alligator clip of the test leads connected. The indicator should read

00.0Ω. When the leads are not connected the display will read

infinity indicated by “OL”. This will ensure that test lead are under

working condition.

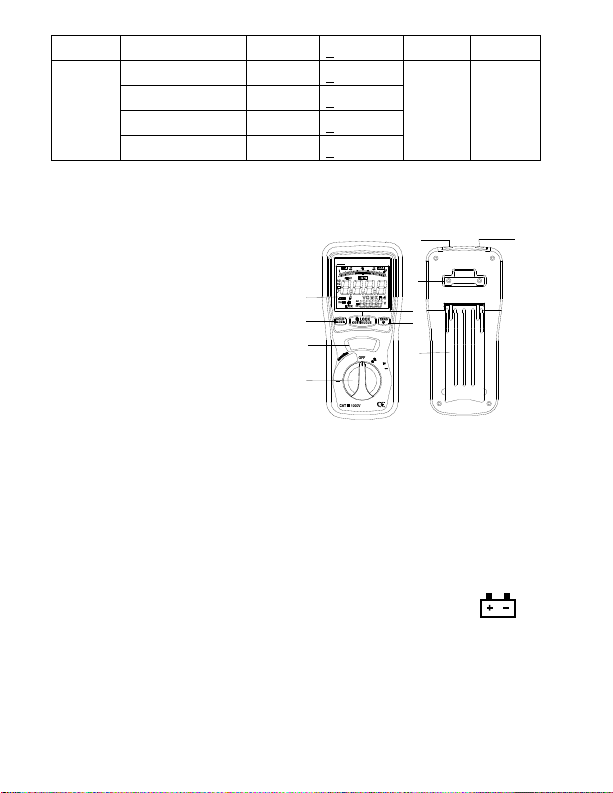

2-4 Rotary Switch positions

Turn the Tester on by selecting any measurement

Lift <1000v,500v,250v,125v (4000MΩ)

OFF 400Ω/BZ, 1000VDC,750VAC >Right

2-5 Buttons and a display Indicators

a). Button

HOLD/MAX.MIN : Instant-pressing the “HOLD”button the 1st time,

the current values will be hold in the primary display., but it will return

in the 2nd pressing ; pressing 2 seconds ,it will enter directly into the

“MAX”status, and one another instant-pressing will switch to the

“MIN”, if instant-pressing once more, it will recycle ,but exit if

pressing 2 seconds again.

LOCK :In the insulation resistance testing function ,press the

“LOCK”button ,and then push down the “TEST”key, it will occur the

high-voltage and enter the insulation resistance testing status. Press

the “TEST”button once more ,it will shutoff the high-voltage and exit

from the insulation resistance testing status.

TEST : In the insulation resistance testing function ,pressing and

holding the “TEST”button, The meter will bring high-voltage, and

enter into the insulation resistance testing, being free from the

“TEST”, it will cutoff the high-voltage and exit form the insulation

resistance testing.

ZERO/LIGHT :Iinstant-pressing the “ZERO/LIGHT”button in the 1st

time, the current values in the primary display will be set

zero,(mainly used for 400Ω, the low resistance testing), ,it will return