Document No: 9961 Revision: F Issue Date: Jan-29-2018 Page 7 of 35

This document and all copies are the property of Spider®. All dimensions and data are indicative only.

The user must ensure that the equipment complies with local rules and regulations.

11.

a. You are wearing a personal fall arrest system that meets or exceeds your application

requirements.

b. You have personally made sure that:

i. the roof support system is complete, properly assembled, counterweighted (or otherwise

ii. hoists and platforms are not overloaded.

c.

d.

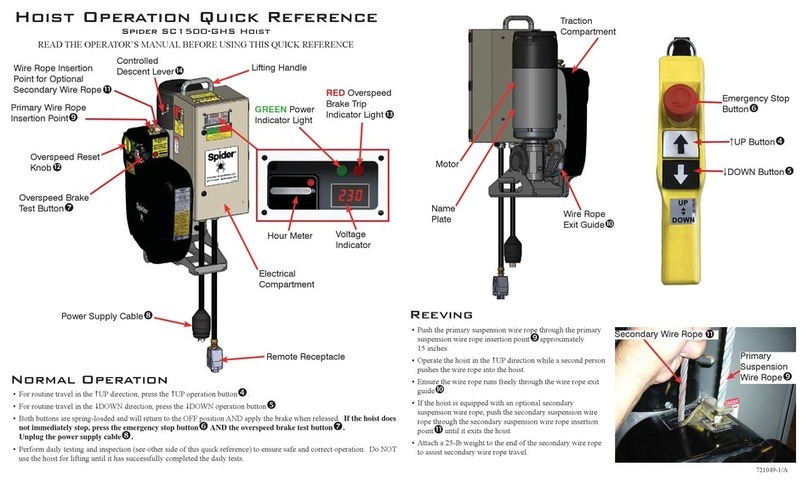

e. The primary suspension wire rope is vertical.

12. Use approved personnel harnesses, lanyards, rope grabs, and independent lifelines at all times. Attach

the lifelines to a structural member of the building or structure, never to part of the rigging unless

13. Avoid electrical power lines. Ensure the platform cannot swing or be blown within 10 feet of a power

line. NEVER, under any circumstances, rig a platform above power lines.

14. Comply with all local, provincial and federal safety codes and equipment instructions.

15. If you hear any strange noises or if the hoist does not appear to work normally, stop using it

immediately. Do not continue to use the equipment until it has been repaired.

16. Do NOT allow anyone under suspended equipment. If necessary, provide protection below the

suspended equipment to prevent injury to people from falling objects. Use lanyards to secure tools and

materials from falling on personnel below.

17.

Troubleshooting Guidelines in this manual.

18. Inspect the wire rope before rigging. Handle, inspect, and maintain wire rope carefully during and after

each job. Lubricate the wire rope according to the manufacturer’s recommendations.

19. Do not use visibly worn, kinked, bird-caged, undersized, or damaged wire rope. Protect wire rope from

corrosive atmosphere, chemicals, passage of electric current, or temperatures above 200° F.

20.

21. Ensure platform is grounded to the structure.

22. Insulate wire rope 4 feet above and below the platform.

23. Insulate wire rope at suspension point and ensure that the wire rope cannot come in contact with the

structure at any point along its entire length, including the tail line.

24. Cover the hoist with an insulating material.