User Manual & Installation Guide AC-73-DH Force Balance Accelerometer

10 / 20 13.04.2021 / V3.9

GS_AC-73-DH_UserManual+InstallationInstructions_V03.docx

3. Installation

1. iSENSOR

a. Make sure the communication with the iSensor is working as described in chapter 4.6.

b. Perform a compass calibration as described in chapter 4.6.4.

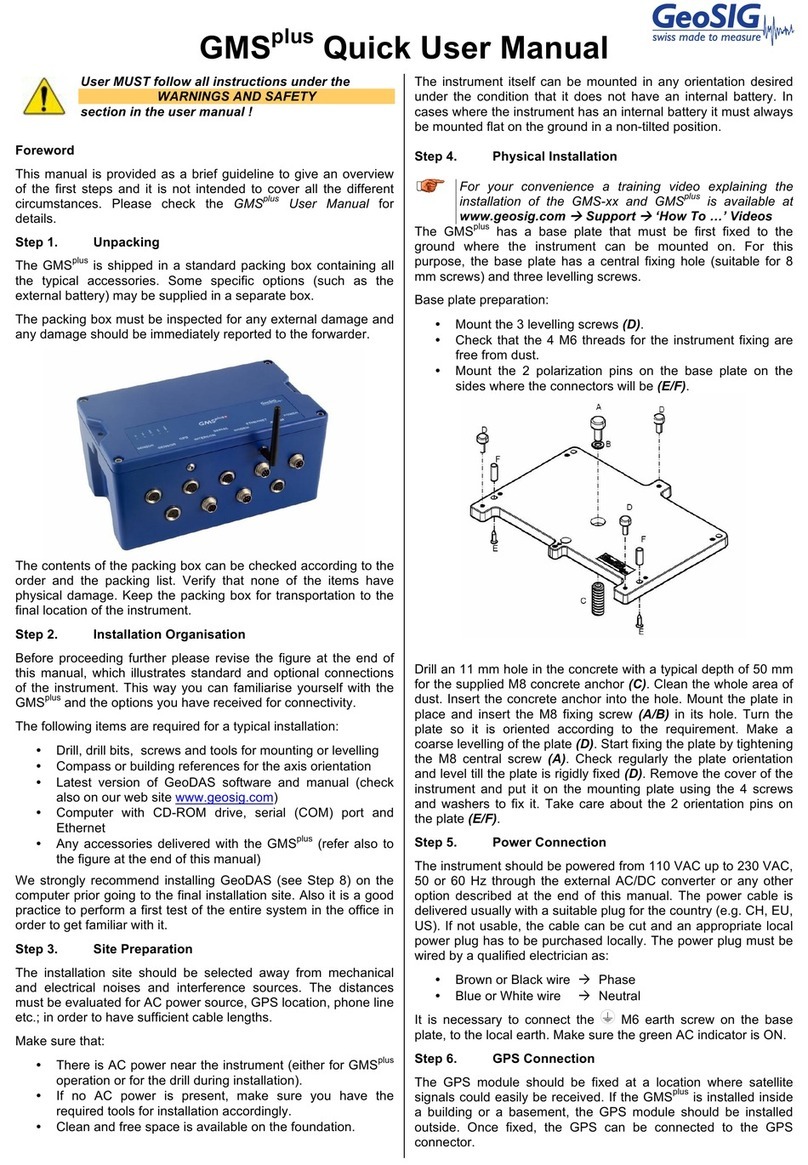

2. SENSOR TORPEDO

a. Verify water level in borehole, if applicable

b. Deposit the equivalent of at least 50 cm of sand (see section 2.3.1 for the volume) in the

borehole/casing.

c. Gently bind the sensor cable about every 3 meters to the suspension wire, ensuring that

the cable will not kink or strain. The sensor cable is not made to support the weight of the

sensor and cable.

d. If applicable, fasten the grout injection tube to the side of the sensor torpedo.

e. Lower the sensor in the casing/borehole until it reaches the sand at the bottom, when the

suspension wire becomes slack. The movement should be controlled using the steel wire.

The sensor cable and cement injection tube should be free of tension.

f. Lift the sensor up by 50 cm so it is suspended by the wire (to ensure it is in a vertical

orientation). See Figure 1.

g. Connect the cable to the junction box at top of borehole (if applicable).

3. INSTRUMENTATION

a. Route the cables from the borehole (junction box or integral cable) to the recorder.

b. Perform a sensor test from GeoDAS or from the recorder console.

c. Test the whole system.

d. A continuous monitoring of the system pre-grout should be performed for a few days. This

ensures the operation/reliability of the sensor (e.g. no water ingress).

e. A longer period of pre-grout monitoring can also be used to ensure that the location of the

sensor suits the customer requirements with regards to noise level or seismic transfer

function to a reference sensor. In this case, it is recommended to temporarily fix the sensor

in place with sand or glass beads.

4. GROUTING

a. Final cementation/grouting of the sensor in the borehole/casing (see Section 3.1).

b. When the cementation is complete (e.g. after curing), sand should be deposited in the

borehole –preferably to the surface –to avoid that the cable and steel wire can sway in

case of earthquake and create triboelectric (parasitic) signals.

c. Release of steel wire.

It is not recommended to perform the cementation of the sensor in the borehole/casing right after its

insertion. The whole installation should be finished and the system should run for several weeks and

show correct operation before the final cementation of the sensor inside the hole is performed.

Care must be taken with the cable to avoid kinking, cutting or abrasion of the cable jacket, which can

lead to water ingress and sensor failure. Always maintain the minimum bending radius of >180mm.

3.1. Grouting

After the sensor has been successfully tested in its place, the cavity between borehole/casing and the sensor

can be grouted. Inject a grouting mixture consisting of 100 liters of water, 50 kg of cement, and 10 kg of

bentonite. The bentonite percentage may be increased or reduced according to the consistency of the

examined soil and water content). It must be liquid enough that it will not form a cavity under the torpedo. Use

low pressure and low flow for the expected required amount of the mixture. The grout should be cured within

one week. Backfill the rest of the internal cavity with sand, if applicable, and add a top cap, if applicable. Note

sensor cable minimum bending radius at casing exit. Perform additional noise measurements after completion.