Part 1 Introduction

1.3 OMD-501D Specications

OMD-501D Trace Oxygen Analyzer

Precision Electrochemical Sensor Technology

Large Color Display w/ User Friendly Menu

5 Standard Analysis Ranges

Auto-Ranging or Manual Range Mode

Two Adjustable Alarm Contacts w/ delay mode

Panel Mount, 1/4 DIN Enclosure Design

Applications:

“Inquiry for Application Expertise”

• InertGloveBoxSystems

• N2andO2Skids

• Laboratories&Universities

• BeverageGradeCO2Monitoring

• AirSeparationPlants

&ManyOthers

Specications:

Ranges: 0-10/100/1000ppm/1%/25%

Accuracy: +/- 1% Full Scale Range*

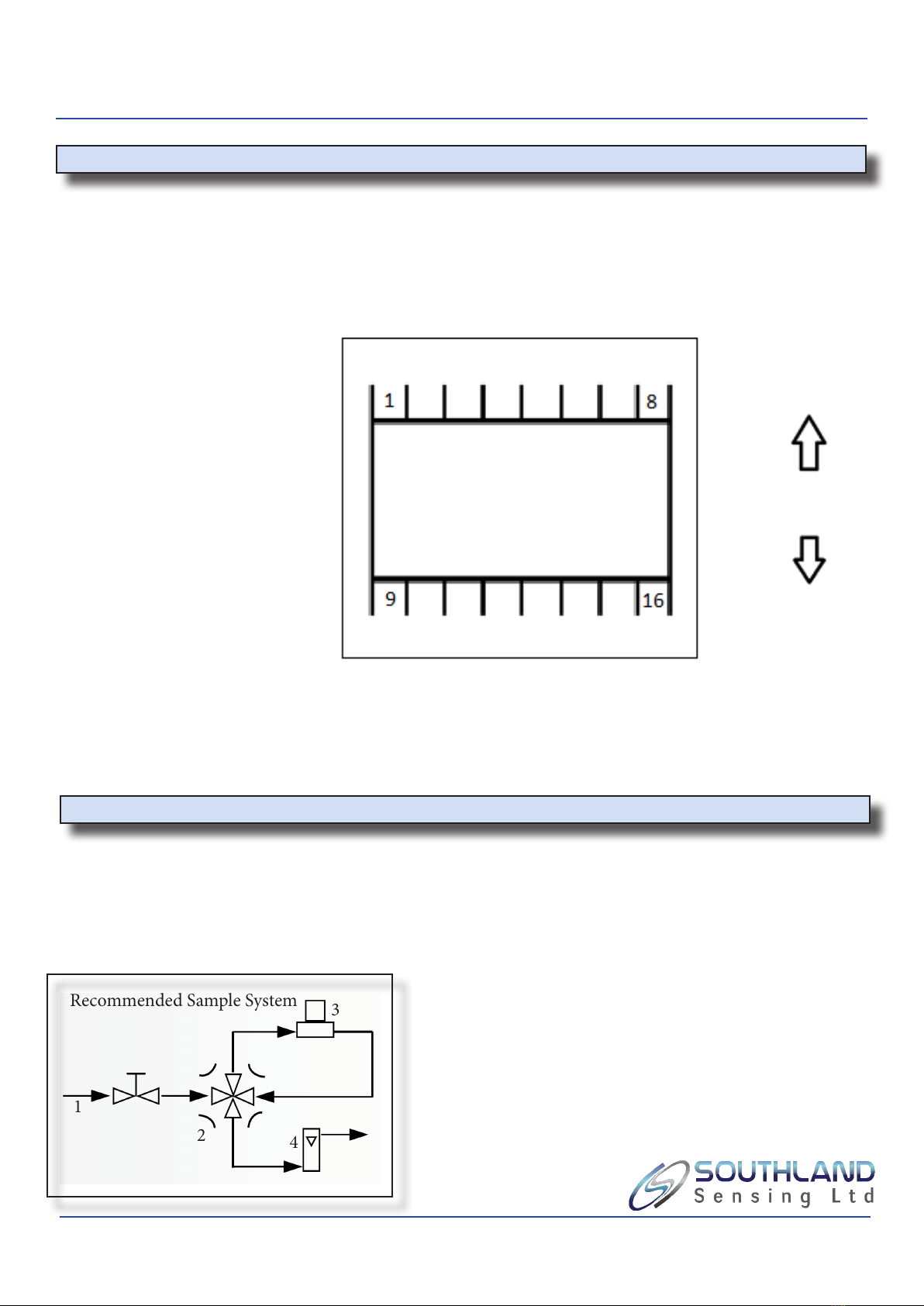

Display: ColorwithBacklight

Dimensions: 1/4 DIN (96 x 96 x 65mm)

Enclosure: FlushMount,ABS

Classication: GeneralPurpose

Temperature: 0 - 50 deg C

Alarms: 2AdjustableNOorNC

Power: 12-28VDCor100-240VAC

SignalOutput: 4-20mA

RangeID: 1-5VDC

Response time: T90 in 10 Seconds

Sensor: TO2-1xTraceOxygen

Sensor Life: 18—25months

Calibration: Periodically

Temperature Compensation: Integral

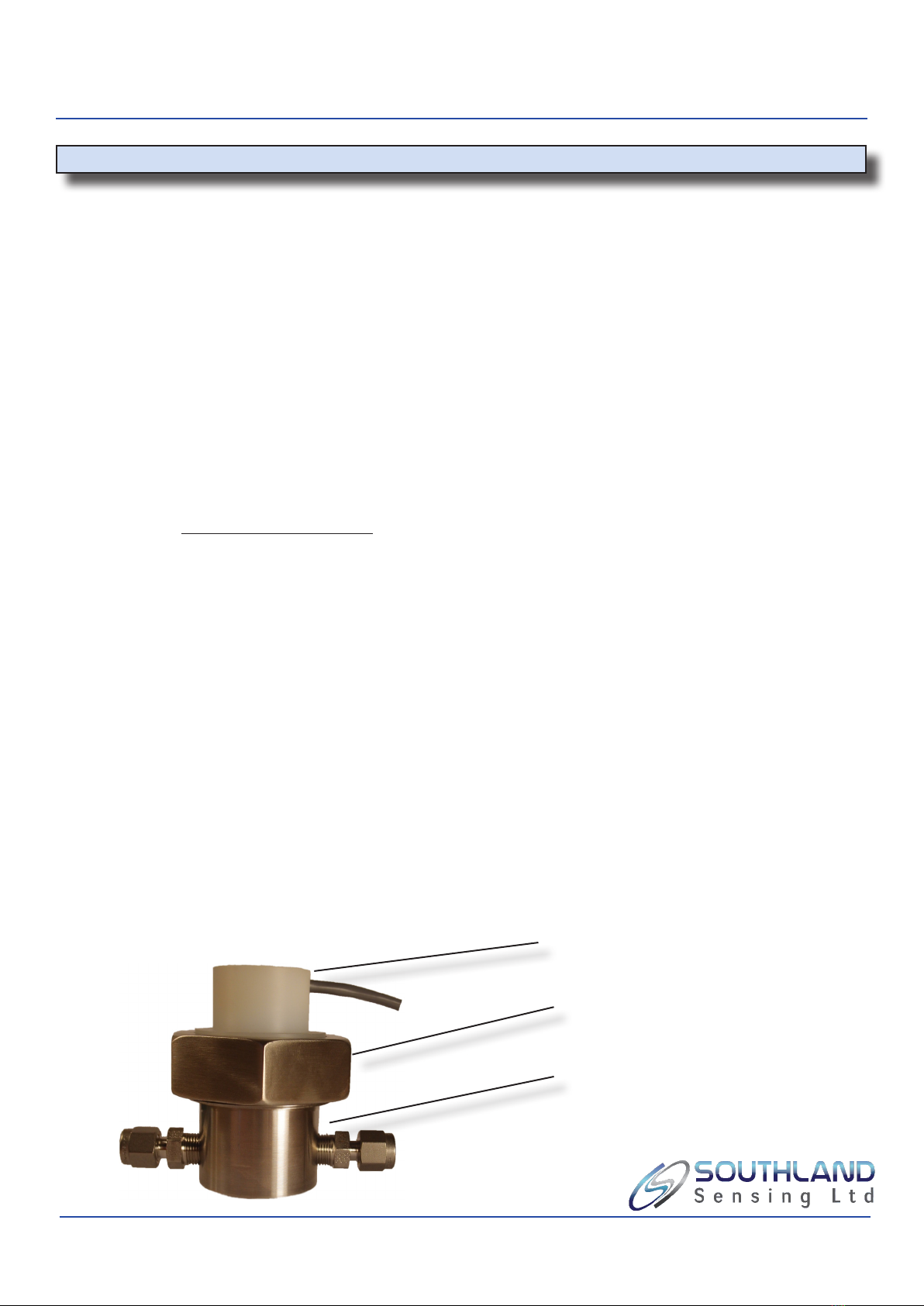

Recommended Flow: 0.5 - 4 SCFH

FlowCell: H3FlowCell,1/8”Swagelok

Warranty: 12MonthsSensor

Warranty: 12MonthsElectronics

*Accuracy at constant conditions

Optional Accessories:

•Optional Ranges: Fully Customizable from Factory

• H3FlowHousing1/4”SwagelokorOtherConnection

• H1DirectInstallKF-40SensorHousing

• IP66EnclosureforOutdoorInstallation

• CustomizeableSampleSystem

• TO2-2xOxygenSensorwith>0.5%CO2Present