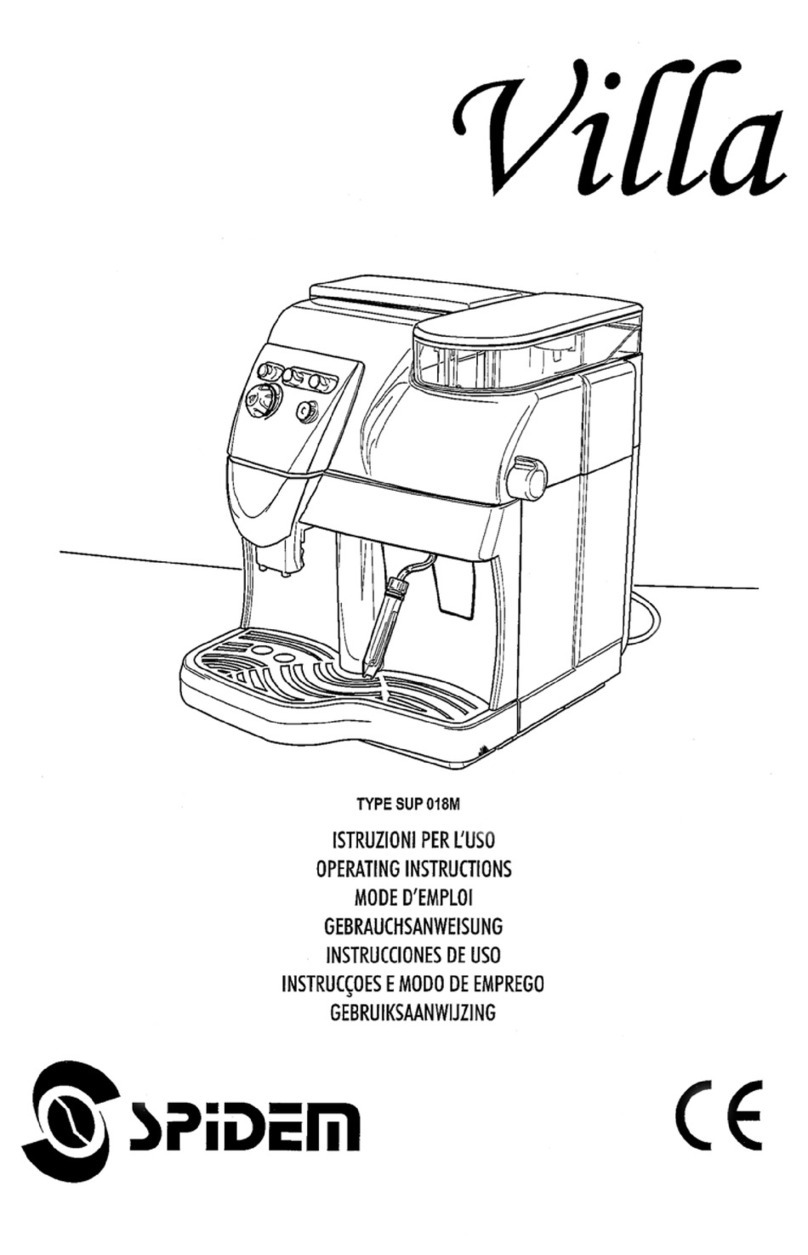

Spidem Villa SUP 018M User manual

Português English

OPERATING INSTRUCTIONS

INSTRUÇÕES DE USO

TYPE SUP 018M

Congratulations!

Thank you for purchasing this highest quality espresso coee machine

and for your condence in our company. Before operating the machine,

we recommend carefully reading the operating instructions that explain

how to use, clean and maintain it in perfect working order. Please refer

to the dealer or to our company, if you have any questions. We will be

happy to clear any doubts you may have.

Parabéns!

Obrigado por ter adquirido esta máquina de café expresso, de quali-

dade superior, e pela conança demonstrada. Antes de pôr a funcio-

nar a máquina, aconselhamos a ler atentamente as instruções de uso

nas quais é explicado como utilizá-la, limpá-la e mantê-la em perfeita

eciência. Para outros esclarecimentos, dirija-se ao revendedor ou direta-

mente ao fabricante. Teremos o prazer em esclarecer quaisquer outras

dúvidas.

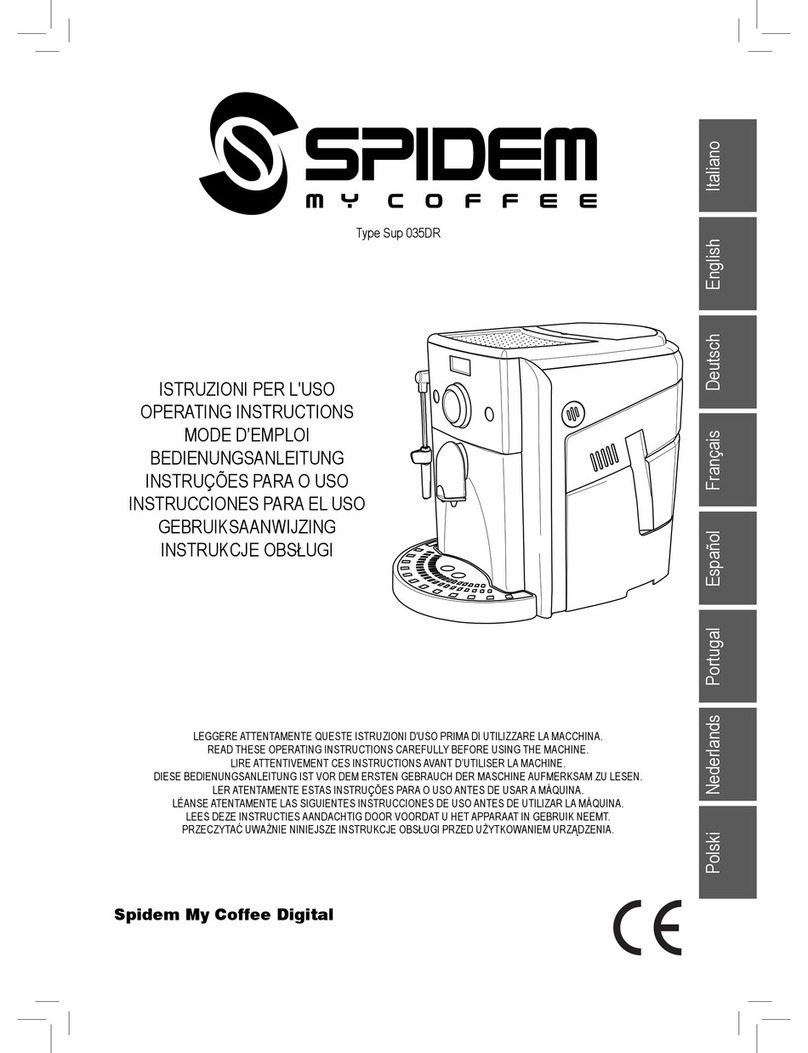

3

12

9

14

4

3

6

7

8

11

13

10

5 23 18 19 20 21 15

17 22

1

2

16

4

+

-

5

6

7

English

GENERAL INFORMATION - TECHNICAL DATA

1 GENERAL INFORMATION

The coee machine is suitable to make espresso coee using

coee beans and is equipped with a device for the distribution

of steam and hot water.

Warning. No liability is assumed for any damage

caused by:

• incorrect use not in accordance with the intended

uses;

• repairs not carried out by Authorized Service Centres;

• tampering with the power cable;

• tampering with any part of the machine;

• the use of non-original spare parts and accessories.

Inthesecases, the warrantyisnotvalid.

1.1 To facilitate reading

A warning triangle draws the attention to all the

instructions that are important for the user’s safety.

Please carefully follow these instructions to avoid

serious injury.

(Fig. 2) - Reference to gures, parts of the machine and

controls is indicated by numbers or letters, like the reference to

gure 2 in this section.

This symbol is used to highlight the information that

is particularly important for ensuring an optimal use

of the machine.

Figures corresponding to the text may

be found on the inside cover.

Keep this page open while reading the

instructions.

1.2 How to use these operating

instructions

Keep these operating instructions in a safe place and

make them available to anyone else who would use the

coee machine.

For further information or in case of problems that are not

included or not completely explained in these instructions,

please contact the Authorized Service Centres.

2 TECHNICAL DATA

• Nominal voltage

See label on the equipment

• Power rating

See label on the equipment

• Power supply

See label on the equipment

• Shell material

Thermoplastic

• Size (mm)

355 x 385 x 337

•Weight (kg)

8,5

• Cable length (mm)

1200

• Control panel

Front

•Water tank

1,7 (l) - Removable

• Coee bean hopper capacity (g)

350 g of coee beans

• Pump pressure (bar)

15

• Boiler

Stainless steel

• Safety devices

Boiler pressure safety valve;

safety thermostat.

Subject to engineering and manufacturing changes due

to technological developments.

8

O I L

sizes in millimeter

SAFETY REGULATIONS

9

English

3 SAFETY REGULATIONS

Never place live parts in contact with water: danger of

short circuit! Steam and hot water may cause scalding!

Do not direct the steam or hot water jet toward parts of

the body; handle the steam/hot water spout with care:

danger of scalding!

Intended use

Do not make any technical changes or use the machine for

unauthorized purposes since this would create serious hazards!

The equipments is not to be used by persons with reduced phy-

sical, mental or sensory abilities or with scarce experience and/

or expertise, unless they are supervised by a person responsible

for their safety, or they are instructed by this person on how to

properly use the machine.

Power supply

Only connect the coee machine to a suitable power socket.

The voltage must correspond to the indication on the machine’s

label.

Power cable

Never use the coee machine if the power cable is defective.

If damaged, the power cable must be replaced by the manufac-

turer or its customer service department.

Do not pass the cable around corners, over sharp edges or over

hot objects and keep it away from oil.

Do not use the power cable to carry or pull the coee machine.

Do not pull out the plug by pulling on the power cable or touch

it with wet hands.

Do not let the power cable hang freely from tables or shelves.

Protecting others

Make sure that the coee machine is use for operator instruc-

ted by person on how to properly use equipments.

Danger of burning

Never direct the jet of hot steam and/or hot water towards

yourself and/or others: danger of scalding!

Always use the handles or knobs provided.

Location

Position the coee machine in a safe place, where nobody may

overturn it or be injured.

SAFETY REGULATIONS

Do not use the coee machine outdoors. Do not place the

machine on hot surfaces and close to open ames to prevent

the body from melting or being damaged.

Cleaning

Before cleaning the machine, the main power button (5) must

be switched to the -0- position and the plug must be removed

from the socket.

Then wait for the machine to cool down.

Never immerse the machine in water!

It is strictly forbidden to tamper with the inside of the machine.

Space foruse and maintenance

To ensure that the coee machine works properly and ecien-

tly, the following conditions are recommended:

• Choose a level surface;

• Select a location that is suciently well-lit, clean and near

an easily reachable socket;

• Allow for a minimum distance from the sides of the machine

as shown in the gure.

Storing the machine

If the machine is to remain out of use for a long time, turn it

o and unplug it. Store it in a dry place, keep it protected from

dust and dirt.

Servicing / Maintenance

In case of failure, faults or a suspected fault after dropping,

immediately remove the plug from the socket. Never attempt

to operate a faulty machine.

Servicing and repairs may only be carried out by Authorized

Service Centres. Repairs must only be carried out by an Autho-

rised Service Centre. All liability for damages caused by works

not carried out in a professional manner is declined.

Fire safety

In case of re, use Carbon Dioxide extinguishers (CO2). Do not

use water or dry-powder extinguishers.

10 SAFETY REGULATIONS - INSTALLATION

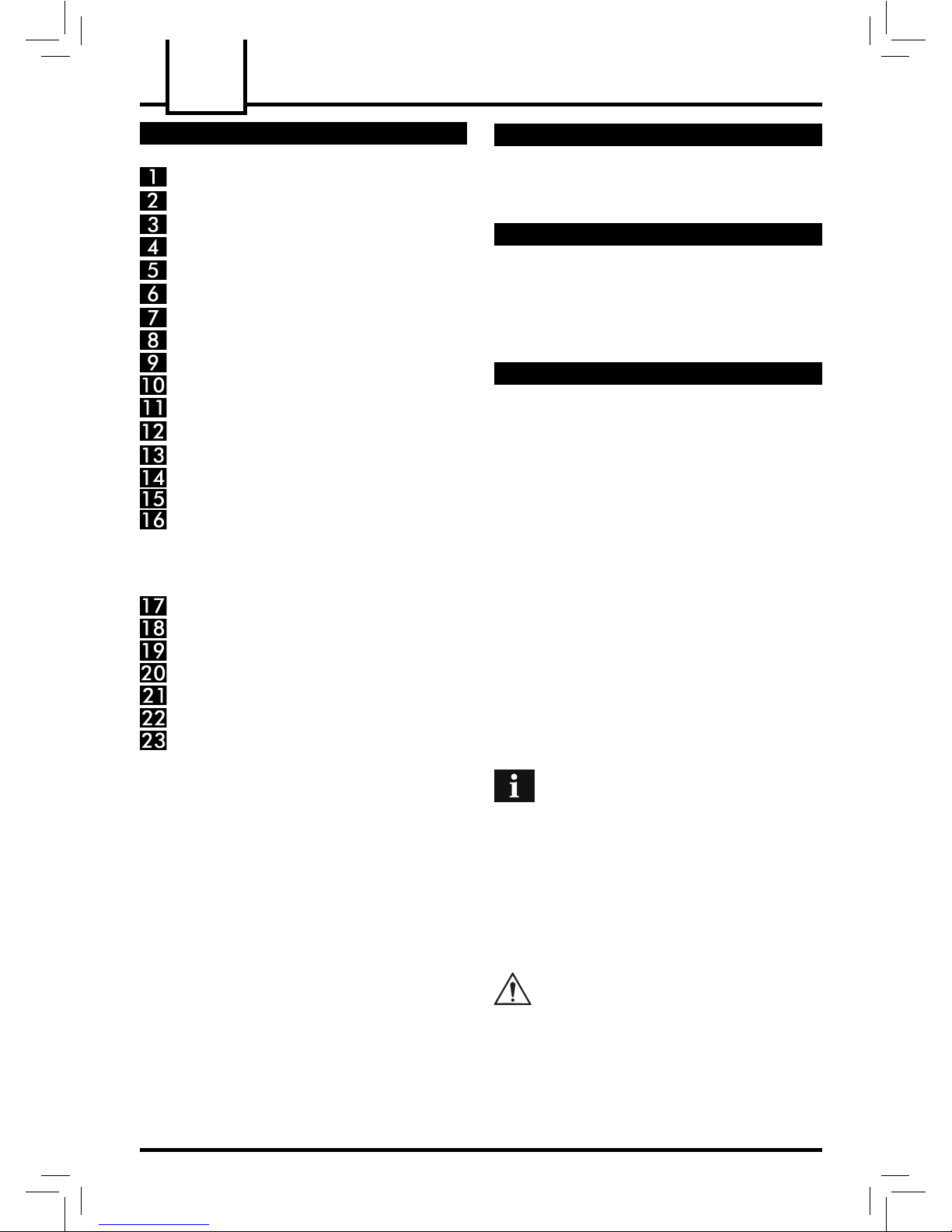

Key to machine components

Coffee bean hopper

Coffee bean hopper cover

Grinder adjustment knob

Coffee dose adjustment knob

Main power button (ON/OFF)

Water tank cover

Water tank

Grounds drawer

Power cable

Drip tray + grill

Height-adjustable dispensing spout

Steam/hot water spout with pannarello

Front door

Steam knob

Coffee Brew Group

Cleaning brush

Control panel

Coffee dose per cup adjustment knob

Coffee button

Temperature ready / coffee function light

Steam function button

Steam temperature light

Alarm light

Machine on light

4 INSTALLATION

For your safety and other people's safety, carefully

follow the "Safety Regulations" in section 3.

4.1 Packaging

The original packaging has been designed and constructed to

protect the machine during transport.

We recommend keeping the packaging material for possible

future transport.

4.2 Preliminary Operations

• Remove the drip tray (10) with grill from the packaging.

• Remove the coee machine from the packaging and

position it in a proper place in compliance with the require-

ments described in the safety regulations (section 3).

• Insert the drip tray (10) into the appropriate seat. Make sure

that the drip tray, the coee grounds drawer (8) and the

coee brew unit (15) are correctly placed and that the front

door (13) is closed.

• Fit the cover of the coee bean hopper (2) onto the coee

bean hopper (1). Keep the cleaning brush (16) to hand.

• Before plugging in the machine, make sure that the power

button (5) is switched to -0-.

If the red light (22) ashes when the machine is turned on, it

means that one of the above mentioned parts is not placed

correctly.

Important Note: Carefully read the explanation

of all the warnings displayed by the machine

to the user by means of the lights on the control panel

(section 13).

• (Fig.25) - Lift and extract the water tank (7) and remove

the cover (6). Rinse and ll it with fresh water taking care

not to overll it. Reinsert the water tank into the appropria-

te seat and replace the cover (6) on top of it.

Always use only fresh, non-sparkling water to ll

the tank (7). Hot water or any other liquid may

damage the tank and/or the machine. Do not turn on

the machine without water: make sure there is enough

water in the tank.

11

English

INSTALLATION - COFFEE GRINDER

• (Fig.24) - Remove the cover (2) and add the coee beans.

Always add only coee beans in the coee bean

hopper (1). Ground coee, instant coee or any

other object may damage the machine.

• Replace the cover (2) on the coee bean hopper (1).

• Insert the plug into a suitable socket.

4.3 Circuit Priming

In the beginning, after dispensing steam or when the water

tank is empty, the machine’s water circuit must be primed.

• The power button (5) is switched to -0-. Press button (5) to

turn on the machine.The light (23) on the control panel will

turn on.

• (Fig.26) - Place a container beneath the steam wand

(Pannarello)(12) to prime the circuit. Turn the knob (14)

counter-clockwise and wait until water ows steadily out of

the steam wand (Pannarello).Turn the knob (14) clockwise

to stop water dispensing.

• The circuit is now primed.

4.4 Using the machine for the rst time

or after a period of inactivity

This simple operation ensures optimum brewing and must be

performed:

- At rst start-up;

- When the machine remains inactive for a long time (more

than 2 weeks).

Dispensed water must be emptied into an

adequate drain. It is not suitable for food use. If

the container lls up, stop dispensing water during the

cycle and empty it before resuming the operation.

1(Fig.25) - Make sure that the water tank (7) is lled with

drinking water; otherwise, empty the tank and replace with

fresh water.

2 Place a container beneath the steam wand (Pannarello) (12)

and turn the knob (14) counter-clockwise.

3 After 30 seconds (or when the container is full) stop dispen-

sing water by turning the knob (14) clockwise.

4Wait about 60 seconds. Repeat the operations from step 2

until emptying out the tank.

5(Fig.25) - Once run out of water, ll the tank again (7) and

carry out a new cycle from step (2) as previously mentioned.

6Once emptied the tank for the second time, ll it again with

water; the machine is now ready for use.

Note: if required, prime the circuit.

• To brew coee, dispense hot water or steam, and for a

proper use of the machine, carefully follow the instructions

provided.

5 COFFEE GRINDER

Caution! The grinder adjustment knob, inside

the coee bean hopper, must be turned only

when the grinder is working. Do not pour ground and/

or instant coee into the bean hopper.

Do not insert any material other than coee beans

into the hopper. The grinder contains moving parts

that may be dangerous. Therefore, do not insert ngers

and/or other objects. Turn the main power button to o

and remove the plug from the socket before carrying out

any type of operation inside the bean hopper. Do not pour

coee beans when the grinder is working.

The quality and avour of coee depend on the grind, as well

as on the blend used.The machine has a knob (3) to adjust

the coee grind.Turn the knob when the grinder is working to

adjust the grind.The digits on the knob indicate the grind.

The manufacturer congures each equipment on an interme-

diate grind setting: if the grind is too ne, rotate the knob to

a higher setting; if the grind is too coarse, turn the knob to a

lower setting.

The variation in grind will only be seen when three/four coees

have been brewed.

Use coee bean blends for espresso machines. Try not to use

very high or very low grind settings (e.g. 1 - 16). Use dierent

12 COFFEE BREWING - HOT WATER DISPENSING

coee blends for dierent settings. Keep coee in a fresh place

in a sealed, airtight container.

The grind must only be regulated if coee is not brewed

properly:

Too fast brewing = too coarse grind > Rotate the knob to a

lower setting;

Drip and/or absent brewing = too ne grind > Rotate the knob

to a higher setting.

6 COFFEE DOSE ADJUSTMENT KNOB

(Fig. 24) -The desired coee quantity (dose) to be ground may

be set in the machine.

The dose is set by the manufacturer to a medium value that

meets all tastes. Reference (A) in correspondence with reference

(B). By turning the knob (4) inside the coee bean hopper

counterclockwise the quantity of ground coee is increased;

by turning the knob clockwise the quantity of ground coee is

decreased.

The dose adjustment must be performed before pressing the

coee button.

This system allows an optimal brewing with any kind of coee

on the market.

7 COFFEE BREWING

Note: If the machine does not brew coee,

make sure that the water tank contains enough

water by verifying the water level on the left side of the

machine.

Before brewing coee, make sure that the gre-

en temperature ready light (19) is permanently

on and that the water tank and the coee hopper are

full.

• (Fig. 27 - 28) - Place 1 or 2 cups beneath the dispensing

spout (11).You may adjust the height of the dispensing

spout to your cups.

• Adjust the desired quantity of coee to be brewed by means

of the knob (17): by turning the knob clockwise the quantity

of coee to be brewed is increased; by turning the knob

counterclockwise the quantity of coee to be brewed is

decreased.

• Press the button (18) to brew coee.The brewing cycle

starts: press the button (18) once to brew 1 coee. Press it

twice to brew 2 coees.

In this operation mode, the machine grinds and

measures automatically the right quantity of

coee. Two coees require two grinding and brewing

cycles that are automatically managed by the machine.

• After the prebrewing cycle, coee begins to come out of the

dispensing spout (11).

• On reaching the dose programmed with the knob (17), the

machine will automatically stop brewing. It is nevertheless

possible to interrupt coee brewing by pressing the button (18).

8 HOT WATER DISPENSING

Warning: at the beginning, short spurts of hot

water may come out: danger of scalding. The hot

water spout may reach high temperatures: do not touch

it with bare hands.

• Before dispensing hot water, make sure that the green

temperature ready light (19) is on.

When the machine is ready to brew coee, proceed as follows:

• Place a cup and/or a container beneath the hot water/steam

spout (12).

• (Fig. 29) - Open the knob (14) by turning it counterclockwi-

se.

• When the desired quantity of hot water has been dispensed,

turn the knob (14) clockwise to stop dispensing. The machi-

ne returns to the normal operating mode.

13

English

STEAM EJECTION - CLEANING AND MAINTENANCE

9 STEAM EJECTION / PREPARING A

CAPPUCCINO

Steam may be used to froth milk for cappuccino and to heat

beverages.

Danger of scalding! At the beginning, short

spurts of hot water may come out. The steam

spout may reach high temperatures: do not touch it

with bare hands.

• When the machine is ready to brew coee, press the button

(20).The machine needs a heating phase.

• Before steam ejection, wait until the green temperature

ready light (21) is permanently on.

• (Fig. 26) - Place a container beneath the steam spout

(pannarello) (12) and open the“hot water/steam”knob (14)

for a few seconds so as to let the remaining water come out

of the steam spout (pannarello). In a short time, only steam

will come out of the spout.

• Close the knob (14).

• Fill 1/3 of the container you wish to use to prepare the

cappuccino with cold milk.

Use cold milk and a cold cup for better results

when preparing a cappuccino.

• (Fig. 30) - Immerse the steam spout (pannarello) in the

milk to be heated and open the knob (14). Move the contai-

ner gently up and down to level the foam formation.

• After using the steam for the desired time, close the knob

(14).

• The same system may be used to heat other beverages.

After using the steam spout (pannarello), clean it as described

in the“Cleaning and Maintenance" section.

9.1 Steam/coee switchover

• Press the button (20) to brew coee.

• During the switchover from steam to coee brewing, the

lights (19) and (21) ash simultaneously showing the

machine’s overtemperature. Coee may not be brewed.

• Discharge water to brew coee. Place a container beneath

the steam spout (pannarello) (12).Turn the steam knob (14)

counterclockwise and wait until only the green temperature

ready light (19) is permanently on.Then close the knob by

turning it clockwise.

10 CLEANING AND MAINTENANCE

General cleaning

• Maintenance and cleaning operations may only be carried

out when the machine has cooled down and has been

disconnected from the power supply.

• Do not immerse the machine in water or place any of its

parts in a dishwasher.

• Do not use sharp objects or harsh chemical products

(solvents) for cleaning.

• Clean the pannarello after every use. Remove the external

part of the pannarello.

Wash the external part of the pannarello under running

water.

• For a thorough cleaning, remove the pannarello from the

steam spout.

Loosen the ring nut and remove the internal part of the

pannarello. After washing it thoroughly, reassemble it

taking care to position it as shown in the gure.

14 CLEANING AND MAINTENANCE - DESCALING

(Fig. 25) - Clean the water tank on a daily basis.

- Remove the lter in the water tank and wash it under

drinking running water.

- Reinsert the lter into its seat by gently pressing and

turning it.

- Fill the tank with fresh drinking water.

• Use a soft cloth moistened with water to clean the equip-

ment.

• Do not dry the machine and/or its components using a

microwave and/or conventional oven.

• (Fig. 31 - 33) - Clean the dispensing outlet.We recommend

emptying and cleaning (on a daily basis):

- the grounds drawer (8)

- the drip tray (10)

10.1 Brew Group

• The Brew Group (15) must be cleaned every time the coee

bean hopper is lled or at least once a week.

• Turn o the machine by pressing the main power button (5)

to -0- and remove the plug from the socket.

• (Fig. 31 - 33) - Remove the grounds drawer (8) and the drip

tray (12).Then open the service door (13).

• (Fig. 34) - Remove the Brew Group (15) by the handle and

press the «PRESS» key. The Brew Group must be cleaned

only with warm water and no detergents.

• (Fig. 35) -Wash the Brew Group with lukewarm water and

carefully clean the upper lter.

• Thoroughly wash and dry all the parts of the Brew Group.

• Thoroughly clean the dispensing outlet.

• Reinsert the Brew Group in the dispensing outlet clicking it

into place without pressing the“PRESS" key.

• Close the door, insert the grounds drawer and the drip tray.

11 DESCALING

Limescale normally forms with the use of the appliance.

Descaling is necessary every 1 - 2 months or if you notice a

reduction in water ow.

In case of conict, priority must be given

to what is indicated in the operation and

maintenance manual over the instructions provided on

separately sold accessories and materials.

Use the Saeco descaling

product. Its formula

has been designed to ensure

better machine performance and

operation for its whole operating

life. If correctly used, it also

avoids alterations in the brewed

product.

Warning! Never drink the

descaling solution or any products dispensed

until the cycle has been carried out to the end. Never

use vinegar as a descaling solution.

Before descaling, remove the Pannarello from the steam wand

as described in the“Cleaning and Maintenance" section.

1Pour the entire content of the Saeco concentrated descaling

solution into the water tank (7), and then ll the tank with

fresh drinking water up to the MAX level.

2(Fig.26) -Turn on the machine at the main power button

(5).

3Using the steam wand, (12) brew 2 cups of descaling solu-

tion (approx. 150 ml each) as described in section 8 "HOT

WATER DISPENSING".

4Disconnect the machine at the main power button (5).

5 Allow the descaling solution to take eect for about 15-20

minutes.

6Repeat steps 2, 3 and 4 at intervals of 3 minutes, until there

is no descaling solution left in the water tank.

7Make sure the machine is on.

8(Fig.25) - Rinse the water tank (7) and ll it with fresh

water.

9(Fig.26) - Rinse the appliance circuits with fresh water until

the tank (7) is empty, by dispensing the water through the

15

English

DISPOSAL

steam wand (12) as described in section 8 "HOT WATER

DISPENSING".

10Repeat the rinse cycle (step 8 and 9) twice consecutively.

Only once reached this step, the descaling cycle is complete.

Note: if required, prime the circuit (Section 4.3).

The descaling solution must be disposed of

according to the manufacturer's instructions

and/or regulations in force in the country of use.

12 DISPOSAL

This product complies with EU Directive 2002/96/EC.

The symbol on the product or on its packaging indi-

cates that this product may not be treated as commons waste.

Instead it shall be handed over to the applicable collection

point for the recycling of electrical and electronic equipment.

By ensuring this product is disposed of correctly, you will help

prevent potential negative consequences for the environment

and human health, which could otherwise be caused by

inappropriate waste handling of this product. For more detailed

information about recycling of this product, please contact your

local city oce.

16 CONTROL PANEL LIGHTS

13 CONTROL PANEL LIGHTS

Warnings Causes Solutions

Green light (23) The machine is on.

Fixed green light (19) The machine has reached the right

temperature and is now ready:

- for coee brewing;

- for hot water dispensing.

Flashing green light (19) The machine is warming up to brew

coee and dispense hot water.

Fixed green light (21) The machine has reached the right

temperature to eject steam.

Flashing green light (21) The machine is warming up to eject

steam.

Green light (19) and

green light (21)

are ashing simultaneously

Machine’s overtemperature: coee may

not be brewed.

Discharge water into the drip tray by tur-

ning the steam knob (14) until the green

temperature ready light (19) is permanen-

tly on and green light (21) turns o.

Fixed red light (22) The water in the tank is insucient. Fill the tank with fresh drinking water,

prime the circuit and start the procedure

again.

The coee bean hopper is empty. Fill the hopper with coee beans and start

the procedure again.

Flashing red light (22) The Brew Group, the grounds drawer,

the drip tray and the front door are

in a wrong position for the machine’s

operation.

Make sure that all components have been

correctly inserted and closed.The xed red

light will now turn o.

17

English

PROBLEMS - CAUSES - SOLUTIONS

Problems Causes Solutions

The machine does not turn on The machine is not connected to the

power supply.

Connect the machine to the power supply.

The service door is open. Close the service door.

Coee is not hot enough The cups are cold. Warm the cups.

No hot water or steam is

dispensed

The hole of the steam spout is clogged. Clean the hole of the steam spout using a pin.

Coee has little foam The coee blend is unsuitable, the

coee is not freshly roasted or the grind

is too coarse.

Change coee blend or adjust the grind (section 5).

Increase the dose (section 6).

The machine takes a long time

to warm up or the amount of

water dispensed from the spout

is too little.

The machine’s circuit is obstructed by

limescale.

Descale the machine.

The Brew Group does not come

out.

The Brew Group is out of place. Turn on the machine. Close the service door. The

Brew Group is automatically placed in the correct

position.

The grounds drawer is inserted. Remove the grounds drawer before removing the

Brew Group.

Coee is not brewed There is no water. Fill the water tank and prime the circuit again

(section 4.3).

The Brew Group is dirty. Clean the Brew Group (section 10.1).

The dose setting is high. Decrease the dose setting (section 6).

The circuit is not primed. Prime the circuit again (section 4.3).

Coee is brewed slowly The dose setting is high. Decrease the dose setting (section 6).

The coee is too ne. Change coee blend or adjust the grind (section

5). Decrease the dose setting (section 6).

The circuit is not primed. Prime the circuit again (section 4.3).

The Brew Group is dirty. Clean the Brew Group (section 10.1).

Coee leaks out of the dispen-

sing spout

The dispensing spout is in a wrong

position.

Replace the dispensing spout in its correct

position.

The dispensing spout is clogged. Clean the dispensing spout and its holes.

Please contact an Authorized Service Centre for any faults not covered in the above table or when the suggested

solutions do not solve the problem.

18

19

Português

GENERALIDADES - DADOS TÉCNICOS

1 GENERALIDADES

A máquina de café é indicada para a preparação de café

expresso, utilizando café em grãos e possui um dispositivo para

o fornecimento de vapor e de água quente.

Atenção. Não assumimos qualquer respon-sabili-

dade para danos eventuais em caso de:

• usoerradoounãoconformecom as nalidades previstas;

• consertos nãorealizados noscentros deassistência

autorizados;

• alteração do cabodealimentação;

• alteração de qualquer componente da máquina;

• usodepeças sobresselentes e acessórios não originais.

Esses casos invalidarão a garantia.

1.1 Para facilitar a leitura

O triângulo de advertência indica todas as instru-

ções importantes para a segurança do utilizador.

Siga atentamente estas indicações para evitar

ferimentos graves!

(Fig.2) - A referência a ilustrações, partes da máquina e órgãos

de comando acontece através de números e letras, como, por

exemplo, a referência à ilustração 2 deste parágrafo.

Este símbolo evidencia as informações a ter em vista,

para uma melhor utilização da máquina.

As ilustrações correspondentes ao tex-

to encontram-se no interior da capa.

Mantenha esta página aberta durante

a leitura do manual de instruções.

1.2 Utilização dessas instruções de uso

Guarde estas instruções de uso em lugar seguro e

anexe-as à máquina de café se por acaso uma outra

pessoa precisar utilizá-la.

Para mais informações ou em caso de problemas não tratados

totalmente ou apenas insucientemente nas presentes instru-

ções, contacte os Centros de Assistência Autorizados.

2 DADOS TÉCNICOS

•Tensão nominal

Veja plaqueta posicionada no aparelho

• Potência nominal

Veja plaqueta posicionada no aparelho

• Alimentação

Veja plaqueta posicionada no aparelho

• Material do corpo

Termoplástico

• Dimensões (mm)

355 x 385 x 337

• Peso (Kg)

8,5

• Comprimento do cabo (mm)

1200

• Painel de comando

Frontal

• Reservatório de água

1,7 (l) - Extraível

• Capacidade do recipiente de café (g)

350 de café em grãos

• Pressão da bomba (bares)

15

• Caldeira

Aço inox

• Dispositivos de segurança

Válvula de segurança de pressão da caldeira;

termóstato de segurança

Sob reserva de alterações de construção e realização

devidas ao progresso tecnológico.

20

O I L

Medida en Milímetros

NORMAS DE SEGURANÇA

Other manuals for Villa SUP 018M

1

Table of contents

Languages:

Other Spidem Coffee Maker manuals

Spidem

Spidem 035DR User manual

Spidem

Spidem Villa User manual

Spidem

Spidem 741452807 User manual

Spidem

Spidem 740617323 User manual

Spidem

Spidem 10002881 User manual

Spidem

Spidem 741453207 User manual

Spidem

Spidem 10001830 User manual

Spidem

Spidem SUP025PY User manual

Spidem

Spidem 741455012 User manual

Spidem

Spidem Villa SUP 018M User manual