arf BH67 User manual

Other arf Toy manuals

arf

arf Tornado Owner's manual

arf

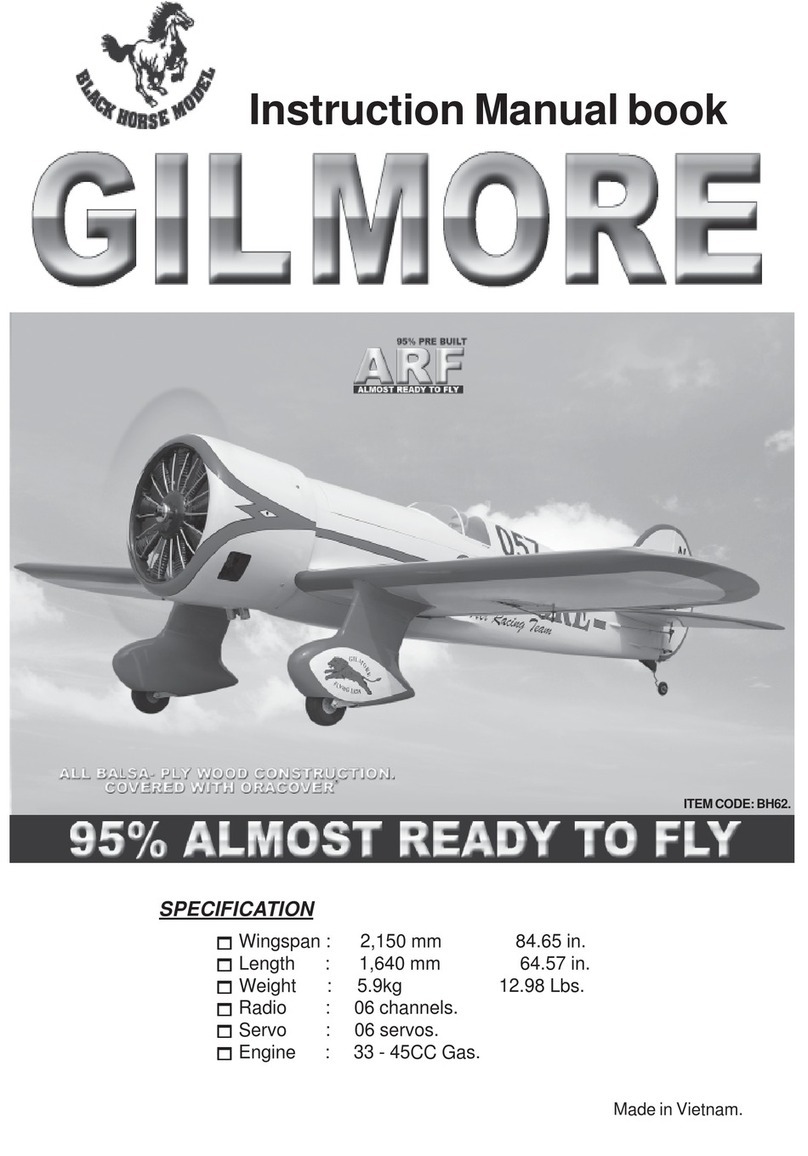

arf GILMORE Owner's manual

arf

arf YAK55M 60CC User manual

arf

arf PA-20 Pacer 10e User manual

arf

arf XPower P-51D MUSTANG User manual

arf

arf HandyKing EP User manual

arf

arf VISION EP User manual

arf

arf PITTS 30CC V2 User manual

arf

arf AVENSIS Owner's manual

arf

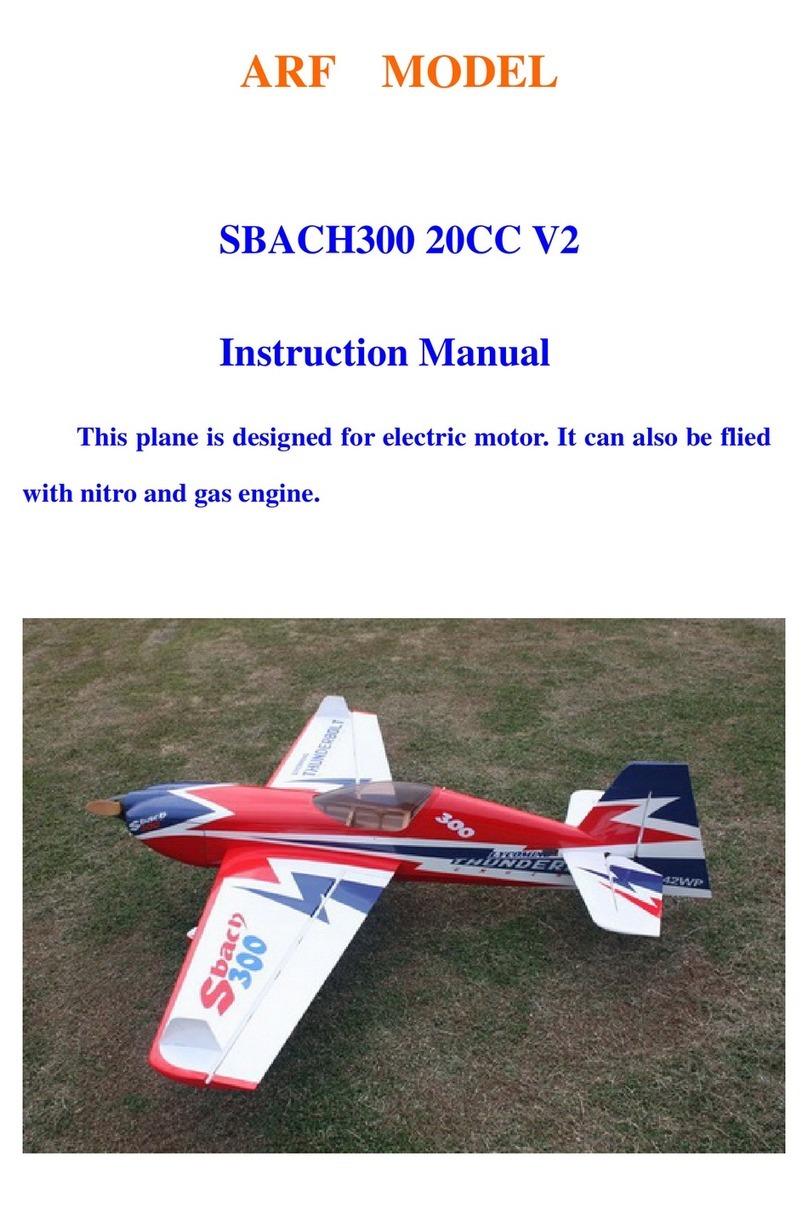

arf SBACH300 20CC V2 User manual

arf

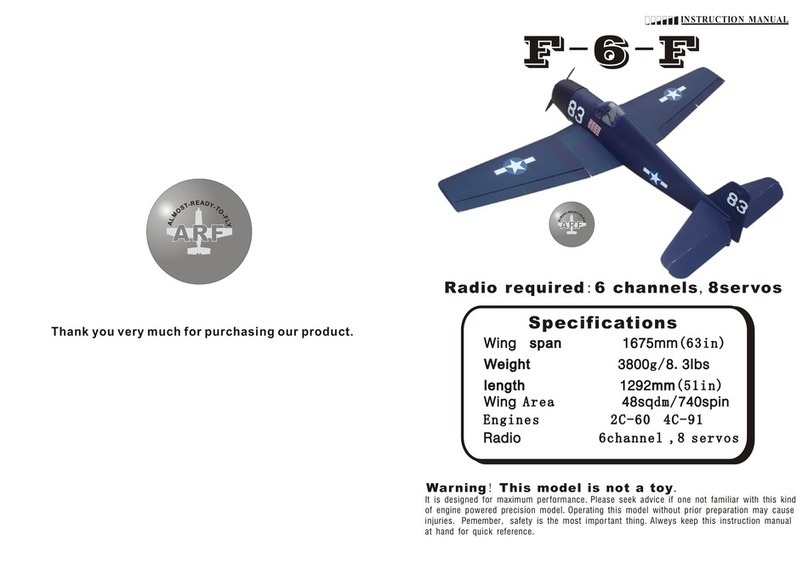

arf F-6-F User manual

arf

arf BO-209 MONSUN Owner's manual

arf

arf AeroPet 50 User manual

arf

arf YAK 55M User manual

arf

arf SLICK540 120E User manual

arf

arf F4U Corsair .60 User manual

arf

arf AT.6-TEXAN Owner's manual

arf

arf P-51 MUSTANG User manual

arf

arf Edge540K User manual

arf

arf Composite QQ Yak 54 2.6 m User manual

Popular Toy manuals by other brands

FUTABA

FUTABA GY470 instruction manual

LEGO

LEGO 41116 manual

Fisher-Price

Fisher-Price ColorMe Flowerz Bouquet Maker P9692 instruction sheet

Little Tikes

Little Tikes LITTLE HANDIWORKER 0920 Assembly instructions

Eduard

Eduard EF-2000 Two-seater exterior Assembly instructions

USA Trains

USA Trains EXTENDED VISION CABOOSE instructions