ indicator will

turn off). Then adjust the pitch by moving the

PITCH ADJ. knob.

The distance from the center position to the

farthest point on the scale represents a change of

10% in the pitch. You can also use the

PITCH BEND + and – buttons to change the pitch

(see “Using the PITCH BEND + and – buttons” on

page 8).

9

If you wish, you can return to normal speed

(33 1/3 or 45 rpm) while the PITCH ADJ. knob is

off center by pressing the QUARTZ lock button

(the QUARTZ indicator will turn on).

Press the QUARTZ lock button again to go back to

the previous pitch setting (the QUARTZ indicator

will turn off).

Note

The PITCH ADJ. knob does not function while the

QUARTZ lock is on (i.e., while the QUARTZ indicator is

on).

10

To adjust the volume, use the respective channel

fader on the mixer, or the volume control on the

stereo component system or amplifier.

To stop play

1Set the cueing lever in the up position and return

the tonearm to the arm stand.

Attach the protective cover onto the cartridge to

prevent damage to the stylus.

2Press Bx START/STOP.

The platter stops rotating.

Secure the tonearm with the arm stopper.

3Turn POWER to OFF.

To pause play

Press Bx START/STOP or set the cueing lever in the

up position to raise the stylus.

Playing a Record

5

8

6

3,8,9

5

8,9

6,7

1

4

2

3

Before playing a record, be sure the PHONO/LINE

switch on the mixer is set to PHONO.

1

Place a record on the platter.

Note

Place only one record on the platter at a time. If two or

more records are stacked on the platter, the stylus will

not make proper contact with the grooves and the

quality of reproduction will be impaired.

2

Turn the POWER switch to ON.

The strobo lamp, the QUARTZ lock indicator, and

SPEED indicator light up.

Turn the POWER switch on the mixer and

amplifier to ON also.

3

Set PITCH ADJ. knob to the center position.

When the turntable is turned on, the platter speed

is automatically set to 33 rpm. Verify that the

green indicator lights up.

4

Press Bx START/STOP.

The platter starts rotating.

If you select 33 rpm when the turntable is

connected to a 50 Hz power source, the uppermost

row of the strobe dots should appear to stand still.

33

45

45

33

50 Hz

60 Hz

(Continued)

8

Operations

To play an another part of the record

1Set the cueing lever to the up position to raise the

stylus.

2Move the tonearm to the desired position.

3Set the cueing lever to the down position.

To play a 45 single

Place the supplied 45 adaptor onto the spindle.

Press SPEED to select 45 rpm.

The green indicator changes to red.

After you have finished using the adaptor, return it to

the adaptor tray.

Using the PITCH BEND + and – buttons

You can use the PITCH BEND + and –buttons to

synchronize the beat of the selection playing on one

turntable with the beat of another selection playing on

the other turntable. You can use these buttons even if

the QUARTZ lock button is turned on or off.

1Use the PITCH ADJ. knob to synchronize the

speed of the selection playing on one of the

turntables with the speed of the selection on the

other turntable.

2Press the PITCH BEND + and –buttons to

synchronize the beat of both selections. Pressing

and holding down the + or –button causes the

selection to play 10% faster or slower than the

normal playing speed.

z

If the strobe dots are not stationary when the PITCH

ADJ. knob is set to the center position

Adjust the platter speed by sliding the PITCH ADJ.

knob toward + or –until the strobe dots become

stationary.

z

If you have an extra headshell, keep it in the

headshell holder.

POWER board

TONE ARM boar