Sparta Huskie Tools EP-430 User manual

OPERATION MANUALOPERATION MANUAL

EP-430

EP-430- 12 Ton Compression Tool

Read and understand all of the instructions and safety information

in this manual before operating or servicing this tool.

195 Internationale Blvd

Glendale Heights, IL 60139

Phone 800-860-6170

Fax 800-345-3767

www.spartacogroup.com

www.spartacogroup.com 800-860-6170

2

REGISTRATION/ TABLE OF CONTENTS

THANK YOU...

for purchasing a Huskie Tools product. Our

mission is to supply the finest steel cable

connecting and cutting tools and cable-related

products to the transmission and distribution

markets. Huskie Tools products represents the

state-of-the-art tools and are dependable & safe.

Trust, integrity, teamwork and mutual respect -

these words are something we take to heart here

at Huskie Tools.

Please take the time to read this manual carefully

to learn how to correctly operate and maintain

your tool.

Table of Contents

Registration/ Contents.......................... 2

Warranty................................................. 3

Safety...................................................... 4

Specs/Kit Includes................................. 5

Operating Instructions......................... 6-7

Breakdown.............................................8

Parts List.................................................9

www.spartacogroup.com 800-860-6170

3

WARRANTY

Warranty

Huskie Tools products carry a warranty that makes us a leader in the tool industry. No other manufacturer dares to back

its tools as we do.

All Huskie REC-SERIES battery operated products carry a 5 year warranty. The ECO-SERIES battery operated products

carry a 1 year warranty. The BP-80 & BP-84 batteries carry a 5 year warranty from the date stamped on the battery. The

BP-82 battery carries a 1 year warranty.

PRODUCT WARRANTY

REC-Series battery operated products 5 Years

ECO-Series battery operated products 1 Years

Batteries (BP-80, BP-84) 5 years/ (BP-82) 1 year

Chargers (CH-90, CH-94) 5 Years

The warranty does not cover any damages incurred from a Huskie tool including damages to property, bodily injuries

and lost wages resulting from such injuries. This warranty solely covers the repair or replacement of tools supplied by

Huskie. These remedies are exclusive, and the total liability of Huskie Tools, LLC whether based on contract, warranty,

negligence, indemnification, strict liability or otherwise, shall not exceed the purchase price of the tool. In no event shall

Huskie Tools, LLC be liable for consequential, incidental or special damages.

HUSKIE TOOLS, LLC MAKES NO OTHER WARRANTIES OF ANY KIND, EXPRESSED OR IMPLIED, AND ALL IMPLIED

WARRANTIES INCLUDING ANY WARRANTY OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE ARE

DISCLAIMED.

Huskie reserves the right to determine all warranty claims. Huskie will not warranty tools containing parts or batteries not

originally supplied by Huskie. Failure due to misuse, improper maintenance, misapplication, not following instructions or

warnings, abuse or repairs attempted by anyone other than Huskie Tools, LLC, or an authorized service center renders

this warranty null and void.

Repair and Warranty Claims

All claims must be sent to Huskie for inspection and authorization. A Return Goods Authorization (RGA) is required

before shipping tools to Huskie. Secure the authorization by telephoning or writing to Huskie’s main oce with details

of the claim. Non-warranty repairs are handled using the same procedure. Repairs exceeding 50 percent of the cost of a

new tool will be advised before repairs are made.

Payment Terms

Upon credit approval Huskie’s standard payment terms are net-30 days. Visa, Mastercard, Discover and American

Express are also accepted.

Freight

All Huskie tools are FOB, Glendale Heights, Illinois. Goods will be shipped pre-paid and added, unless otherwise

specified. Freight shipments over $17,000 are pre-paid.

Quotations

Special quantity quotations should be phoned in to discuss the scope of your tool requests.

Complete Support Services

Our customers have direct access to us for training, service, and problem solving. As specialists in tools, we maintain

a trained repair sta and a large stock of parts. This contrasts with many tool suppliers who carry tools as a sideline

without oering support services. Here are some reasons why our customers love to do business with us:

• Quick delivery

• We maintain inventory at our headquarters.

• Training and troubleshooting services.

• Fast repair service.

• Design and engineering service for special tool needs.

www.spartacogroup.com 800-860-6170

4

SAFETY

Safety Alert Symbol:

is safety alert symbol indicates a potential

personal injury hazard; it is not used for messages

related to property damage only.

Wear eye protection:

when operating this tool.

Failure to wear eye

protection could result in

serious eye injury from ying

debris.

Electric Shock hazard:

Use proper personal protective equipment when

using this unit on or near energized electrical lines.

Pinch Point Hazard:

Compression Dies at high

force can cause severe

personal injury. Keep all

body parts away from

moving parts of the tool

while operating.

www.spartacogroup.com 800-860-6170

5

SPECIFICATIONS & KIT INCLUDES

• 1 Compression Tool

• 1 Carrying Case

•Protective Rubber Boot on “C” Head

•External Pressure Adjustment

Specifications

Output 12 Ton

Weight 13.5 lbs.

Size 24”L

Jaw Opening 1-3/16”

Connector Range

Lugs Up to 750 MCM Cu

Splices Up to 600 MCM Cu

Features

The EP-430 is unique in that it has a large jaw opening of 1-3/16” and is able to splice up to

600 MCM. This tool was designed for the electrical contractor or electric utility lineman who

is confronted with larger cable diameters and larger connectors. Similar competitive tools are

limited to a .95” jaw opening that drastically reduces their connecting range. Most internal

hydraulic components are the same as the EP-410 and EP-510.

www.spartacogroup.com 800-860-6170

6

OPERATING INSTRUCTIONS

Compression

MAINTENANCE AND INSPECTION

1. Daily maintenance is required to ensure that the tool is kept in good working condition.

2. Do not store the tool in a humid environment.

3. Wipe away any excess oil with a soapy cloth.

4. Provided that maintenance of the tool is carried out regularly, the tool should provide

many years of service.

5. Should you experience any difficulty with the operation and maintenance of this tool,

contact Huskie’s technical support department at 1-800-860-6170.

1. Select the appropriate compression die set for the connector and cable being used.

The “U” style Huskie HT41-series dies are to be used with the EP-430

2. To insert the dies, depress the die release pin on the ram, and slide die into place.

Then, depress release pin on “C” head as well and slide other die half in place. Be sure

both die halves are secure before operating the tool.

3. Position the connector between the dies and pump tool handle until the connector is

held in place. Fully insert the cable into the barrel of the connector.

4. Continue to pump the tool handle and completely crimp the connector. These tools

all have a built in by-pass cartridge that will automatically activate when full pressure

is reached. There will be a notice-able decrease in handle pressure when the by-pass

is reached. a high pitched squeaking sound is normal when the tool is operating in the

high pressure stage.

5. To release the tool, lift pump handle out and rotate clockwise until handle stops. With

handle twisted, push down so the pin on the handle contacts the release pin on the

tool body. The ram will retract and the tool is ready to begin its next cycle. In the event

the tool will not release due to excess flash, hold release pin down with handle and pry

tool jaws apart.

6. A compression gauge, model PG-4 is available for the EP-430 for checking output pres-

sure. Consult factory for proper adjusting procedure.

www.spartacogroup.com 800-860-6170

7

OPERATING INSTRUCTIONS

PRECAUTION FOR THE TOOL

1. Always point the tool AWAY from other people.

2. If the tool is stored for an extended period at a temperature of less than 25º F (-5ºC), the tool

should be allowed to return to room temperature to ensure smooth operation Use the tool only

after it has been at room temperature for 1 hour.

3. Do not drop the tool. Dropping the tool may damage the hydraulic circuit and result in the tool

not functioning correctly.

4. Keep the head and ram clean and free of debris. Solvents can be used to clean the head, but

should not be used on the plastic body. Use soap and water to clean the body.

5. Do not use tool for continous use. If any sign of over heating, allow the tool to cool for 15 mins.

6. Do not allow tool to be submerged in water. The tool may be used to in damp or wet

environments. However it is recommended for tool to be air-dried before use.

1. Never operate tools without dies in place. Failure to insert dies before operation will

cause damage to the “C” frame and tool ram.

2. Never attempt to adjust pressure setting without the use of the proper test gauge.

Consult factory for proper adjusting procedure.

3. All manually operated hydraulic compression tools are equipped with our external re-

placeable bypass cartridge. These cartridges should not have to be replaced for 10,000

to 12,000 compressions.

4. Die hang up is common with all types of compression tools. Should this occur, the jaws

can easily be separated by holding the pump handle in the release position while pry-

ing the jaws apart. Never attempt to hit connector or tool jaw withhammer as this will

damage connector and tool.

5. If tool fails to advance upon receipt or after an extended period of storage, invert tool

and rap compression head sharply on ground. The suction valve check ball can become

stuck after extended storage or during shipment, not allowing the tool to advance.

6. Always clean tool after use to keep ram track clear of dirt and debris.

TROUBLESHOOTING FOR THE TOOL

www.spartacogroup.com 800-860-6170

8

BREAKDOWN

www.spartacogroup.com 800-860-6170

9

PARTS LIST

51 P-8 O-Ring (C.P.) 410-43 1

52 Valve Screw (10) 410-44 2

53 Spring (67) 85-39 2

54 9/32" Ball 16-40 2

55 Spring (66) 85-40 1

56 3/16" Ball 16-49 1

57 Body 430-08 1

58 Suction Valve Plug 410-46 1

59 P-4 Back-Up Ring (B.C.) 410-47 2

60 P-4 O-Ring (C.P.) 410-48A 2

61 Spring (4) 16-48 1

62 7/32" Ball 16-26 3

63 M4 X 4 Screw (F.P.) 85-47 1

64 1/8" Ball 40-20 1

65 M5 X 8 Screw 410-49 1

67 Strainer 410-72A 1

68 Filter Screen 410-73 1

69 SI-20 Ring 410-74 1

70 Spring (43) 85-49 2

71 Valve Screw (22) 410-80 1

72 Spring Holder 410-51 1

73 Valve Plug (1) 410-52 1

74 Body Insulation 430-11 1

75 G-30 O-Ring 75-26 1

76 Oil Reservoir 430-09 1

77 Reservoir Cap 410-55 1

78 G-40 O-Ring P100A-05 1

79 Body Handle Ass'y 430-10A 1

80 Handle Extension Insulation 410-59 1

81 Body Handle Grip 412-05 1

82 Spring (440) 412-04 1

83 Magnet ROB-25 1

CODE

NO.

DESCRIPTION

QTY.

1 2 X 12 Drive Pin (AW) 40-21 1

2 Knob 510-01 1

3 Screw (16) 510-02 1

4 Spring (257) 510-03 1

5 Retainer Pin (A) 510-04 1

6 2.5 X 25 Drive Pin (BW) 410-04 1

7 Head 430-01 1

8 Guide Screw 510A-15 1

9 M5 Lock Washer (Small) 510-12 1

10 Key 510A-06 1

12 M5 Lock Washer 410-09 2

13 M5 X 6 Screw 410-10 2

14 Retainer Pin (B) 410-12 1

15 2.5 X 14 Drive Pin (BW) 410-11 1

16 Spring (177) 410-01 1

18 Die Release Pin 430-21 1

19 Ram 430-02 1

20 2.5 x 8 Dowel Pin (B) 410-17 1

21 Dust Seal 430-03 1

22 P-40 Back-Up Ring (B.C.) 22-16 1

23 P-40 O-Ring (C.P.) 410-70 1

24 Spring Holder 430-04 1

25 Spring (323) 430-05 1

26 Ram Spring Support 430-06 1

27 OV-36 Snap Ring 410-21 1

28 CE-7 Snap Ring 40-49 2

29 Pin (85) 410-22 1

30 Pin (84) 410-23 1

31 5 X 32 Dowel Pin (G) 85-57A 1

32 Pump Handle Head 410-24 1

33 Bushing 410-25 4

34 4 X 26 Dowel Pin (G) 410-26 1

35 Handle Head Insulation 410-27 1

36 Spring (146) 85-60 1

37 Push Pin 85-61 1

38 Pump Handle Ass'y (Yellow) 410-30B 1

39 Pump Handle Grip (2) 410-31 1

40 Pump Piston 410-32 1

41 P-20 X-Ring 410-33 1

42 P-20 O-Ring (C.P.) 410-34A 1

43 P-8 Back-Up Ring (B.C.) 85-33 1

44 PS-8 Pent Seal 16-44 1

45 Release Valve Screw (7) 85-35 1

46 Release Valve Stem 410-35 1

47 P-3 O-Ring (C.P.) UC-27 1

48 Spring (144) 85-37 1

49 Bypass Cartridge 410-36 1

50 S-9 O-Ring 410-71 1

NO.

DESCRIPTION

QTY.

CODE

www.spartacogroup.com 800-860-6170

10

NOTES

www.spartacogroup.com 800-860-6170

11

NOTES

195 Internationale Blvd

Glendale Heights, IL 60139

Phone 800-860-6170

Fax 800-345-3767

www.spartacogroup.com

Table of contents

Other Sparta Tools manuals

Sparta

Sparta Huskie Tools SL-B510 User manual

Sparta

Sparta Huskie Tools PRO LINE IL-MK7ND User manual

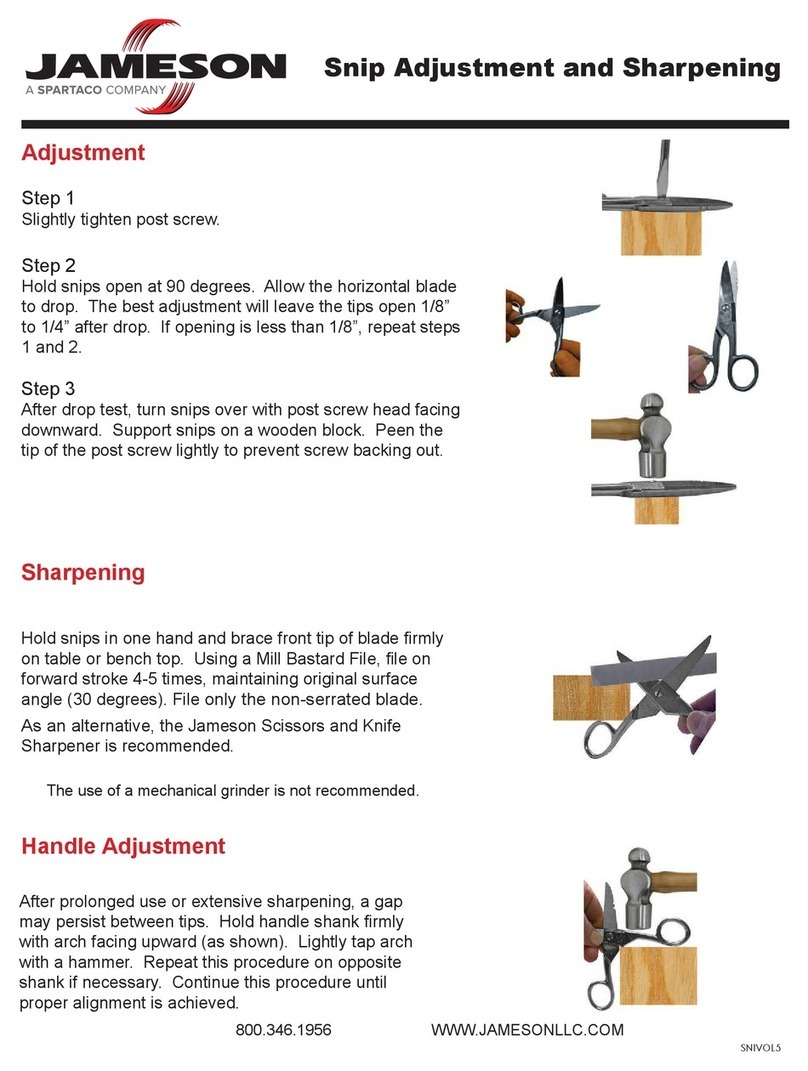

Sparta

Sparta JAMESON Snip Grip 32-40 User manual

Sparta

Sparta Huskie Tools PRO LINE IL-7NDBG User manual

Sparta

Sparta Huskie Tools REC-B6510 User manual

Sparta

Sparta Huskie Tools REC-B6750 User manual

Sparta

Sparta Huskie Tools ECO-MK7EZ User manual