1

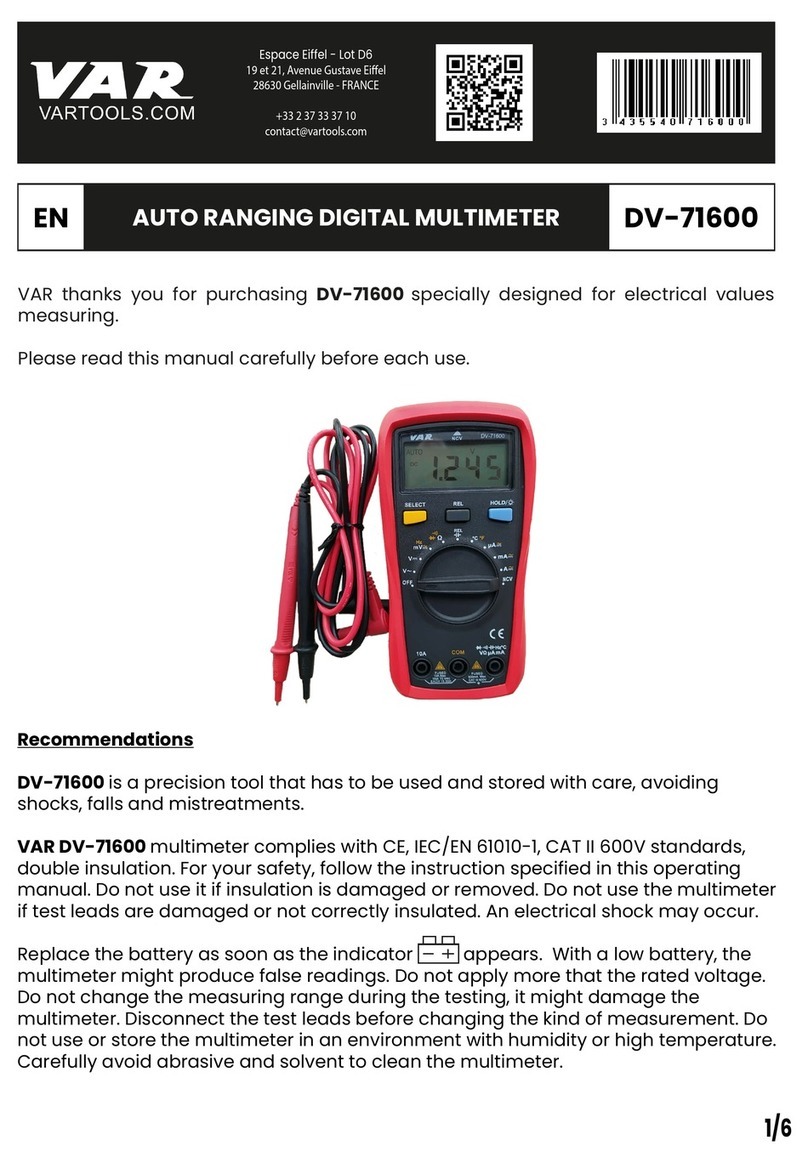

Introduction

WARNINGS

The Southwire 11060S multimeter measures AC and DC voltage

and current, resistance, temperature, capacitance, frequency and

duty cycle. It also tests continuity and diodes. Readings are

displayed on a large backlit LCD. This meter is fully tested and

calibrated and, with proper use, will provide many years of reliable

service.

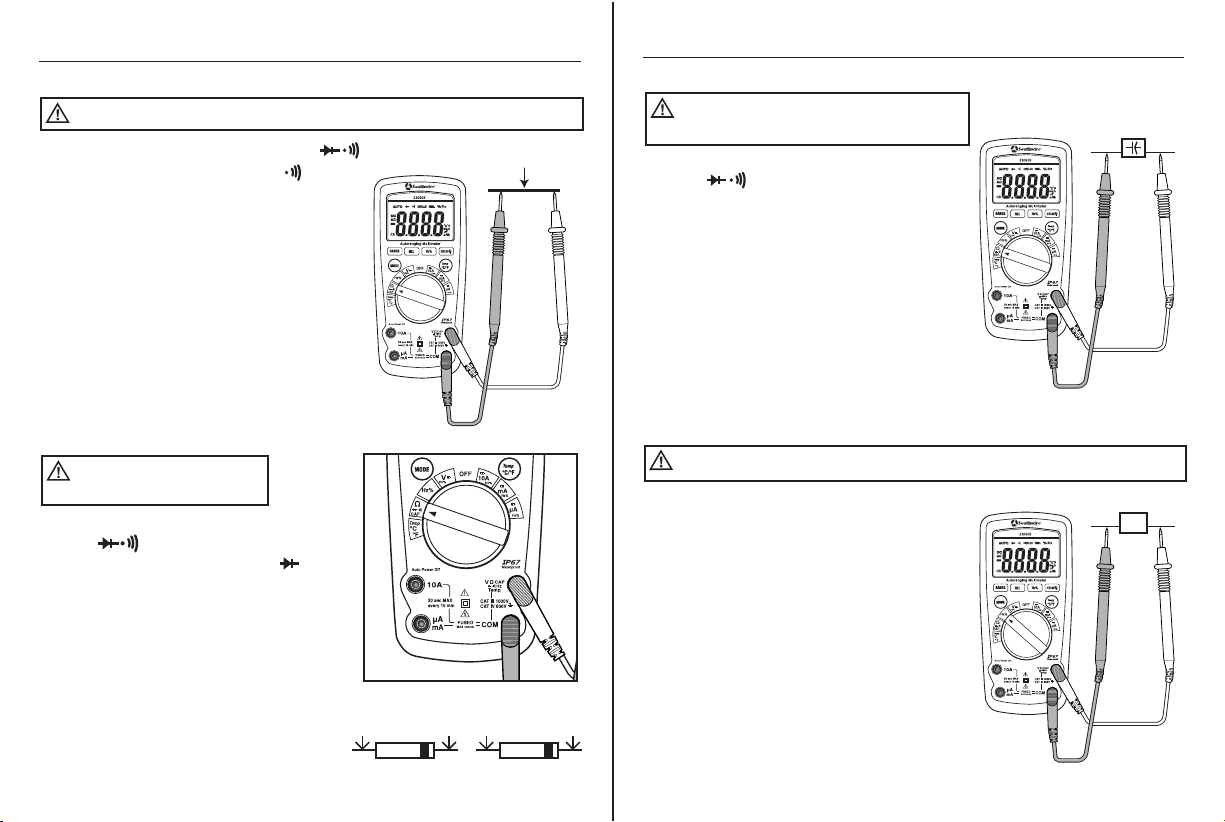

• Read, understand and follow the Safety Rules and Operating

Instructions in this manual before using this meter.

• The meter’s safety features may not protect the user if not

used in accordance to the manufacturer’s instructions.

• Ensure that the test leads are fully seated in the input jacks and

keep fingers away from the metal probe tips when taking

measurements.

• Confirm operation of test leads by checking resistance.

The resistance reading should be 0.5Ω or less when the red

and black probe tips are touching each other.

• Use only UL listed test leads with the proper safety category

rating.

• Before changing functions using the selector switch, always

disconnect the test leads from the circuit under test.

• Comply with all safety codes. Use approved personal protective

equipment when working near live electrical circuits -

particularly with regard to arc-flash potential.

• Use caution on live circuits. Voltages above 30 V AC RMS,

42 V AC peak, or 60 V DC pose a shock hazard.

• Do not use meter or test leads if they appear damaged.

• Verify meter’s operation by measuring a known voltage.

• Do not use the meter in wet or damp environments or during

electrical storms.

• Do not use the meter near explosive vapors, dust or gasses.

• When replacing the battery or fuses, be sure to secure the back

cover panel and battery compartment door firmly to maintain

the waterproof and dust proof integrity of the meter. Loose or

overtightened screws, or an improperly seated o-ring may

compromise the meter's water and dust ingress protection.

2

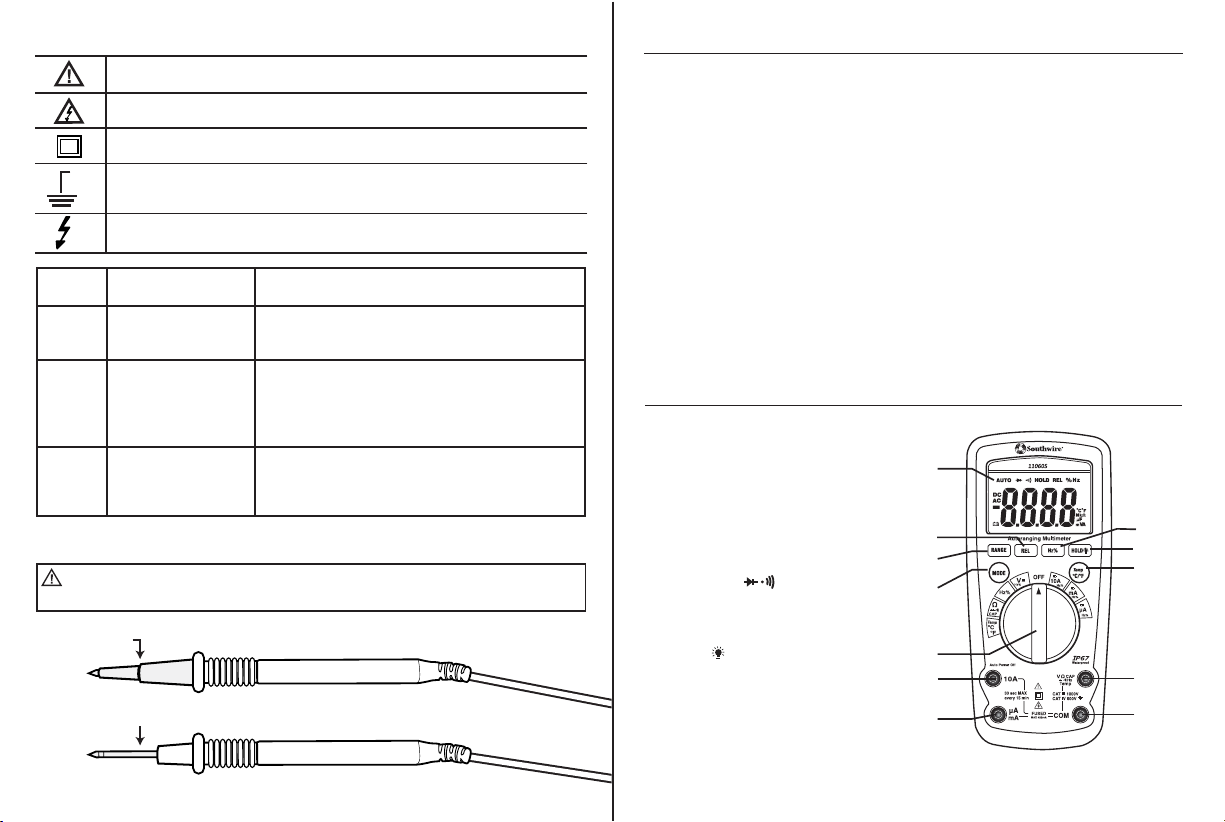

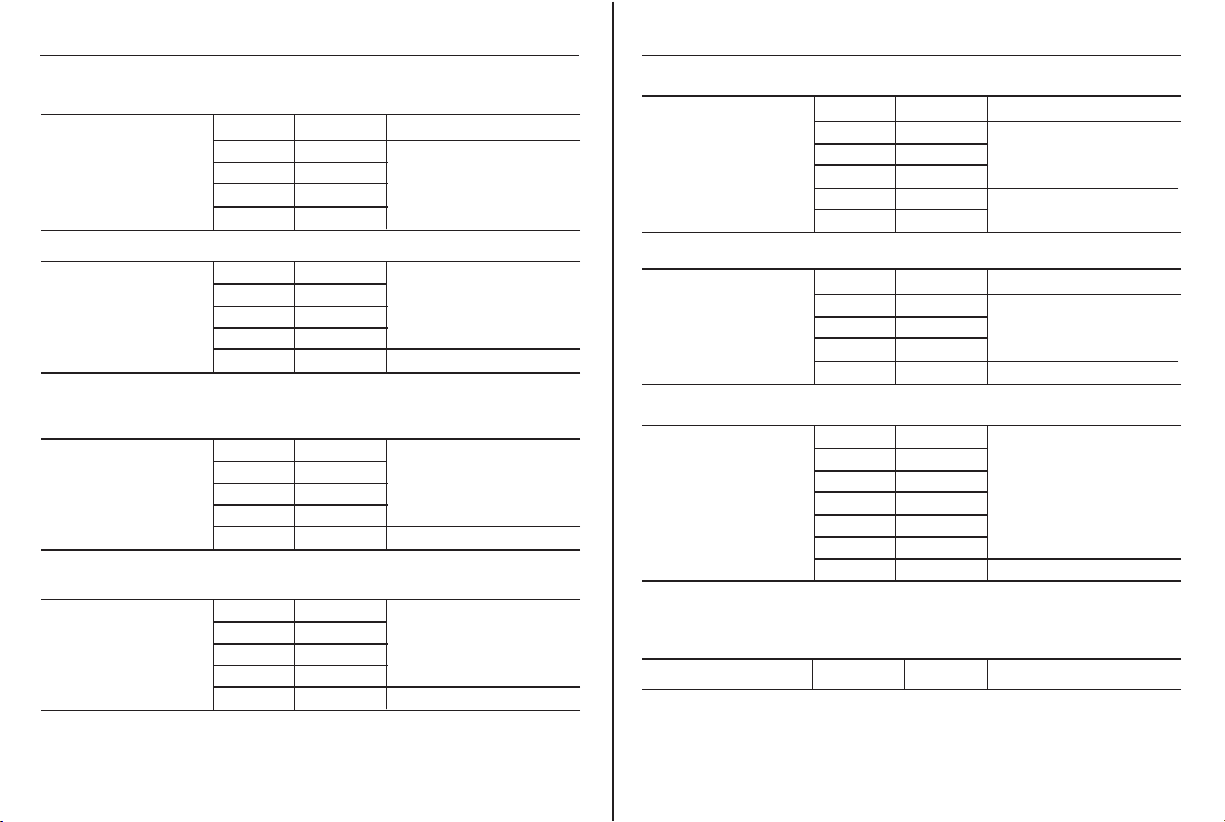

Input Limits

Function Maximum Input

Voltage AC or DC

µA Current AC or DC

mA Current AC or DC

10A AC or DC

Resistance, Continuity,

Diode Test, Frequency, Duty Cycle

Temperature

1000VAC rms, 1000VDC

4000µA AC rms, 4000µA DC ; 1000VAC rms, 1000VDC

400mA AC rms, 400mA DC ; 1000VAC rms, 1000VDC

10A AC rms, 10A DC ; 1000VAC rms, 1000VDC

1000VAC rms, 1000VDC

1000VAC rms, 1000VDC

• Do not apply voltage or current that exceeds the meter’s

maximum rated input limits.

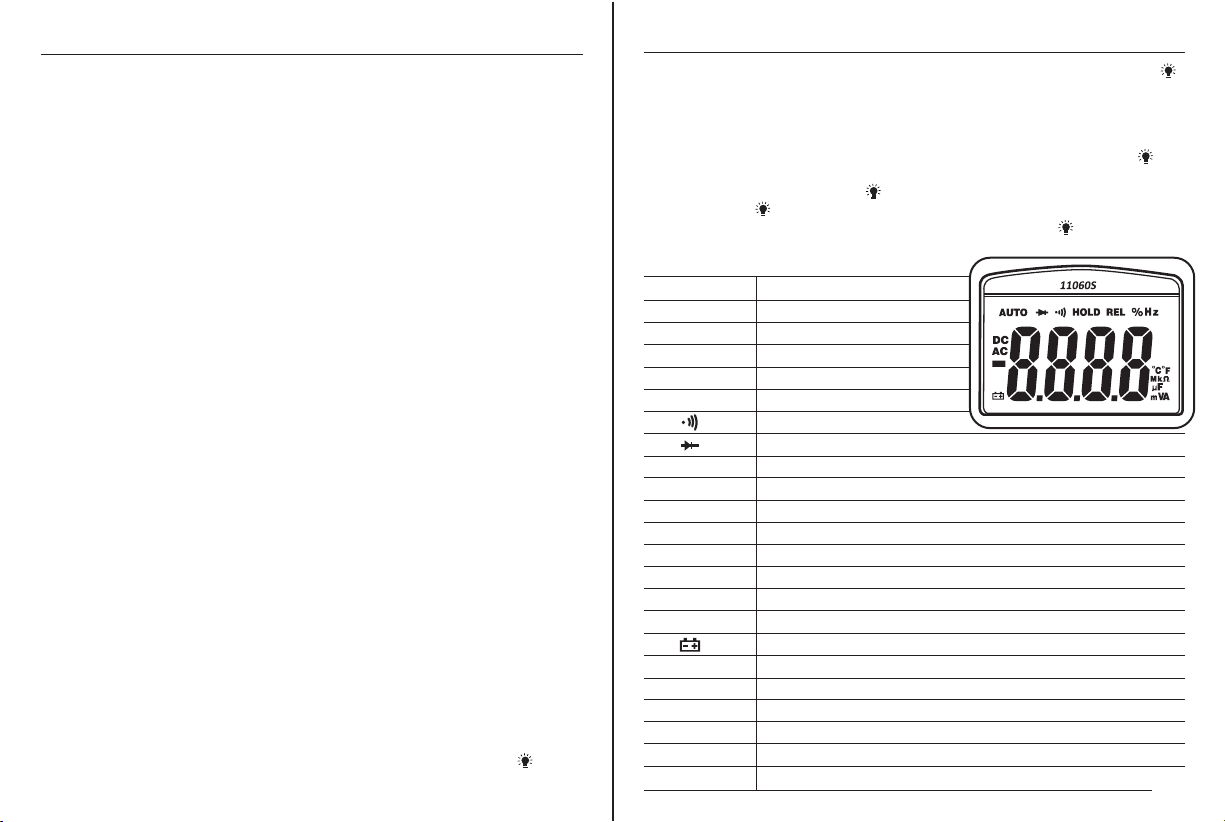

General Specifications

• Replace the battery as soon as the low battery warning appears.

Insulation: Class II, Double Insulation

Overvoltage category: CAT IV 600V, CAT III 1000V UL 61010-1 standards

Maximum voltage between any

terminal and earth ground: 1000V DC/AC RMS

Display: 4000 count LCD display

Polarity: Automatic, (-) negative polarity indication

Over-range: “OL” mark indication.

Low battery indication: A battery “ ”symbol is displayed when the

battery voltage drops below the operating level

Measurement rate: 2 times per second nominal

Auto power off: Meter automatically shuts down after approx.

30 minutes of inactivity

Operating environment: 41°F to 104°F (5°C to 40°C) at < 80% relative humidity

Storage temperature: -4°F to 140°F (-20°C to 60°C) at < 80% relative humidity

Relative humidity: <80%

Altitude: 7000ft (2000m)

Pollution degree: 2

Power: One 9V battery, NEDA 1604, IEC 6F22 or equivalent

Dimensions/Weight: 6.8” x 3” x 2”/Approx. 0.83lb) (172 x 77 x 52mm/Approx. 375g)

IP67: Dust protected and water protected

(immersion up to 1m for up to 30 minutes)

Safety: The instrument complies with IEC/EN 61010-1, 2nd edition