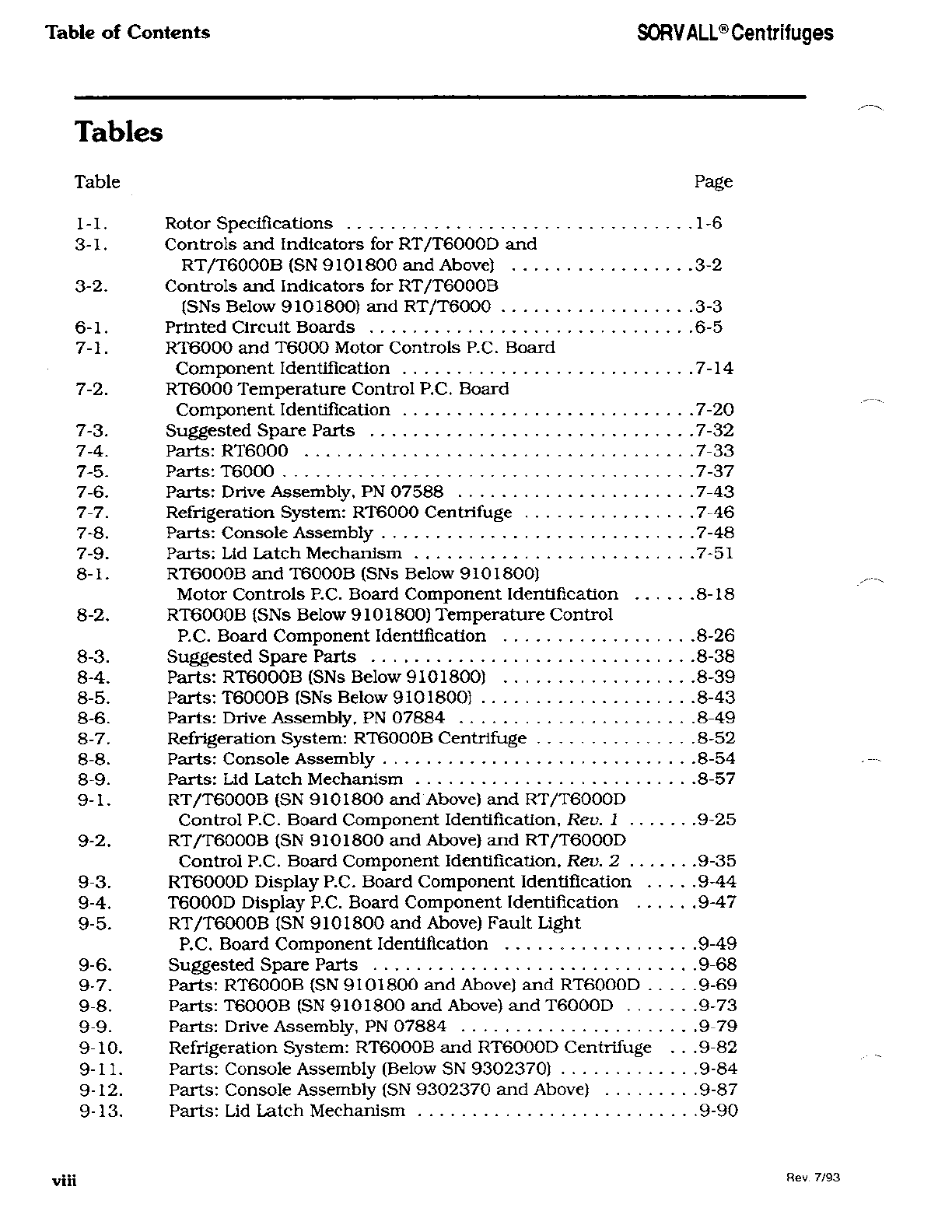

Table of Contents SORV ALL® Centrifuges

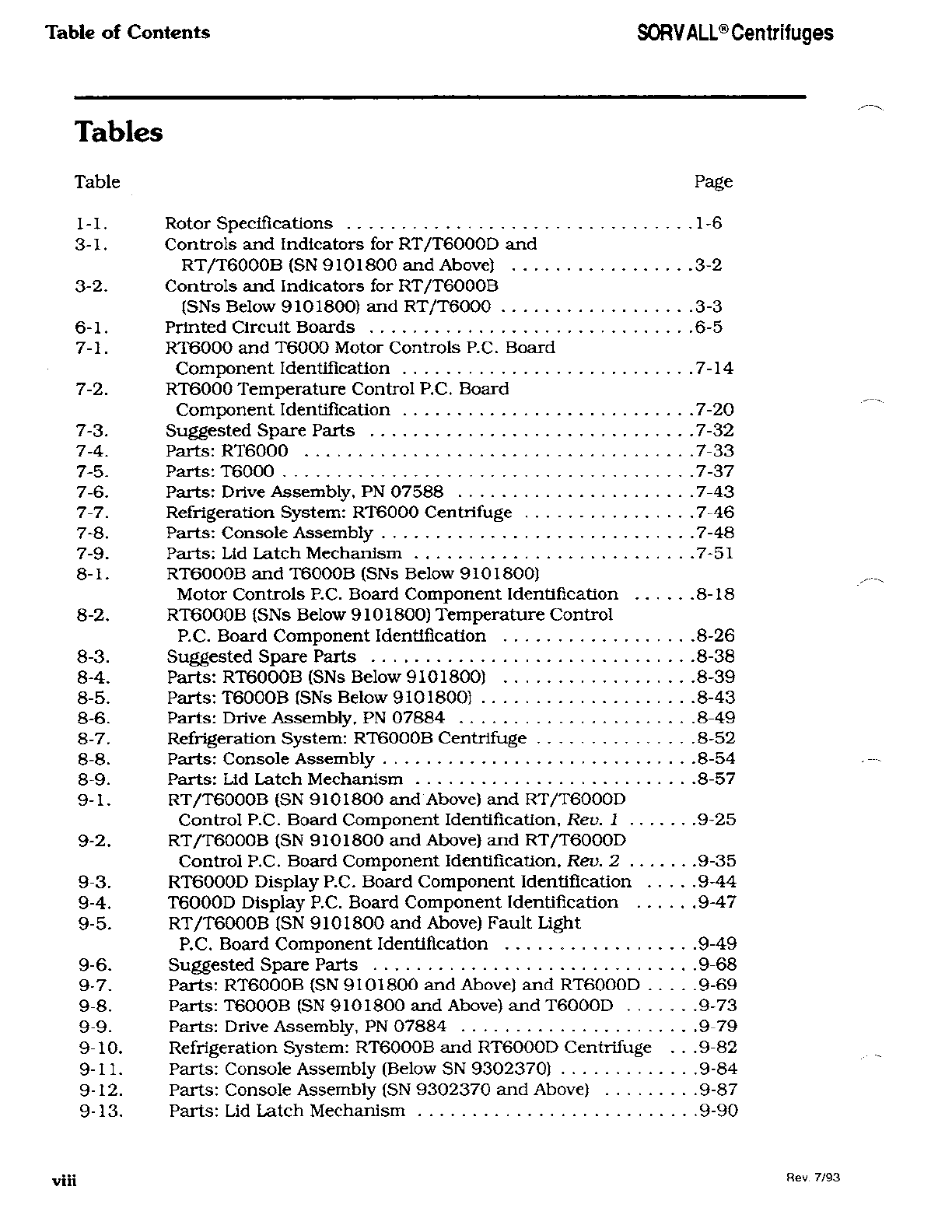

Tables

Table Page

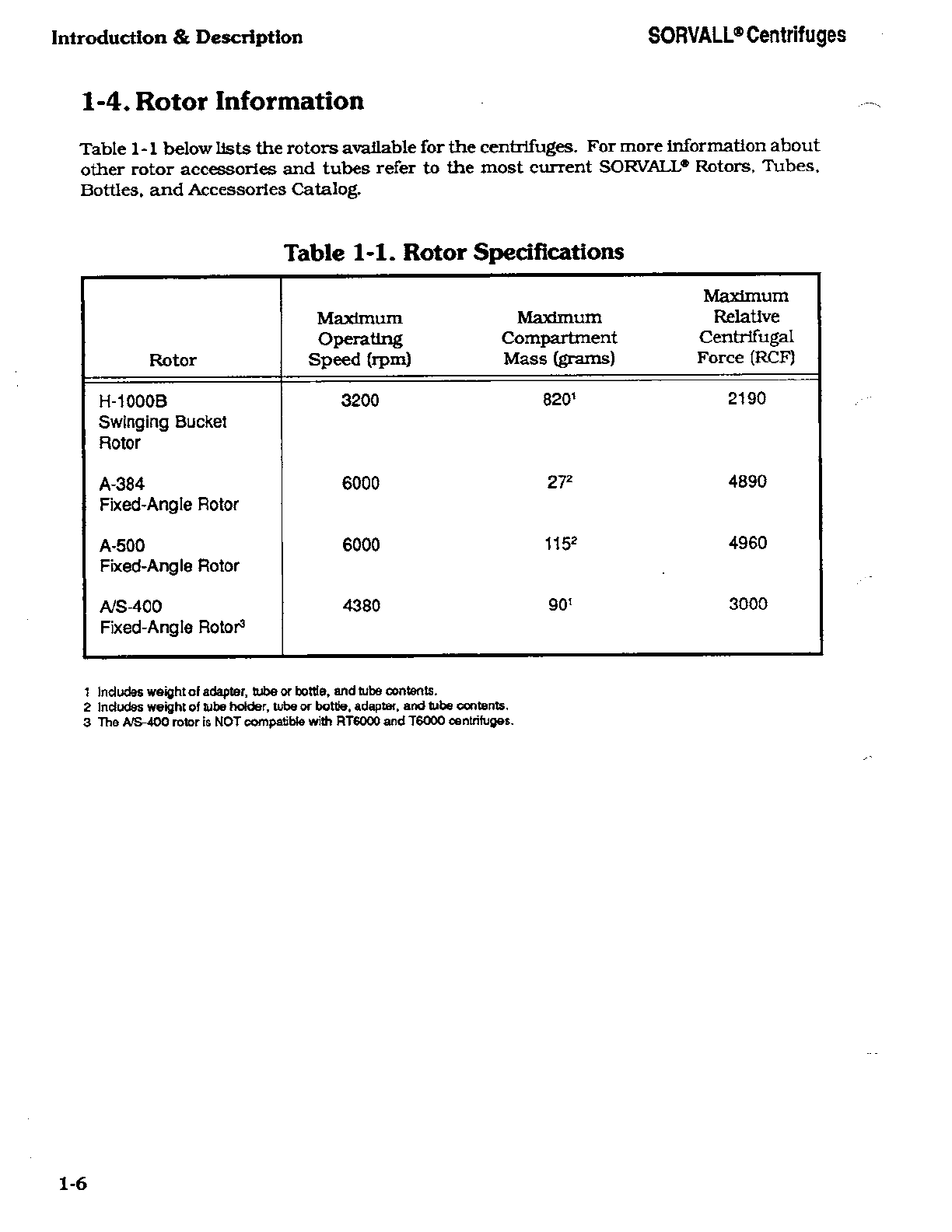

1-1. Rotor Specifications ................................ 1-6

3-1. Controls and Indicators for RT/T6000D and

RT/T6000B (SN 9101800 and Above) ................ .3-2

3-2. Controls and Indicators for RT/T6000B

(SNs Below 9101800) and RT/T6000 ................. .3-3

6-1. Printed Circuit Boards ............................. .6-5

7-1. RT6000 and T6000 Motor Controls P.C. Board

Component Identification .......................... .7-14

7-2. RT6000 Temperature Control P.C. Board

Component Identification ........................... 7-20

7-3. Suggested Spare Parts ............................. .7-32

7-4. Parts: RT6000 .................................... 7-33

7-5. Parts: T6000 ...................................... 7-37

7-6. Parts: Drive Assembly, PN 07588 ...................... 7-43

7-7. Refrigeration System: RT6000 Centrifuge ................ 7-46

7-8. Parts: Console Assembly ............................. 7-48

7-9. Parts: Lid Latch Mechanism ......................... .7-51

8-1. RT6000B and T6000B (SNs Below 9101800)

Motor Controls P.C. Board Component Identification ..... .8-18

8-2. RT6000B (SNs Below 9101800) Temperature Control

P.C. Board Component Identification ................. .8-26

8-3. Suggested Spare Parts ............................. .8-38

8-4. Parts: RT6000B (SNs Below 9101800) ................. .8-39

8-5. Parts: T6000B (SNs Below 9101800) ................... .8-43

8-6. Parts: Drive Assembly, PN 07884 ..................... .8-49

8-7. Refrigeration System: RT6000B Centrifuge .............. .8-52

8-8. Parts: Console Assembly ............................ .8-54

8-9. Parts: Lid Latch Mechanism ......................... .8-57

9-1. RT/T6000B (SN 9101800 and Above) and RT/T6000D

Control P.C. Board Component Identification, Rev. 1 ...... .9-25

9-2. RT/T6000B (SN 9101800 and Above) and RT/T6000D

Control P.C. Board Component Identification, Rev. 2 ...... .9-35

9-3. RT6000D Display P.C. Board Component Identification .... .9-44

9-4. T6000D Display P.C. Board Component Identification ..... .9-47

9-5. RT/T6000B (SN 9101800 and Above) Fault Light

P.C. Board Component Identification ................. .9-49

9-6. Suggested Spare Parts ............................. .9-68

9-7. Parts: RT6000B (SN 9101800 and Above) and RT6000D .... .9-69

9-8. Parts: T6000B (SN 9101800 and Above) and T6000D ...... .9-73

9-9. Parts: Drive Assembly, PN 07884 ..................... .9-79

9-10. Refrigeration System: RT6000B and RT6000D Centrifuge . . .9-82

9-11. Parts: Console Assembly (Below SN 9302370) ............ .9-84

9-12. Parts: Console Assembly (SN 9302370 and Above) ........ .9-87

9-13. Parts: Lid Latch Mechanism ......................... .9-90

VIII Rev. 7/93