3

GB

English Operating Instructions

Table of Contents

1. Important Safety Notes.............................................................................................................................4

1.1 Intended use........................................................................................................................................5

1.2 Non-intended use.................................................................................................................................5

2. Technical data ..........................................................................................................................................5

3. Transport ..................................................................................................................................................5

4. Your foiler / foiler ETL...............................................................................................................................6

4.1 Type plate and identification..................................................................................................................6

4.2 Scope of delivery..................................................................................................................................6

4.3 Overview of the device parts .................................................................................................................7

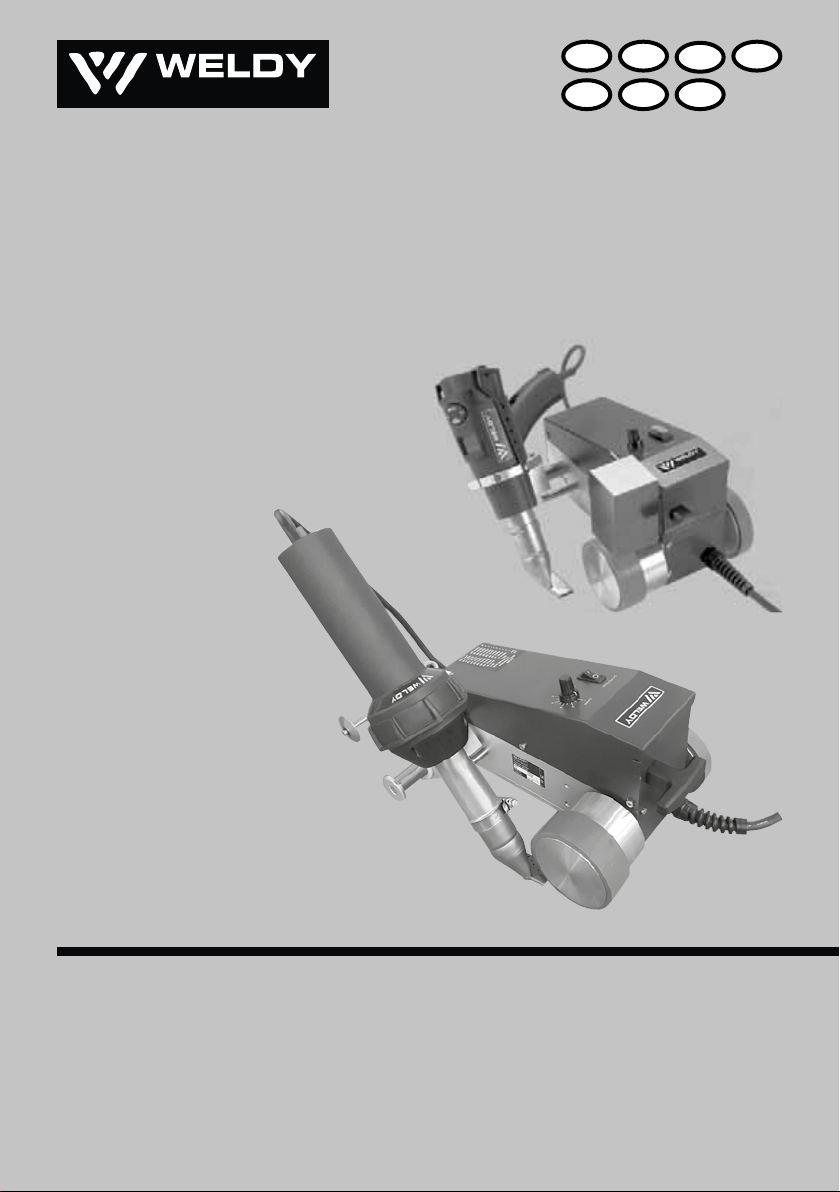

4.3.1 Overview of the foiler device parts................................................................................................7

4.3.2 Overview of the foiler ETL device parts..........................................................................................8

5. Settings on the foiler / foiler ETL..............................................................................................................8

5.1 Welding nozzle settings.........................................................................................................................9

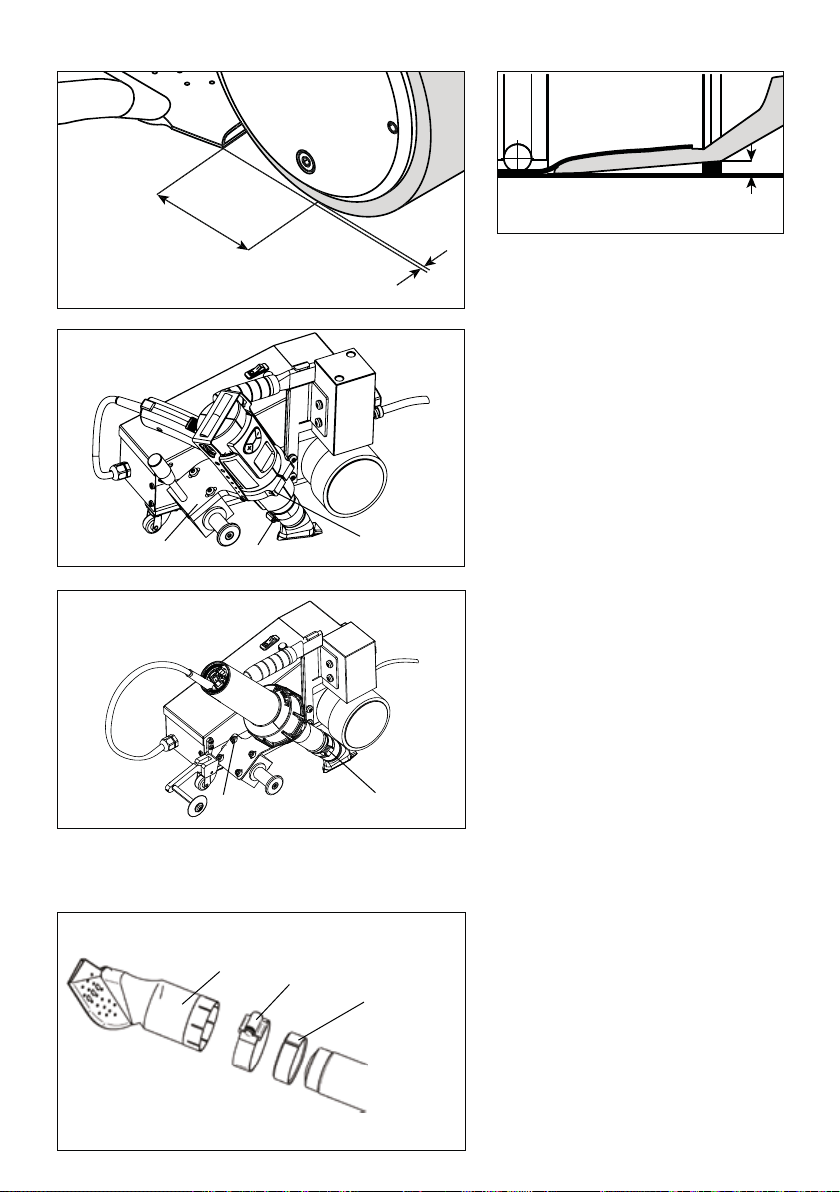

5.2 Changing the welding nozzle.................................................................................................................9

5.3 Setting the track guide roller (foiler ETL only)........................................................................................10

6. Commissioning your foiler......................................................................................................................10

6.1 Working environment and safety..........................................................................................................10

6.2 Operating conditions...........................................................................................................................11

6.3 Switching on ......................................................................................................................................11

6.4 Adjusting the settings on the terminal (10) ...........................................................................................11

6.5 Welding parameters ...........................................................................................................................12

6.6 Tool positioning..................................................................................................................................12

6.7 Welding procedure .............................................................................................................................12

6.8 Switching o......................................................................................................................................12

7. Quick Reference Guide for the foiler ......................................................................................................12

7.1 Switching on / Starting........................................................................................................................12

7.2 Switching o......................................................................................................................................13

8. Commissioning your foiler ETL...............................................................................................................13

8.1 Working environment and safety..........................................................................................................13

8.2 Operating condition ............................................................................................................................13

8.3 Track guide roller (foiler ETL)...............................................................................................................13

8.4 Welding parameters ...........................................................................................................................14

8.5 Tool positioning..................................................................................................................................14

8.6 Welding procedure .............................................................................................................................14

8.7 Switching o......................................................................................................................................14

9. Quick Reference Guide for the foiler ETL................................................................................................14

9.1 Switching on / Starting........................................................................................................................14

9.2 Switching o......................................................................................................................................14

10. Frequently asked questions, causes and measures.............................................................................15

11. Accessories ..........................................................................................................................................15

12. Service and repair ................................................................................................................................15

13. Warranty...............................................................................................................................................15

14. Declaration of conformity.....................................................................................................................15

15. Disposal................................................................................................................................................15