Sorvall Cellwasher 2 User manual

Cellwasher 2 Service SORVALL®lnstrumentS

This manual is a guide for service of the

SORVALL® Cellwasher 2 Cell Washing System

Data herein has been verified and validated and is believed adequate for the intended use

of the instrument. If the instrument or procedures are used for purposes over and above

the capabilities specified herein, confirmation of their validity and suitability should be

obtained, otherwise, DuPont does not guarantee results and assumes no obligation or

liability. This publication is not a license to operate under, nor a recommendation to

Infringe upon, any process patents.

This service manual is intended as a service aid. While the manual is kept current and

includes information regarding significant design changes, specific designs may still vary

from instrument to instrument.

This service manual is intended for use only by service personnel who have been trained

by DuPont. Due to the high electrical potential in this centrifuge, untrained individuals

must not attempt any of the procedures in this service manual.

NOTES, CAUTIONS, and WARNINGS within the text of this manual are used to emphasize

important and critical instructions:

WARNING A Warning informs the operator of a hazard or an unsafe practice that could

result in personal injury, affect the operator's health, or contaminate the

environment.

CAUTION A Caution informs the operator of an unsafe practice that could result in

damage of equipment.

NOTE A Note highlights essential information.

Ili^^^^^^^^^^^^^^^^^^^^^^^^^^ ! ' ' ^^^NG';'^'^'6'!;''1:^;":,!^

When using radioactive, toxic, or pathogenic material, be aware of all .:

characteristics of the material and the hazards associated with it. In the .

I?''lew^^^ltt'lii^^

rotor can protect you from the particles dispersed into the air. To protect

^['licit^

^'eiiilitiil^^

!:::^::;^3(m£te::NOTS!USi:iM^^

^'^oi'iilltBiiivl'ti^^

ii

Sorvall® Instruments Cellwashcr 2 Service

Table of Contents

Paragraph Page

1-1.

1-2.

1-3.

1-4.

2-1.

2-2.

2-3.

2-4.

2-5.

2-6.

3-1.

3-2.

3-3.

4-1.

4-2.

4-3.

4-4.

4-5.

4-6.

4-7.

4-8.

4-9.

4-10.

Section I. INTRODUCTION

Intended Users .................................... 1-1

Warnings and Cautions ..............................1-1

Service Decontamination Policy. ....................... 1-1

Warranty Responsibility ............................. 1-2

Section 2.

DESCRIPTION, INSTALLATION and OPERATION

Description of the Cellwasher 2 ........................ 2-1

Cellwasher 2 Specifications ........................... 2-1

Installation Information. ............................. 2-2

Cellwasher 2 Operation .............................. 2-10

Emergency Sample Recovery .......................... 2-17

Condensed Operating Instructions ..................... 2-18

APPENDED: Condensed Operating Instructions ........... 2-19s

Section 3. MAINTENANCE

Inspection and Cleaning ............................. 3-1

Tubing Replacement ................................ 3-5

Cellwasher 2 Preventive Maintenance Procedure ........... 3-5

APPENDED: Preventive Maintenance Checklist ........... 3-9

Section 4. MECHANICAL THEORY

Controls ......................................... 4-1

Flexible Drive Mounting ............................. 4-1

Cabinet ......................................... 4-1

Air Flow ......................................... 4-1

Motor ........................................... 4-1

Safety Latch ...................................... 4-1

Saline Pump System ................................ 4-2

Flow Detector ..................................... 4-2

Flow Control Clamp ................................ 4-2

Motor Antirotation Clutch ............................ 4-2

in

Rev. 11/90

Cellwashcr 2 Service Sorvall® Instruments

Table of Contents (continued)

Paragraph Page

5-1.

5-2.

5-3.

5-4.

5-5.

6-1.

6-2.

6-3.

6-4.

8-1.

8-2.

8-3.

8-4.

8-5.

8-6.

8-7.

8-8.

8-9.

8-10.

8-11.

Section 5. ELECTRICAL THEORY

System Description ................................. 5-1

Touch Switch Panel. ................................ 5-31

Interface PC Board ................................. 5-31

Microcomputer PC Board ............................ 5-37

Electronics Module ................................. 5-50

Section 6. APPLICATIONS

Cellwasher 2 Application ............................. 6-1

Compatibility Testing ............................... 6-1

Cellwasher 2 Washing Cycle .......................... 6-2

Glossary of Blood Banking Terms ...................... 6-6

Section 7. TROUBLESHOOTING

Section 8. REPAIR and REPLACEMENT PROCEDURES

Base Plate Removal................................. 8-1

Cabinet Removal................................... 8-1

Front Panel Removal ................................ 8-2

Power Switch Replacement ........................... 8-3

Pump Replacement................................. 8-3

Pump Motor Replacement ............................ 8-3

Flow Detector Replacement........................... 8-4

Motor Replacement................................. 8-4

Interface Printed Circuit

Board Replacement................................ 8-4

Microcomputer Printed Circuit

Board Replacement................................ 8-5

Fuse Replacement.................................. 8-5

IV

Rev. 11/90

Son/all® Instruments Cellwasher 2 Service

Table of Contents (continued)

Paragraph Page

Section 9. KIT INSTRUCTIONS

9-1.

9-2.

9-3.

9-4.

9-5.

9-6.

9-7.

Figure

2-1.

2-2.

2-3.

2-4.

2-5.

3-1.

3-2.

5-1.

5-2.

5-3.

5-4.

5-5.

5-6.

Tubing Replacement Kit (PN 04632) .................... 9-2

Collector Seal Replacement Kit (PN 04353) ............... 9-9

Retainer Ring Replacement Kit (PN 12850) ............... 9-12

Lid Latch Assembly Replacement

Kit (PN 12792).................................... 9-14

Saline Shield Kit (PN 12811) .......................... 9-19

Triac-Interface Printed Circuit Board

Replacement Kit (PN 12816) ......................... 9-20

Adapter Clip Installation Kit (PN 04330) ................. 9-23

Section 10. ILLUSTRATED PARTS LIST

List of Illustrations

Page

Cellwasher 2 Tubing Diagram ......................... 2-4

Stainless Steel Rotating Bowl Installation ................ 2-2

Distributor Installation .............................. 2-9

Cellwasher 2 Controls and Indicators ................... 2-10

Location of Mechanical Override ....................... 2-18

Exploded View, Collecting Ring Assembly

(SN 8702302 and higher) ........................... 3-3

Exploded View, Collecting Ring Assembly

(SN 8702301 and lower) ............................ 3-5

System Schematic, Cellwasher 2 ....................... 5-3

Wiring Diagram, Cellwasher 2 ......................... 5-5

Microcomputer PC Board ............................ 5-7

Schematic, Microcomputer PC Board ................... 5-11

Triac-Interface PC Board (PN 04834 Revision 0,

SN 8503865 and higher) ............................ 5-16

Schematic, Triac-Interface PC Board (PN 04537

Revision 2, SN 8503865 and higher) ................... 5-17

v

Rev. 11/90

Cellwasher 2 Service SORVALL®lnstrumentS

List of Illustrations (continued)

Figure Page

5-10. Schematic, Onterface PC Board (PN 04537

Revision 1, SN 8503864 and below) ........................ .5-25

5-11. Cellwasher 2 Automatic Wash Sequence ...................... .5-30

5-12. Indicator Current Path ................................... .5-31

5-13. Schematic, Touch Switch Panel ............................ .5-33

5-14. Interface PC Board, Test Set-Up #1 .......................... .5-35

5-15. Interface PC Board, Test Set-Up #2 .......................... .5r36

5-16. Microcomputer Board Input/Output Configuration .............. .5-38

5-17. Microcomputer Scan Routine .............................. .5-39

5-18. Creating New Input/Output Formats ........................ .5-41

5-19. Digital Time Display Segments ............................. .5-42

5-20. Starting in Manual (High or Low) Mode, Logic Flow Chart ......... .5-47

5-21. Starting from Check Mode, Logic Flow Chart ................... .5-48

5-22. Starting in Auto Mode, Logic Flow Chart ...................... .5-49

7-1. Location of Decant Coil and Drive Ring ....................... .7-7

7-2. Location of Lift Plate Ring ................................. .7-7

9-1. Tubing Diagram: Parts Location ............................ .9-2

9-2. Adjustable Tubing Clamp Location .......................... .9-6

9-3. Adjustable Tubing Clamp ................................. .9-8

9-4. CW-1 Collecting Ring Assembly Exploded View ................. .9-10

9-5. Cellwasher 2 Collecting Ring Assembly Exploded View ........... .9-11

9-6. Cabinet Machine Drawing ................................. .9-17

9-7. Adhesive Location ....................................... .9-20

9-8. Installing an Adapter Clip ................................. .9-24

10-1. Cellwasher 2 Assembly .................................... 10-5

10-2. Chassis and Component Assembly ........................... 10-11

10-3. Drive Motor Assembly ..................................... 10-15

List of Tables

Table Page

2-1. Parts Location: Tubing Diagram ............................ .2-4

2-2. Cellwasher 2 Controls and Indicators ........................ .2-9

5-1. Component Identification, Microcomputer PC Board .............. 5-8

5-2. Component Identification, Triac-Interface PC Board

(PN 04834, Revision 0, SN 8503865 and higher) ............... .5-15

5-3. Triac PC Board Component Identification ..................... .5-19

5-4. Component Identification, Interface PC Board

(PN 04536, Revision 2, SN 8503864 and below) ............... .5-23

5-5. Automatic Wash Sequence ................................ .5-30

5-6. Microcomputer Scan Map ................................. .5-40

5-7. Electronics Control System ................................ .5-43

vi Rev. 4/96

SORVALL® Instruments Cellwashcr 2 Service

List of Tables (continued)

Table Page

6-1. Applications Troubleshooting Chart: False Negative Results ........ 6-3

6-2. Applications Troubleshooting Chart: False Positive Results ........ .6-4

6-3. Applications Troubleshooting Chart: Inconsistent Reaction

Strength ............................................. .6-5

7-1. Troubleshooting Chart: Drive Motor ......................... .7-2

7-2. Troubleshooting Chart: Power .............................. .7-3

7-3. Troubleshooting Chart: Saline Fill ........................... .7-4

7-4. Troubleshooting Chart: Decant .............................. 7-5

7-5. Troubleshooting Chart: Lid Latch ........................... .7-6

10-1. Suggested Spare Parts, CeUwasher 2 ......................... 10-2

10-2. CeUwasher 2 Assembly .................................... 10-3

10-3. Chassis and Component Assembly ........................... 10-7

10-4. Drive Motor Assembly ..................................... 10-13

Rev. n/90 vii/viii

SORVALL® Instruments Cellwasher 2 Service

Section 1. INTRODUCTION

This manual is a service guide for the Sorvall Cellwasher 2 Cellwashing

System. It contains descriptive information; preventive maintenance

procedures; mechanical and electrical theories of operation; applications

information; a troubleshooting guide; field procedures for repairs and

replacements; and an illustrated parts list for ordering replacement

parts.

1-1. Intended Users

This manual has been written for qualified service personnel who are

familiar with factory methods for performing repairs, adjustments and

calibrations. While the descriptive information and operating

procedures contained in this manual are useful to the cellwasher

operator, the replacement and calibration procedures (especially those

involving electrical circuitry) should be performed only by qualified

service personnel.

1-2. Warnings and Cautions

Warnings and cautions appear throughout the manual. Service personnel

are expected to be familiar with their meaning (see page ii) and to

read them before servicing an instrument.

1-3. Service Decontamination Policy

———————————————————————— WARNING ————————————————————————

Either biological or radioactive contamination of the

instrument and/or rotor can occur because of the samples

likely to be processed. Always be aware of this

possibility and take normal precautions. Use appropriate

decontamination procedures should exposure occur.

If an instrument or rotor that has been used with biohazardous material

requires servicing by DuPont personnel, either at the customer's

laboratory or at a DuPont facility, comply with the following procedure

to ensure the safety of DuPont personnel:

• Clean the instrument and/or rotor to be serviced of all

encrusted material, and decontaminate it prior to servicing by

the representative. There must be no radioactivity detectable

by survey equipment.

• Attach a completed Decontamination Information Certificate

(SORVALL Instruments Form No. IPDP-59) to the instrument or

rotor.

Rev. 11/90 1-1

Cellwasher 2 Service SORVALL® Instruments

If the instrument and/or rotor to be serviced does not have a

Decontamination Information Certificate attached, and in DuPont's

opinion presents a potential biohazard, the DuPont representative will

not service the equipment until proper decontamination and certification

is complete. If DuPont receives an instrument or rotor at its Service

facilities which, in DuPont's opinion is a biohazard/ the sender will

be contacted for instructions as to the disposition of the equipment.

Disposition costs will be borne by the sender.

Decontamination Information Certificates are included with these

instructions. Additional certificates are available from the local

Technical or Service Representative. In the event these certificates

are not available, a written statement certifying that the instrument

and/or rotor has been properly decontaminated and outlining the

procedures used will be acceptable.

NOTE

The Service Representative will note on the Customer

Service Repair Report if decontamination was required, and

if so, what the contaminant was and what procedure was

used. If no decontamination was required, it will be so

stated.

1-4. Warranty Responsibility

Whenever service of the instrument is attempted by anyone other than

an employee of DuPont or an authorized DuPont representative, the

individual performing the service is assuming the risk of voiding the

instrument warranty, which is as follows:

E. I. Du Pont de Nemours and Company makes no warranty of any

kind, expressed or implied, except as stated in this warranty

policy.

The Sorvall® Cellwasher 2 Cell Washing instrument and DA-12

Rotor are warranted to be free from defects in materials and

workmanship for a period of one (1) year from the date of

delivery. DuPont will, at its option, repair or replace and

return free of charge any part which is returned to its factory

within said period, transportation prepaid by user, and which

is found upon inspection to have been defective in materials

or workmanship. This warranty does not include normal wear

from use; it does not apply to any instrument or part which

has been altered by anyone other than an employee of DuPont,

nor to any instrument which has been damaged through accident,

negligence, failure to follow operating instructions, the use

of electric currents or circuits other than those specified

on the plate affixed to the instrument, misuse or abuse.

DuPont reserves the right to change, alter, modify or improve

any of its instruments without any obligation to make

corresponding changes to any instrument previously sold or

shipped.

1.2 Rev. 11/90

SORVALL® Instruments Cellwasher 2 Service

THE FOREGOING OBLIGATIONS ARE IN LIEU OF ALL OTHER OBLIGATIONS AND

LIABILITIES INCLUDING NEGLIGENCE AND ALL WARRANTIES/ OF

MERCHANTABILITY OR OTHERWISE, EXPRESSED OR IMPLIED IN FACT OR BY

LAW, AND STATE OUR ENTIRE AND EXCLUSIVE LIABILITY AND BUYER'S

EXCLUSIVE REMEDY FOR ANY CLAIM OR DAMAGES IN CONNECTION WITH THE

SALE OR FURNISHING OF GOODS OR PARTS/ THEIR DESIGN, SUITABILITY

FOR USE, INSTALLATION OR OPERATION. DUPONT WILL IN NO EVENT BE

LIABLE FOR ANY SPECIAL OR CONSEQUENTIAL DAMAGES, AND OUR LIABILITY

UNDER NO CIRCUMSTANCES WILL EXCEED THE CONTRACT PRICE FOR THE GOODS

FOR WHICH LIABILITY IS CLAIMED.

If there are any questions concerning the effect of service on the

warranty, contact the nearest representative of Sorvallo Instruments.

1-3/1-4

SORVALL® Instruments Cellwasher 2 Service

Section 2. DESCRIPTION, INSTALLATION and OPERATION

This section describes the Sorvall® Cellwasher 2 and provides speci¬

fications, installation information, and instructions for operating

the instrument.

2-1. Description of the Cellwasher 2

The SORVALL® Cellwasher 2 is designed to perform the washing phase of

the Coomb's Procedure automatically. The centrifuge and saline pump

are contained in one cabinet, with the operating controls on the front

panel.

The Cellwasher 2 is microprocessor-controlled, featuring a front panel

with sensor-touch controls and a digital timer for the wash cycle. Other

features include a saline detect system with an audible low-saline

warning and an agitate cycle that ensures complete resuspension of

cells and eliminates manual agitation.

2-2. Cellwasher 2 Specifications

Dimensions:

Width ............

Depth ............

Height, lid closed

Height, lid open .

Mass (Weight)

Electrical Requirements*:

Motor Type

Speed** for 60 Hz models:

Low

High

Decant

Speed** for 50 Hz models:

Low ...................

High ..................

Decant ................

31.8 cm (12.5 in)

35.6 cm (14.0 in)

36.8 cm (14.5 in)

57.2 cm (22.5 in)

16.4 kg (36.0 Ib)

115 V + 10%, 60 Hz, 5A

or

230 V + 10%, 50 Hz, 2A

3 speed induction

1150 to 1200 rpm

3500 to 3600 rpm

600 rpm

1450 to 1500 rpm

2950 to 3000 rpm

600 rpm

(continued)

2-1

Cellwasher 2 Service SORVALL® Instruments

Decibel .................................... 67 Db

Length of Modes:

Automatic ................................ Total cycle time 80

seconds

Manual ................................... High or low, optional,

up to 999 seconds if

timed; indefinite if

in HOLD

Tube Sizes:

Diameter ................................. 12 mm + 0.09 mm

or

10 mm + 0.09 mm*

Length ................................... 75 mm + 2 mm

Tube Material: ............................. High strength glass, such

as Pyrex® or Corex®

WARNING

Use only tubes which are guaranteed to be within the

specifications given above. If tubes outside these

specifications are used, test results will be affected,

the rotor and distributor could be damaged, and personal

injury could result.

2-3. Installation Information

a. Location

Place the Cellwasher 2 on a sturdy/ level bench or table near a sink,

drain, or waste container to receive decanted saline. The following

factors should be considered when selecting a location:

• Allow a 15 cm (6 inch) clearance behind the instrument for the

saline pump and tubing.

Allow a 61 cm (24 inch) clearance above the tabletop or bench

surface for the lid to open.

"Adapter Clips (PN 04330) are required when using 10 mm x 75 mm tubes in the DA-12 Rotor.

2-2 Rev. 11/93

SORVALL® Instruments Ccllwasher 2 Service

Drainage in the Cellwasher 2 is accomplished by gravity, so the

drain tubing must extend downward from the instrument to the

drain, sink, or waste receptacle.

The preferred location for the saline supply is either at or

above instrument level.

To obtain the best results, minimize tubing length from the

saline supply to the cellwasher.

CAUTION

Cooling air is drawn into the Cellwasher 2 from all four

sides of the base. Be sure that the entrances are not

obstructed.

If the saline supply reservoir is moved from its original location,

recheck the saline volume by priming the system as explained in

paragraph 2-4, b.

b. Electrical Requirements

The power cord for the Cellwasher 2 has a universal keyed plug that

inserts into a receptacle at the back of the instrument. The other end

must be connected to the appropriate power supply:

115 V + 10%, 60 Hz, 5A or 230 V + 10%, 50 Hz, 2.5A

as specified on the rating plate on the back of the instrument.

————————————————————— WARNING —————————————————————

The receptacle used should be a 3-wire system. If it is

not, the equipment must be grounded to earth to avoid the

possibility of electrical shock.

c. Tubing Installation

The Cellwasher 2 is shipped with the tubing already connected to the

instrument, but not installed in the peristaltic pump. To install the

tubing in the peristaltic pump, unwrap the bundle of tubing at the back

of the instrument and proceed as follows (refer to figure 2-1):

2-3

Cellwashcr 2 Service SORVALL® Instruments

1. Remove the four knurled thumbscrews from the peristaltic pump

and remove the front half of the pump housing. (Do not remove

the pump roller assembly.) Make sure that the pump rollers are

clean and move freely.

2. Turn the roller assembly so that one of the rollers is in the

11 o'clock position.

3. Without turning the rollers, place the pump tubing around the

rollers (the end with the connector should be on the left side) .

4. Pull up on the two ends of the pump tubing, and fit the tubing

into the pump housing around the rollers.

Figure 2-1. Cellwasher 2 Tubing Diagram

2-4 Rev. 4/96

SORVALL® Instruments Cellwasher 2 Service

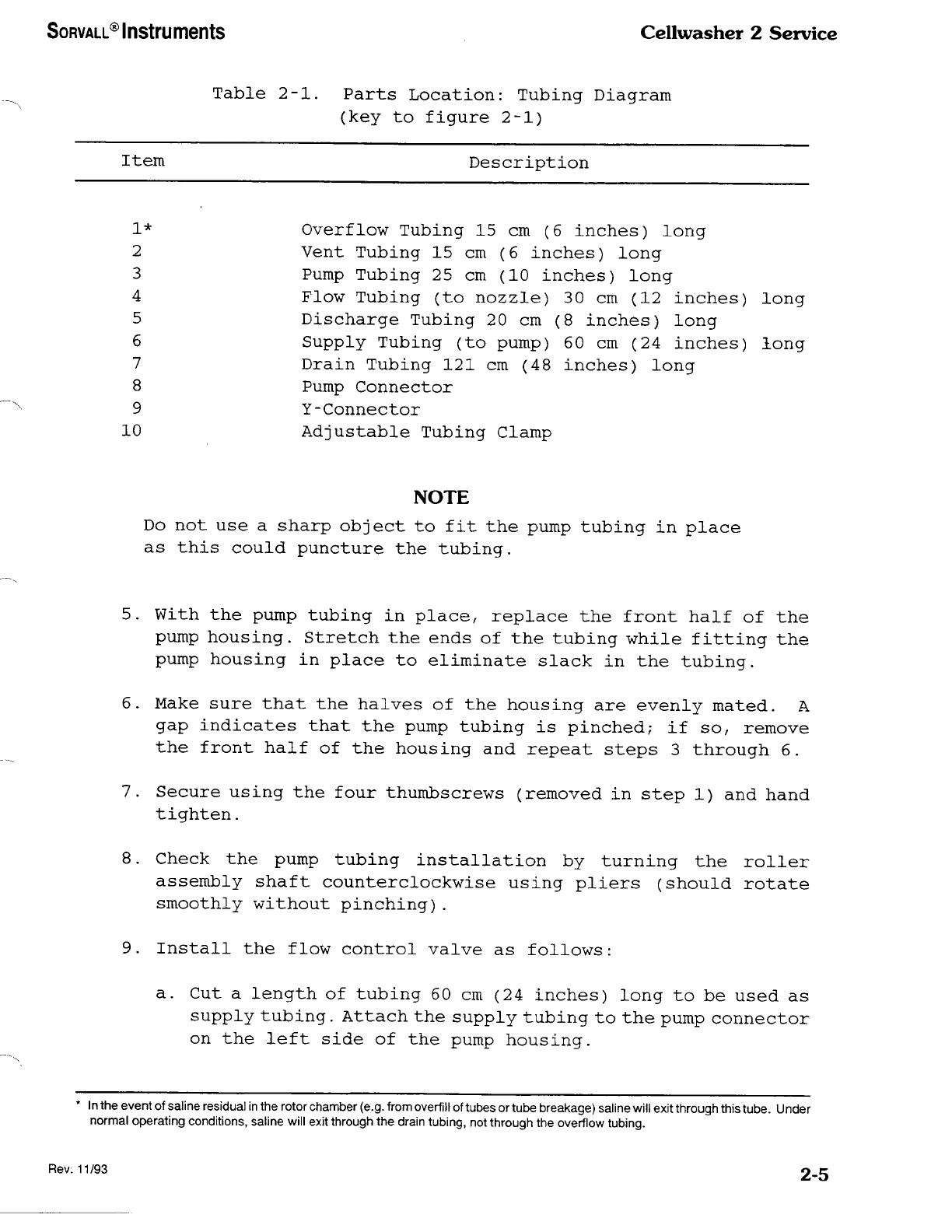

Table 2-1. Parts Location: Tubing Diagram

(key to figure 2-1)

Item Description

I*

2

3

4

5

6

7

8

9

10

Overflow Tubing 15 cm (6 inches) long

Vent Tubing 15 cm (6 inches) long

Pump Tubing 25 cm (10 inches) long

Flow Tubing (to nozzle) 30 cm (12 inches) long

Discharge Tubing 20 cm (8 inches) long

Supply Tubing (to pump) 60 cm (24 inches) long

Drain Tubing 121 cm (48 inches) long

Pump Connector

Y-Connector

Adjustable Tubing Clamp

NOTE

Do not use a sharp object to fit the pump tubing in place

as this could puncture the tubing.

5. With the pump tubing in place, replace the front half of the

pump housing. Stretch the ends of the tubing while fitting the

pump housing in place to eliminate slack in the tubing.

6. Make sure that the halves of the housing are evenly mated. A

gap indicates that the pump tubing is pinched; if so, remove

the front half of the housing and repeat steps 3 through 6.

7. Secure using the four thumbscrews (removed in step 1) and hand

tighten.

8. Check the pump tubing installation by turning the roller

assembly shaft counterclockwise using pliers (should rotate

smoothly without pinching).

9. Install the flow control valve as follows:

a. Cut a length of tubing 60 cm (24 inches) long to be used as

supply tubing. Attach the supply tubing to the pump connector

on the left side of the pump housing.

* In the event of saline residua] in the rotor chamber (e.g. from overfill of tubes or tube breakage) saline will exit through this tube. Under

normal operating conditions, saline will exit through the drain tubing, not through the overflow tubing.

Rev. 11/93 2-5

Cellwasher 2 Service SORVALL® Instruments

b. Place the valve over the supply line at a convenient point

and insert the end of the supply tubing into a saline supply

reservoir.

c. Connect the pump tubing from the right side of the pump

housing to the inlet port of the flow detector.

10.Into the adjustable tubing clamp located to the left of the

peristaltic pump, position the bottom leg of the Y-Connector

(with discharge tubing attached).

11. Holding the Y-Connector in place with one hand, fold the inner

strap over the Y-Connector/discharge tubing. Then, fold the

outer strap over the inner strap and push on the outer strap

to lock in place. You will hear a "click" when the clamp is

secured.

12 .Make sure the drain tubing flows downward to an open sink, drain,

or waste receptacle since drainage in the Cellwasher 2 is

accomplished by gravity. Use the shortest length of drain tubing

possible and make sure the tubing is positioned so there is no

upward travel to result in a "trap" for collected waste fluid.

13.Ideally, the drain tubing should be positioned so that it can

not become immersed in collected waste fluid. However, if there

is a possibility that the drain tubing will become immersed in

waste fluid, cut the drain tubing at a convenient point near

the waste receptacle and insert the Y-Connector. Always insert

a Y-Connector in the drain line when using a waste container

for discharged saline.

NOTE

The Y-Connector prevents pressure from building up in

the line due to submerged tubing or air blockage. Failure

to vent the drain tubing by installing a Y-Connector can

result in improperly decanted samples.

If the saline supply reservoir is moved from its original

location, recheck the saline volume by priming the system

as explained in paragraph 2-4, b.

14.If necessary, use additional tubing and connectors from

the Tubing Kit to supply saline and discharge waste

properly.

2-6 "s"-4/^

SORVALL® Instruments Ccllwasher 2 Service

WARNING

Saline solution from some manufacturers contains sodium

azide as a preservative. If this solution is discharged

directly down the drain, explosive azide salts may form

as the sodium azide reacts with the plumbing. Check with

your saline supplier before discharging saline from the

Cellwasher 2 into a drain.

CAUTION

All saline solutions have long term corrosive effects.

Routine cleaning and maintenance (as described in Section

3) are essential to ensure safe and efficient operation

of the Cellwasher 2.

d. DA-12 Dual Angle Rotor and Distributor Installation

1. Open the lid of the Cellwasher 2.

———————————————————— WARNING ————————————

All Sorvall® Cellwashers manufactured prior to February

1984 were supplied with a plastic rotating bowl assembly

which required annual replacement. All plastic rotating

bowl assemblies are more than one (1) year old and should

be removed from service and discarded immediately. Failure

to do so can result in damage of equipment and/or personal

injury. Replace the plastic rotating bowl assembly with

a stainless steel rotating bowl assembly (PN 12796).

NOTE

There may be one or more holes in the stainless steel

rotating bowl assembly (PN 12796). These holes are for

balancing purposes only and will not effect the perform¬

ance of the stainless steel rotating bowl.

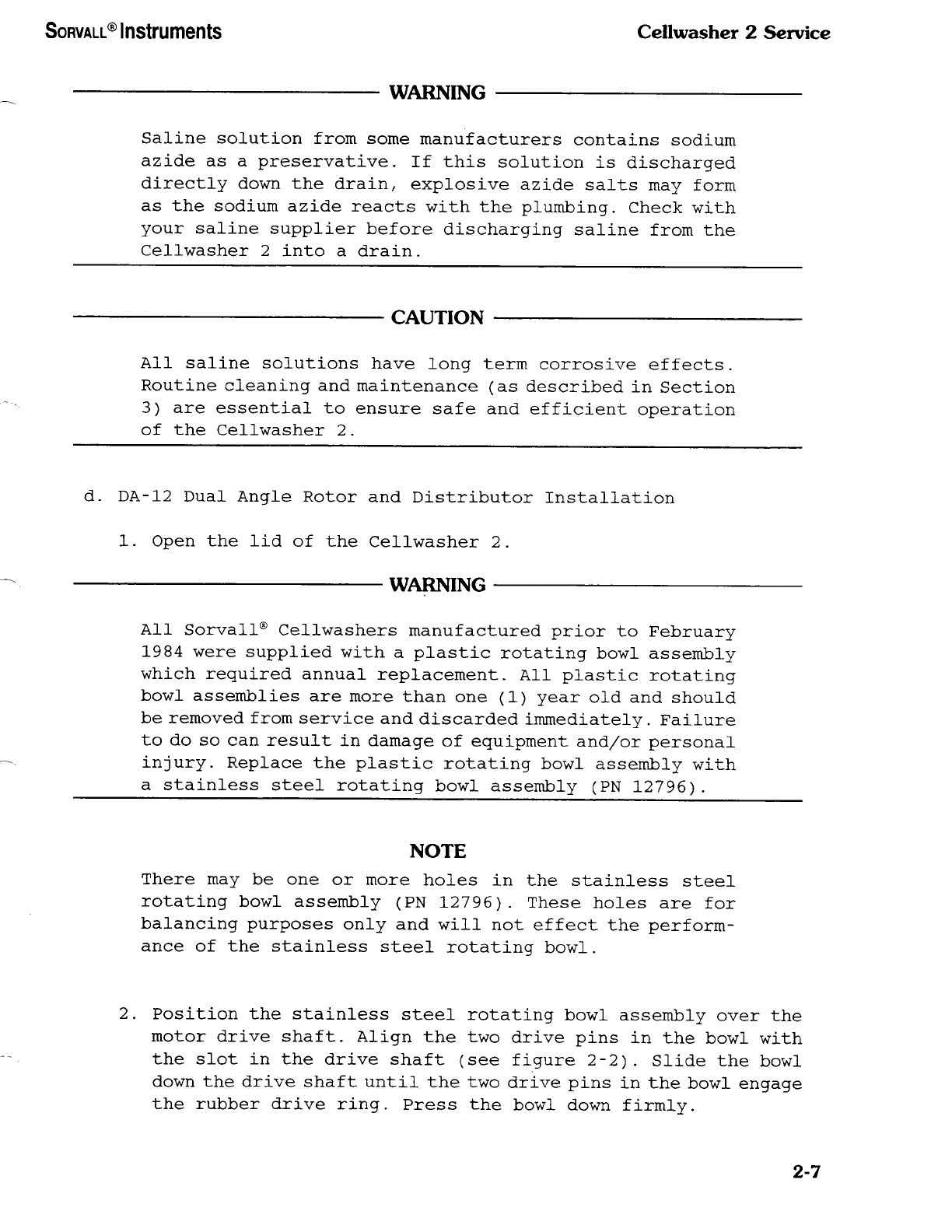

2. Position the stainless steel rotating bowl assembly over the

motor drive shaft. Align the two drive pins in the bowl with

the slot in the drive shaft (see figure 2-2). Slide the bowl

down the drive shaft until the two drive pins in the bowl engage

the rubber drive ring. Press the bowl down firmly.

2-7

Cellwasher 2 Service SORVALL® Instruments

MOTOR DRIVE

SHAFT

SLOT

ALIGNMENT

STAIN LESS STEEL

ROTATING BOWL

ASSEMBLY

DRIVE PINS

Figure 2-2. Stainless Steel Rotating

Bowl Installation

3. Slide the DA-12 Rotor over the drive shaft and lower it gently

into the rotating bowl.

4. Hold the edge of the rotating bowl and turn the rotor slowly

until the drive pins in the rotating bowl engage the rotor and

the rotor drops down onto the rotating bowl.

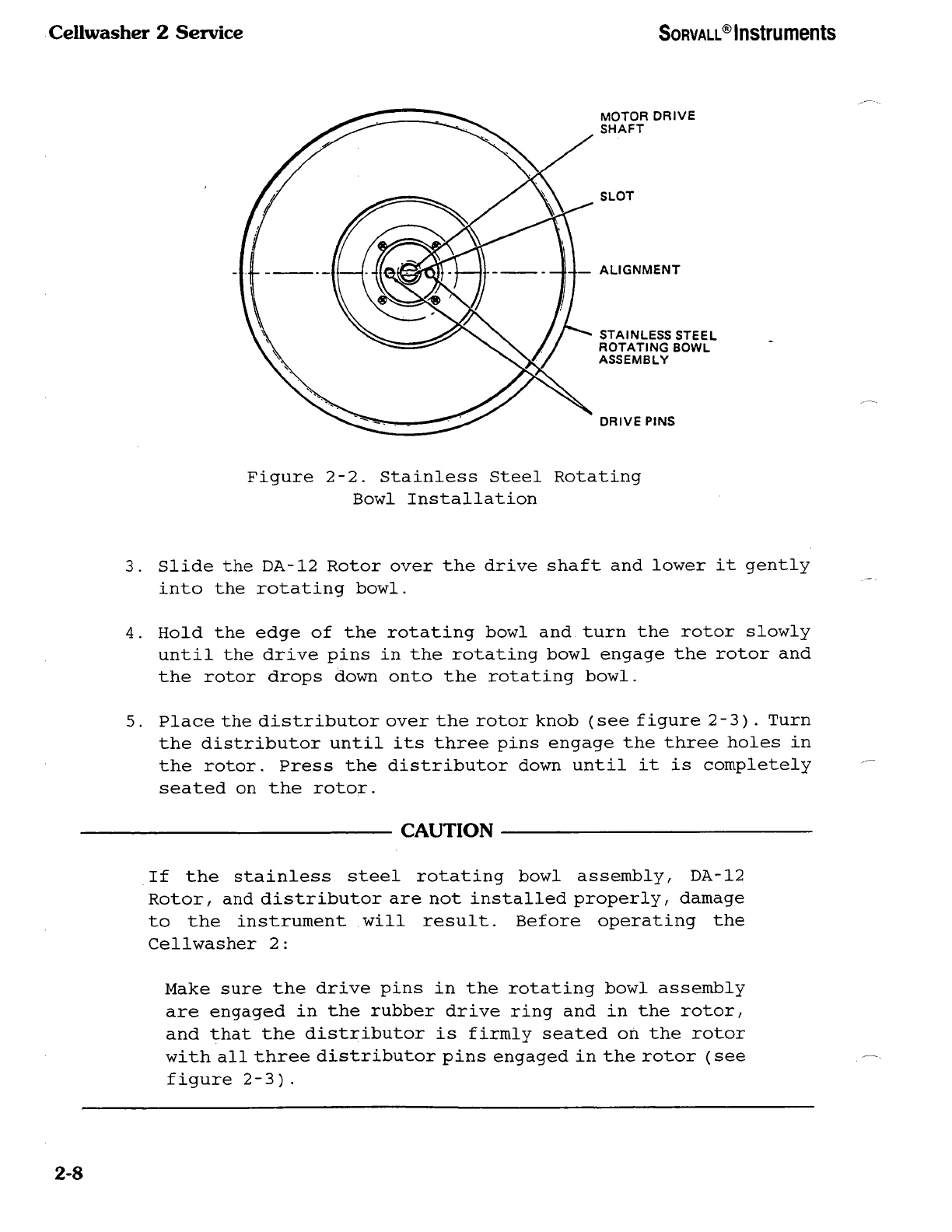

5. Place the distributor over the rotor knob (see figure 2-3) . Turn

the distributor until its three pins engage the three holes in

the rotor. Press the distributor down until it is completely

seated on the rotor.

CAUTION

If the stainless steel rotating bowl assembly, DA-12

Rotor, and distributor are not installed properly, damage

to the instrument will result. Before operating the

Cellwasher 2:

Make sure the drive pins in the rotating bowl assembly

are engaged in the rubber drive ring and in the rotor,

and that the distributor is firmly seated on the rotor

with all three distributor pins engaged in the rotor (see

figure 2-3).

2-8

SORVALL® Instruments Cellwasher 2 Service

DISTRIBUTOR

CANNULA

DISTRIBUTOR

PIN

ROTOR

KNOB

DUAL

ANGLE

ROTOR

Figure 2-3. Distributor Installation

e. Rotor Loading and Balancing:

The Cellwasher 2 can process any balanced load up to twelve tubes. When

using less than a full complement of tubes, place the tubes in opposing

compartments to ensure that the rotor is symmetrically balanced. The

volume of saline delivered through the distributor will be the same/¬

at the locations without tubes, saline will be centrifuged into the

basin and drained off.

WARNING

Use only tubes which are guaranteed to be within the

specifications given in paragraph 2-2. If tubes outside

these specifications are used, test results will be affected,

the rotor and distributor could be damaged, and personal

injury could result.

Rev. 11/93 2-9

Cellwasher 2 Service SORVALL® Instruments

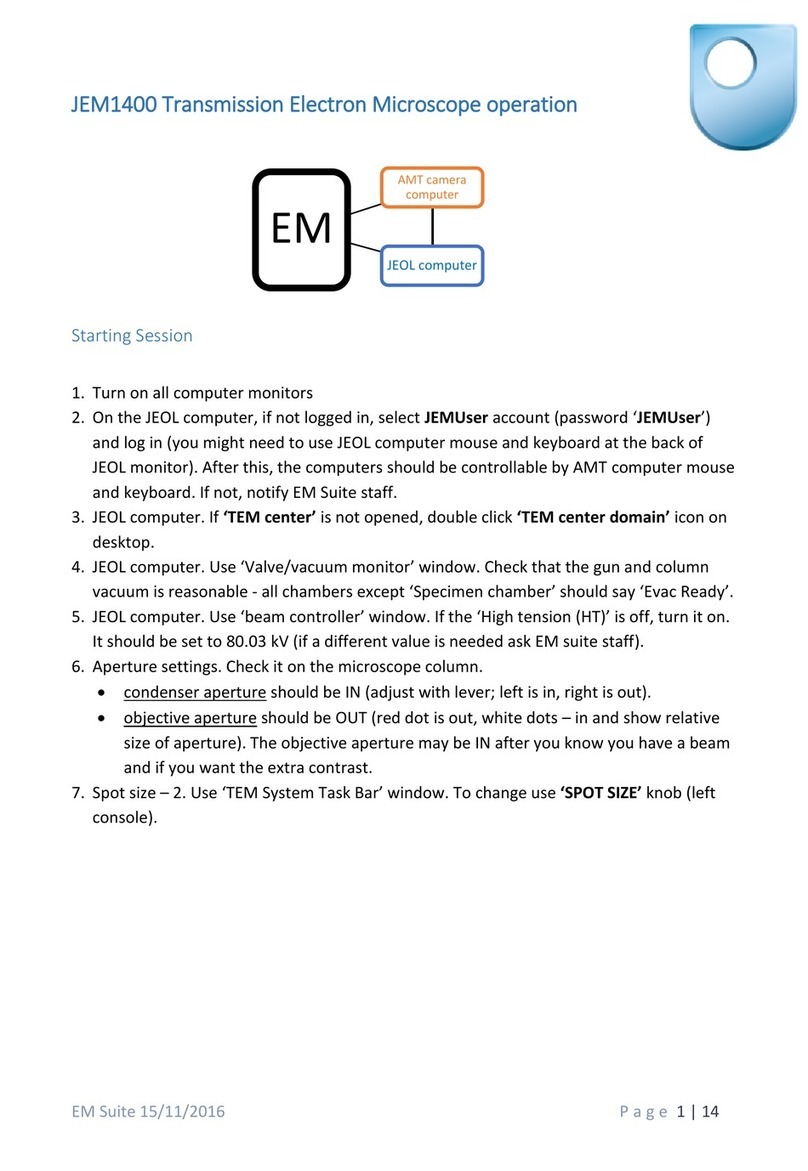

2-4. Cellwasher 2 Operation

a. Controls and Indicators

All controls and indicators for the Cellwasher 2/ except the power

switch, are located on the front panel keyboard. The sensor-touch

controls register commands visually and/or audibly.

Power to the instrument is controlled by a switch located in the lower

right hand corner of the cellwasher, beneath the keyboard. The symbol

"1" indicates ON while the symbol "0" indicates the OFF position.

Switching the power off erases any manually programmed spin times from

the memory.

Table 2-2 describes the controls and indicators on the front panel.

Figure 2-4 shows their locations on the keyboard.

20 19 18 16 17 15 14 13

Figure 2-4. Cellwasher 2 Controls and Indicators

*LED, or light emitting diode, refers to the small amber light adjacent to the panel button.

2-10

Other Sorvall Laboratory Equipment manuals

Popular Laboratory Equipment manuals by other brands

Organomation

Organomation MICROVAP 11801 instruction manual

Topcon

Topcon Compu-Vision CV-5000 Repair manual

Heidolph

Heidolph VV Micro instruction manual

AMA Instruments

AMA Instruments The GC 5000 BTX operating manual

TQC Sheen

TQC Sheen SP7310 operating instructions

IKA

IKA RH basic 1 operating instructions

Carl Roth

Carl Roth ROTIPHORESE PROfessional Acetate Instructions for use

MixRite

MixRite 12500 user manual

Image Engineering

Image Engineering CAL3-XL user manual

JENTNER

JENTNER DIGITAL II operating instructions

Fisher Scientific

Fisher Scientific 04-978-229 instructions

Peak Scientific

Peak Scientific Precision Hydrogen installation guide