Sorvall TC6 User manual

Service Manual

IMPORTANT INFORMATION REGARDING USE OF THIS MANUAL

READ BEFORE USING

This manual provides technical information for the proper servicing of the product(s) specified. This manual is

intended only for use by Sorvall Service personnel, or by qualified technicians who have been trained by Sorvall

in the safe, proper servicing of that product.

This manual has been designed as a supplement to training, not a substitute for training; servicingshould not

be attempted by untrained personnel. Technicians who have not been trained by Sorvall are not familiar with the

product design or the hazards that may be encountered during servicing. In addition, lack of training can result

in faulty repair – possibly making subsequent product use dangerous, or product yields unreliable.

Although content of this manual is believed to be adequate for its intended use, Sorvall makes no representa-

tion or warranty regarding completeness, adequacy or otherwise (not even as a supplement to a given training

course) and assumes no obligation or liability. In the event a qualified, trained technician is unable to repair the

product using this manual, Sorvall Technical Service should be contacted for additional guidance.

PN 78006

SORVALL

TC6

Parts Section

Updated March '02

Sorvall Products, L.P.

Newtown, Connecticut

U.S.A.

PN 78006-1

Issued August 1996

OPERATING

INSTRUCTIONS

SORVALL TC6

Tabletop

Centrifuge

Table of Contents

SORVALLCentrifuges

ii

This manual is a guide for service of the

SORVALL TC6 Tabletop Centrifuge

Data herein has been verified and validated and is believed adequate for the intended use of the

centrifuge. Because failure to follow the recommendations set forth in this manual could produce

personal injury or property damage, always follow the recommendations set forth herein. Sorvall does

not guarantee results and assumes no obligation for the performance of rotors or other products that are

not used in accordance with the instructions provided. This publication is not a license to operate under,

nor a recommendation to infringe upon, any process patents.

This service manual is intended as a service aid. While the manual is kept current and includes

information regarding significant design changes, specific designs may still vary from centrifuge to

centrifuge.

This service manual is intended for use only by service personnel who have been trained by Du␣Pont.

Due to the high electrical potential in this centrifuge, untrained individuals must not attempt any of the

procedures in this service manual.

WARNINGS, CAUTIONS, and NOTES within the text of this manual are used to emphasize important

and critical instructions:

WARNING

:A Warning informs the operator of a hazard or an unsafe practice that could result in

personal injury, affect the operator's health, or contaminate the environment.

CAUTION:

A Caution informs the operator of an unsafe practice that could result in damage of

equipment.

NOTE:

A Note highlights essential information.

W A R N I N G

When using radioactive, toxic, or pathogenic material, be aware of all characteristics of the material and

the hazards associated with it. In the event that leakage or rotor failure occurs, neither the centrifuge nor the rotor

can protect you from the particles dispersed into the air. To protect yourself, we recommend additional precautions

be taken to prevent exposure to these materials, for example, controlled ventilation or isolation. DO NOT USE

MATERIALS CAPABLE OF PRODUCING FLAMMABLE OR EXPLOSIVE VAPORS.

!

© 1996 by Sorvall Products, L.P.

TC6®

Table of Contents

iii

Table␣ of␣ Contents

Paragraph Page

Section 1.␣ ␣ ␣ INTRODUCTION and DESCRIPTION

1-1. Intended Use of Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1-2. Service Decontamination Policy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1-3. Warranty Responsibility. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

1-4. Centrifuge Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

1-5. Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

1-6. Controls, Displays, Switches and Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Section 2.␣ ␣ INSTALLATION and OPERATION

2-1. Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2-2. Preinstallation Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2-3. Electrical Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

2-4. Voltage Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

2-5. Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

2-6. Rotor Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

2-7. Running Hazardous Material . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

2-8. Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

2-9. Emergency Sample Recovery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

Installation Checklist

Section 3. SYSTEM DESCRIPTIONS

3-1. General System Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3-2. Power System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

3-3. Drive Motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

3-4. Brushless Motor Drive Electronics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

3-5. Speed Control. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

3-6. Timer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

3-7. Door Latching Mechanism. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

Section 4. PRINTED CIRCUIT BOARDS and

SCHEMATIC DIAGRAMS

Table of Contents

SORVALLCentrifuges

iv

Table␣ of␣ Contents (continued)

Paragraph Page

Section 5. REPAIR and REPLACEMENT

5-1. Latch Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

5-2. Latch Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

5-3. Door Latched Microswitch Adjustment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

5-4. Hinge Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

5-5. Door Closed Sensor Check. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

5-6. Door Closed Sensor Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

5-7. Fuse Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-8

5-8. Precautions for Handling of Printed Circuit Boards . . . . . . . . . . . . . . . . . . . . . . . 5-9

5-9. Printed Circuit Board Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-9

5-10. Motor Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-10

5-11. Fan and Grille Replacement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-11

5-12. Power Connector Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-13

5-13. Speed Potentiometer Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-15

Section 6. TROUBLESHOOTING

Section 7. MAINTENANCE

7-1. Routine Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

7-2. Preventive Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-3

Preventive Maintenance Checklist

Section 8. ILLUSTRATED PARTS

TC6®

Table of Contents

v

List of Tables

Table Page

1-1. Description of Controls, Displays, Switches and Indicators . . . . . . . . . . . . . . . . 1-6

4-1. Component Description, Control Printed

Circuit Board, PN 78189 Rev. 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-11

4-2. Component Description, Display Printed

Circuit Board, PN 78178 Rev. 4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-17

4-3. Component Description, Display Printed

Circuit Board, PN 78178 Rev. 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-23

4-4. Component Description, Power Supply Printed

Circuit Board, PN 78049 Rev. 4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-26

4-5. Component Description, Power Supply Printed

Circuit Board, PN 78049 Rev. 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-29

4-6. Component Description, Power Supply Printed

Circuit Board, PN 78049 Rev. 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-32

4-7. Component Description, Motor Control Printed

Circuit Board, PN 78230 Rev. 4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-36

4-8. Component Description, Motor Control Printed

Circuit Board, PN 78230 Rev. 4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-42

4-9. Component Description, Motor Control Printed

Circuit Board, PN 78230 Rev. 0 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-48

6-1. TC6®Troubleshooting Chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

8-1. Parts: TC6®Main Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-3

8-2. Parts: TC6®Chassis Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-5

List of Illustrations

Figure Page

1-1. TC6®Controls and Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

2-1. Voltage Selection (SN 9501733 and below) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

2-2. Location of Mechanical Override . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

4-1. System Wiring Diagram, Rev. 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

4-2. System Wiring Diagram, Rev. 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

4-3. Schematic for Control Printed Circuit Board, PN 78189 Rev. 3 . . . . . . . . . . . . . . 4-7

4-4. Control Printed Circuit Board Assembly, PN 78189 Rev. 3 . . . . . . . . . . . . . . . . . 4-9

4-5. Schematic for Display Printed Circuit Board, PN 78178 Rev. 4 . . . . . . . . . . . . . . 4-13

4-6. Display Circuit Board Assembly, PN 78178 Rev. 4 . . . . . . . . . . . . . . . . . . . . . . . . 4-15

4-7. Schematic for Display Printed Circuit Board, PN 78178 Rev. 2 . . . . . . . . . . . . . . 4-19

4-8. Display Printed Circuit Board Assembly, PN 78178 Rev. 2 . . . . . . . . . . . . . . . . . 4-21

4-9. Schematic for Power Supply Printed Circuit Board, PN 78049 Rev. 4 . . . . . . . . 4-24

4-10. Power Supply Printed Circuit Board Assembly, PN 78049 Rev. 4. . . . . . . . . . . . 4-25

4-11. Schematic for Power Supply Printed Circuit Board, PN 78049 Rev. 2 . . . . . . . . 4-27

4-12. Power Supply Printed Circuit Board Assembly, PN 78049 Rev. 2. . . . . . . . . . . . 4-28

4-13. Schematic for Power Supply Printed Circuit Board, PN 78049 Rev. 1 . . . . . . . . 4-30

Table of Contents

SORVALLCentrifuges

vi

List of Illustrations (continued)

Figure Page

4-14. Power Supply Printed Circuit Board Assembly, PN 78049 Rev. 1. . . . . . . . . . . . 4-31

4-15. Schematic for Motor Control Printed Circuit Board, PN 78230 Rev. 4 . . . . . . . . 4-33

4-16. Motor Control Printed Circuit Board Assembly, PN 78230 Rev. 4 . . . . . . . . . . . 4-35

4-17. Schematic for Motor Control Printed Circuit Board, PN 78230 Rev. 4 . . . . . . . . 4-39

4-18. Motor Control Printed Circuit Board Assembly, PN 78230 Rev. 4 . . . . . . . . . . . 4-41

4-19. Schematic for Motor Control Printed Circuit Board, PN 78230 Rev. 0 . . . . . . . . 4-45

4-20. Motor Control Printed Circuit Board Assembly, PN 78230 Rev. 0 . . . . . . . . . . . 4-47

5-1. Latch Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

5-2. Door Closed Sensor Parts Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-7

5-3. Fuse Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-9

5-4. Fuse Replacement/Voltage Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-9

5-5. Reinstalling the Cabinet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-14

8-1. TC6®Main Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-2

8-2. TC6®Chassis Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-4

TC6®

Table of Contents

vii

Contents

Section 1. Introduction and Description

Page

1.1. Intended Use of Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1-2. Service Decontamination Policy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1-3. Warranty Responsibility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

1-4. Centrifuge Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

1-5. Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

1-6. Controls, Displays, Switches and Indicators . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

TC6®

Introduction and Description

1-1

Section 1: INTRODUCTION and␣ DESCRIPTION

This manual is a service guide for the SORVALL® TC6®Tabletop Centrifuge. It contains descriptive

information, repair and replacement procedures, schematics, troubleshooting, calibrations, and an

illustrated parts list for ordering replacement parts.

1-1. Intended Use of Manual

This manual is for qualified service personnel who are familiar with

factory methods for performing repairs, adjustments and calibra-

tions.

Warnings, Cautions, and Notes are used throughout this manual to

emphasize important and critical instructions. Service personnel

are expected to be familiar with their meaning (see page ii) and to

read them before servicing the centrifuge.

1-2. Service Decontamination

Policy

If a centrifuge or rotor that has been used with radioactive or

pathogenic material requires servicing by Sorvall personnel, either

at the customer’s laboratory or at a Sorvall facility, comply with the

following procedure to ensure the safety of all personnel:

1. Clean the centrifuge or rotor to be serviced of all encrusted

material and decontaminate it prior to servicing by the Sorvall

representative or returning it to the Sorvall facility. There must

be no radioactivity detectable by survey equipment.

The SORVALL®Rotors, Tubes, Bottles, Adapters and Accesso-

ries Catalog contains descriptions of commonly used decon-

tamination methods and a chart showing method compatibility

with various materials. This service manual contains specific

guidance about cleaning and decontamination methods appro-

priate for the centrifuge or rotor it describes (see paragraph 7-1).

Clean and decontaminate your centrifuge or rotor as follows:

For TC6®

tabletop centrifuges:

a. Remove rotor from the rotor chamber.

b. Remove motor cover and wash with appropriate

decontaminant.

c. Decontaminate door, rotor chamber, chamber door seal,

and drive, using an appropriate method.

W A R N I N G

Because of the character-

istics of the samples likely to be pro-

cessed in this centrifuge, biological

or radioactive contamination may oc-

cur. Always be aware of this possibil-

ity, and take normal precautions. Use

appropriate decontamination proce-

dures should exposure occur.

W A R N I N G

Toavoidpersonal injury, all

replacement and calibration proce-

dures should be performed by quali-

fied service personnel.

!

!

Introduction and Description

SORVALLCentrifuges

1-2

For rotors:

Remove tubes, bottles, and adapters from the rotor and

decontaminate rotor using an appropriate method. If tubes

or rotor caps are stuck in the rotor, or the rotor door is stuck,

notify Sorvall representative; be prepared with the name

and nature of the sample so the Sorvall Chemical Hazards

Officer can decide whether to authorize the rotor's return to

a Sorvall facility.

2. Complete Decontamination Information Certificate (SORVALL®

products Form No. IPDP-59 or E53603) and attach it to the

centrifuge or rotor before servicing or returning to Sorvall facil-

ity. Certificates are included in the back of this manual. Addi-

tional certificates are available from the local Account Repre-

sentative or Field Service Engineer. In the event that these

certificates are not available, it will be acceptable to include a

written statement certifying that the unit has been properly

decontaminated and outlining the procedures used.

If the centrifuge or rotor must be returned to a Sorvall facility:

1. Contact your Sorvall representative to obtain a Return Service

Order Number (RSO No.). Be prepared with the name and

serial number of the centrifuge or rotor and the repairs re-

quired.

2. Send item(s) with the RSO No. clearly marked on the outside

packaging to the address obtained from your Sorvall represen-

tative.

NOTE

United States federal regulations require that parts and

centrifuges

must

be decontaminated before being trans-

ported. Outside the United States, check local regula-

tions.

If a centrifuge or rotor to be serviced does not have a

Decontamination Information Certificate attached and, in Sorvall's

opinion presents a potential radioactive or biological hazard, the

Sorvall representative will not service the equipment until proper

decontamination and certification is complete. If Sorvall receives a

centrifuge or rotor at its Service facilities which, in its opinion, is a

radioactive or biological hazard, the sender will be contacted for

instructions as to disposition of the equipment. Disposition costs

will be borne by the sender.

NOTE

The Field Service Engineer will note on the Customer

Service Repair Report if decontamination was required

and, if so, what the contaminant was and what proce-

dure was used. If no decontamination was required, it

will be so stated.

TC6®

Introduction and Description

1-3

1-3. Warranty Responsibility

Whenever service of the centrifuge is attempted by anyone other

than an employee of Sorvall or an authorized representative, the

individual is assuming the risk of voiding the centrifuge warranty,

which is as follows:

Sorvall Products, L.P. makes no warranty of any kind, expressed or

implied, except as stated in this warranty policy.

The SORVALL®TC6®Tabletop Centrifuge is warranted to be free

from defects in materials and workmanship for a period of one year

from the date of delivery. Sorvallwill repair or replace and return

free of charge any part which is returned to its factory within said

period, transportation prepaid by user, and which is found upon

inspection to have been defective in materials or workmanship.

This warranty does not apply to any damage to any instrument

resulting from: normal wear and tear; misuse; abuse; use of electri-

cal currents or circuits other than those specified on the plate affixed

to the instrument; or use of any rotor other than those intended for

use in this instrument.

Sorvall reserves the right to change, alter, modify or improve any of

its instruments without any obligation whatsoever to make corre-

sponding changes to any instrument previously sold or shipped.

The foregoing obligations are in lieu of all other obligations and liabilities

including negligence and all warranties, of merchantability or otherwise,

expressed or implied in fact or by law, and state our entire and exclusive

liability and buyer's exclusive remedy for any claim or damages in connec-

tion with the sale or furnishing of goods or parts, their design, suitability

for use, installation or operation. Sorvall will in no event be liable for any

special or consequential damages, and our liability under no circum-

stances will exceed the contract price for the goods for which liability is

claimed.

Introduction and Description

SORVALLCentrifuges

1-4

1-4. Centrifuge Description

The TC6®is a lowspeed, non-refrigerated tabletop centrifuge that

features digital readout displays, a dc brushless (maintenance free)

motor, a closed-loop speed control, a removable stainless steel rotor

chamber, ergonomically designed front panel control knobs and

switches, and has a see-through chamber door that allows rotor

calibration and visual inspection of a run in progress. The chamber

door is counterbalanced for easy opening and safe closing. The

door latch automatically locks when the chamber door is closed

and an interlock prevents the chamber door from being opened

during operation.

1-5. Specifications

Maximum Operating Speed: . . . . . . . . 6000 rpm*

Maximum heat output

during operation: . . . . . . . . . . . . . . . . . 650 Btu/hour (190 Watts)

Electrical Requirements: . . . . . . . . . . . . 100 - 120 Vac, 60Hz,

3.15A, single phase

220 - 240 Vac, 50 Hz,

2A, single phase

Dimensions:

Width . . . . . . . . . . . . . . . . . . . . . . . . . . . 39.4 cm (15.5 inches)

Depth . . . . . . . . . . . . . . . . . . . . . . . . . . . 55.9 cm (22.0 inches)

Height . . . . . . . . . . . . . . . . . . . . . . . . . . . 26.7 cm (10.5 inches)

Height (with door open) . . . . . . . . . . . 78.7 cm (31.0 inches)

Mass (Weight): . . . . . . . . . . . . . . . . . . . . . 31 kg (70 lbs)

Decibel Level: . . . . . . . . . . . . . . . . . . . . . <60 dB at 3500 rpm

Operating Temperature Range: . . . . . . 10°C to 35°C

(50°F to 95°F)

Relative Humidity

(Normal Operating Range): . . . . . . . . 20% to 70%

*Speed in revolutions per minute (rpm) is related to angular velocity,

ω

, according to the

following:

ω

= (rpm) = (rpm) (0.10472)

Where

ω

= rad/s. All further references in this manual to speed will be designated as rpm.

2π

60)

(

TC6®

Introduction and Description

1-5

1-6. Controls, Displays,

Switches and Indicators

Figure 1-1 shows the TC6®control panel and provides a brief de-

scription for each control, display, switch and indicator. Table 1-1

(on the next page) gives a complete description.

Figure 1-1. TC6®

Controls and Indicators

R

SPEED

RPM

TIME

MIN

READY DOOR

DOORSTOPSTARTHOLD

234

567 8910

1

SPEED DISPLAY

Displaysactual rotor speed

from 0 to 6000 rpm (±1%

or 10 rpm, whichever is

greater).

DOOR INDICATOR

Blinks at end of run indi-

cating the chamber door

may be opened.

TIME DISPLAY

Displays set run time and,

duringa run, remaining run

time.

READY INDICATOR

When lit, indicates that the

chamberdoorisclosed and

latched and that the centri-

fuge is ready for operation.

DOOR SWITCH

Opens the cham-

ber door.

STOP SWITCH

Stops the centri-

fuge run.

START SWITCH

Starts the centri-

fuge run.

HOLD SWITCH

Selects a continu-

ous run.

SPEED DIAL

Sets desired rotor

speed.

TIME DIAL

Sets length of run

time up to 99 min-

utes.

Introduction and Description

SORVALLCentrifuges

1-6

Table 1-1. Description of Controls,

Displays, Switches and Indicators

SPEED display Indicates actual rotor speed from 0

to 6000 rpm (±1% or 10␣rpm, which-

ever is greater).

TIME display Indicates set run time at the begin-

ning of the run and the remaining

run time after the START switch is

pressed. In HOLD mode, two dashes

are displayed.

READY indicator light When lit, indicates that the chamber

door is closed and latched and that

the centrifuge is ready for operation.

DOOR indicator light At the end of the run this light blinks

indicating that the rotor has stopped

spinning and that the chamber door

may be opened.

SPEED dial Sets the desired rotor speed in rpm.

As indicated by the symbol, turn the

dial to the right to increase speed.

TIME dial Sets length of run time up to 99 min-

utes.

HOLD switch Selects a continuous run (two dashes

will appear in the TIME display to

indicate a run in HOLD mode).

START switch Starts the centrifuge run.

STOP switch Stops the centrifuge run.

DOOR switch At the end of a run, after the rotor

has stopped spinning and the DOOR

light blinks, this switch releases the

chamber door.

POWER switch The power switch is a rocker switch

that toggles on and off. When set to

"I", applies power to the centrifuge.

MIN

(NOT SHOWN)

Table of Contents

SORVALLCentrifuges

viii

Page

2-1. Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2-2. Preinstallation Requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2-3. Electrical Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

2-4. Voltage Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

2-5. Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

2-6. Rotor Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

2-7. Running Hazardous Material . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

2-8. Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

2-9. Emergency Sample Recovery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

Installation Checklist

Contents

Section 2. Installation and Operation

TC6®

Installation and Operation

2-1

Section 2: INSTALLATION and OPERATION

This section contains information to install and operate your SORVALLTC6®Tabletop Centrifuge.

C A U T I O N

Thecentrifugecan be dam-

aged if connected to the wrong volt-

age. Check the voltage before plug-

ging the centrifuge into any power

source. Sorvall is not responsible for

incorrect installation.

!

W A R N I N G

The TC6®weighs 70 lbs.

Refer to the unpacking instructions

for proper care when lifting and in-

stalling the centrifuge. Failure to use

proper lifting techniques can result in

personal injury and/or possible dam-

age to the centrifuge.

C A U T I O N

Do not lift the centrifuge by

the front panel or the door. To do so

can result in damage to these parts.

!

2-1. Inspection

When you receive your centrifuge, carefully inspect it for any signs

of shipping damage. If you find damage, report it immediately to

the transportation company and file a damage claim, then notify

Sorvall.

Check the parts received with the centrifuge against the shipping

list; if any parts are missing, contact Sorvall (see office list in back of

manual).

2-2.␣ Preinstallation Require-

ments

The TC6®centrifuge is ordered for a specific voltage. The nameplate

on the back of the centrifuge tells the voltage ordered. Before using

the TC6®, be sure the proper operating voltage and corresponding

fuse is selected. If required (for instruments serial number 9501733

and below), the voltage setting and fuses can be changed (refer to

page 2-2, paragraph 2-4, Voltage Selection for procedure to change

the voltage).

Other preinstallation requirements include:

• providing a flat, level surface to support the weight of the

centrifuge (31 kg; 70 lbs),

• allowing adequate space for proper air circulation (5 cm;

2␣inches),

• allowing for the proper height clearance to open the chamber

door (78.7 cm; 31.0 inches); and

• providing the proper electrical requirements.

!

Installation and Operation

SORVALLCentrifuges

2-2

2-3. Electrical Requirements

The centrifuge has specific power requirements and must be

connected to the correct power supply for proper performance. The

nameplate on the back of the centrifuge specifies one of the following:

100 - 120 Vac, 60 Hz, single phase, 3/15 amps*

220 - 240 Vac, 50 Hz, single phase, 2 amp*

Check line voltage with a voltmeter. Then, verify that the voltage

indicated on the nameplate on the back of the centrifuge agrees

with the measured line voltage.

If the line voltage is beyond the ±10% tolerance (of nominal) given,

the result can be variations in the performance specifications and

damage to the centrifuge.

The power cord has a keyed plug that inserts into a receptacle at the

back of the centrifuge. The other end of the power cord has a three-

prong molded cap with a ground pin and parallel blades. (60 Hz

instruments require receptacle NEMA5-15R and 50 Hz instruments

require NEMA 6-15 R.).

For connection to other receptacles, the power cord may have to be

replaced. Follow local electrical regulations.

Check that the gound lug of the electrical plug is properly grounded

and is shorted to the frame of the centrifuge.

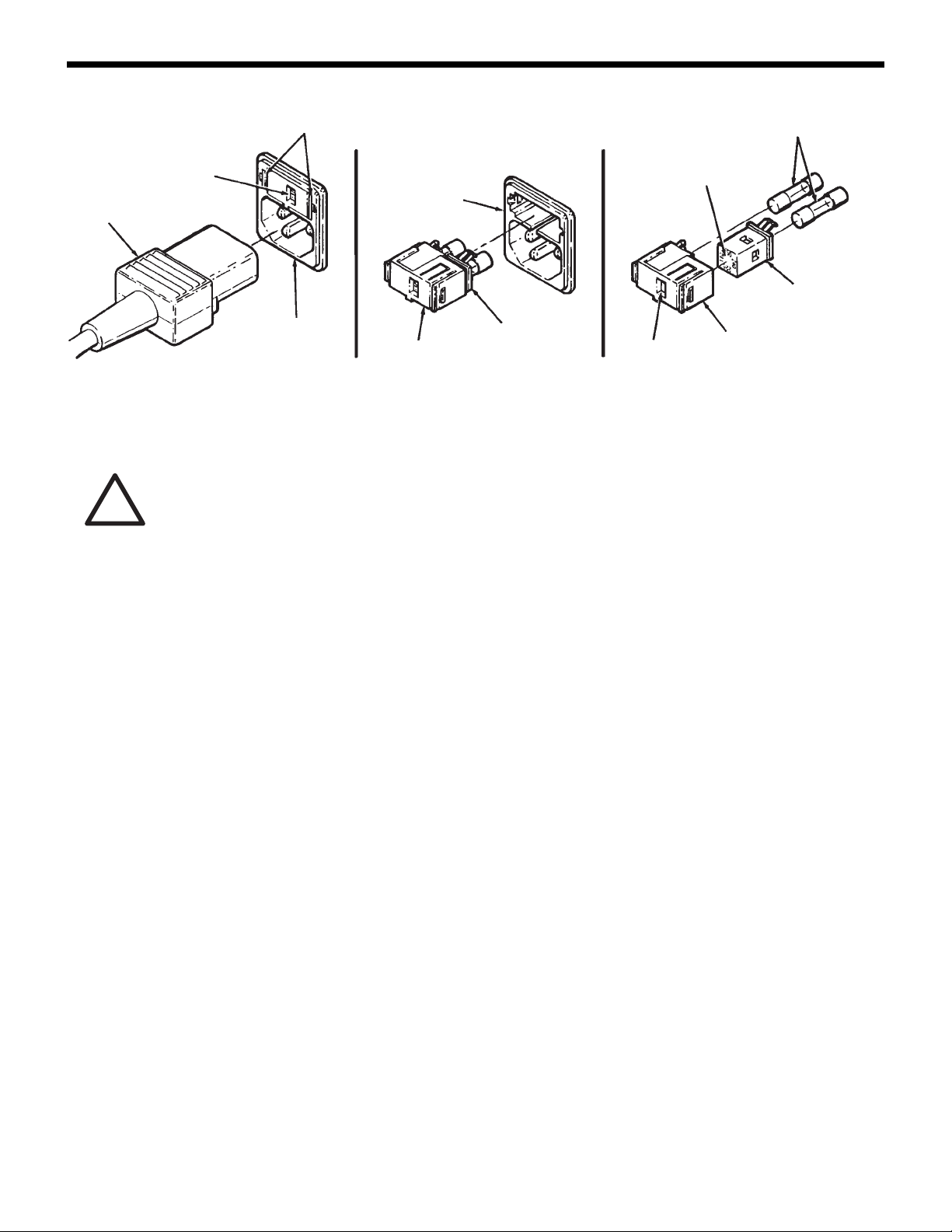

2-4. Voltage Selection

(SN 9501733 and Below)

The voltage is set by the voltage selector (in the fuse block) located

in the power connector on the back of the TC6®(refer to figure 2-1

for SN 9501733 and below). The current voltage setting (100, 110**,

220, or 240) is displayed in the window of the fuse block.

To change the voltage:

1. Unplug the power cord from the wall receptacle and from the

power connector.

2. Squeeze the two tabs located on either side of the fuse block and

carefully remove the fuse block from the power connector.

NOTE

Voltage can only be changed on instruments with serial

numbers 9501733 and below. Instruments with serial

numbers 9501734 and above must be ordered prewired

for specific voltages.

!

C A U T I O N

If the power cord is

connected to the wrong voltage, it

can cause damage to the centrifuge.

Check the voltage listed on the

nameplatebeforeplugging the power

cord into the power source. Sorvall is

not responsible for incorrect

installation.

*CSA and UL Certified.

**For 120 V operation, the voltage selector is set to 110.

TC6®

Installation and Operation

2-3

POWER

CORD

SELECTED

VOLTAGE

WINDOW

TABS

POWER

CONNECTOR

POWER

CONNECTOR

FUSE

BLOCK

FUSE

BLOCK

VOLTAGE

SELECTOR

VOLTAGE

SELECTOR

VOLTAGE

WINDOW

SELECTABLE

VOLTAGES

FUSES

Figure 2-1. Voltage Selection (SN 9501733 and below)

3. Gently pull the voltage selector from the fuse block.

4. Rotate the voltage selector until the desired voltage is aligned

with the window in the fuse block. Then, reinstall the voltage

selector into the fuse block.

5. Check that proper fuses are installed. Fuses are Type T, 250 V,

but change amperage rating depending on the voltage selected:

•100 or 110 setting requires two 3.15-amp fuses, (PN 91428),

•220 or 240 setting requires two 2-amp fuses, (PN 91203).

Change fuses if necessary.

6. Reinstall the fuse block into the power connector and plug in

the centrifuge power cord.

NOTE

If the voltage was changed from 100-110 setting to 220-

240 setting, a different power cord is required.

!

C A U T I O N

Whenchangingthe voltage

setting, be sure that the voltage

selectorisinstalled sothat the voltage

displayed in the voltage window

matches the intended input voltage.

Also, be sure that the proper fuses

have been installed, and that you are

using the proper power cord.

Incorrect installation can result in

damage to the centrifuge. Sorvall is

not responsible for incorrect

installation.

Installation and Operation

SORVALLCentrifuges

2-4

2-5. Installation

To install the centrifuge:

1. Place the centrifuge on a sturdy bench or work table that will

support its weight, leaving space for sample preparation. Be

sure to leave a minimum clearance of 10 cm (4 inches) on all

sides for proper air circulation.

2. Make sure the centrifuge is level.

3. Make sure the centifuge is set for the proper voltage (see page

2-3, Voltage Selection).

4. Make sure the power switch is set to "O" (OFF position).

5. Insert the universal keyed end of the power cord into the power

connector at the back of the centrifuge and the other end into a

wall receptacle. The centrifuge is now ready for use.

2-6. Rotor Considerations

a. Rotor Temperature

Centrifugation creates an increase in rotor temperature. The increase

in temperature is caused by variables including rotor speed, length

of the run, and the type of rotor.

Air flow through the TC6®Centrifuge is designed to minimize the

increase in rotor temperature. Air enters through the air vent in the

front panel and exits through the fan vent located at the back of the

centrifuge.

When running temperature-sensitive material, a trial run is

recommended.

b. Rotor Installation, Loading and Balancing

Before placing the rotor on the drive spindle, make sure that there

are no loose objects inside the rotor chamber; for example, clips,

tubing, tape, or labels, and that the rotor centerhole and drive

spindle are clean and free of nicks and scratches. Wipe these surfaces

before each use.

Gently place the rotor body on the tapered spindle of the centrifuge,

aligning the shaft pin with the slots in the rotor. Secure the rotor to

the drive spindle by turning the rotor locking knob clockwise.

C A U T I O N

Do not lift the centrifuge by

the front panel or the chamber door.

To do so can result in damage to

these parts.

If the power cord is connected to the

wrong voltage, it can cause damage

to the centrifuge. Check the voltage

listed on the nameplate before

plugging the power cord into the

power source. Sorvall is not

responsible for incorrect installation.

Do not operate the centrifuge without

making sure the rotor is properly

balanced. Also, when installing a

rotor, carefully place it on the

centrifuge drive spindle. The

centrifuge spindle bearings can be

damaged if rotor is dropped on the

drive spindle.

!

W A R N I N G

Blocking the air flow enter-

ing and/or exiting the TC6®centri-

fuge will cause an increase in tem-

peraturewithin therotor chamber.The

temperatureincreasecan temporarily

distort non-metal surfaces allowing

particles to exit the rotor chamber

resultingin personalinjuryand/orcen-

trifuge damage should tube break-

age or rotor failure occur.

When loading the rotor, be sure not

toexceedthemaximumcompartment

mass of the rotor (see the individual

rotorinstructionmanual). If maximum

compartment mass is exceeded,

maximum rotor speed must be

lowered as described in the rotor

instruction manual, Compartment

Loads in Excess of Design Mass.

Failureto dosocancauserotor failure

which could result in personal injury

and/or centrifuge damage.

!

TC6®

Installation and Operation

2-5

NOTE

The rotor locking knob cannot be tightened if the rotor is

not properly installed on the drive spindle.

Refer to the rotor instruction manual for bucket loading and balanc-

ing procedures as well as information regarding the selection and

use of tubes, bottles, and adapters.

2-7. Running Hazardous

Material

Because the centrifuge chamber of the TC6®is not designed for

biocontainment, some vapors or aerosols released from uncapped,

leaking or broken tubes may leak from the chamber during operation.

Once a run is completed and the chamber door is opened, the

vapors or aerosols which have concentrated in the chamber will be

released into the laboratory area. For this reason, when materials

which are radioactive, pathogenic, toxic, or otherwise hazardous in

nature are to be run, the centrifuge should be located in a biohazard

safety enclosure and operated using all appropriate safety

precautions. If desired, we recommend the use of sealed bucket

assembly (Catalog No. 78016) to offer increased protection from

contamination from uncapped, leaking or broken tubes.

NOTE

The sealed bucket assemblies (Catalog No. 78016) are

designed to seal tightly during operation and meet the

British Standards BS 4402:1982 Appendix D. They have

been tested at the Public Health Laboratory Service

Centre for Applied Microbiology and Research, Porton

Down, United Kingdom, and found suitable for use with

materials up to ACDP Category 3.

Use appropriate decontamination procedures should exposure to

any hazardous material occur. Read paragraph 1-2, page 1-1 for the

procedure to follow if a centrifuge or rotor that has been used with

a hazardous material must be returned to our service facilities for

repair.

!

C A U T I O N

Do not operate the centri-

fuge without making sure the rotor is

properlybalanced.Also, when install-

ing a rotor,

carefully

place it on the

centrifuge drive spindle. The centri-

fuge drive spindle bearings can be

damaged if the rotor is dropped on

the drive spindle.

W A R N I N G

When using radioactive,

toxic, or pathogenic materials, be

aware of all characteristics of the

materialsandthe hazards associated

with them in the event leakage oc-

curs during centrifugation. If leakage

doesoccur,neither the centrifuge nor

the rotor can protect you from par-

ticles dispersed in the air. To protect

yourself, we recommend additional

precautions be taken to prevent ex-

posure to these materials, for ex-

ample, use of controlled ventilation

or isolation areas.

Always be aware of the possibility of

contamination when using radioac-

tive, toxic, or pathogenic materials.

Take all necessary precautions and

useappropriatedecontamination pro-

cedures if exposure occurs.

Theuse ofsealedrotors,bucketsand/

or sample containers will provide in-

creased protection from contamina-

tion during routine operation. How-

ever, these items will not guarantee

contamination protection from acci-

dents resulting in damage to the rotor

orbuckets.Do notrunhazardous ma-

terial in the centrifuge unless it is

placed in a biohazard enclosure and

operatedusing appropriatesafety pre-

cautions.

!

Table of contents

Other Sorvall Laboratory Equipment manuals

Popular Laboratory Equipment manuals by other brands

SPEX SamplePrep

SPEX SamplePrep Genomax 2050 Operation manual

TSI Instruments

TSI Instruments 3775 Operation and service manual

Agilent Technologies

Agilent Technologies G1574A installation guide

Flight Dental Systems

Flight Dental Systems Clave 23+ instruction manual

Milestone

Milestone HistoDream M Operator's manual

Agilent Technologies

Agilent Technologies G1364B user guide