3, Hagavish st. Israel 58817 Tel: 972 3 5595252, Fax: 972 3 5594529

Section 5

OPERATION

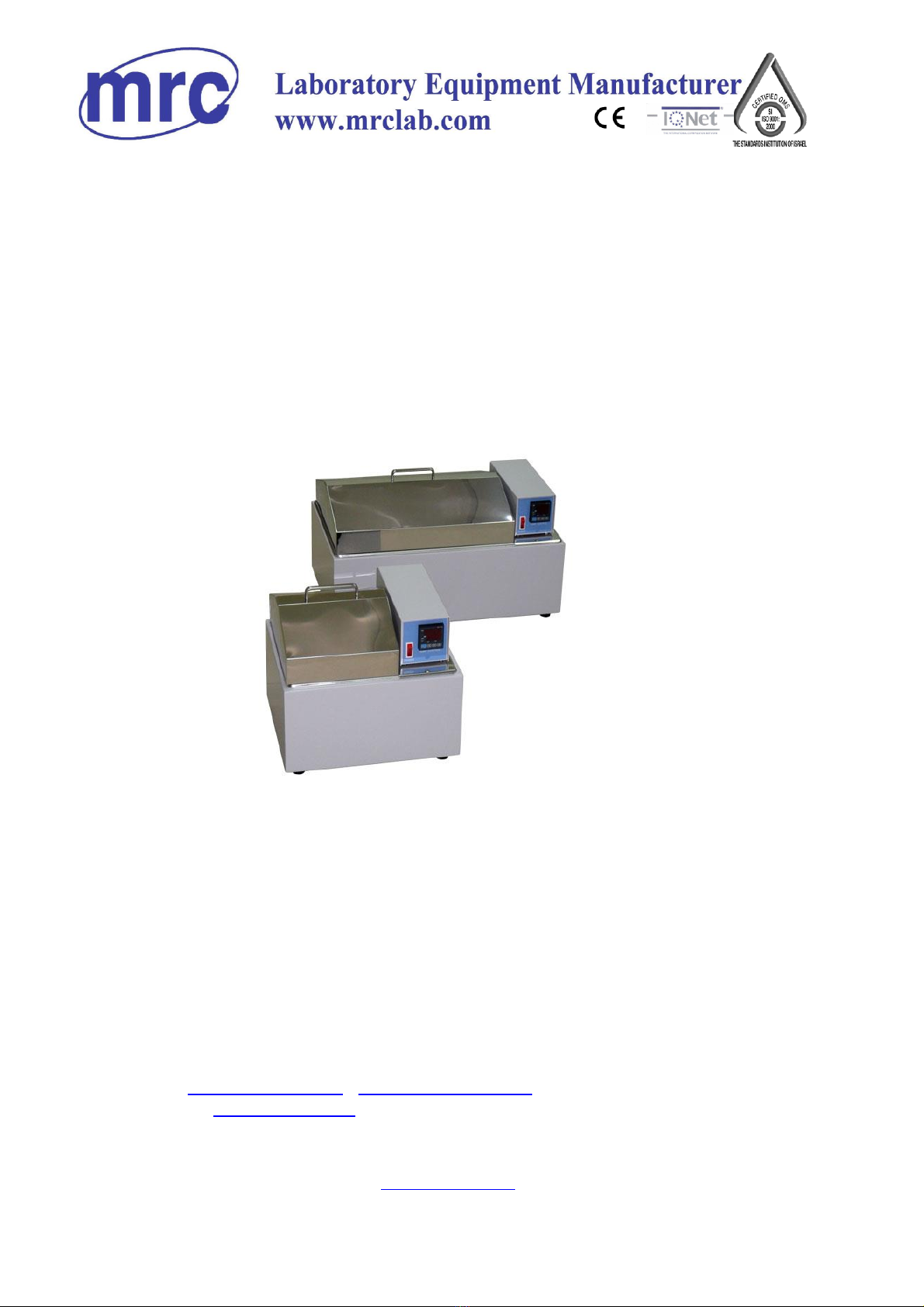

Warning: These baths are not intended for use as acid baths. Use as an acid

bath will cause severe damage to bath components and void your warranty. Do

not use deionized water, tap water, or chemicals. USE DISTILLED WATER

ONLY.

Turning On the Unit

To turn on the unit, perform the following steps:

1. Check power supply against unit serial plate; they must match.

2. Plug service cord into the electrical outlet. If supplied with a detachable

cordset, plug the female end into the unit inlet and the male plug into the power

supply. 3. Fill bath to your required depth with DISTILLED WATER.

DO NOT USE TAP WATER, DEIONIZED WATER, OR CHEMICALS. Normal

depth is 5 ½ inches (14 cm), but depth must be at least 4.7 inches (12 cm) over

the bottom of the rack. Check water level frequently, add water to appropriate

levels if needed. At higher operating temperatures, or under circumstances

where a cover cannot be used, it will be necessary to check the water level

more frequently.

4. Push the Main power switch to the ON position.

Bath Cover

Using the bath cover supplied with your accessories will accelerate heat-up time

and reduce evaporation.

The cover must be used to reach set points above 60ºC. The bath cover is not

designed to be airtight and create a pressurized environment.

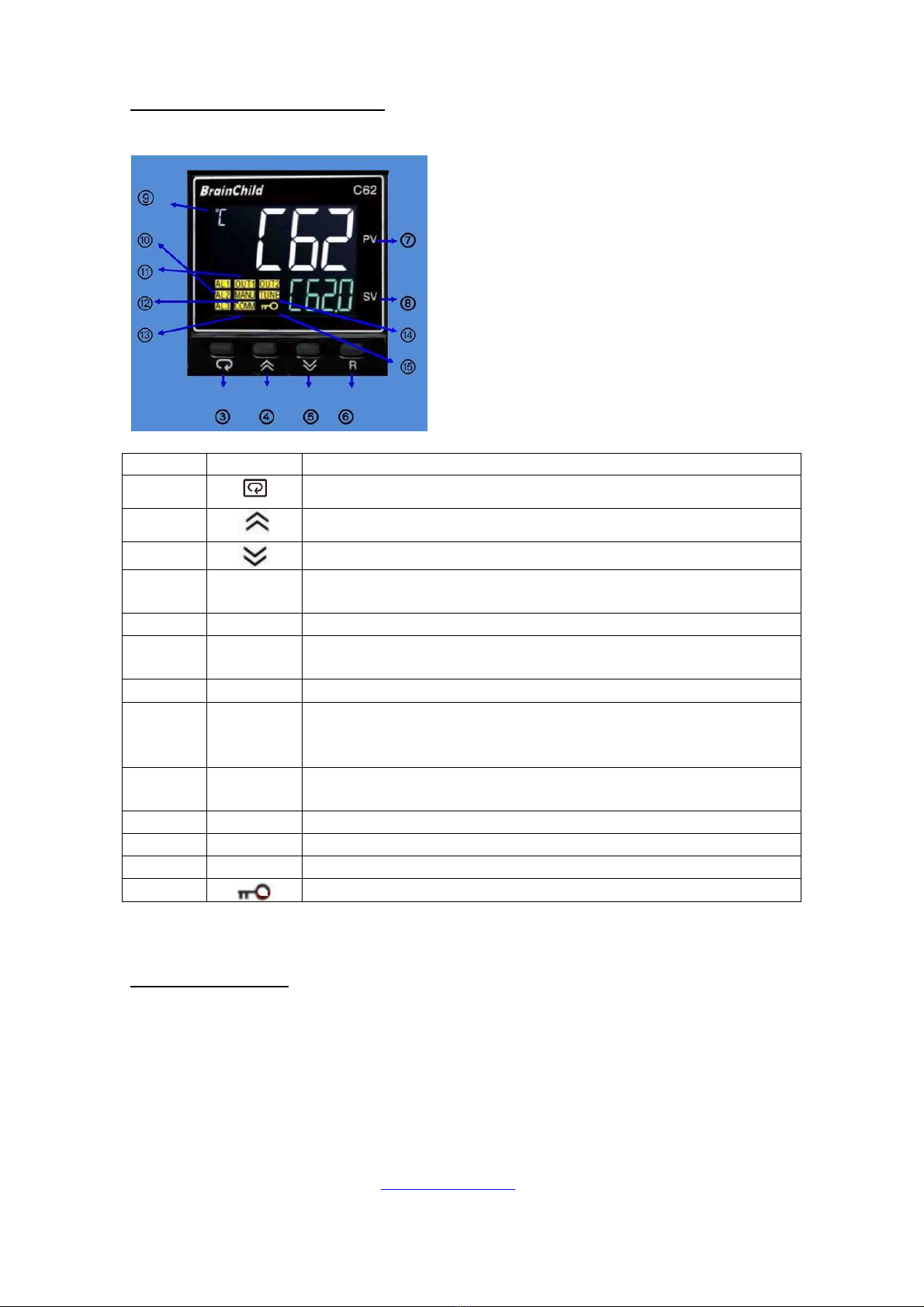

Setting Main Temperature Control

Turn on the temperature controller/power switch. The temperature displays light

up and after a few seconds, the upper display shows the present value (PV)

temperature. The lower display shows the set value (SV) or set temperature.

To enter set point mode on the control, push and release either the UP or

DOWN arrow pad one time and the digital display will start to blink.

Press to increase temperature gradually.

Press to decrease temperature gradually.

While blinking, the digital display shows the set point that can be changed.

Allow at least two (2) hours for the temperature to stabilize.

Warning: If the tank boils dry while containing plastic ware, the plastic will melt.

If you intend to use test tube racks, remember that plastic coated wire racks

may wear and expose metal that can cause damage. Preferably, use all plastic

racks.

Note: The heating element of this bath does not contact the tank bottom and

burn out if the tank is allowed to run dry.

Never turn on the unit if the tank is empty from water or if the water level is

too low