Spheros CC 355 User manual

Air Conditioning

System

“CC 355”

March 2013

Contents

1. Introduction

2. Spheros Warranty Terms

3. CC 355 –Data Sheet

4. CC 355 –System Components

4.1. System Components Picture

4.2. System Components Explanation

4.3. Ordering Spareparts - Equipment

Identification

4.4. Modelnumber

4.5. Equipment Components

4.6. Refrigerant Circuit

4.7. Installation Drawing

5. Controller & Operating

5.1. Controller WG-14164-00

5.2. Controller WG-14164-00 Operating

5.3. Controller

5.4. Numeric Display –Set-point

Index

5.5. Reading the temperature –Ventilation

Mode

5.6. Automatic Control Mode

5.7. Refrigeration –Compressor –Fans

5.8. Pressure switch –ICE sensor

5.9. Heating –Auxiliary Heaters

5.10 Reheating Mode

5.11. Air Refreshment Mode

5.12. Operation without panel

6. Maintenance, Troubleshooting

6.1. Preventive Maintenance

6.2. Preventive Maintenance Frequency

Schedule

6.3. Troubleshooting General

6.4. Troubleshooting Faults

6.5. Troubleshooting Failure Diagnosis Table

7. Technical Data Sheet Overview

8. Notes

Spheros develops its products with a view to

offering passengers a comfortable environment,

always seeking for the best condition of personal

well-being.

The equipment offers a design that provides

seamless integration with the vehicle, facilitating

its operation and maintenance. With optimized

design, high-cooling capacity and low noise

assured.

This manual was developed for the purpose to

present some important aspects of function,

operation and maintenance, so as to get optimum

performance out of the air conditioning equipment.

To ensure that the equipment has a long, useful

and trouble free life, it is essential that the

operations and maintenance instructions

described in this manual are followed and

performed regularly.

1. Introduction

The controls installed by Spheros, which are used

by the driver, are duly illustrated and explained in

this manual. It’s important to read the manual

before starting to operate the air conditioning

equipment.

Spheros maintains a network of authorized

services providers with tools, equipment and a

team of professionals trained to perform any type

of maintenance within the quality standards.

Thank you for choosing Spheros products. For

questions please contact the nearest Spheros

authorized services provider or contact the

technical assistance department.

3

1 - The warranty period starts with the day of installation of the

goods and the initial registration of the vehicle in which the

initial installation is made, respectively. The warranty period

ends at the latest 24 months after delivery of goods.

2 - Should the equipment be installed by a third party, Spheros

warrants only the product and not its installations.

3 - During the stipulated period, the warranty completely covers

the workman-ship and spare parts used to repair defects

duly identified as being premature failure of material and

component defects used on its manufacturing.

4 - Only a technician from the Spheros authorized network of

services is qualified to repair the defects covered under the

warranty.

5 - The warranty approval is subject to the technical analysis of

the defects shown in the components and operational

conditions to which the equipment has been subjected.

6 - No claims will be accepted if the vehicle is still in use after

the defect is found, even if there is lack of replacement parts,

delay in transportation or any other such incident.

7 - The warranty of the components used in the assembly of

Spheros equipment, which have their own technical

assistance network, will be obtained from their own network

by presenting the Spheros warranty certificate. Taking for

example an alternator from the supplier Bosch, the request

should be forwarded directly to the service network of

Bosch.

8 - The warranty looses its validity:

a) if the installation or use of the product is not in accordance

with the Spheros technical recommendations.

b) if the product suffers any damage by accident, force of

nature, misuse or alterations and repairs performed by

unauthorized personnel.

c) if the warranty certificate and/or the serial number of the

product are adulterated, overwritten or damaged.

d) if defects or unsatisfactory performance are caused by the

use of non-original spare parts and in disagreement with the

technical specifications of Spheros.

e) if no original warranty certificate can be presented.

9 - The warranty does not cover:

a) the displacement of the bus for repairing the equipment. In

case the customer requests to be attended in the same

place where the product is operating, it will be up to the

authorized service provider to decide whether the visit will

be chargeable or not.

b) the support of customers in cities that do not have

authorized services providers. There the expenses for the

displacement are the sole responsibility of the owner.

c) lack of proper preventive maintenance, as described in the

preventive maintenance item in this manual.

d) parts that wear out naturally: bearings, belts, filters in

general, lubricating oil, relays and fuses.

e) losses or losses of profits caused by the grounding of the

vehicle due to the equipment not functioning.

2. Spheros Warranty Terms

4

3. CC 355 –Data Sheet

March 2013

5

3. CC 355 –Data Sheet

6

Technical Data CC 355

Max. Cooling capacity (kW) * 40

Air flow evaporator (free-blowing, m³/h) 6300

Quantity of blowers 6

Max. outside temperature (°C) 60

Refrigerant (CFE-free) R-134a

Quantity of refrigerant (kg) ** 8,5

Compressor (cm³) 650

Weight (roof top unit, kg) 165

Dimensions (L x B x H in mm) 3480 x 1700 x 200

* evap. air in 40°C/ 46% r.h. ; ambient 35°C

** The quantity of refrigerant gas can vary according to the application and installation

4. CC 355 –System Components

March 2013

7

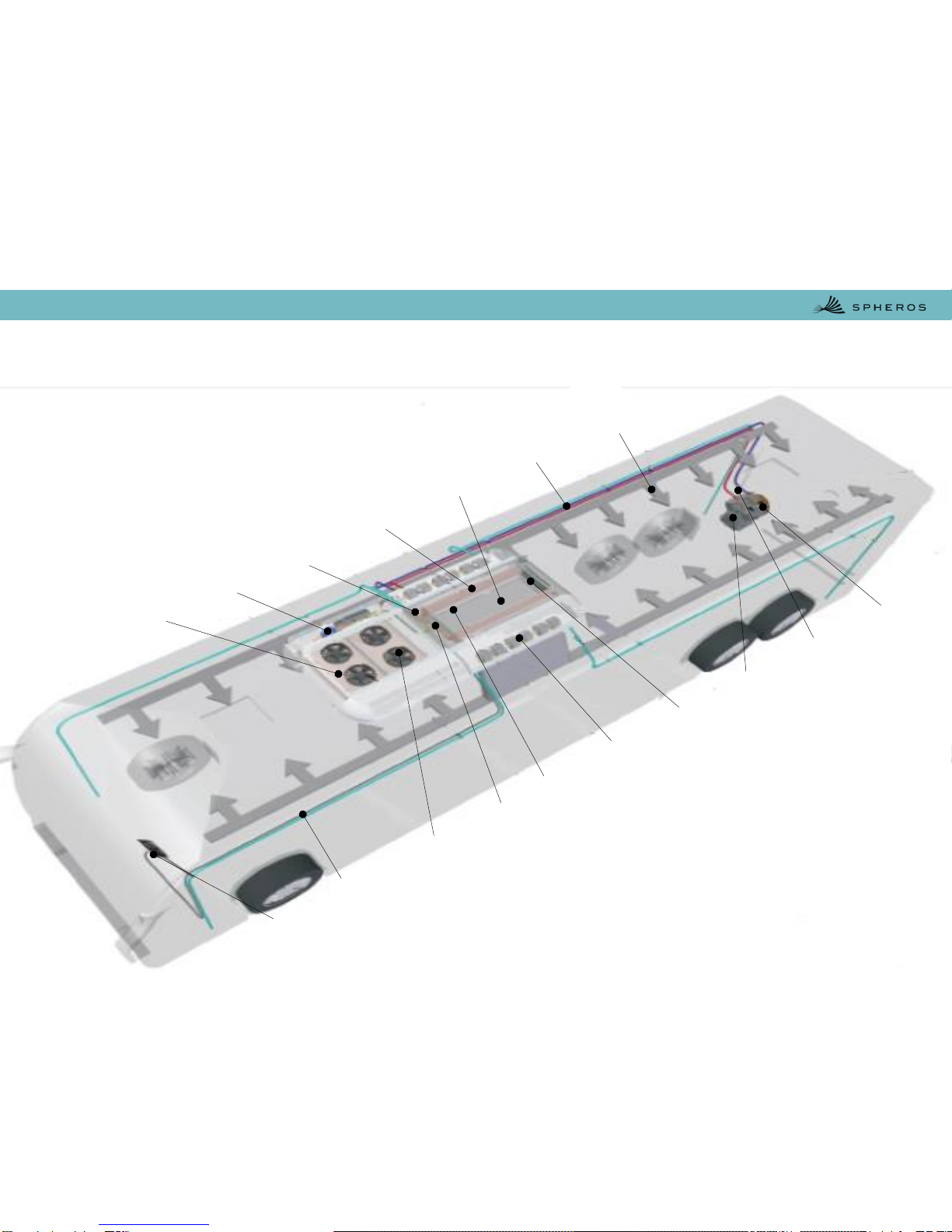

4.1. CC 355 System Components Picture

1

12

15

13

16

14

11

2

3

4

5

6

7

17

10

9

8

4.2. CC 355 System Components Explanation 1 –9

No. Description No. Description

1 Condenser: Its main function is to dissipate

the heat absorbed by the refrigerant throughout

the system. In the condenser, the overheated

refrigerant, change its gassy state into a liquid.

6 Fluid Refrigerant: Spheros products use only

R134a refrigerant in order to protect the

environment as its globally accepted standard.

The refrigerant is used to cool down the

passenger compartment by changing its state.

2 Filter Dryer: Used to retain some dross and/or

humidity that might be in the system to avoid

damaging or blocking the expansion valve. 7 Air Circulation: The air, after being cooled in

the evaporator is distributed inside of the bus

through some ducts.

3 Expansion Valve: The thermostatic expansion

valve restricts the entry of the high-pressure

refrigerant that is coming from the condenser

and its function is to regulate the refrigerant

flowing through the evaporator so as to

maintain the pressure and temperature at the

coil outlet.

8 Controller: Installed on the bus dashboard, the

controller enables the driver to choose the set-

point temperature and view the internal bus

temperature, thereby giving the driver complete

climate control inside the bus.

Set-point is the value of the desired

temperature inside of the vehicle.

4 Evaporator: In the evaporator the refrigerant

fluid, now at low pressure, changes its state

from liquid to gas, absorbing heat in this

process from the internal environment of the

bus.

9 Drains: These are used to conduct the

condensate humidity in the evaporator coils

from the evaporator tray to the outside of the

vehicle.

5 Air Filter: The air return filter retains the dross

suspended in the air so as to avoid the

accumulation of waste in the evaporator coils.

4.2. CC 355 System Components Explanation 10 –17

No. Description No. Description

10 Condenser Fan: The condenser fans, as well

as the compressor, will only be on when the air

conditioner operates in ‘cooling mode’. The

Conderser Fan helps to keep the condenser

cool and protects it from overheating.

14 Air Refreshment: This permits the entry of

outside air in order to increase the oxygen level

and to expel unwanted odors and impurities

from inside the vehicle.

11 Relay Plate: The relay plate receives the

orders from the controller and turns on the

condenser fans, evaporator blowers and the

compressor according to the selected operation

mode.

15 Compressor: When it is functioning, the

compressor draws the refrigerant from the

evaporator at its gassy state at low pressure,

compresses it by raising the pressure and

temperature and discharges it into the

condenser.

12 Temperature Sensor: Sensor to measure the

temperature and therefore providing important

data to the control system for an optimized air

conditioning performance.

16 Pressure Switch: The pressure switch is an

electrical device that monitors the working

pressures of the air-conditioner. Whenever

there is a change in the normal operational

pressure the compressor will shut down

immediately so to avoid breaking. Note: The

working pressure is monitored continuously

even when the air conditioner is off.

13 Evaporator Blower: The evaporator blowers

are on in both ventilation and cooling mode and

can operate at two speeds. The speed control

can be automatic or manual. The blowers blow

the cold air into the passenger compartment.

17 Clutch: The compressor is powered by the

vehicle engine with a belt transmission power

system and a magnetic clutch whenever the air

conditioner is operating in ‘cooling mode’.

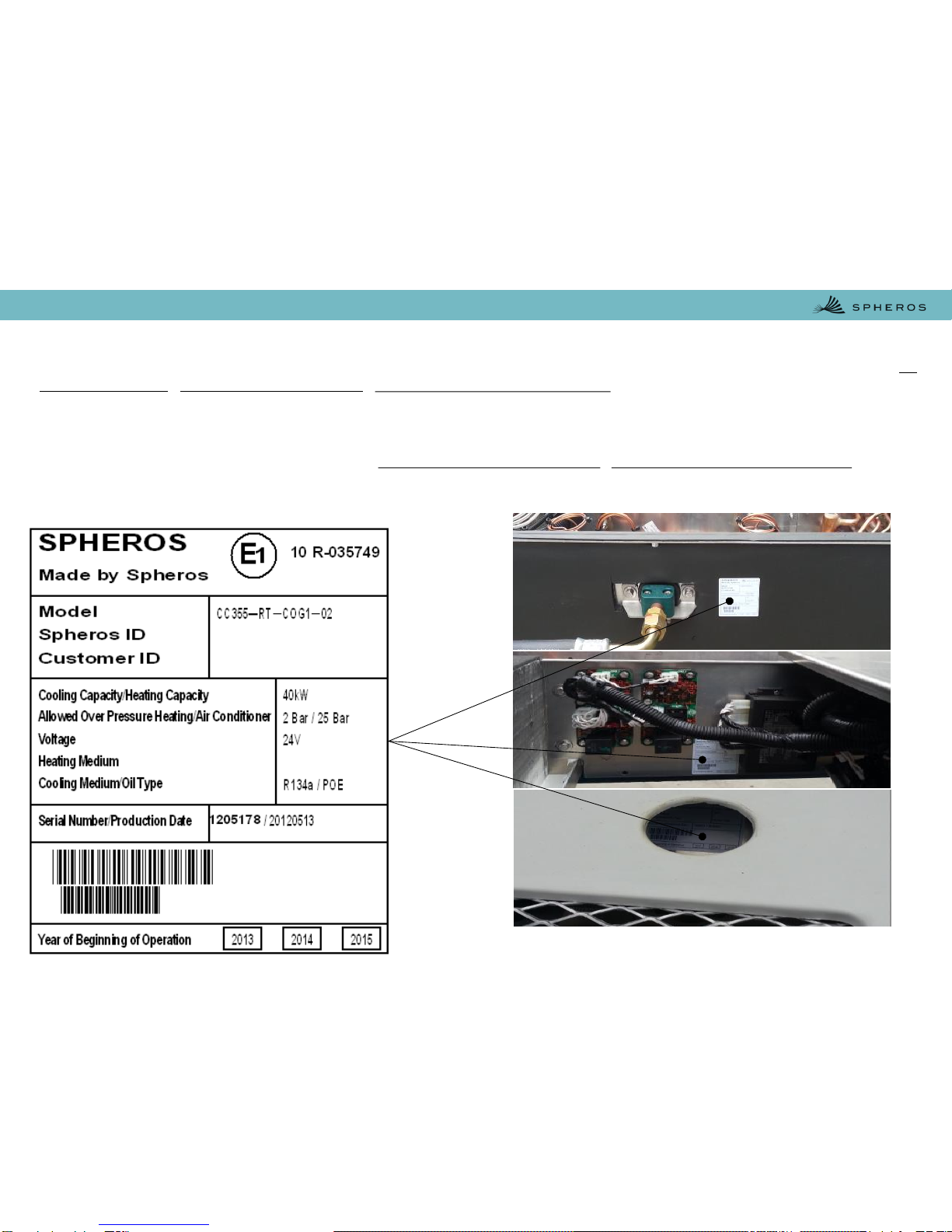

4.3. Ordering Spare Parts –Equipment Identification

It is extremely important when ordering spare parts and sending other correspondences, that the customer identifies the air

conditioner model, mentioning serial number, model and manufacturing date. This information may be found on the air

conditioner’s warranty certificate and on the identification tag. On this tag you will also find listed the refrigerant gas to be

used and the necessary quantity for the model.

Information regarding the application such as: body serial number and model, chassis serial number and model are also

important to identify the spare parts that comprise the air conditioner system. To identify the body and the chassis, their

manuals should be consulted.

11

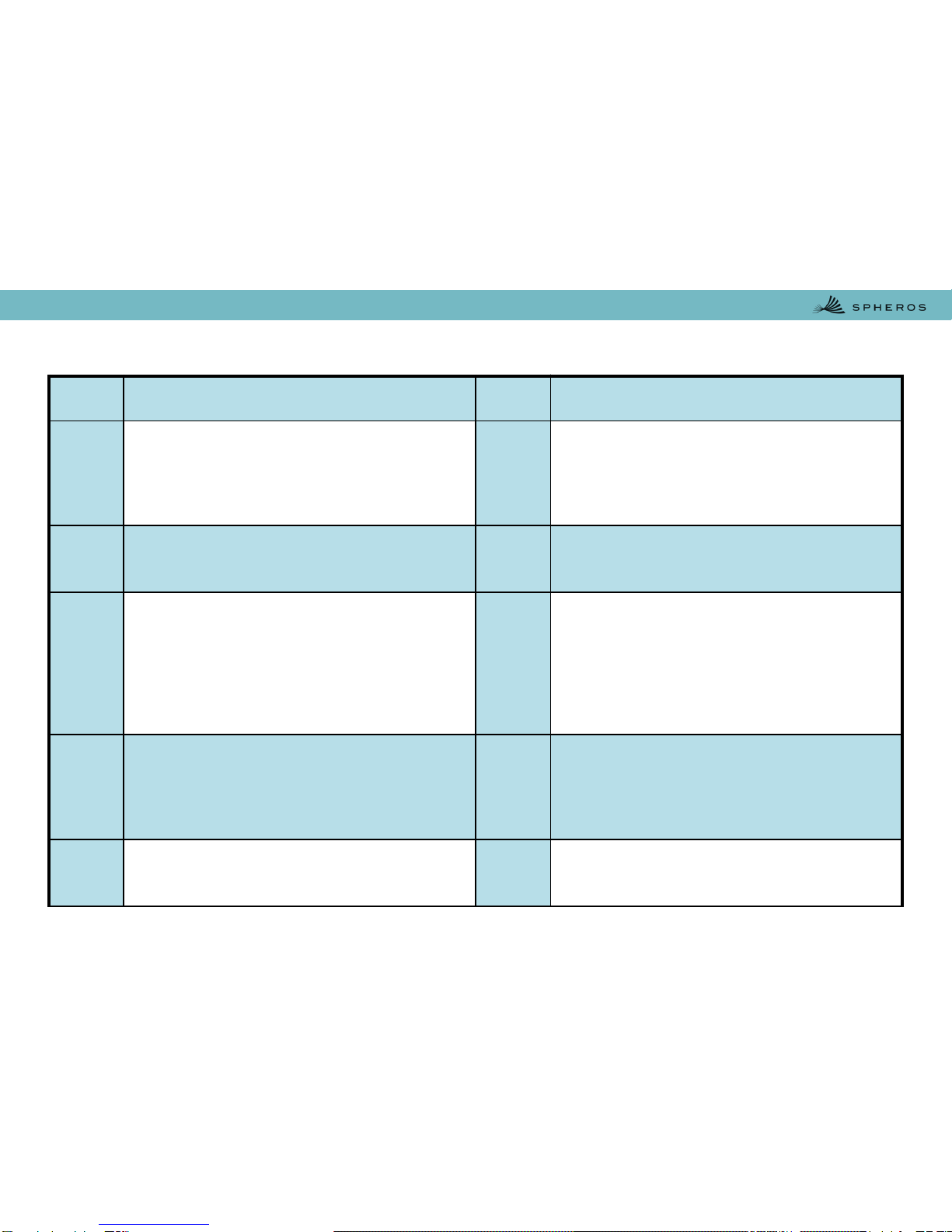

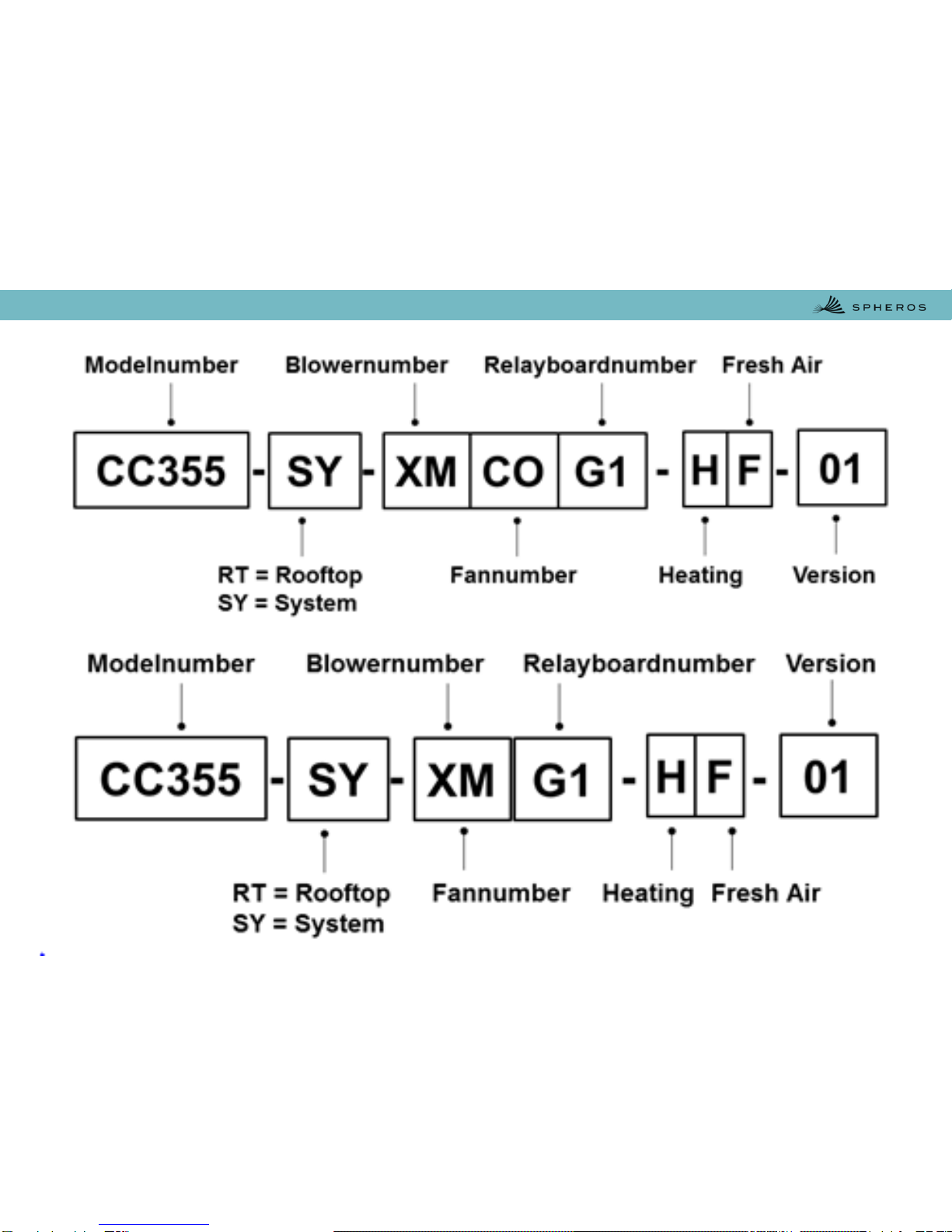

4.4. CC 355 Modelnumber

4.4. CC 355 Modelnumber

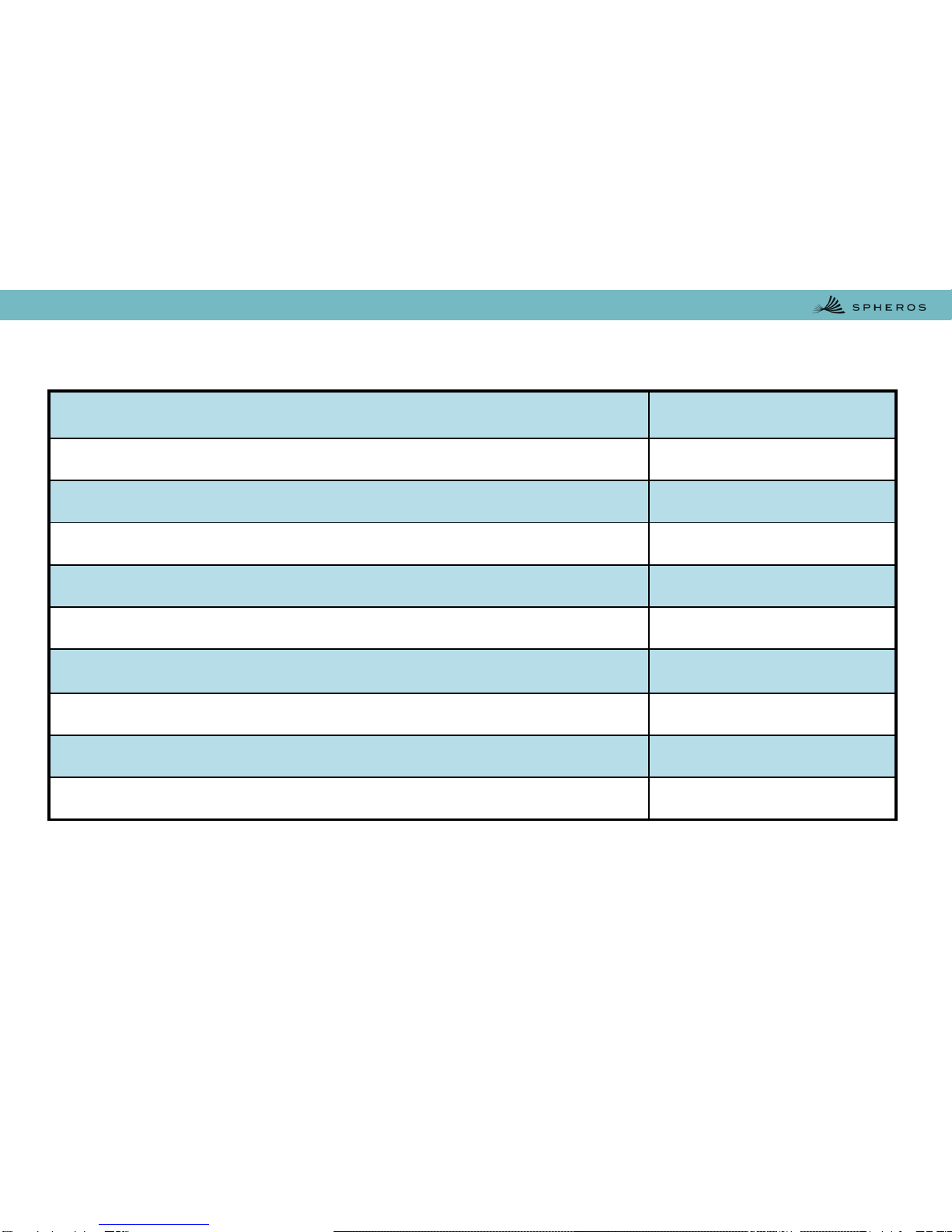

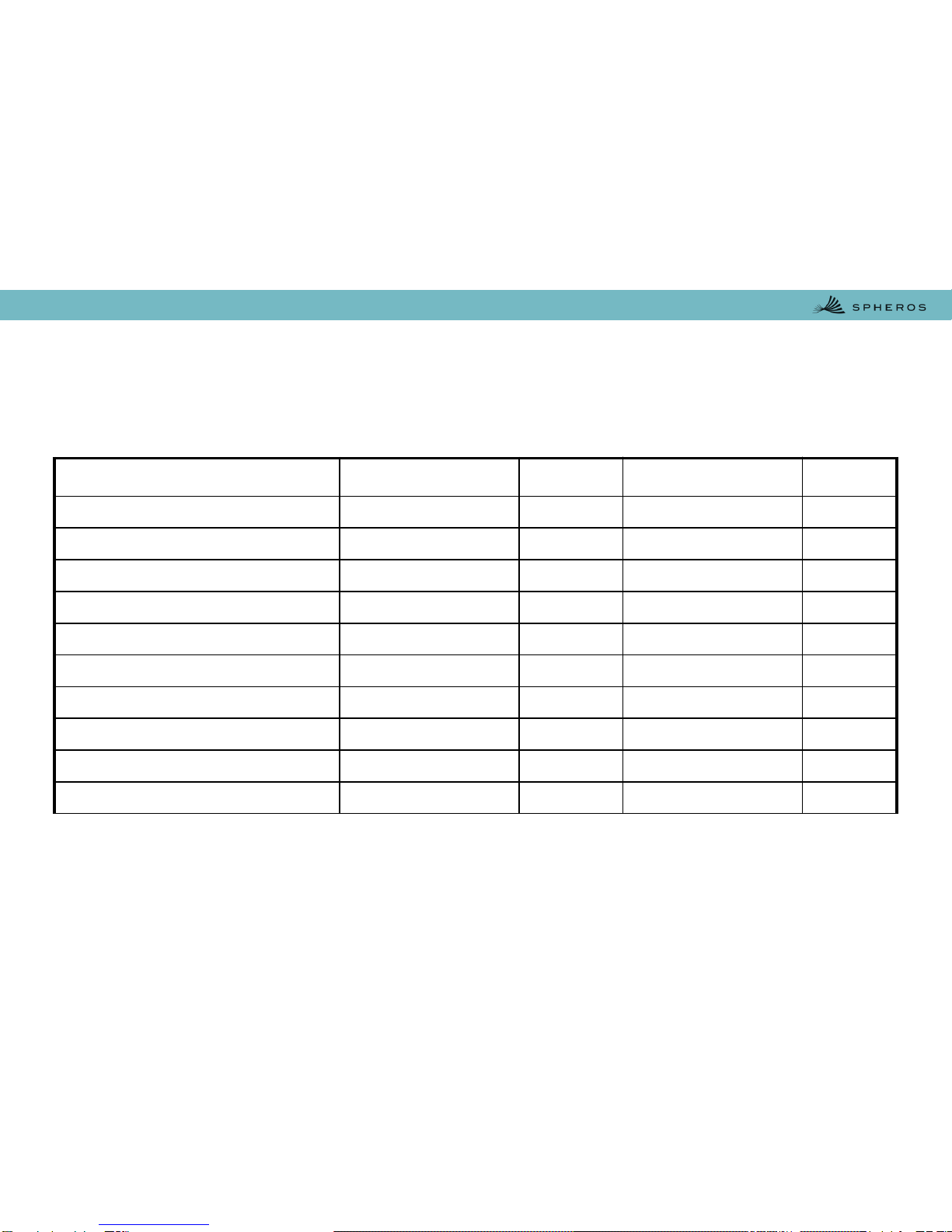

Serialnumber Fan QTY Blower QTY

CC355-RT-COG1-01 to -06 WG-14034-00 4 WG-14092-00 6

CC355-RT-COG1-F-01 to -04 WG-14034-00 4 WG-14092-00 6

CC355-RT-COG4-H-01 WG-14034-00 4 WG-14092-00 6

CC355-RT-COHE-01 to -05 WG-14034-00 4 WG-14092-00 6

CC355-RT-SPG1-01 WG-14014-00 4 WG-14061-00 6

CC355-RT-SPG1-F-01 to -02 WG-14014-00 4 WG-14061-00 6

CC355-RT-XMCOG5-01 WG-14034-00 5 WG-14081-00 6

CC355-RT-XMG1-01 WG-14035-00 4 WG-14081-00 6

CC355-RT-XMG1-F-01 to -02 WG-14035-00 4 WG-14081-00 6

CC355-RT-XMG3-HF-01 to -05 WG-14035-00 4 WG-14081-00 6

CC355-RT-XMG5-HF-02 WG-14035-00 4 WG-14081-00 6

CC355-RT-XMSPG5-01 WG-14014-00 4 WG-14081-00 6

CC355-RT-XMSPG8-01 WG-14014-00 4 WG-14081-00 6

CC355-RT-XXG1-F-01 XXX 0 XXX 0

CC355-RT-XXHE-01 XXX 0 XXX 0

CC355-RT-XXSPG1-01 WG-14034-00 4 XXX 0

CC355-RT-XXXX-F-01 XXX 0 XXX 0

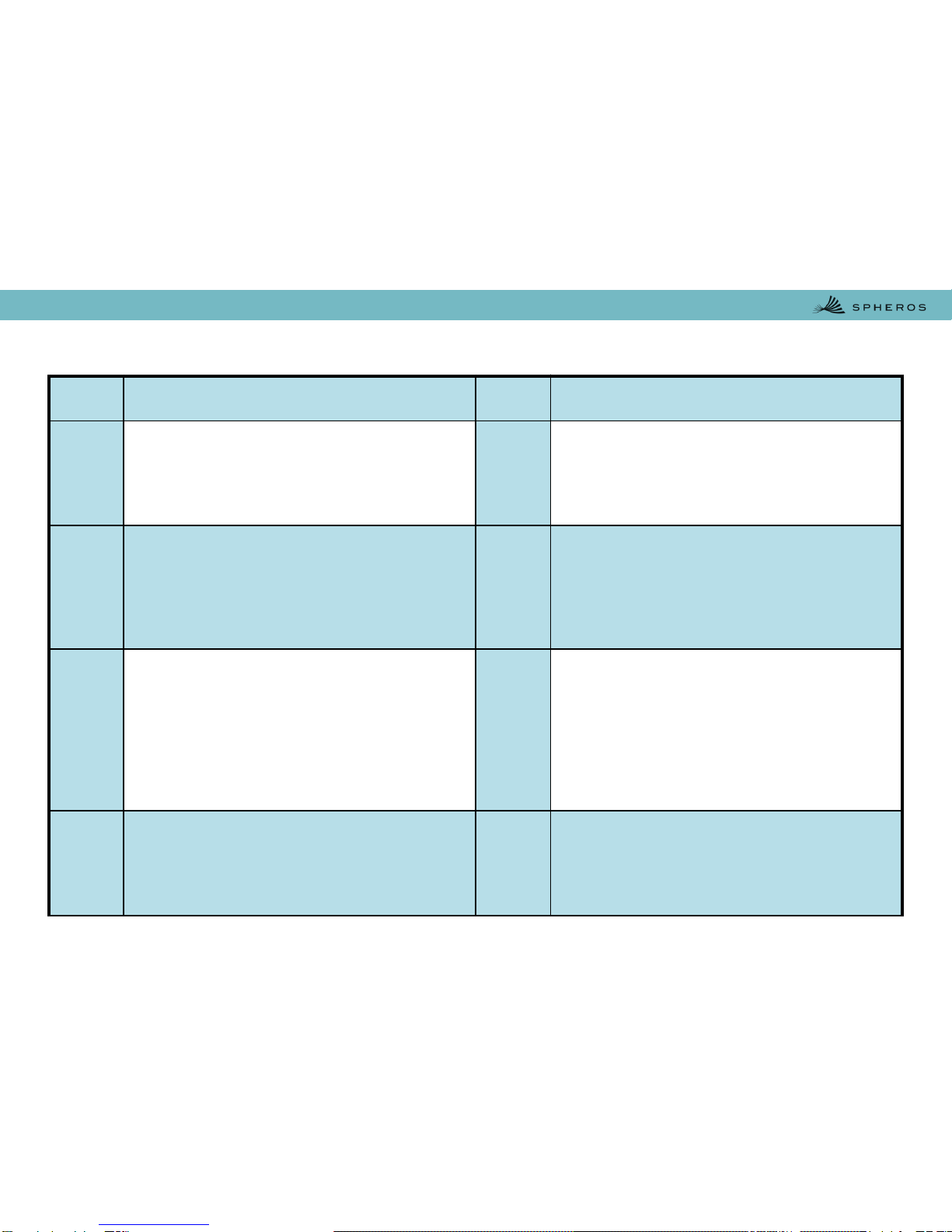

4.4. CC 355 Modelnumber

Serialnumber Fan QTY Blower QTY

CC355-SY-COG1-01 to -06 WG-14034-00 4 WG-14092-00 6

CC355-SY-COG1-F-01 to -04 WG-14034-00 4 WG-14092-00 6

CC355-SY-COG4-H-01 WG-14034-00 4 WG-14092-00 6

CC355-SY-COHE-01 to -08 WG-14034-00 4 WG-14092-00 6

CC355A-SY-COHE-01 WG-14034-00 4 WG-19092-00 6

CC355-SY-SPG1-F-01 to -03 WG-14014-00 4 WG-14061-00 6

CC355-SY-XMCOG5-01 WG-14034-00 5 WG-14081-00 6

CC355-SY-XMG1-01 to -03 WG-14035-00 4 WG-14081-00 6

CC355-SY-XMG3-HF-01 to -10 WG-14035-00 4 WG-14081-00 6

CC355-SY-XXHE-01 XXX 0 XXX 0

4.5. CC 355 Equipment Components

No. Name Reference-No.

1 Evaporator

Coil right CC355-07200-00

2 Evaporator

Coil left CC355-07100-00

3 Relay Plate 9100187

4 Expansion

Valve WG-06008-00

5

(alt.) Condenser

Fan 12” 24V WG-14014-00

WG-14034-00

WG-14035-00

6 Condenser

Coil CC355-05100-00

7 Filter Dryer WG-09006-00

8 Service Valve WG-10009-00

9 Receiver

Bottle CC355-09056-00

10 Temperature

Sensor WG-14601-00

11

(alt.) Evaporator

Blower WG-14092-00

WG-14061-00

WG-14081-00

12

(opt.) Heating -left

Coil -right CC355-07400-00

CC355-07300-00

13

(opt.) Fresh Air WG-14201-00

1

2

3

4

5

6

7

8

9

10

11

12

13

4.6. Refrigerant Circuit

No. Name

1 Refrigeration Compressor

2 Condenser

3 Receiver

4 Filter Dryer

5 Expansion Valve

6 Evaporator

7 Cold Air

8 WarmAir

9 Temperature Sensor

10 Blower

11 Sight Glass

12 Filling Fixture

(for servicing only)

13 Pressure Switch

14 Hot Air

15 Outside Air

16 Fan

16

4.7. CC 355 Installation Drawing

17

5. Controller & Operating

March 2013

18

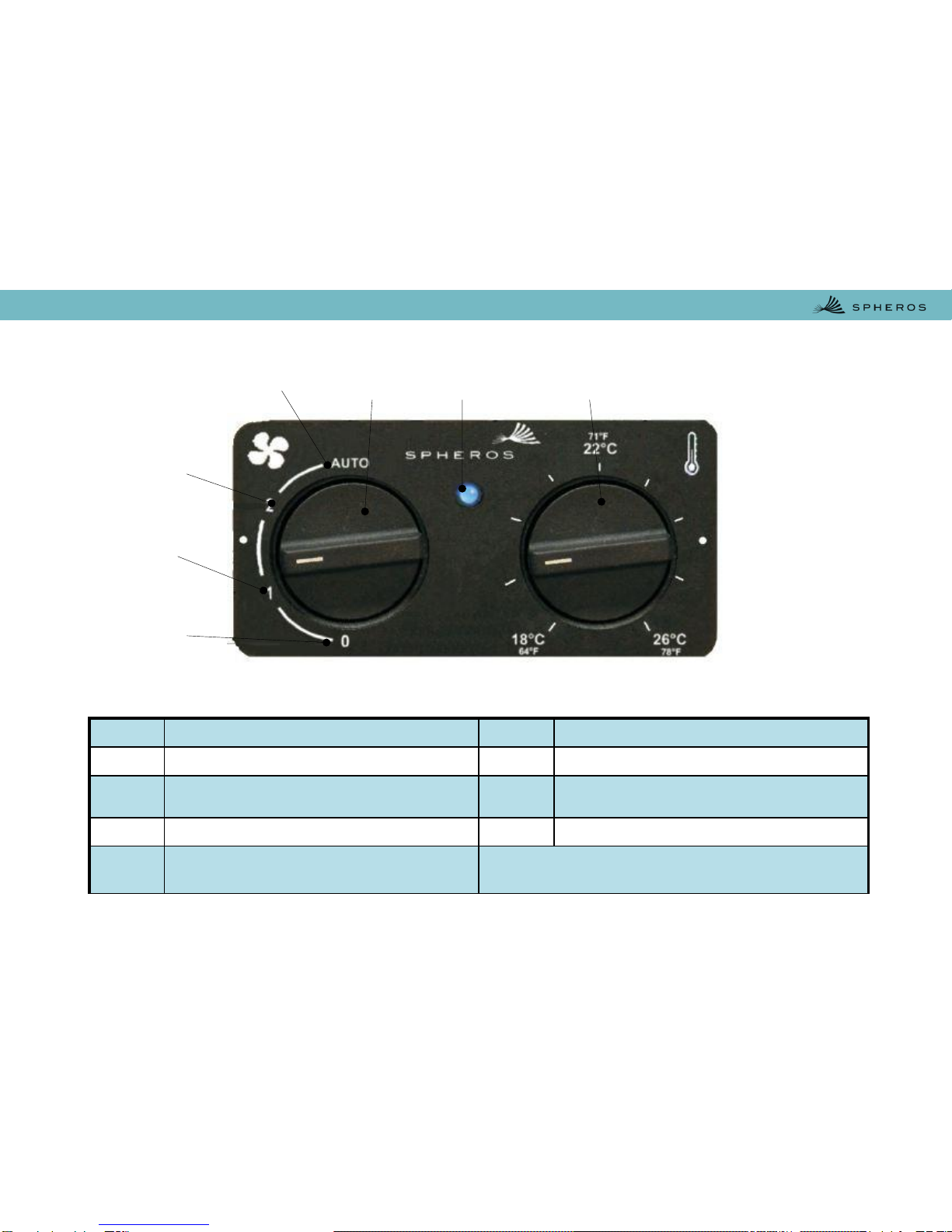

5.1. Controller WG-14164-00

No. Description No. Description

1 Blower and Air Conditioning OFF (0) 5 Blower and Air Conditioning Switch

2 Blower and Air Conditioning Low Mode (1) 6 Cooling Compressor LED

3 Blower and Air Conditioning High Mode (2) 7 TemperatureAdjust Switch

4 Blower and Air ConditioningAuto-

Regulation Mode (AUTO)

1

7654

3

2

The air conditioner control panel WG-14164-00 has two control switches, one for the blower speed and

one for the temperature adjustment. It also is featured with has an LED indicator to signal the activation

of the air conditioning clutch.

Temperature Adjust Switch

The TemperatureAdjust Switch (7) is used to set the ideal or desired temperature value of the user. This

can be varied between approximately 18°C and 26°C. The system is then automatically regulated

when the set value is attained.

Cooling Compressor

The Cooling Compressor LED (6) lights blue whilst the air conditioning compressor clutch is activated,

the condenser fans are running and the cooling is taking place. The LED goes off when the cabin

temperature falls to the level the user has set.

Blower and Air Conditioning Switch

The blowers have three modes of activation by the Blower andAir Conditioning Switch (5) –Low (2),

High (3) andAuto-regulation (4). The blowers do not run and no cooling takes place at the OFF position

(1). The Low and High switch positions keep the blowers continuously running at low or high fixed speed

respectively, independent of the set or actual temperature values.

In Auto-regulation mode, the speed of the blowers is low when the cabin temperature is below the set

value. The speed becomes high when cooling is taking place and the actual cabin temperature exceeds

to the users set.

High speed blowing starts only after the temperature difference exceeds to + 2°C between the set value

and the cabin temperature. It stops when the cabin temperature is equal to the set value.

5.2. Controller WG-14164-00 Operating

This manual suits for next models

1

Table of contents

Other Spheros Air Conditioner manuals

Spheros

Spheros CC-140 User manual

Spheros

Spheros CC335SL User manual

Spheros

Spheros CC 145 User manual

Spheros

Spheros CC 305 User manual

Spheros

Spheros CC-160T User manual

Spheros

Spheros Aerosphere 300 Tropical User manual

Spheros

Spheros CC-230 User manual

Spheros

Spheros CC 305 User manual

Spheros

Spheros REVO User manual