3

P11544 R3 CO#2643

TABLE OF CONTENTS

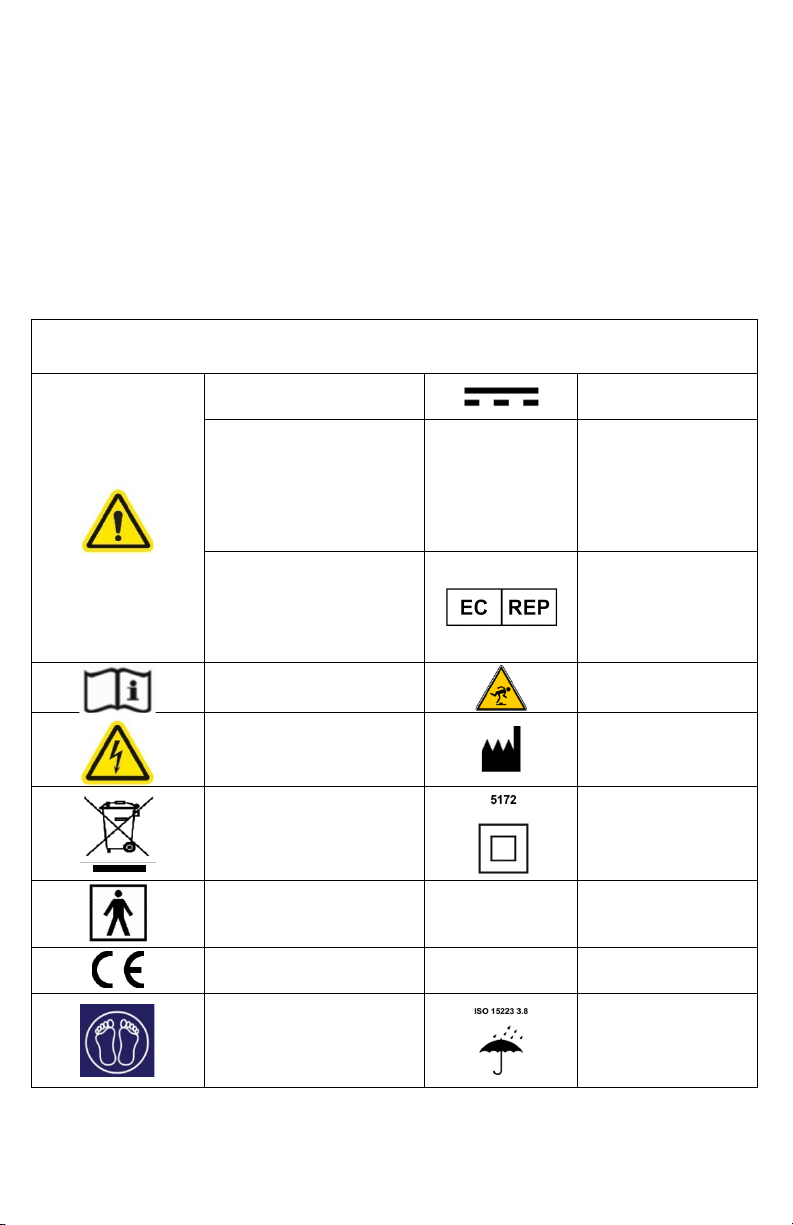

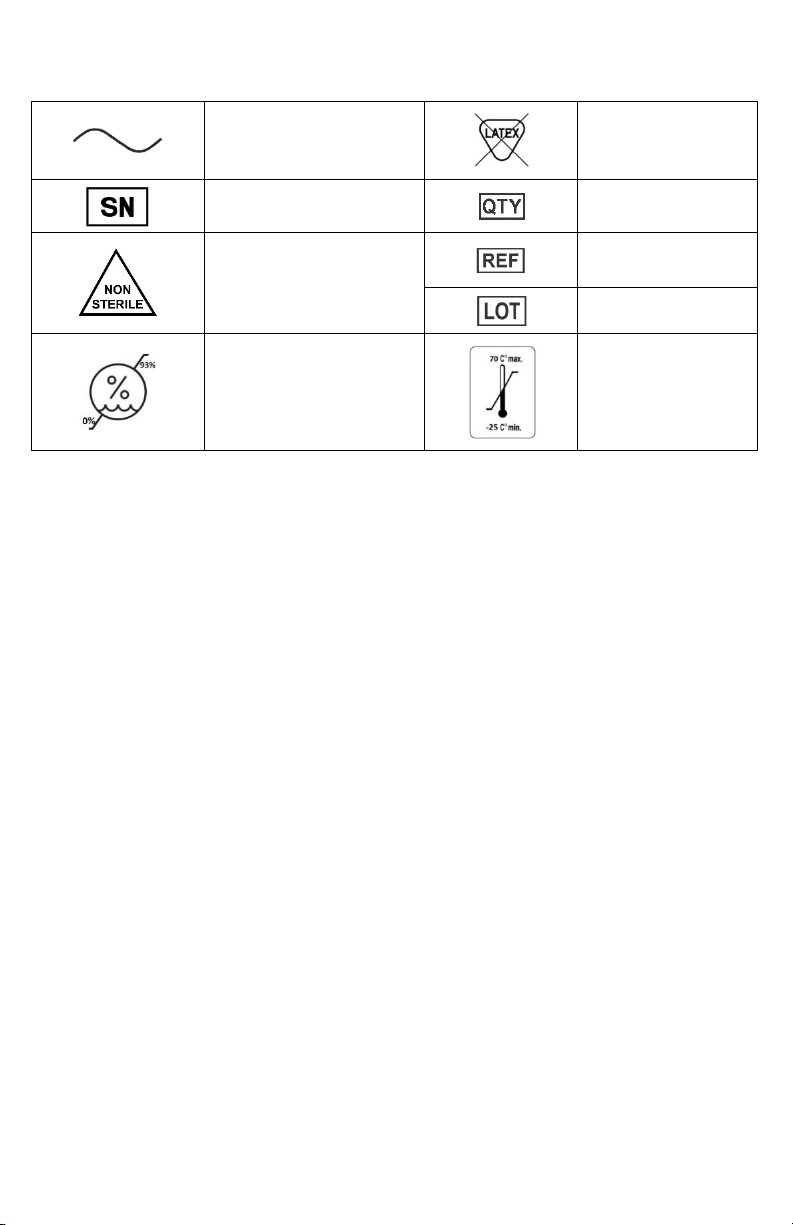

DOCUMENT SYMBOLS........................................................................................... 4

INTRODUCTION ..................................................................................................... 6

INDICATIONS FOR USE

GENERAL DESCRIPTION

MODES OF OPERATION

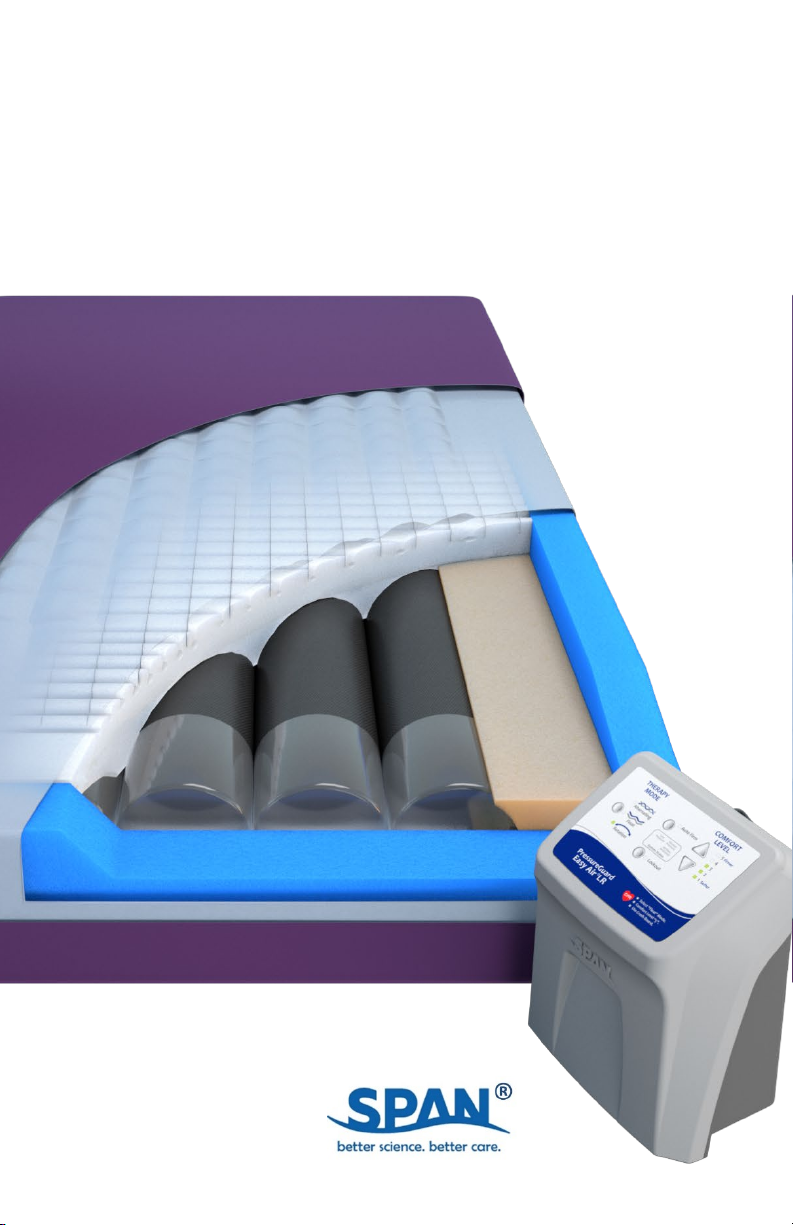

PRODUCT DESCRIPTION ........................................................................................ 7

THE SCIENCE BEHIND THE EASY AIR MICROCLIMATE MANAGEMENT DESIGN... 10

MATTRESS AND CONTROL UNIT SETUP DIRECTIONS .......................................... 11

ELECTROMAGNETIC OR OTHER INTERFERENCE .................................................. 13

CONTROL UNIT FUNCTIONS ................................................................................ 20

GENERAL DIRECTIONS FOR USE

ELEVATING HEAD OF BED.................................................................................... 23

BED RAILS ............................................................................................................ 23

CPR ...................................................................................................................... 23

PATIENT TRANSPORT .......................................................................................... 24

POWER LOSS ....................................................................................................... 24

BED LINENS.......................................................................................................... 24

INCONTINENCE PADS .......................................................................................... 24

SERVICE ............................................................................................................... 24

ENVIRONMENTAL CONDITIONS FOR USE............................................................ 25

STORAGE AND TRANSPORTATION ...................................................................... 25

CLEANING

MATTRESS COVERS ............................................................................................. 26

AIR CONTROL UNIT.............................................................................................. 27

PREVENTIVE MAINTENANCE

FILTER MAINTENANCE......................................................................................... 28

POWER CORDS .................................................................................................... 29

MATTRESS ........................................................................................................... 30

SPECIFICATIONS .................................................................................................. 32

ORDERING INFORMATION .................................................................................. 35

TROUBLE SHOOTING GUIDE................................................................................ 38

APPENDIX: PREVENTIVE MAINTENANCE LOG ..................................................... 42