IM-P054-08 CH Issue 2

MPC2 Spirax-Monnier

High Efficiency Compressed Air Filter / Regulator

Installation and Maintenance Instructions

IM-P054-08

CH Issue 2

0549750/2

Printed in the UK © Copyright 2001

What is the MPC2 used for?

The MPC2 is used to provide very high

quality compressed air.

There are an ever increasing number of

applications where compressed air of a

particularly high quality is required. Typical

examples include air bearings on machine

tools, air gauging equipment, instrument air

supplies, fluidic systems, breathing air,

pneumatic positioners, etc.

How efficient is the MPC2?

Spirax-Monnier coalescing filters when

tested to BS 3928 or the D.O.P. test, are

more than 99.999% efficient.

Inthesodiumflametest(BS3928)theelement

ischallengedbyacloudofsaltparticlesofmass

mean diameter of 0.6 micron. In the American

D.O.P. test, a cloud of droplets of mass mean

diameter 0.3 micron is used.

How does the MPC2 work?

These units filter out solid contaminants

and remove oil and water liquids and

aerosols, by coalescing.

Contaminated air flows to the inside of the

filter cartridge. The cartridge contains a

labyrinth of micro fibres which will trap solid

particles down to sub micron size. Fine liquid

mist and aerosols on their journey through

the depth of the element, will strike one or

other of the fibres and will be retained on

them by inter-molecular forces.

As the droplets migrate through the element

due to the air flow, they will join (coalesce)

with others, growing in size. A specially

designed porous plastic sock forms the outer

layer of the filter cartridge. This encourages

furthercoalescing,sothatthedropletmass is

sufficienttoallowittogravitatetothesumpof

the filter from which they can be drained

manually. The porous plastic sock also

reduces the possibility of re-entrainment.

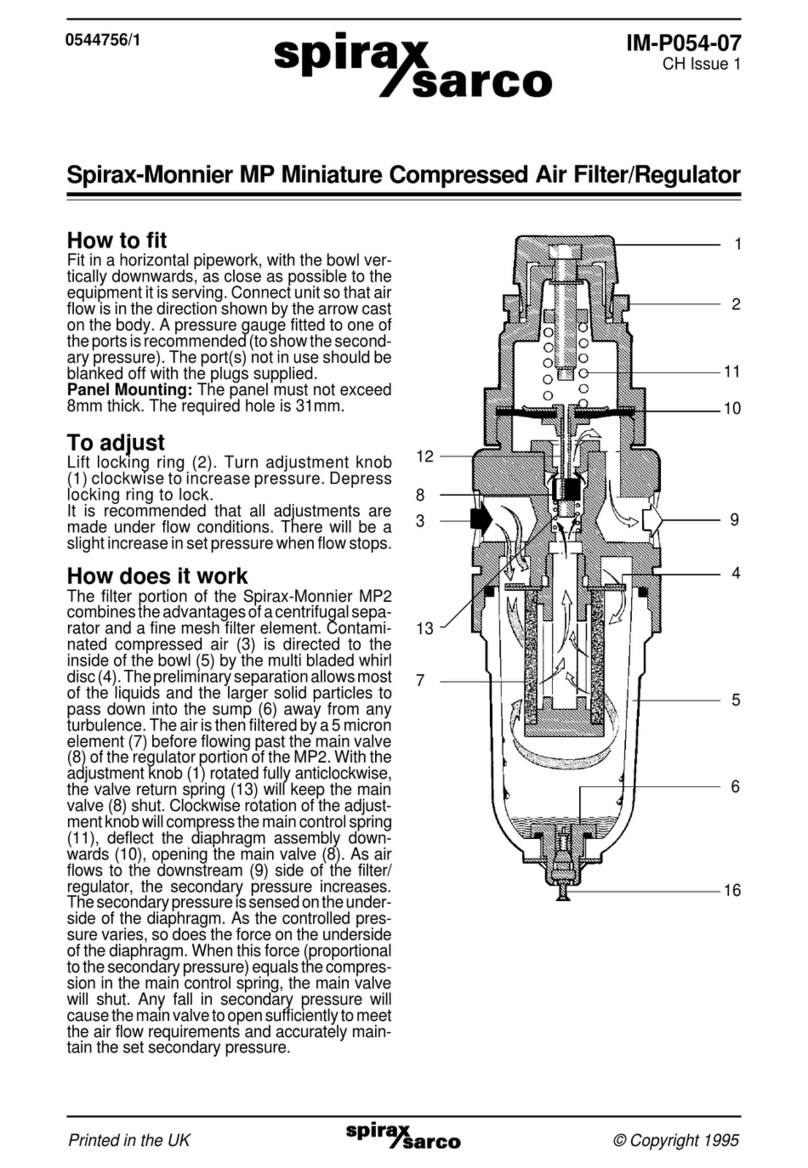

With the adjustment knob (1) rotated fully

anticlockwise, the valve return spring (13) will

keepthemainvalve(8)shut.Clockwiserotation

of the adjustment knob will compress the main

control spring (11), deflect the diaphragm

assembly downwards (10), opening the main

valve (8). As air flows to the downstream (9)

side of the filter/regulator, the secondary

pressureincreases.The secondary pressureis

sensed on the underside of the diaphragm. As

the controlled pressure varies, so does the

forceontheundersideof the diaphragm. When

this force (proportional to the secondary

pressure) equals the compression in the main

control spring, the main valve will shut. Any fall

insecondarypressurewillcausethemainvalve

to open sufficiently to meet the air flow

requirements and maintain the set secondary

pressure.

Anyappreciablerisein the secondary pressure

from its set value will cause the diaphragm and

the push rod (12) to lift. This will allow air to

escape through the centre of the push rod to

atmosphere.Whenexcesspressurehasvented,

theorificeinthepushrodwillreseatonthemain

valve.

Ensure that the bowl is regularly drained by

means of the quick action drain valve (16).

11

12

13

1

2

10

8

9

16

17

Tamper

proof cap