SPIDER UpPro Series User manual

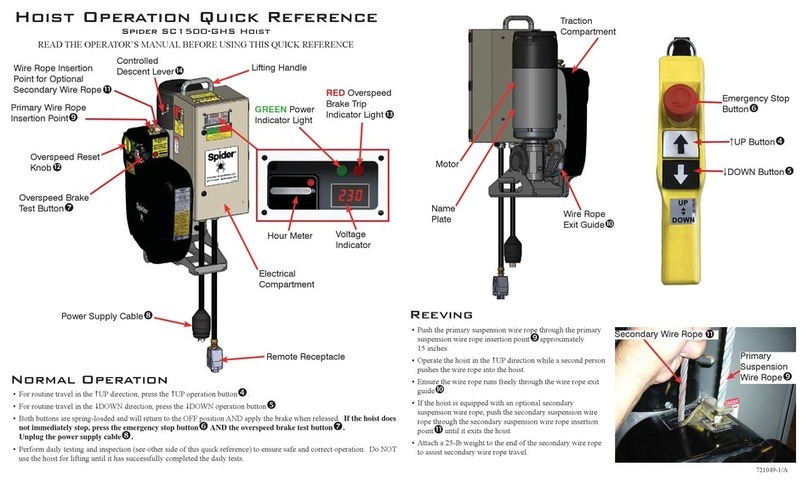

Reeving

• Push the primary suspension wire rope through the the wire

rope inlet of the overspeed safety lock and guide it into the

wire rope inlet of the hoist’s traction compartment15.

• When you cannot push the wire rope into the hoist’s traction

compartment any further (because the traction roller has

gripped it), operate the hoist in the UP direction until the

wire rope passes through the hoist’s traction compartment

exit.

• If the hoist is equipped with an optional secondary suspension

wire rope, push the secondary suspension wire rope through

the wire rope inlet in the inclination safety lock11 until it

passes through the ISL exit13 and the brackets.

• Attach a 25-lb (11.5-kg) weight to the end of the secondary

wire rope to assist secondary wire rope travel.

Hoist Operation Quick Reference

UpPro Series Hoists

READ THE OPERATOR’S MANUAL BEFORE USING THIS QUICK REFERENCE

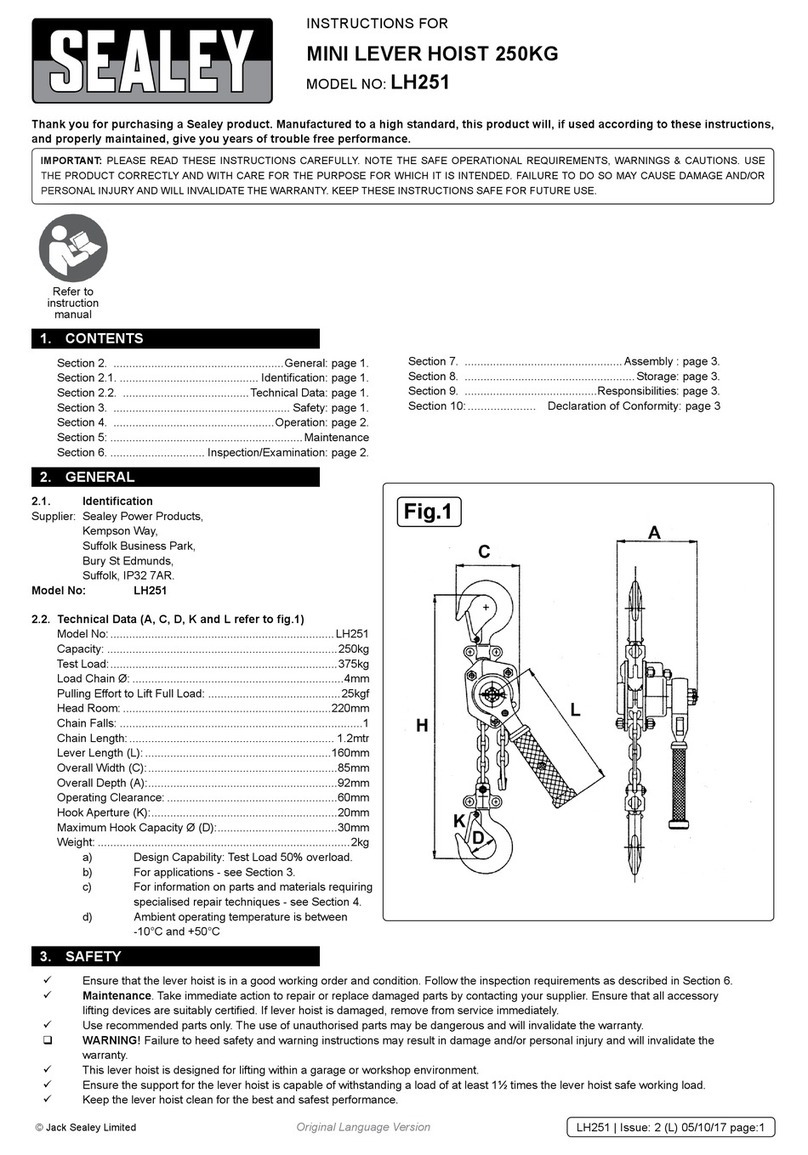

UP Operation Button

Emergency Stop (Power

Supply Cut-off)

GREEN Power Indicator Light

Primary Wire Rope Inlet

DOWN Operation Button

Operating Instructions

Manual and Schematic

Carrying Handle

Power Supply Cable

Primary Suspension

Wire Rope Exit14

Normal Operation

• Switch the control unit on by turing the red emergency stop button on the pendant in the clockwise direction until it pops out.

• For routine travel in the UP direction, push in the UP operation button. For routine travel in the DOWN direction,

push in the DOWN operation button.

• The UP/DOWN buttons have two pressure points. The first pressure point is for the slower speed. Push the UP or

DOWN button again for the faster speed. On 4-speed models, press the

yellow

yellow buttonfor the next highest speed.

• The UP/DOWN buttons are spring-loaded and will return to the OFF positionAND apply the brake when released.

• If the hoist does not immediately stop the platform, press the emergency stopAND turn the overspeed brake

ACTIVATION lever12 in the LOCK direction. Unplug the power supply cable.

• Perform daily testing and inspection (see over) to ensure safe and correct operation. Do NOT use the hoist for

lifting until it has successfully completed the daily tests.

• WARNING! Do NOT operate the hoist if, at any time, you cannot see the flywheel turning.

Platform Mounting

Stirrup Bar

Primary Suspension

Wire Rope Inlet

Inlet for Optional

Secondary

Suspension Wire

Rope

Inlet for Optional

Secondary Wire Rope

721022-1/A

RED Overload Trip Indicator Light

Brake Release Lever

(Storage Position)

Hand Wheel

(Storage Position)

Hour Meter

Optional Secondary Wire Rope

Exit for Optional Secondary

Wire Rope13

Optional Inclination Safety Lock

(ISL)11

Overspeed Brake ACTIVATION

Lever12

Overspeed Brake RESET Lever17

Overspeed Safety Lock (OSL)16

Electrical Box

Traction Compartment

Pendant

Flywheel Observation Window

25-lb Weight for Optional

Secondary Wire Rope

Motor Brake Release Lever

(Operating Position)

Hand Wheel

(Operating Position) Primary Wire Rope Inlet in

Traction Compartment15

YELLOW

YELLOW 2-Speed Button/ Low Voltage

Indicator (3-Phase Models only)

De-reeving Primary Suspension Wire Rope

For hoists equipped with the optional secondary wire rope, the secondary wire rope must be removed before

the primary wire rope is removed.

• WARNING! To prevent hoists and platform from tipping and to avoid injuries, ensure that the platform is

properly supported on a stable, flat surface before putting slack in the primary suspension wire rope.

• Push in the DOWN operation buttonto wind the primary suspension wire rope out of the hoist. When the wire

rope stops moving, pull the wire rope upward out of the overspeed safety lock16 SLOWLY to avoid tripping the

overspeed brake. To release the overspeed brake, run the hoist UP and turn the overspeed brake RESET lever17

clockwise in the UNLOCK direction.

De-reeving Secondary Suspension Wire Rope

• In order to remove the optional secondary suspension wire rope, there must be NO SLACK on the primary

suspension wire rope and the PLATFORM MUST BE SUPPORTED on a flat, stable surface.

• Remove the counterweight from the end of the secondary suspension wire rope.

• Pull the secondary suspension wire rope out of the ISL11 by hand.

• If necessary, the primary suspension wire rope can now be removed from the hoist.

Resetting the Overload

• Push in the emergency stop buttonon the pendant and wait until the RED light on the electrical box goes out.

• Switch the unit on again by turning the emergency stop button clockwise until it pops out.

Daily Testing and Inspection

• Before operating the hoist, inspect all of the following:

Wire rope

Power supply

Rigging

Platform

Hoist

All parts are present, in proper working order, and are not

damaged.

Bolts, nuts, and clamps are well secured.

Ensure the hoist is secured to the stirrup with SAE Grade 5

fasteners and lock nuts that are properly installed.

• In a dirty environment that contains epoxy, paint, cement, sand blast residue, or corrosive material, inspect the operation

of the overspeed brake several times a day. Protective hoist covers are recommended. Contact your supplier.

Test the Emergency Stop Button

• Conduct a test run with the hoist’s maximum working load (2,200 lbs or 1000 kg).

• Press the red emergency stop buttonwhile running the hoist in either direction.

• Once the emergency stop button has been pressed, the hoist should not move at all.

• To reset the emergency stop button, turn the button clockwise until it pops out.

Test the Controlled Descent

• Raise the platform approximately 3 feet (1 meter) and then disconnect the power supply cable.

• Remove the brake release leverfrom its storage cylinder, insert into the opening in the motor cover, and lift the

brake release lever. This will allow the platform to be lowered slowly.

WARNING! If the overspeed brake trips while testing the controlled descent, the controlled descent system is not

working properly and THE HOIST SHOULD NOT BE USED.

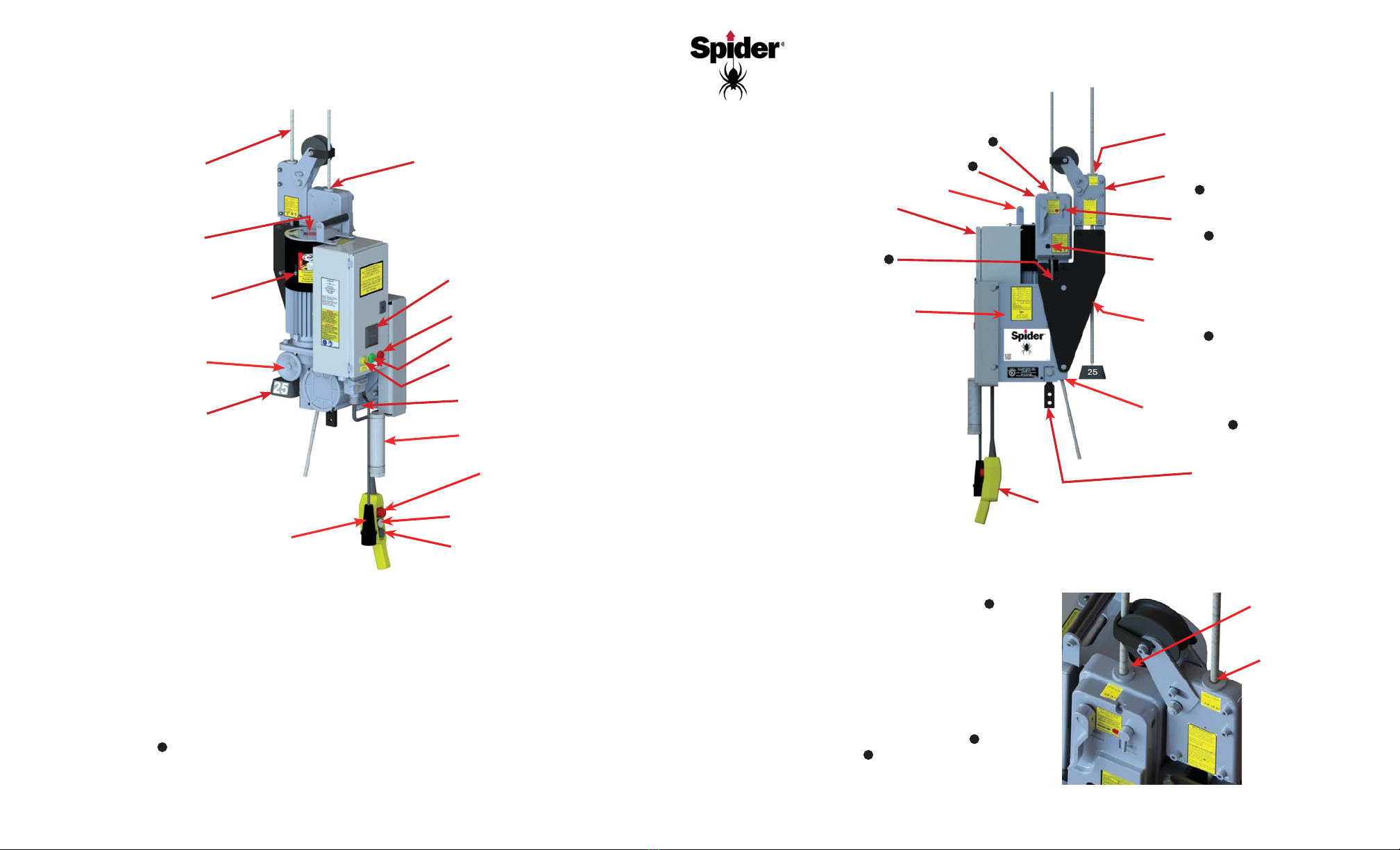

Test the Overspeed Brake & Actuation Lever

• While powering the hoist UP and DOWN

approximately 3 feet (1 meter), look through

the round window into the overspeed safety

lock to see whether the flywheel is turning.

• De-reeve the wire rope.

• Re-insert the wire rope about 12" (30 cm) into

the hoist’s OSL wire rope inlet.

• Holding the wire rope firmly, pull it out

quickly. If the overspeed brake is working

correctly, it will grip and hold the wire rope in

less than 4" (10 cm).

• Repeat this test at least 3 times. If the

overspeed brake does not work correctly every

time, DO NOT USE THE HOIST. Return the

hoist to your supplier.

• Release the overspeed brake by turning the

overspeed brake RESET lever17 clockwise in

the UNLOCK direction. The overpseed brake

ACTIVATION lever12 should return to its

vertical, locked position.

• While raising or lowering the hoist, activate the

overspeed brake by turning the overspeed

Flywheel

Observation

Window

Turn overspeed brake

RESET lever17

clockwise

Overspeed brake

ACTIVATION

lever12 returns to

locked position

brake ACTIVATION lever12 on the OSL in the counterclockwise or LOCK direction. The hoist should not travel in

the DOWN direction.

• Release the overspeed brake by turning the overspeed brake RESET lever17 clockwise in the UNLOCK

direction. The overspeed brake ACTIVATION lever12 should return to its vertical, locked position.

Test the Hand Wheel

NOTE: The purpose of the hand wheelis to crank the platform upwards just enough to untrip the overspeed brake if it

has been tripped due to power loss or something else that has prevented upward movement.

• Activate the overspeed brake by turing the overspeed brakeACTIVATION lever12 counterclockwise in the LOCK

direction.

• Remove the small cap in the motor cover and unscrew the screw that retains the hand wheel enough to remove the

hand wheel.Insert the hand wheel into the motor in place of the small cap and tighten the screw.

• Remove the motor brake release leverand insert into the opening in the motor cover. Hold the hand wheel still

while pushing the brake lever up, then turn the hand wheel clockwise. The hoist will move up a small amount with

each turn until the overspeed brake releases and can be reset with the overspeed brake RESET lever17.

Other SPIDER Chain Hoist manuals

Popular Chain Hoist manuals by other brands

Hercules

Hercules H-F 1000 Original operating instructions

R&M

R&M STAGEMAKER SM5 Installation, operation and maintenance instructions

Harrington

Harrington TCS Series owner's manual

SVERO

SVERO 20123A manual

Yale Industrial Products

Yale Industrial Products TIGRIP TBL 0,5 operating instructions

Sumake

Sumake SA-22030 Operation manual