OMD-625 Oxygen Analyzer Product Specications

Oxygen Analyzer: Oxygen Sensor Technology:

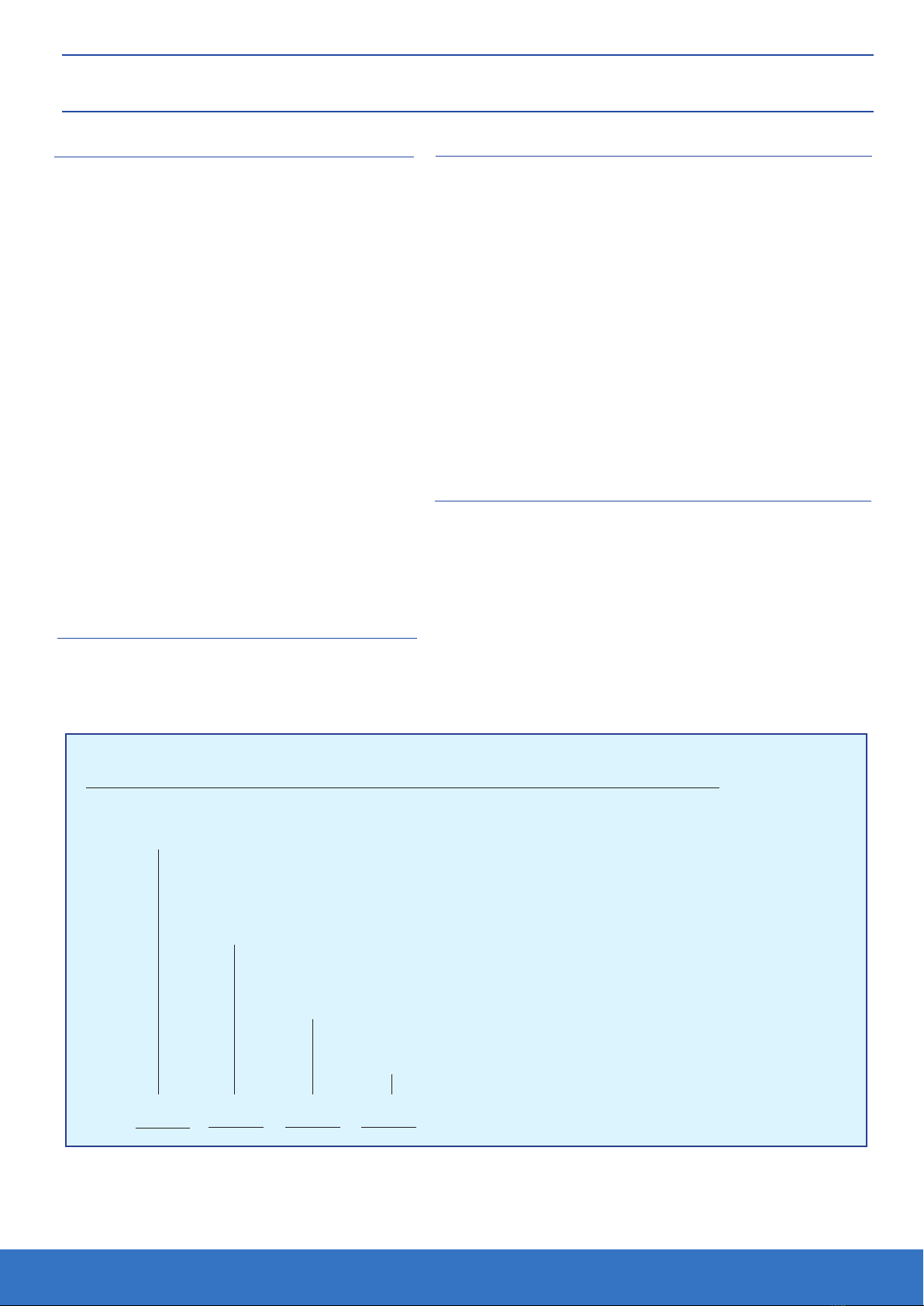

Order Information:

Oxygen Sensors:

Record Part Number with selected options in Blank Indicated Area of Form

Model Number:

OMD-625 Oxygen Analyzer

OMD-625D Oxygen Analyzer (Delete Sample System, 1/8” Compression Tube Gas Inlets)

Selected Range & Sensor:

3T Trace Analysis Standard (TO2-133): 0 - 10ppm, 0 - 100ppm, 0 - 1000ppm, 0 - 10000 PPM 0 - 25%

4T Trace Analysis Standard (TO2-233): 0 - 10ppm, 0 - 100ppm, 0 - 1000ppm, 0 - 10000 PPM 0 - 25%

5T Trace Analysis < 500 PPM H2S (TO2-238): 0 - 10ppm, 0 - 100ppm, 0 - 1000ppm, 0 - 10000 PPM 0 - 25%

5P Percent Analysis Standard (PO2-160): 0 - 1%, 0 - 5%, 0 - 10%, 0 - 25%, 0 - 100%

6P Percent Analysis Standard (PO2-24): 0 - 1%, 0 - 5%, 0 - 10%, 0 - 25%, 0 - 100%

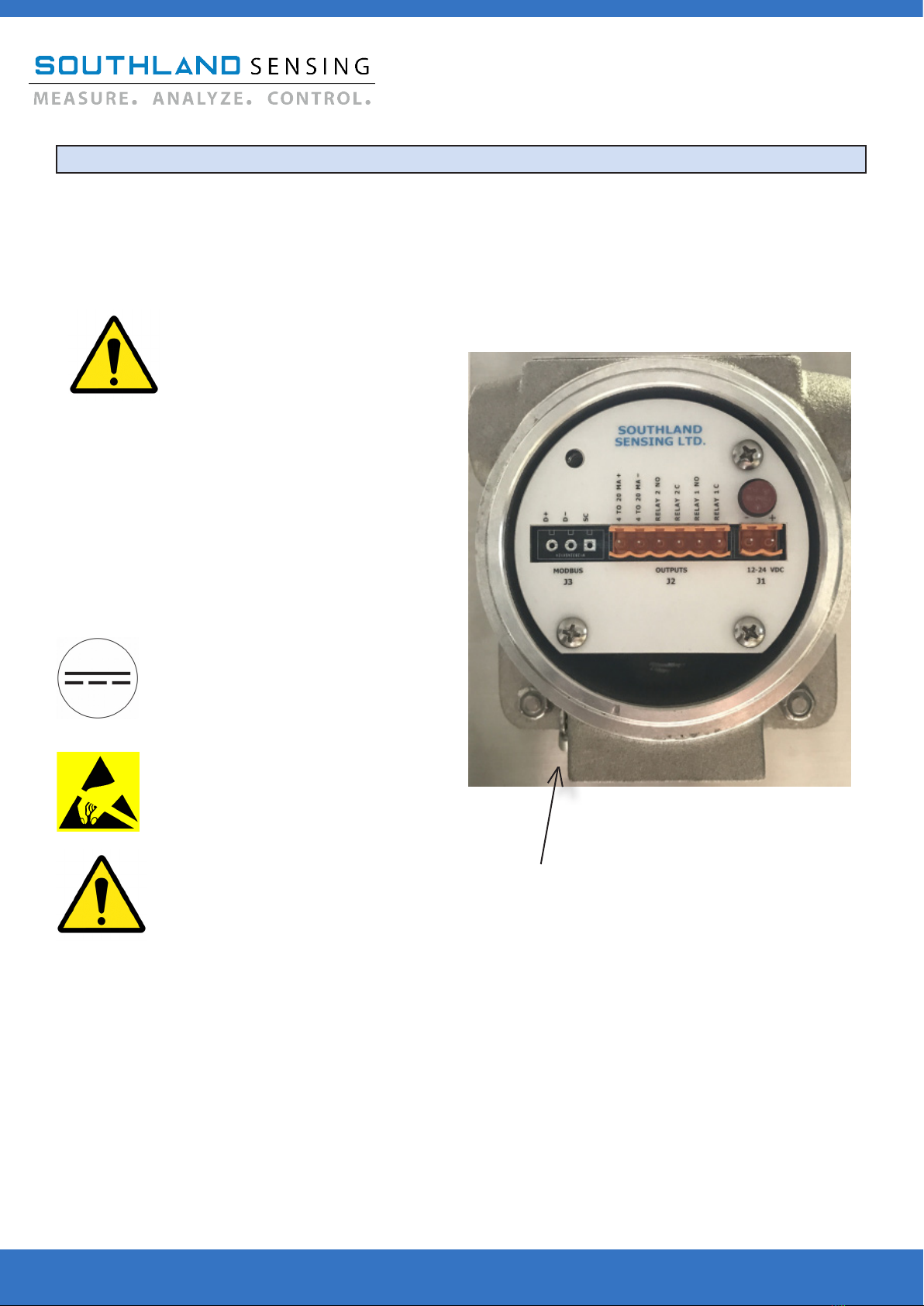

Electronics Package:

2 12 - 24V DC 2-wire Loop (delete backlight, delete alarm relay contacts)

4 12 - 24V DC 4-wire Input Power

7 100 - 240V AC Input Power

M 12 - 24V DC Input Power w/ Bi-Directional MODBUS RS485 RTU

OMD-625 - - -

The oxygen sensor used in the OMD-625 is based on the

galvanic electrochemical fuel cell principal. All oxygen sensors

are manufactured in house by Southland Sensing Ltd. under a

strict quality program.

The standard cells are unaected by other background gases

such as H2, He or Hydrocarbons. The acidic cells work well

when acid gases such as CO2 or natural gas are present.

The sensors are self-contained and minimal maintenance is

required - no need to clean electrodes or add electrolyte.

The SSO2 precision oxygen sensors oer excellent perfor-

mance, accuracy and stability while maximizing the expected

life.

TO2-133 PPM Oxygen Sensor: Trace Analysis, Standard

TO2-233 PPM Oxygen Sensor: Trace Analysis, Acidic

TO2-238 PPM Oxygen Sensor: Trace Analysis, < 500PPM H2S

PO2-160 Percent Oxygen Sensor: Percent Analysis, Standard

PO2-24 Percent Oxygen Sensor: Percent Analysis, Acidic

Oxygen sensors should be periodically calibrated. Factory

recommendation is every 2 - 3 months or as the application

dictates. Sensors oer excellent linearity with an air calibra-

tion, or calibrate to a certied span gas to maximize accuracy.

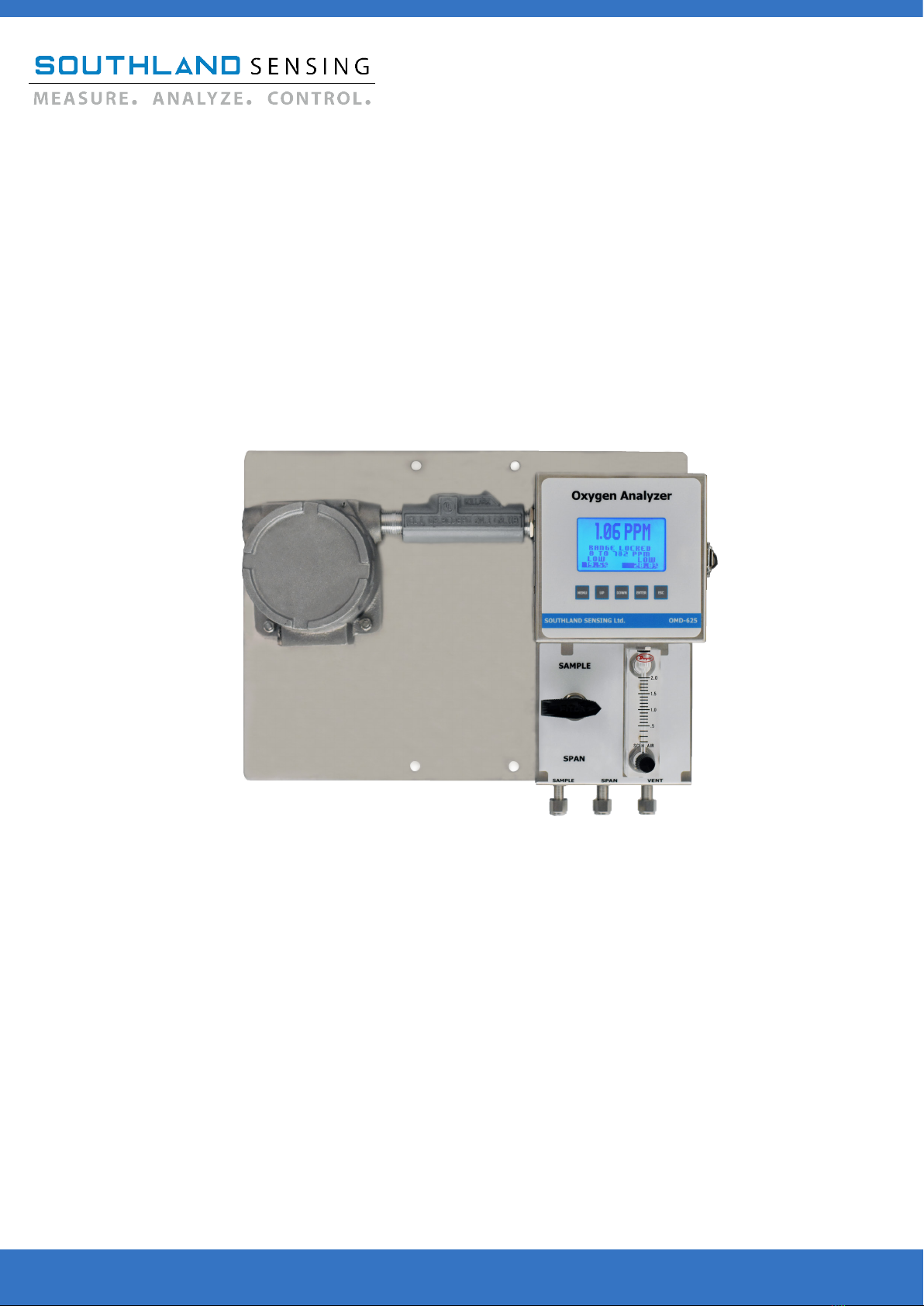

The model OMD-625 oxygen analyzer combines a

rugged design with SSO2’s precision oxygen sen-

sors. The result is a highly reliable and cost eec-

tive compact design with easy-to-use user interface

designed specically for the natural gas industry.

The oxygen analyzer is designed to meet standards

for Class 1, Div 1, Groups B, C, D installation.

The oxygen analyzer is isolated both on the power

input and analog output. This eliminates most

electronic gremlins seen with existing competitive

equipment in the eld.

Standard ranges include 0 - 10ppm, 0 - 100ppm, 0 -

1000ppm, 0 - 10000ppm, 0 - 25%.

Optional Percent Analysis Ranges: 0 - 1%, 0 - 5%,

0 - 10%, 0 - 25%, 0 - 100%.

Custom Range: The unit comes with the ability to

customize a 6th range (i.e. 0 - 94 ppm).

Standard Power Requirements:

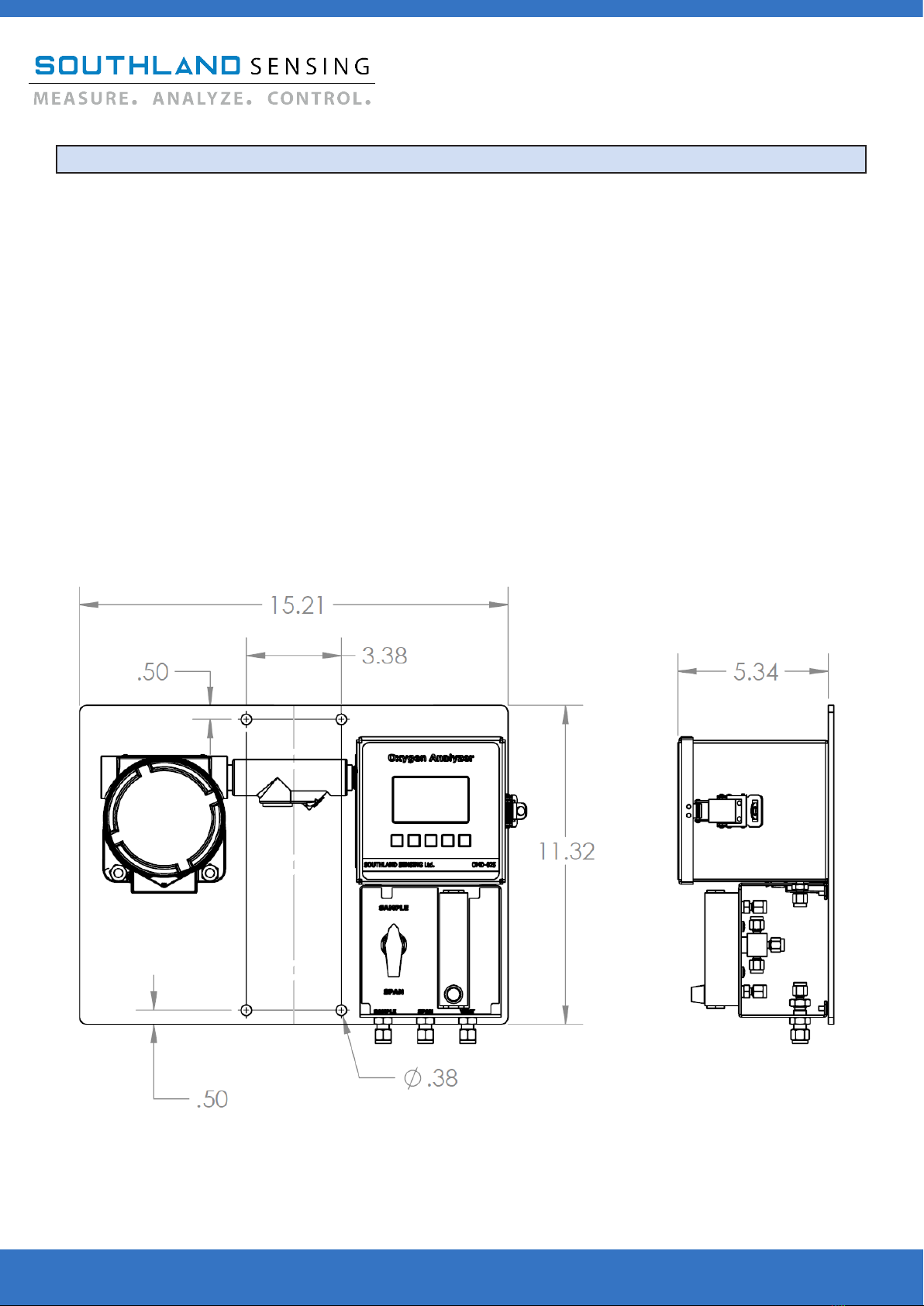

Gas Connections:

4 1/4” Compression Tube Fittings

6 6mm Compression Tube Fittings

8 1/8” Compression Tube Fittings

Input Power: 12 - 24 V DC

Current Draw: 50 mA

** Optional power input choices available

Use This Part Number When Ordering

Designed, Tested and Assembled in California, USA

4045

E.

Guasti

Rd.

#203

Ontario,

CA

91761

US

A

:

1-949-398-2879

:

[email protected] :

www

.sso2.com

Rev 1.12 August 27, 2020_BB