SoundWater Camano Manual

SoundWater CamanoTM

Fluid flow sensing, redefined

Transit Time Ultrasonic Flowmeter

Instruction Guide

For Camano

Camano Instructions

2SoundWater Technologies, LLC

Contents

General Information Page

General Information ........................................................................3

Meter Features ............................................................................3

Specifications..............................................................................4

Dimensions................................................................................5

Technology ................................................................................6

Getting Started

App Features ..............................................................................8

Connecting Power & Communications ........................................................9

Wiring Diagrams ..........................................................................10

App Installation ...........................................................................12

Parameter Set Up .........................................................................13

Flowmeter Installation

Straight Pipe Recommendations ............................................................14

Full Pipe Recommendations ................................................................15

Flowmeter Orientation .....................................................................15

Transducer Spacing .......................................................................16

Installing the Flowmeter ...................................................................17

Do’s and Don’ts ...........................................................................17

Operation

Collecting Your Data .......................................................................18

Data Logging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Explanation of Recording Times............................................................ 20

Troubleshooting

Troubleshooting Guide .....................................................................21

This device complies with Part 15 of FCC Rules and Industry Canada license-exempt RSS standard(s). Operation is subject to the following two conditions: (1) this device may not cause

harmful interference, and (2) this device must accept any interference received, including interference that may cause undesired operation. Contains FCC ID: XDULE40-S2, Contains IC:

8456A-LE4S2. CAN ICES-1/NMB-1; CAN ICES-3 (B)/NMB-3(B)

MODEL: SWT CAMANO-01

Contents

1-509-899-7838 :: soundwatertech.com 3

General Information

General Information

When you want accurate, reliable and dedicated flow

measurement quickly—with minimum set up time and

maximum ease of use, in a wide range of applications—

here’s your device.

Meet SoundWater Camano.

Ultrasonic. Installs outside the pipe. And as easy to use as

a typical mobile app.

What is Camano?

New from SoundWater, Camano is a powerful, dedicated

ultrasonic flowmeter that’s accurate, easy to use, and

a snap to set up—and that’s just for starters. Camano

is engineered to accept ongoing enhancements as

applications and capabilities evolve.

Quick to install. Flexible brackets let you quickly and

easily wall-mount the Camano control unit. The Camano

Sensor mounts quickly and easily—outside the pipe—using

standard straps.

Connect with SCADA & PLC. Camano can deliver a range

of outputs, including 4–20 mA, 1–10 V, pulse, and to your

automated systems. You can also set digital alarms for

high/low flow, open circuit, and low signal events. Use

the built-in USB port for thumb drive-based data logging

downloads at any time.

Works with cellular data. Simply combine Camano with

the Ayyeka Wavelet TM to seamlessly transmits flow data

from your Camano using mobile networks—and you

access your data through any web browser.

Easy to use. The built-in, touchscreen is your access

to the Camano app, with its familiar Android-app user

experience. Swipe, tap, scroll, and (if needed) use an on-

screen keyboard to specify application parameters.

Pre-set menus, plain-language dialogs, and intuitive

navigation let you easily choose from pre-loaded pipe and

fluid data (or enter your own)—no more complex codes or

cumbersome instructions. In seconds, Camano displays

optimal transducer spacing and flow measurements.

Next, quickly install the Camano Sensor on the pipe,

secure power and data output wiring, and you’re ready

to monitor, log, and output to data collection systems.

Start viewing flow directly on the built-in touch screen

and instantly toggle between flow volume and rate with a

simple swipe.

Along with fast, easy installation and set up—and no

need to break pipe—Camano works with a wide range of

applications. With Camano’s ultrasonic technology, you

(and your automated systems) can get started tracking

flow quickly and easily.

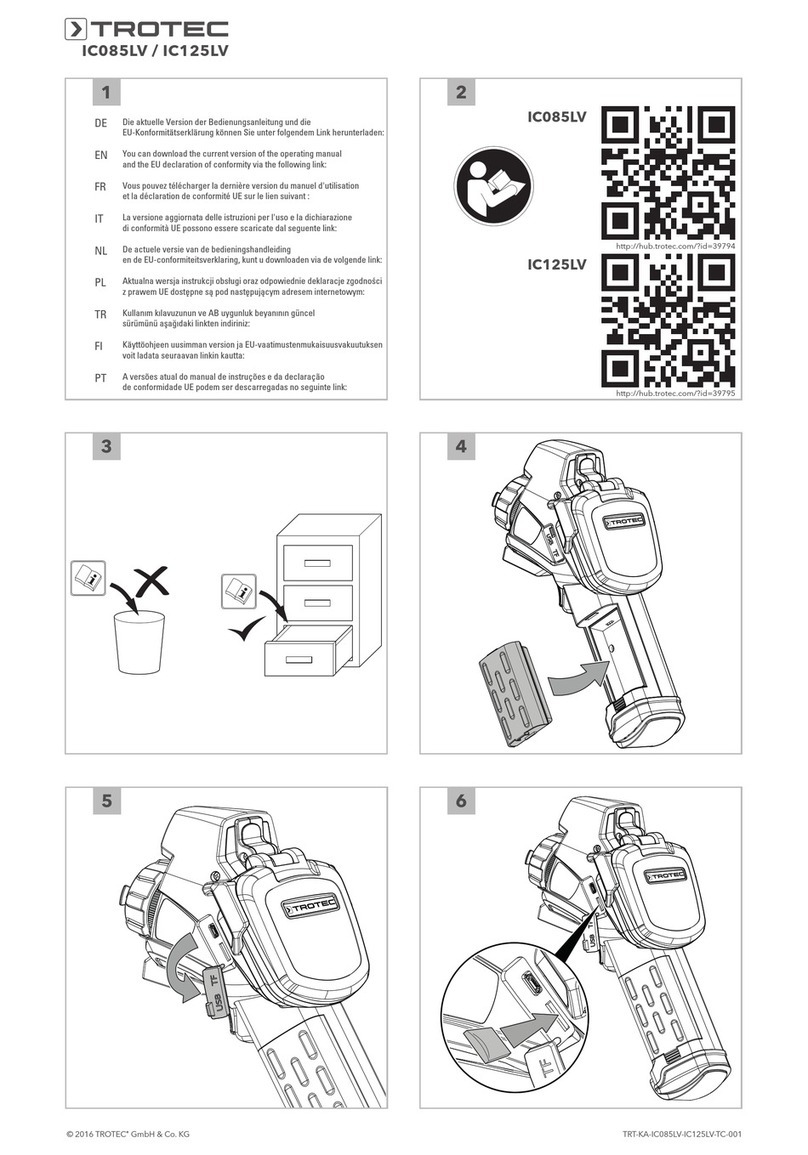

Meter Features & Control Unit

Moveable acoustic transducer

Cable strain relief / conduit connection

Anodized aluminum channel

Hose clamp

slot with

quick release

Rugged acetal end

housing and foot

Integrated ruler

Fixed acoustic

transducer

Bi-directional

flow sensing

All Camano models include the features as shown below.

Easy

mount

bracket

Color touch

screen display

Power and Outputs

(4-20 mA, 1-10 Volt,

Pulse, Digital Alarm

Camano Instructions

4SoundWater Technologies, LLC

Camano Specifications*

General Information

Installation 15 pipe diameters upstream, 5 diameters downstream for optimal performance (typical)

Flow Detection Bi-directional; 0.1 /s to 20 /s (0.03 m/s to 6 m/s)

Pipe Size 1" to 24" (nominal)

Performance PIPE SIZE ACCURACY OPERATING RANGE REPEATABILITY

3” to 24” ±1.0% to 2.0% typical -20 to 20 /s (-6 to 6 m/s) 0.5%

1” to 2” ±2.0% to 3.0% typical -20 to 20 /s (-6 to 6 m/s) 0.5%

*Under standard conditions, assuming fully developed and symmetrical flow profile (typically taken on a straight run of 15

diameters upstream and 5 diameters downstream; flow rate above 3 /s or 1m/s; non-aerated liquids).

If the equipment is used in a manner not specified by the manufacturer, the protection provided by the equipment may

be impaired.

Turndown 200:1

Environmental IP65 splash proof; weather and corrosion resistant

Materials CONTROL BOX

Polycarbonate enclosure, glass touch screen, stainless steel circular connector, nickel plated

brass USB connector, nickel plated brass transducer connector, EPDM rubber

BACKPLATE

Stainless steel

TRANSDUCER ASSEMBLY

Anodized aluminum housing, acetal footings, aluminum transducer strain relief, PVC strain relief,

EPDM O-rings, EPDM strain relief gasket, stainless steel fasteners, epoxy silk screen, PVC coaxial cable,

nickel plated brass coaxial cable connectors

MOUNTING STRAPS

Stainless steel

Temperature Ambient & Fluid: -20˚ to 150˚ F (-29˚ to 65˚ C)

Data Logging Built-in; export via USB thumb drive; maximum data samples: 100,000

Display Android-based touchscreen user interface; backlit; 20+ year lifetime with power save mode

3+ year lifetime with full-power, continuous use

Metric and English units

Soware Android OS/Android-based app; easy soware updates via USB thumb drive

Power 12-24 V DC or AC, external power; 400mA typical@20 V, 1 A inrush

Recommended external AC-DC converter part #PLUS ML30.241

Security 6-digit passcode protects configuration/set up, volume reset, and data logging

Specifications continued on next page

* Specifications subject to change.

1-509-899-7838 :: soundwatertech.com 5

Specifications continued on next page

Outputs NOTE: The isolation for all outputs is as a group; that is, all of the outputs share a common reference.

CURRENT (4-20 MA)

Isolated 4-20 mA, directly proportional to flow—4 mA/zero flow (fixed),

20 mA/user programmable flow. Accuracy (linearity): 16-bit (15 ppm);

VOLTAGE (1-10 VDC)

Isolated 1–10 Vdc, directly proportional to flow—0 V/zero flow (fixed),

10 V/user programmable flow.

PULSE

Isolated, NFET (NPN type) open drain output with a frequency directly proportional to flow

Maximum frequency: 10 kHz; mark: space ratio = 50.0: 50.0 (accurate to < 1 ppm)

DIGITAL ALARM

Isolated, NFET (NPN type) open drain output, configured to change state at any user-selected

combination of: (1) high flow, (2) low flow, (3) poor acoustic signal (e.g., empty pipe, disconnected

transducers, etc.), (4) open 4-20 mA circuit

Manufacture United States

Camano Specifications* — continued

General Information

* Specifications subject to change.

Dimensions

For 8" to 24" pipe (requires two) For 1" to 4.5" pipe

For 2" to 12" pipe

6.09" (15.47 cm) 11.34" (28.80 cm)

2.37"

(6.02cm)

3.9"

(9.78 cm)

15.07" (38.28 cm)

Camano Instructions

6SoundWater Technologies, LLC

Technology

The transit time flowmeter operates by alternately transmitting and

receiving a burst of sound energy between the two transducers.

The burst is first transmitted in the direction of fluid flow

and then against fluid flow.

Since sound energy in a moving liquid is carried faster when it travels in the direction of fluid flow (downstream) than it

does when it travels against fluid flow (upstream), a dierence in the travel times will occur. The sound’s travel time is

accurately measured in both directions and then used to compute the flow rate.

Sound waves can bounce in many directions as they travel through various materials. The more the sound waves scatter,

the fewer actually reach the second transducer. The Camano uses sophisticated methods to maximize transducer

eciency, thus allowing the unit to run on very low power. Focusing of the sound wave is also important to ensure it

reaches the second transducer without degrading. This is accomplished by accurately spacing the transducers to allow

for optimum sound transit between transducers. The Camano app computes this spacing based on the pipe size, pipe

material, and type of liquid.

Transit time technology works best in clean or mildly dirty water or fluids with minimal turbulence or flow distortion.

General Information

1-509-899-7838 :: soundwatertech.com 7

Camano Instructions

8SoundWater Technologies, LLC

Getting Started

The Camano Control Unit and Camano App Features

Camano Features

Easy to Mount

Camano comes with an easy-mount wall bracket

that puts your control unit right where you need it,

yet out of the way—in just a few minutes.

Easy to Connect

Use the included cable to connect the control

unit to the Camano Sensor (transducers). Power

connections are just as easy—cable is included—

and linking to your automated systems is both fast

and flexible.

Easy to Set up

The full-color Camano App and extensive, built-in

parameter libraries help you easily specify pipe,

fluid and other values—then shows you how to

space transducers.

App Features

Android-based, interactive touchscreen

Easy configuration for 4-20 mA, 1-10 Vdc,

pulse, and digital alarms

Built-in data logging

Programmable alarms

Select from a wide range of fluids

and pipe types

Flexible control unit mounting and

connections

Backlit for maximum visibility in

darkness or sunlight

English or metric units

Complete monitoring and data

Output flow data—in a range of analog or digital

formats—plus alarms/alerts can be automatically

transferred to your automated systems. Download

data logs any time with a thumb drive.

Cellular Data & IoT Web Interface

For remote applications (or where hard-wired

communication is impractical), make Camano an

IoT device by adding the Ayyeka Wavelet. Wavelet

seamlessly transmits flow data from your Camano

using mobile networks—and you access your data

through any web browser.

Ongoing enhancement

Upgrade your Camano with ease—just download

the latest soware and load it to the control unit

with a thumb drive. You’ll always have the latest,

most capable version.

Easy mount bracket

To transducers Power and Out-

puts (4-20 mA,

1-10 Volt, Pulse,

Digital Alarm

1-509-899-7838 :: soundwatertech.com 9

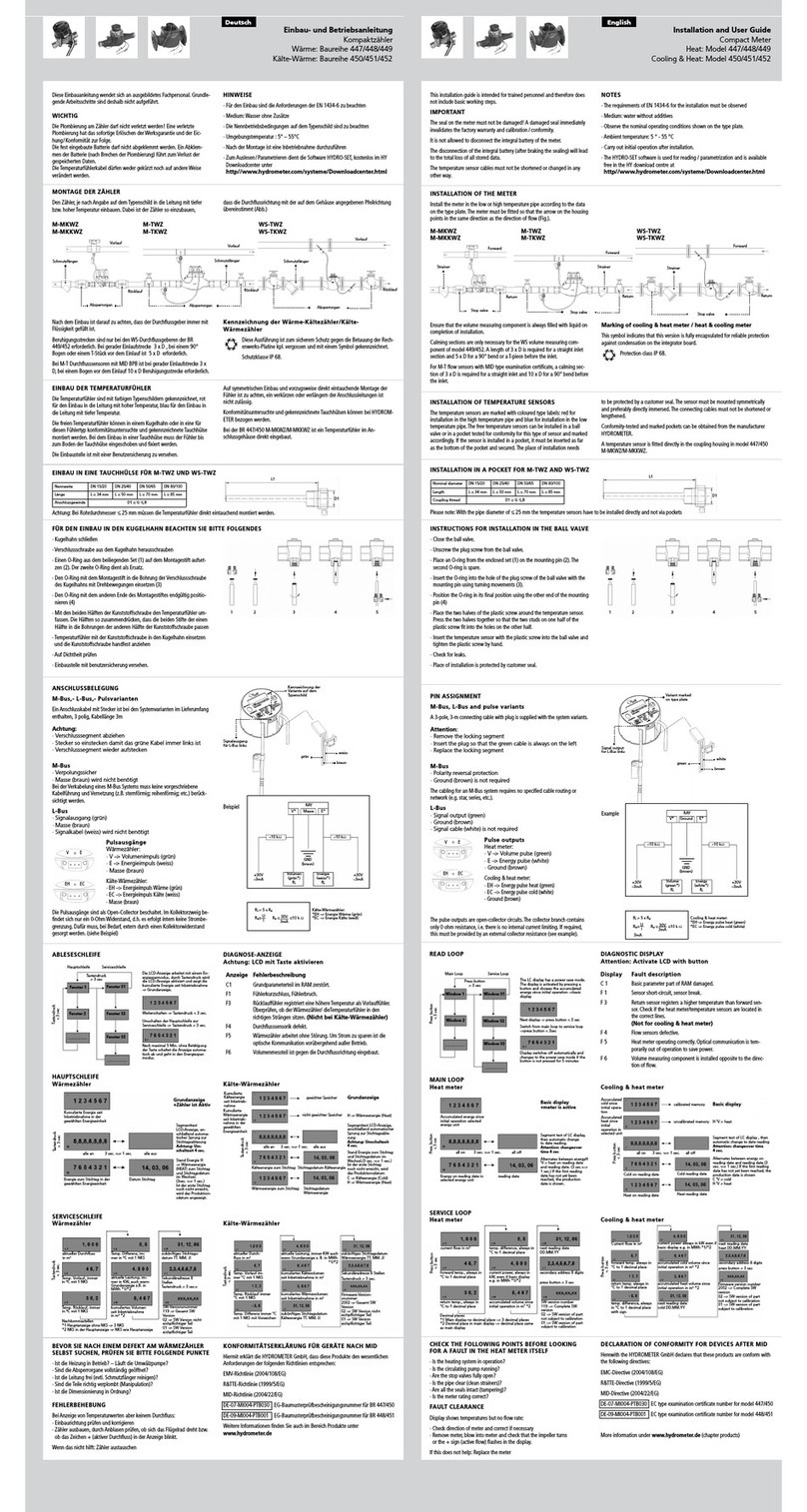

Connecting to Power & Communications

Getting Started

Getting StartedControl Box

9.23"

(23.44 cm)

7.5"

(19.08 cm)

4.63" (11.76 cm)

Control Box, bottom view

ø .31" (.78 cm)

Mount the Control Unit

Camano comes with an easy-mount wall bracket. The

flexible brackets let you quickly and easily wall-mount the

Camano control unit.

Connect to a Power Source

Connect the supplied cable to your 12-24V DC or AC

power, by attaching the red wire to the positive supply

terminal, and the black wire to the 0V terminal.

For all wired connections, check the wire color code table,

and pinout diagrams below for proper set up. Also, refer

to wiring diagrams on the following pages for guidelines.

If not using the supplied cable for wiring power and

communications, be sure to use a compatible part to

Turk USA # RKSV 12T.

Once power and communications have been wired

properly. Plug the power and communications cable into

the flowmeter display at the mating circular connector.

Supplied Cable Pinout:

1 Analog & digital isolated ground 0V

2 NC

3 Pulse output, open drain

4 4-20mA output

5 NC

6 NC

7 0-10V output

8 Power 12-18V DC or AC

9 Alarm output, open drain

10 NC

11 Power ground 0V

12 NC

Flowmeter Display Pinout:

Wiring Color Definitions:

Camano Instructions

10 SoundWater Technologies, LLC

User Digital Input Device SoundWater Flowmeter

+ DC powerPowerDigital & Analog Gnd

White wire, Pin 1

Common

Digital input Alarm

Orange wire, Pin 9

User Digital Input Device SoundWater Flowmeter

Digital input

Power

Digital & Analog Gnd

White wire, Pin 1

+ DC power

Common Alarm

Orange wire, Pin 9

R

User Digital Counter SoundWater Flowmeter

+ DC powerPowerDigital & Analog Gnd

White wire, Pin 1

Common

Digital input Alarm

Green wire, Pin 3

Wiring

Alarm Output (sourcing input)

Alarm Output (sinking input)

Pulse Output (sourcing input)

Getting Started

1-509-899-7838 :: soundwatertech.com 11

User Digital Counter SoundWater Flowmeter

+ DC powerPowerDigital & Analog Gnd

White wire, Pin 1

Common

Digital input Alarm

Green wire, Pin 3

User Current Input Devic

eS

oundWater Flowmeter

Current input 4-20mA Output

Yellow wire, Pin 4

0 V Digital & Analog Gnd

White wire, Pin 1

User Voltage Input Device SoundWater Flowmeter

Voltage input 0-10V Analog Output

Blue wire, Pin 7

0 V Digital & Analog Gnd

White wire, Pin 1

Pulse Output (sinking input)

4-20mA Analog Output

0-10 V Analog Output

Getting Started

Camano Instructions

12 SoundWater Technologies, LLC

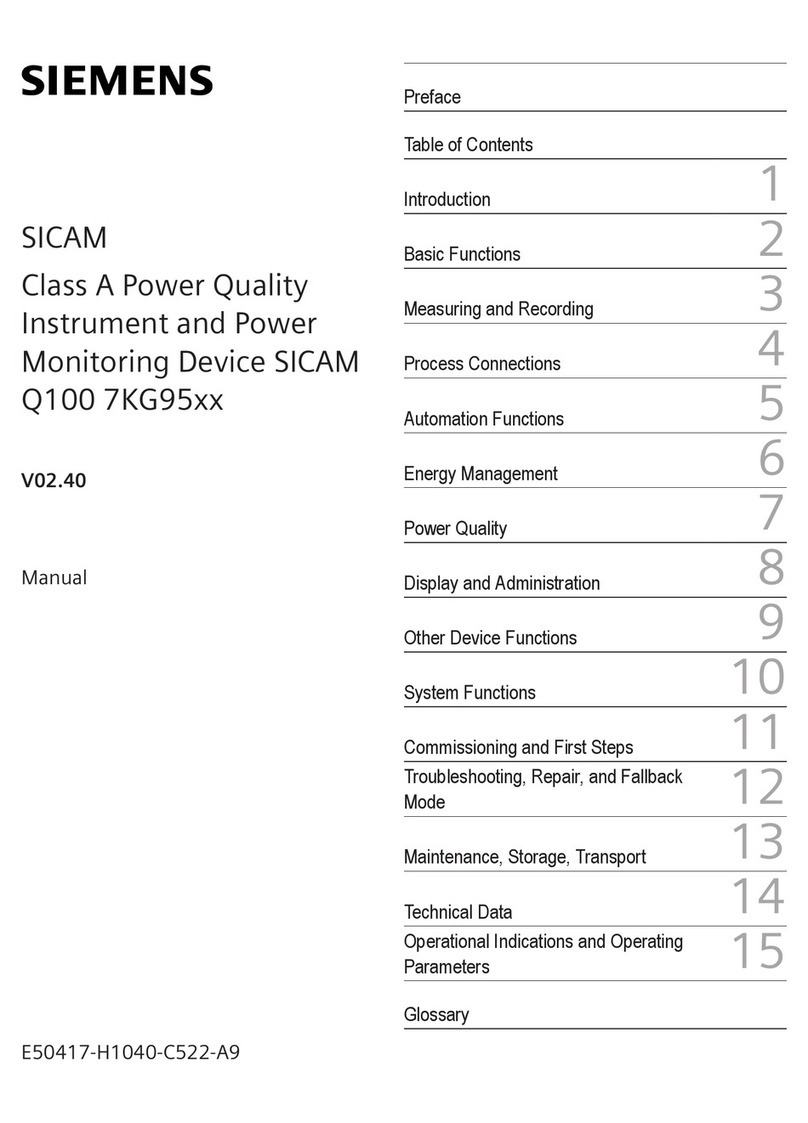

Selecting a PIN

Choose and enter your own PIN (6-digit access code)—

and remember it, as you’ll need it going forward to access

the app. Prepare for Set up

Use the Drawer Icon ( ) to access Camano’s menu—then

select ‘Set Up’ for parameter settings.

Parameter settings are protected behind a lock. To unlock,

simply tap on the Lock icon ( ) and enter your PIN.

SPEED OF SOUND

liters/min

000.000

Flow

Data Log In Progress

00:00:00

Time Remaining

SPEED OF SOUND

liters/min

000.000

Flow Readings

Data Log In Progress

00:00:00

Time Remaining

Flow

Set Up

Lock

Output

Alarm

Diagnostics

Settings

D

0

g

s

s

6

App Installation

Setting up the App

Your Camano ships complete with power cabling.

Getting Started

1-509-899-7838 :: soundwatertech.com 13

The Set up Screen

Use the handy parameter selection

screens to set your units of

measure and display preferences.

Conveniently select pipe, liner, and

liquid specifications from lists of

pre-loaded values. Don’t see the

right option? Add your custom

values.

Units

Toggle between Imperial and metric

units of measure.

Select Flow Rate, Volume, and

Velocity from Camano’s pre-loaded

values or add your own custom

values.

Pipe

Select Pipe Type,Size, and Wall

Classifications from our pre-loaded

values or add custom values by

selecting Custom under Pipe Type.

When entering a custom type, you

must supply the outer diameter, wall

thickness, speed of sound through

the pipe material, and the surface

roughness—enter zero if unknown

roughness.

Liner

Switch between liner and no liner.

When selecting Liner Enabled,

enter Liner Thickness and choose

Liner Material from our pre-loaded

list or add custom values. When

adding a custom material, you must

enter the speed of sound through

that material.

Liquid

Select Liquid Type and

Temperature from our pre-loaded

list of values or add a custom liquid

type. When adding a custom liquid,

you will need to enter the speed

of sound through that liquid, the

viscosity, and the density.

Transducer

Select the Transducer Type and

Orientation.

Parameter Set Up

Units

Input

English

Flow Rate

gallons/min

Volume

ga

ll

ons

Velocity

f

t

/

sec

Pipe

Input

Standard

Nominal Size

Wall Classification

Customize

Liner

Input

Thickness

Materials

Customize

0.0 i

n

Liquid

Input

Temperature

Liquid Type

Customize

Type

S

PACING

SAVECANCEL

Transducer

Set Up

Units Pipe

Liner Liquid

Transducer

Transducer Spacing:

––

Getting Started

Camano Instructions

14 SoundWater Technologies, LLC

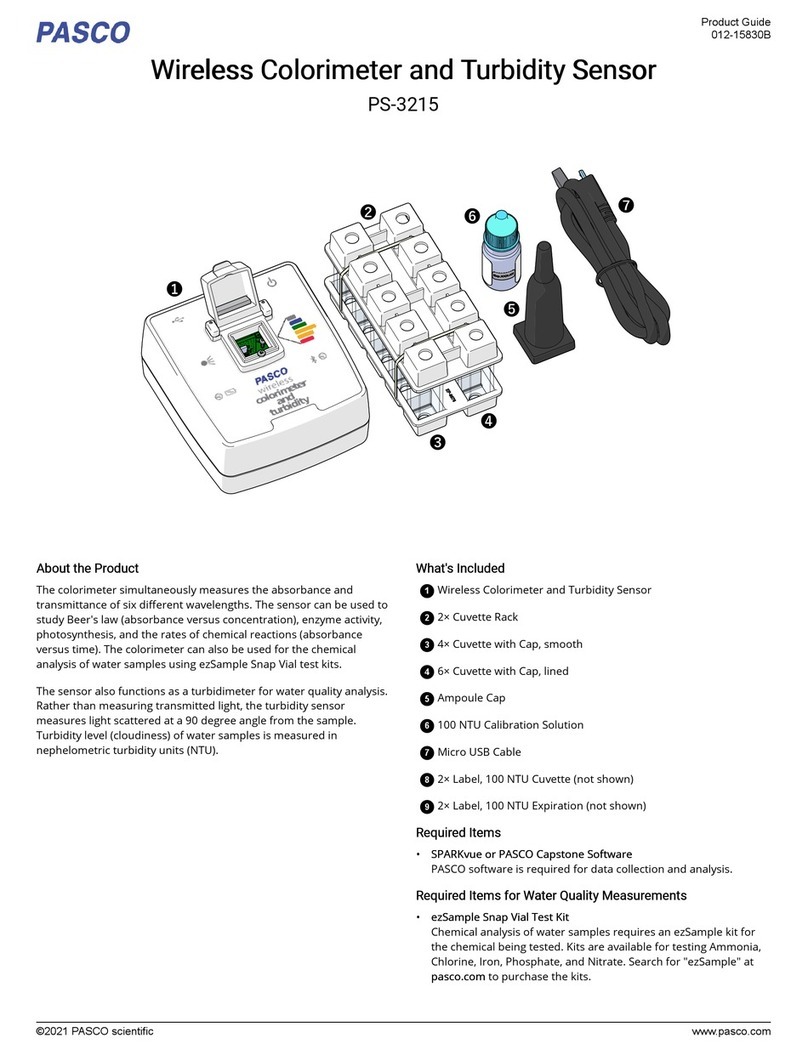

Flowmeter Installation

Straight Pipe Recommendations (X = diameter)

5X15X

20X

40X

5X15X

30X

40X

Reduced Pipe

Two Elbows In Plane

Two Elbows, Out Of Plane

Expanded Pipe

5X

5X

5X

5X

Swirling Flow:

Propeller Meter

Flowmeter installation

Swirling Flow:

Partially Open

Butterfly Valve

1-509-899-7838 :: soundwatertech.com 15

Full Pipe Recommendations

Flowmeter Installation

This is a view looking directly into a pipe,

with the meter in multiple possible positions

on the side of the pipe. Horizontal (3 o’clock

or 9 o’clock position) is the preferred installation

orientation, since it avoids problems with

trapped air and sediment.

Flowmeter Orientation

Fair — Unacceptable if

pipe contains air

Best Position

Air bubbles

Sediment

Not Ideal:

Allows air pockets to form at meter

Recommended:

Keep pipe full at meter for accuracy

Not Ideal:

Air can be trapped

Recommended:

Allows air to bleed o

Not Ideal:

Post-valve cavitation can create air pocket

Recommended:

Keeps pipe full at meter for accuracy

Fair — Unacceptable if

pipe contains sediment

Camano Instructions

16 SoundWater Technologies, LLC

Set Up

Units Pipe

Liner Liquid

Transducer

Transducer Spacing:

2.0 in

Transducer Spacing

Once you entered your parameters in the previous section, the app automatically

computed the proper transducer spacing. This is shown at the bottom of the main

app screen.

The next step is to adjust the transducer spacing on the flowmeter, as follows:

1. Rotate the black knob to unlock the horizontal motion for each transducer.

2. Move the transducers to the specified transducer spacing by sliding them

along the integrated ruler. Note: It is not necessary to start at zero on the

ruler, so long as the actual spacing is correct.

3. Lock into place using the black knobs. This is important to prevent the

transducer spacing from moving when mounting the flowmeter!

Flowmeter installation

Black locking knob on transducer Integrated ruler

1-509-899-7838 :: soundwatertech.com 17

Rotate silver knobs counter-clockwise to raise

the transducers, clockwise to lower.

Cover bottom face of transducers with coupling gel.

Wrap cords around pipe and secure with cam cleats.

Flowmeter installation

Installing the Flowmeter

Once the transducer spacing has been set and locked in

place, you are ready to install the flowmeter on your pipe.

1. Wall mount the display.

2. Rotate the silver knobs counter clockwise until

they stop. This raises the transducers up above the

meter footings.

3. Apply coupling gel liberally to the transducer faces,

covering the entire bottom face of each transducer.

4. Place flowmeter on pipe, assuring that the footings

are flush with the pipe and the meter is aligned

with the axis of the pipe.

Do’s and Don’ts

Do store your Camano in a dry, inside area when not in

use.

Do keep your Camano in its protective case when

transporting to prevent damage.

Do gently clean the transducer pads regularly with

isopropyl alcohol to prevent hardening and build up

of used coupling gel.

Do periodically check that there is suceint coupling gel.

Don’t store, transport, or use your Camano where the

device may exceed 150˚F (65˚C).

Don’t bang or drop the Camano on hard objects or

surfaces.

Don’t nick the transducer pads.

To prevent damage, you must use the

recommended coupling gel.

5. Strap the meter to pipe with the mounting straps.

6. Rotate silver knobs clockwise to press transducers

onto the pipe. Hand tighten only until seated firmly.

Warning: Tightening too much can li the meter

away from the pipe, causing incorrect readings.

Camano Instructions

18 SoundWater Technologies, LLC

Operation

Operation

Collecting Your Data

Connect power to the flowmeter.

Periodically we update the app with new features and enhancments. All

updates will be posted to our website and available for download.

Your flow data will display on the Camano App.

Data Logging

All data logging functions are accessed by tapping the Data Logging button in

the measurement view.

The purpose of the Camano’s built-in data logger is to record flow for a

specified period of time. It may be used to conveniently record flow for as long

as 365 days or as little as one minute. Only one data log may be used at any

one time.

The Camano’s data logger stores only one data set at any

time, selecting “Rec” (which creates a new data log) will

write over the existing data log. A message appears when

selecting the “Rec” button indicating that the existing data

log will be over-written if a new data log is started and gives

the user the ability to continue with the new data log or to

cancel.

FLOW RATE

liters/day

000.000

FLOW VOLUME

liters

000.000

Data Log In Progress

00:00:00

Remaining

Flow

Data Log

Data Log

00:00:00

REC

Set Recording Time: 0

1 h7 d

1-509-899-7838 :: soundwatertech.com 19

Data Log

Data Log In Progress

00:32:01

Time Remaining

STOP

Set Recording Time: 18 h

1 h7 d

Making a Recording

• Tap the Data Logging button to access the data logger features.

• Enter your 4-digit PIN to unlock the data logging screen.

• Using the slider bar in the app’s data logger set up view, set the

recording time. (See Explanation of Recording Times on the next page.)

• Tap “Rec” to start the recording. Data will start recording on the meter.

You can disconnect the mobile app during recording. The meter will turn

o when done to save power, unless still connected to the app.

• To stop recording prior to completing the time period, tap the “Stop”

button.

Retrieving the Data-Log File from the App

You may want to copy the data log file from the app to use on your computer.

To do this:

1. Insert a Flash thumb drive into the USB port located on the

bottom of the Camano box.

2. Navigate to the Data Log set up and tap the ‘download’ icon.

3. Wait until all data has transferred to the USB drive before

disconnecting from the port.

Sharing Data

Shared data is formatted in a CSV file (comma delimited file). The file name is

unique and contains both the date and time that the data log was started as

well as the location name. Set up information such as the date and time the

data log was started, the number of samples, sampling period, and location

name are located at the top of the data file. The data is arranged in rows,

where each row contains a single flow measurement including sample number,

time stamp, flow rate, velocity, volume, and quality. The data file can be viewed

or printed as a text file or formatted using most spreadsheet and database

programs, such as Microso®Excel or Access.

Operation

Data Log

Data Log

00:00:00

REC

Set Recording Time: 18 h

1 h7 d

Camano Instructions

20 SoundWater Technologies, LLC

Explanation of Recording Times

The sampling rate (time between each recorded flow measurement) and total number of recorded measurements is

controlled by the Camano. The maximum possible number of measurements is 100,000 and each includes five values—

flow rate, total, velocity, time stamp, and quality. The maximum sampling rate is two seconds.

The Camano data logger will attempt to maximize the sampling rate, based on the your selected recording time. For

example, if you select to record flow for one minute, then the Camano maximizes the sampling rate at two seconds and

will record 31 flow measurements (covering a total of 60 seconds).

If you select to record flow for four days, then the Camano again attempts to maximize the number of flow measurements;

however since there is not enough memory to record flow every two seconds for four days, it configures the sampling

period to maximize the number of flow measurements. For the case of four days, the Camano sets the sampling period at

4 seconds giving you over 86,400 flow measurements.

Length Sample Period

1 minute 2 seconds

1 hour 2 seconds

10 hours 2 seconds

1 day 2 seconds

4 days 4 seconds (1 min., 32 sec.)

10 days 9 seconds

14 days

30 days

180 days

365 days

13 seconds

26 seconds

156 Seconds (2 min., 36 sec.)

316 Seconds (5 min., 16 sec)

Operation

Table of contents

Other SoundWater Measuring Instrument manuals