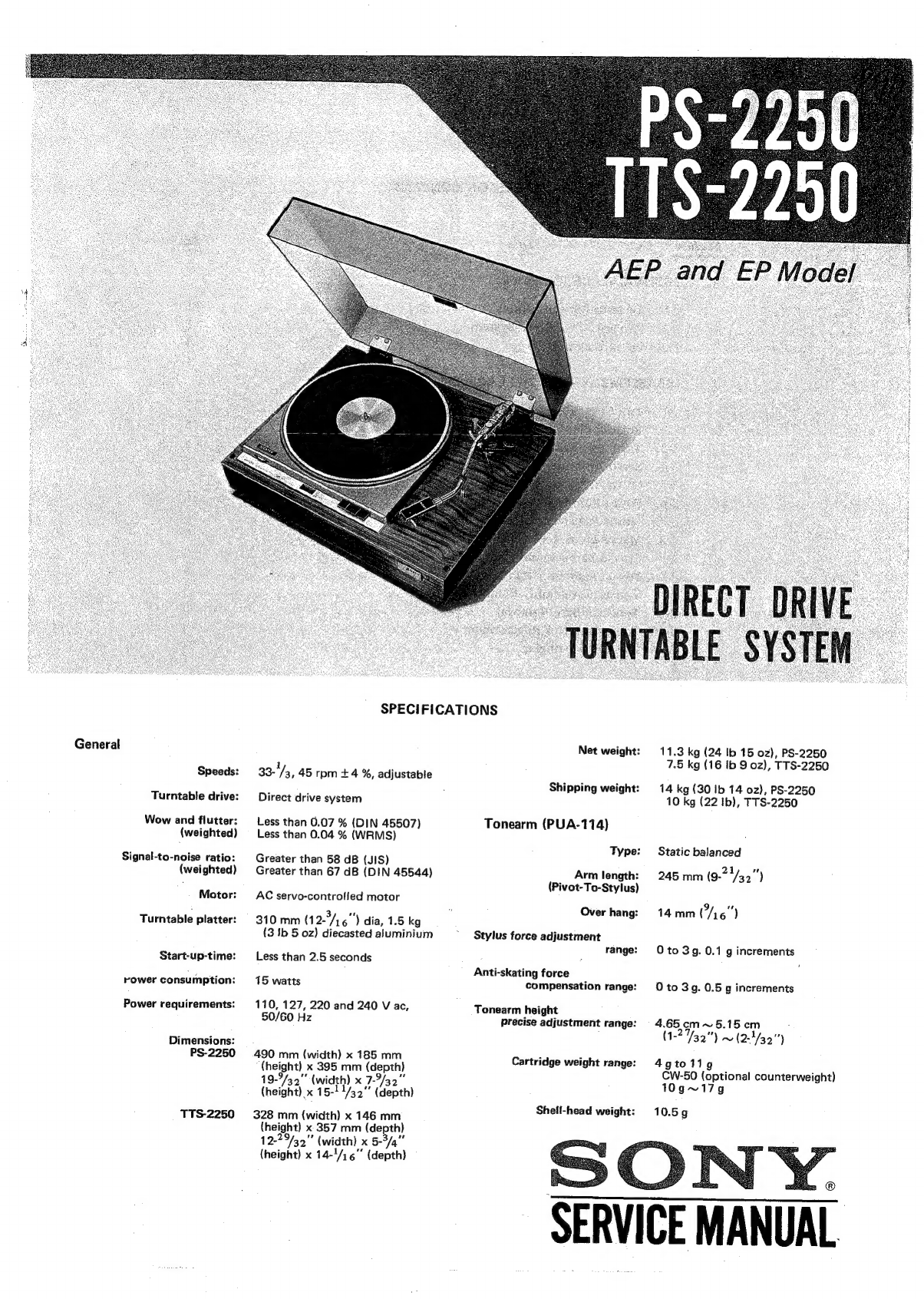

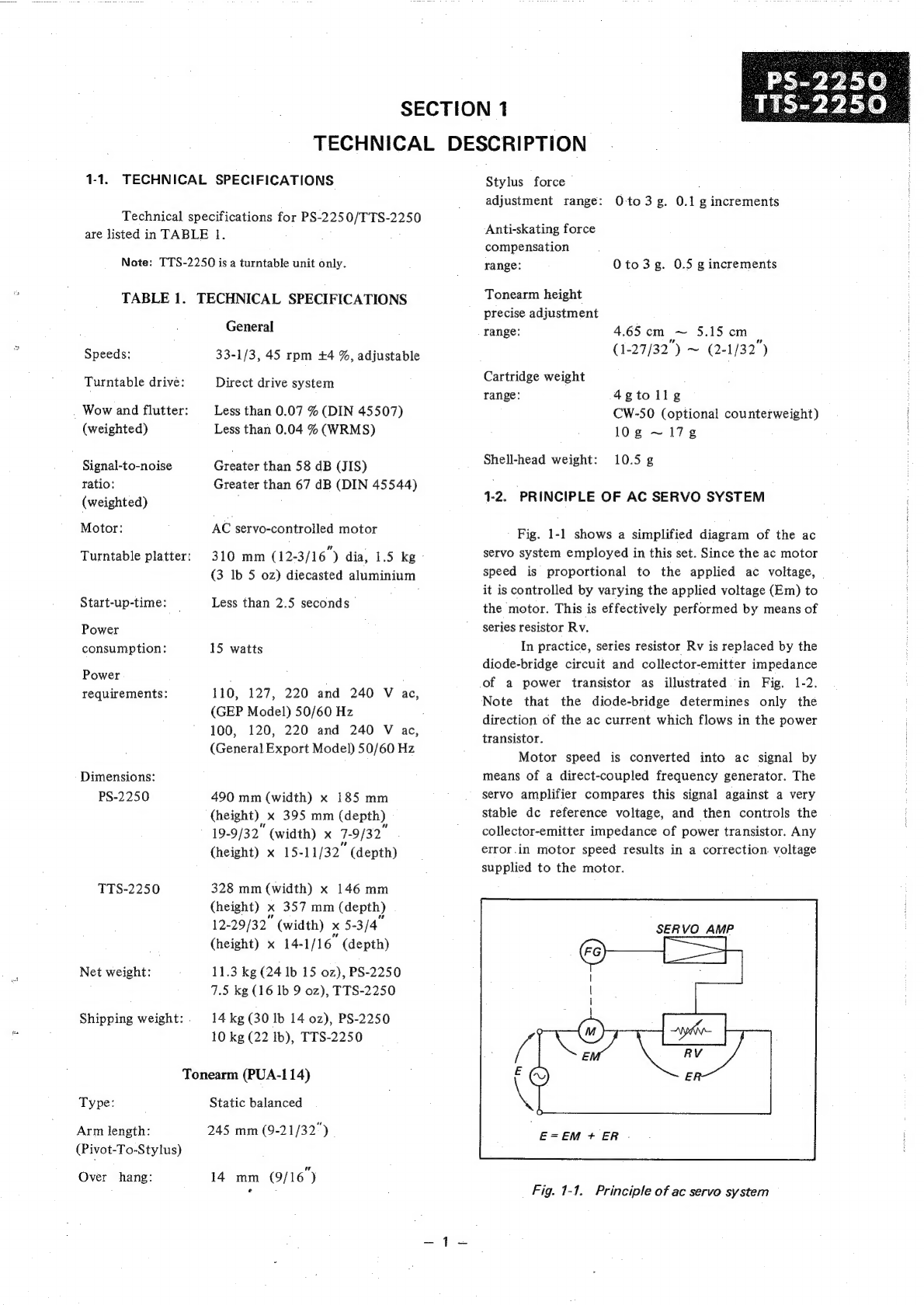

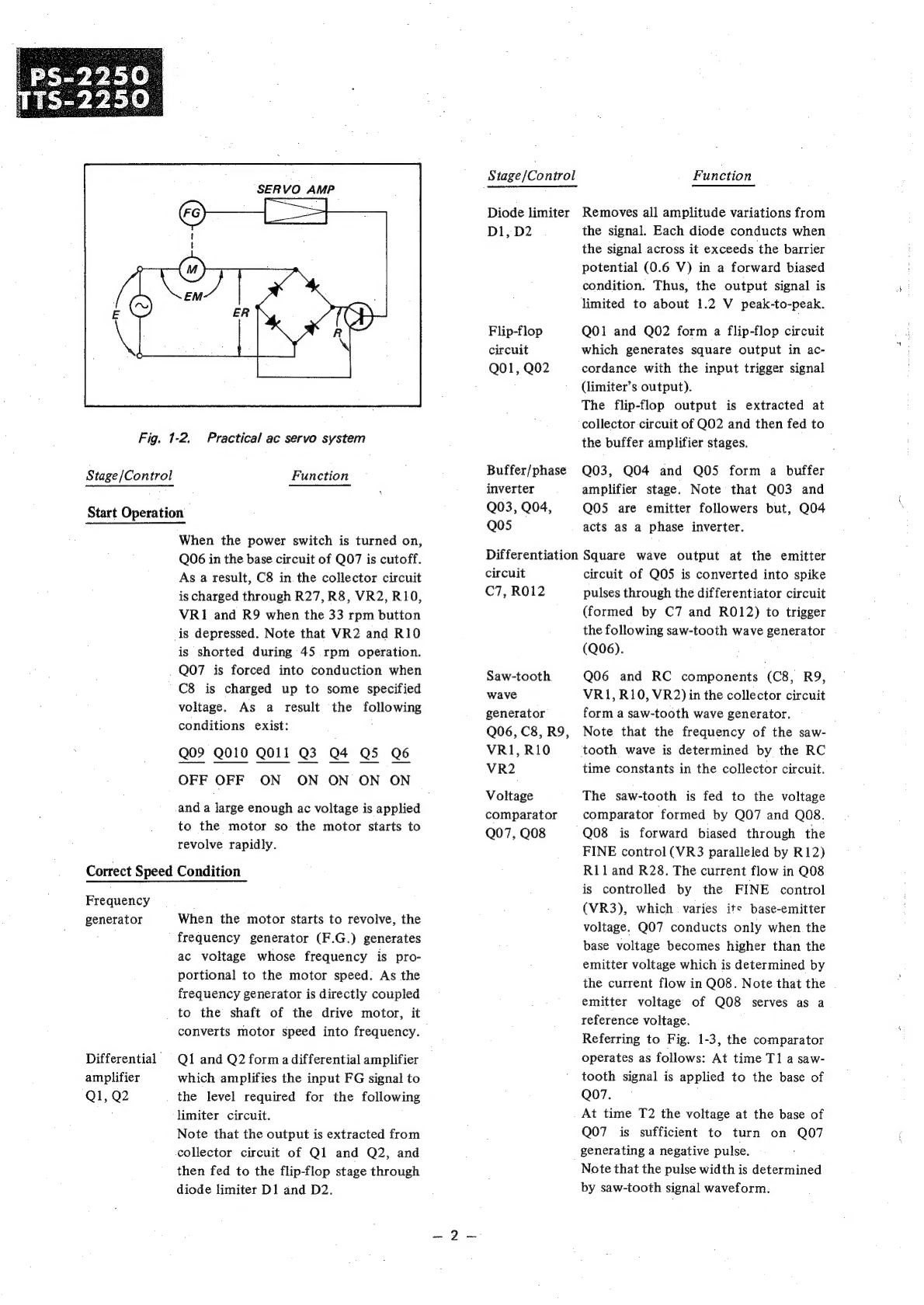

Sony PS-2250 User manual

Other Sony Turntable manuals

Sony

Sony XD-AX10 User manual

Sony

Sony PS-J11 Primary User manual

Sony

Sony PS-LX2C User manual

Sony

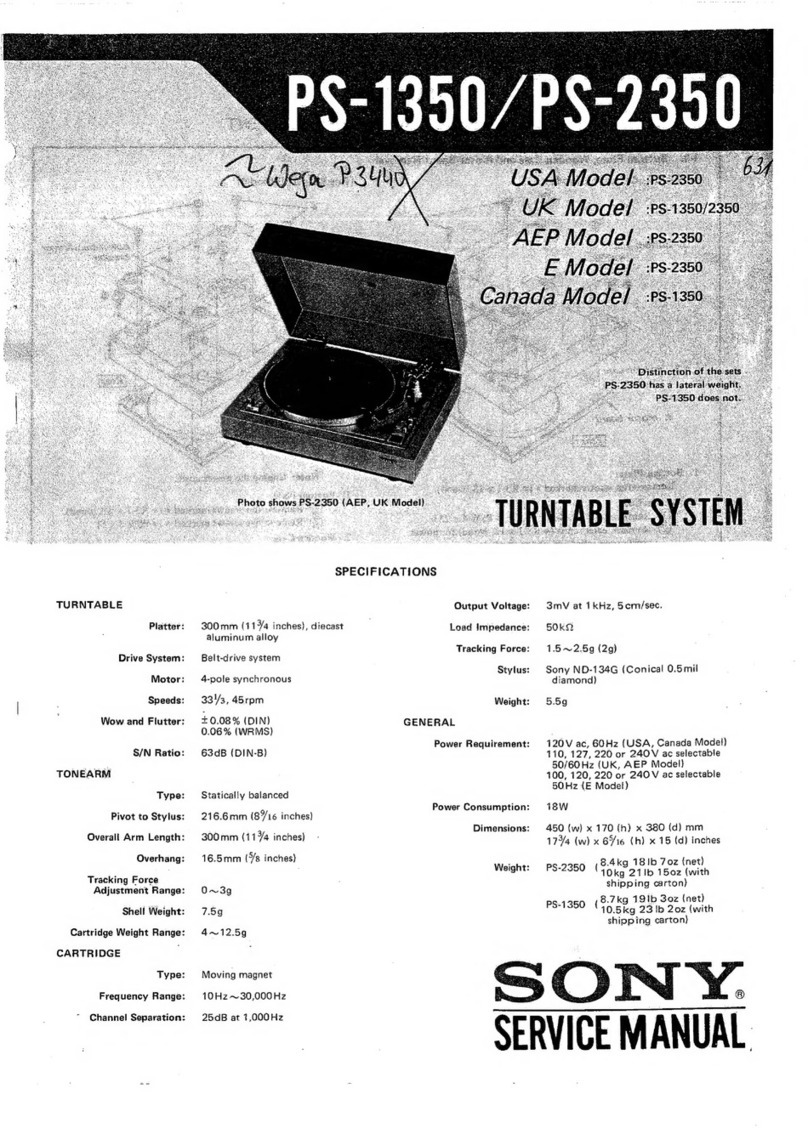

Sony PS-1350 User manual

Sony

Sony Walkman WM-EX162 User manual

Sony

Sony DVW-522 User manual

Sony

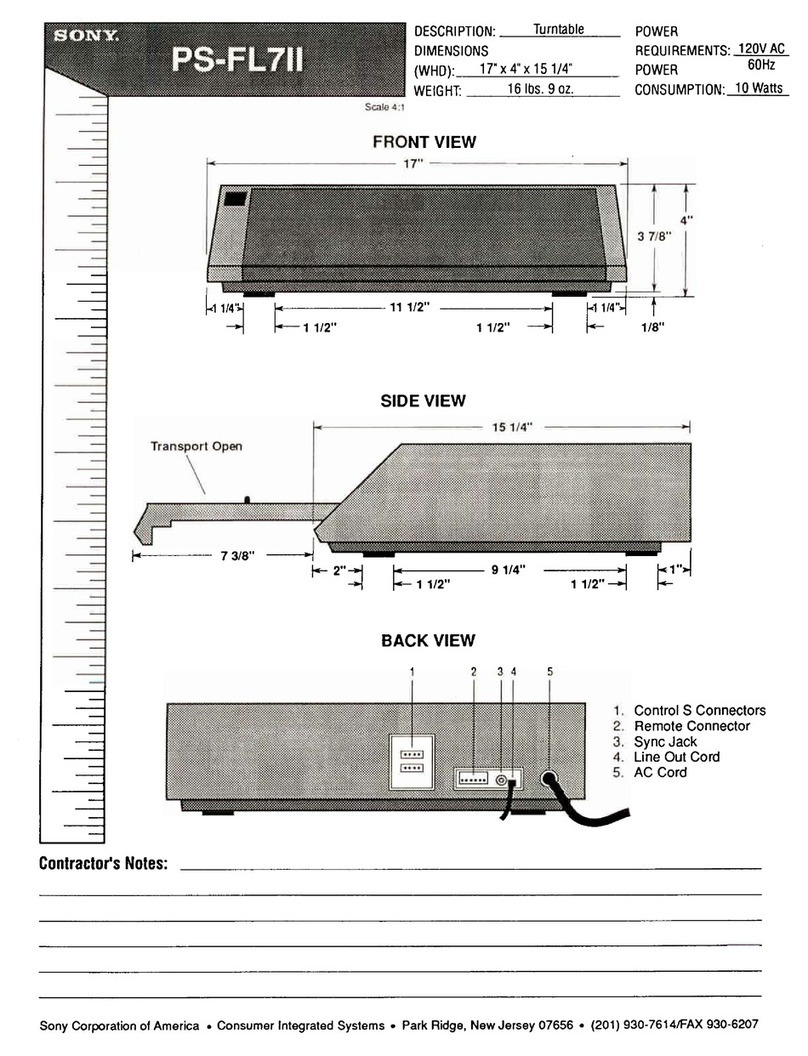

Sony PS-FL7II - Stereo Turntable Parts list manual

Sony

Sony D-F181 - Fm/am Portable Cd Player User manual

Sony

Sony WALKMAN NW-WM1A User manual

Sony

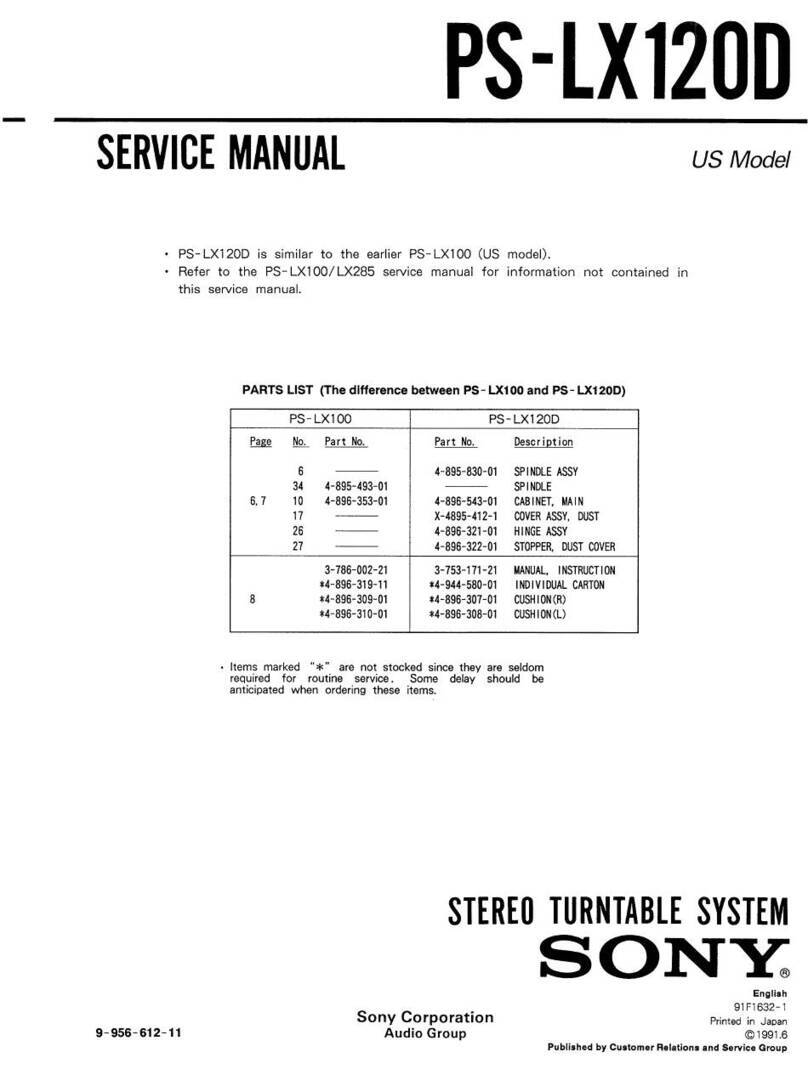

Sony PS-LX120D User manual

Sony

Sony DD-10EX User manual

Sony

Sony PS-LX110 User manual

Sony

Sony PS-LX250H User manual

Sony

Sony PS-DJ9000 - Stereo Turntable System User manual

Sony

Sony PS-LX55 User manual

Sony

Sony PS-LX76 User manual

Sony

Sony PS-F5 User manual

Sony

Sony MDH-10 User manual

Sony

Sony PS-LX110 User manual

Sony

Sony NW-A45 User manual