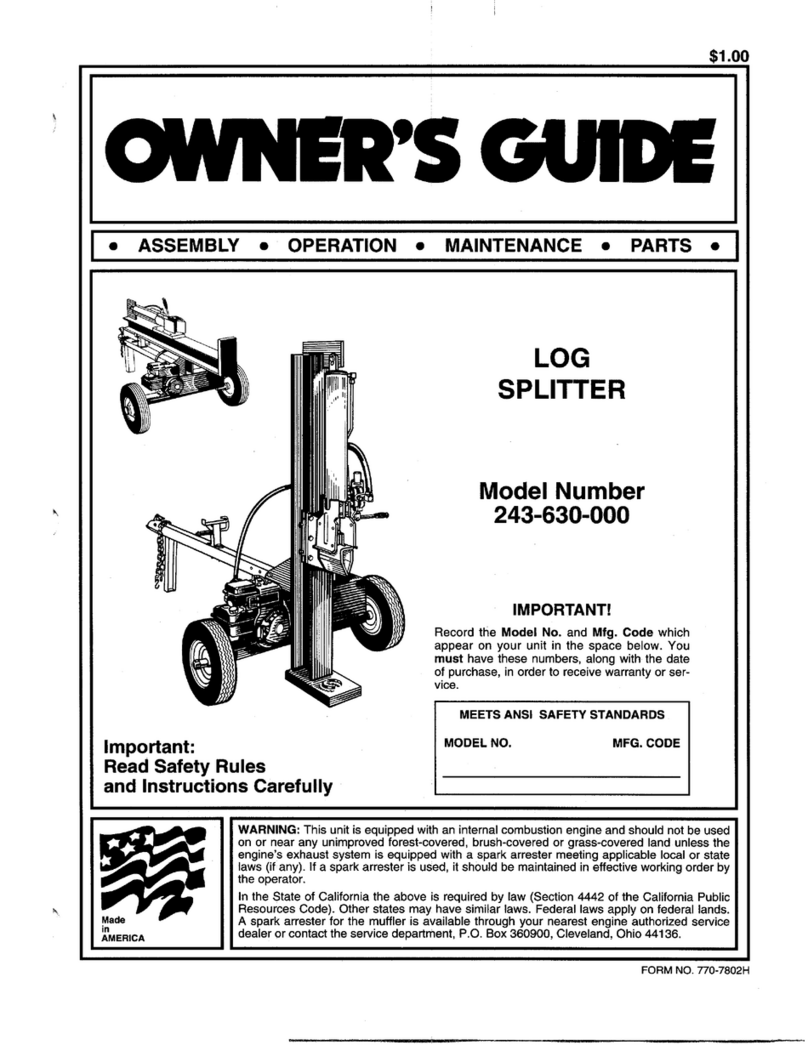

NOTE: Thislogsplitterwaspartiallyassembledatthefactory.Refertothedrawingandpartslistshoulditbecomenecessarytodisassembletheunitfor

repairorreplacementofparts.

STEP 1: Removeallthecomponentsfromthecrate.Inspecteachpieceforshippingdamage.Ifanypartisdamaged,contactyourdealerordelivery

carrier.

STEP 2: Attachthetongue(3)tothetank/axle(2)asshowninthediagramusingthetwo1/2in.NCx4-1/2in.hexcapscrews(48), 1/2in.lockwashers

(47)and1/2in.NChexnuts(46).Tightenthenuts.NOTE:Flatwashersareincludedinthehardwarekitshoulditbenecessarytousethemas

spacerstoeliminateplaybetweenthetongueandtank/tonguemountingplate.

STEP 3: Attachthetonguejack(24)byaligningtheholeinthetubeonthejackwiththeholeinthebushingonthelogsplittertongue(3).Insertthelocking

pinintheverticalpositionthroughtheholes.

STEP 4: Removetherubbercoveringfromthetwospindlesonthetank/axle(2).Thewheelbearingcups,bearingcones,greasesealsandhubcaps

arealreadyassembled.Bearingconeshavebeengreasedatthefactory.Removethehubcap(62)by pryingitloosewithacommontip

screwdriver.Mountthewheels(54)tothespindlesonthetank/axle(2)usingthe3/4in. lightflatwasher(59)and3/4in.slottednut(60)fromthe

hardwarekit.Tightenthenutuntilbearingplayisremovedandthe wheelwillstillrotatefreely.Installthecotterpin(61)andhubcap(62).

Repeatstep4 fortheotherwheel.

STEP 5: Standthebeam(1)uponend.Checktomakesurethatthebeamisstable.Thenrolltheaxle/tongueassembly(2&3)into positionbetween

thetwotabsonthebeam(1).Slidethepivotpin(52)throughtheholesandlockinplacewiththeclippin (53).

STEP 6: Removethecapandthenconnecttheendofthe1/2in.I.D.x44in.hydraulichose(21)comingfromthefitting(20)ontopof thepump(9)to

thefitting(73)onthevalve(5).

STEP 7: Slideonehoseclamp(18)ontheendofthe3/4in.I.D.x44in.hydraulichose(49)thatcomesfromthefitting(69)onthe valve(5).Remove

thecapfromthetank(2).Thenconnectthehosetothefittingonthetank(2).Tightenthehoseclamp (18).

STEP8: Attachthefenders(44)tothetank/axle(2)usingthe1/4in.NCx3/4in.hexcapscrews(43),1/4in.flatwashers(42),1/4in. lockwashers(41)

and1/4in.hexnuts(40).Tighten.

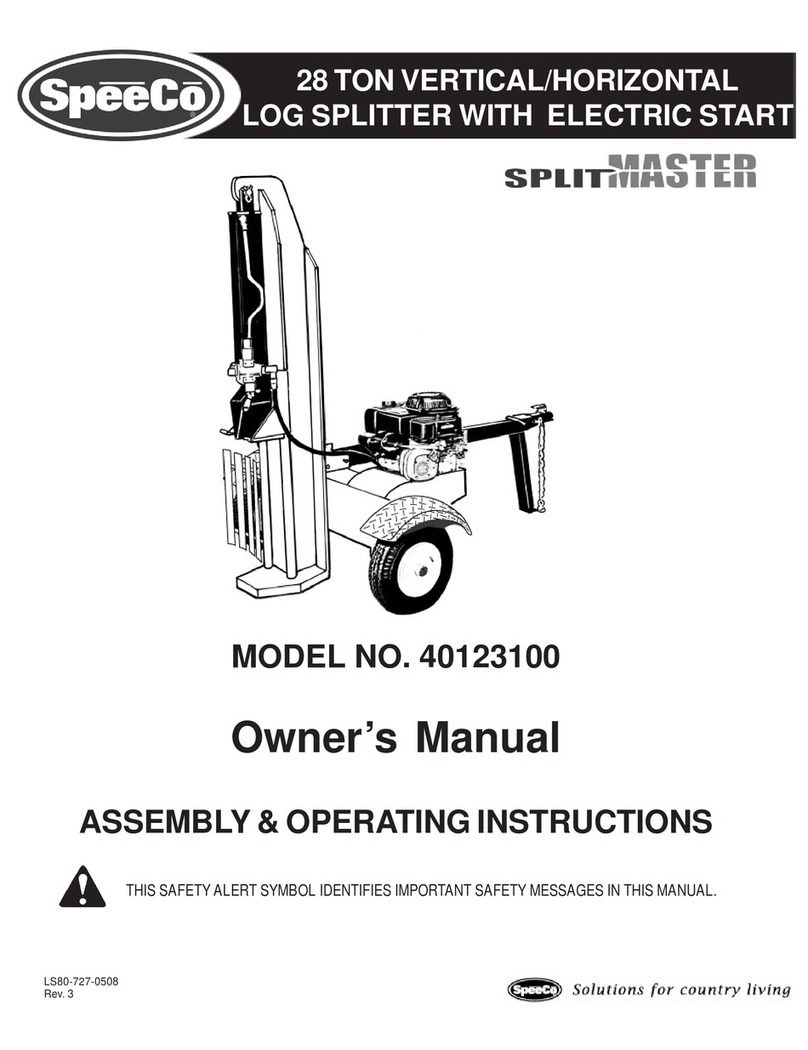

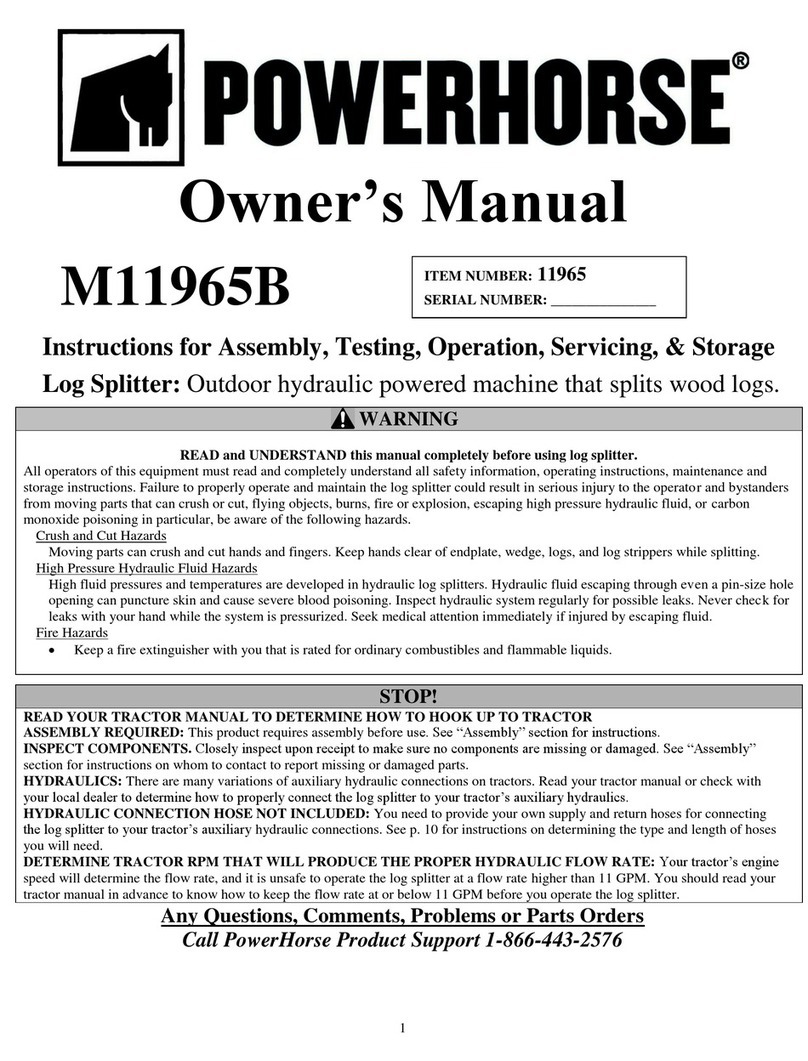

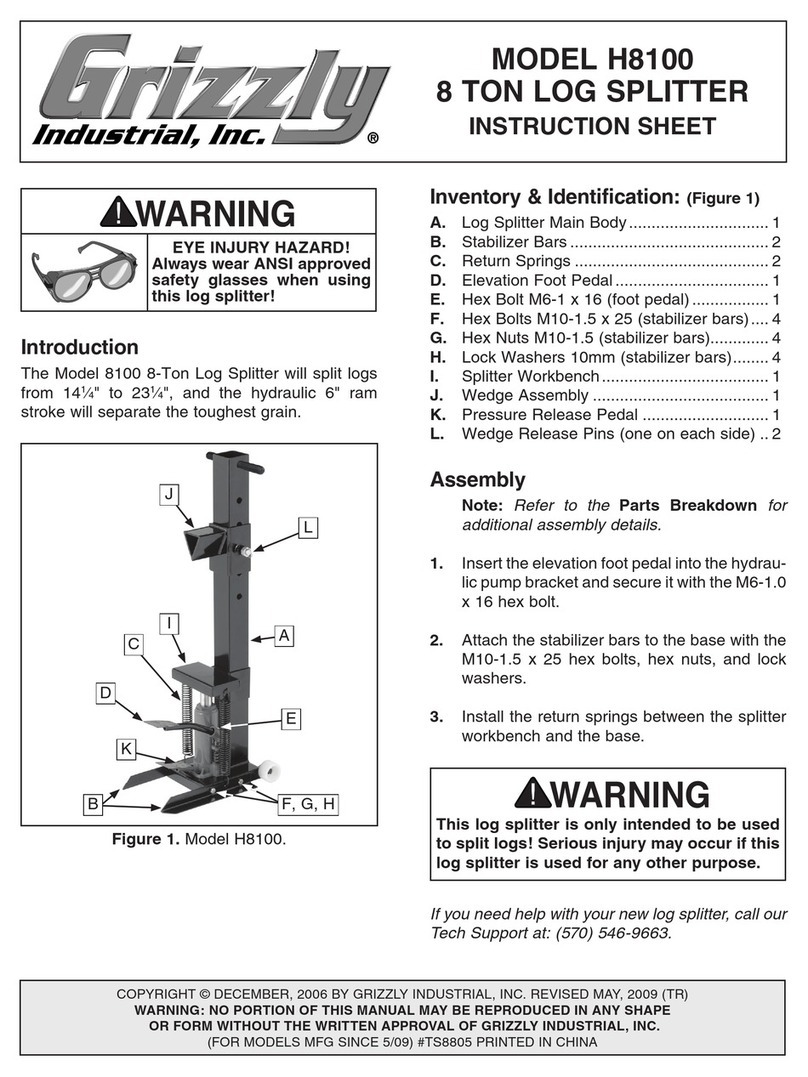

WARNING: Read thoroughlyunderstand all instructions and safety information before operating this log

splitter. Failure to do so may cause serious injury or death. Do not allow anyone to operate this log splitter

who has not read this manual. As with all power equipment, a log splitter can be dangerous if assembled or

used improperly. Do not operate this log splitter if you have doubts or questions concerning safe operation.

Callourcustomer service department at 1-800-525-8322 to address theseconcerns.

Si no entiende ingles, se prefiere que busque alguien que interprete las instrucciones para usted.

IMPORTANT:THIS LOG SPLITTER IS SHIPPED WITH HYDRAULIC OILIN THE TANK (2). USE CARE WHEN REMOVING CAPSFROM

THE END OF THE HOSEAND TANK.

THE ENGINE IS SHIPPED WITHOUTOIL. SEE THE HONDAENGINE OPERATINGAND MAINTENANCE INSTRUCTIONS

MANUALFOR TYPE OF CRANKCASE OIL, FUEL, STARTING, ETC.THE ENGINE MANUFACTURER RECOMMENDS

LEAD-FREE GASOLINE FOR BEST OPERATION.

IMPORTANT: BEFORE OPERATING THIS LOG SPLITTER, READAND UNDERSTAND THIS MANUALCOMPLETELY.

BECOME FAMILIAR WITH IT FOR YOUR OWN SAFETY. TO FAILTO DO SO MAY CAUSE SERIOUS

INJURY. DO NOT ALLOWANYONE TO OPERATE YOUR LOG SPLITTER WHO HAS NOT READ THIS

MANUAL.READEACHSTEPCOMPLETELYBEFOREPROCEEDING.

Page7

ASSEMBLYINSTRUCTIONS

OPERATING INSTRUCTIONS

CAUTION: DO NOT STARTOR RUN THE ENGINE WITHOUT OIL IN THE HYDRAULIC RESERVOIR AND

OILINTHEENGINE CRANKCASE.