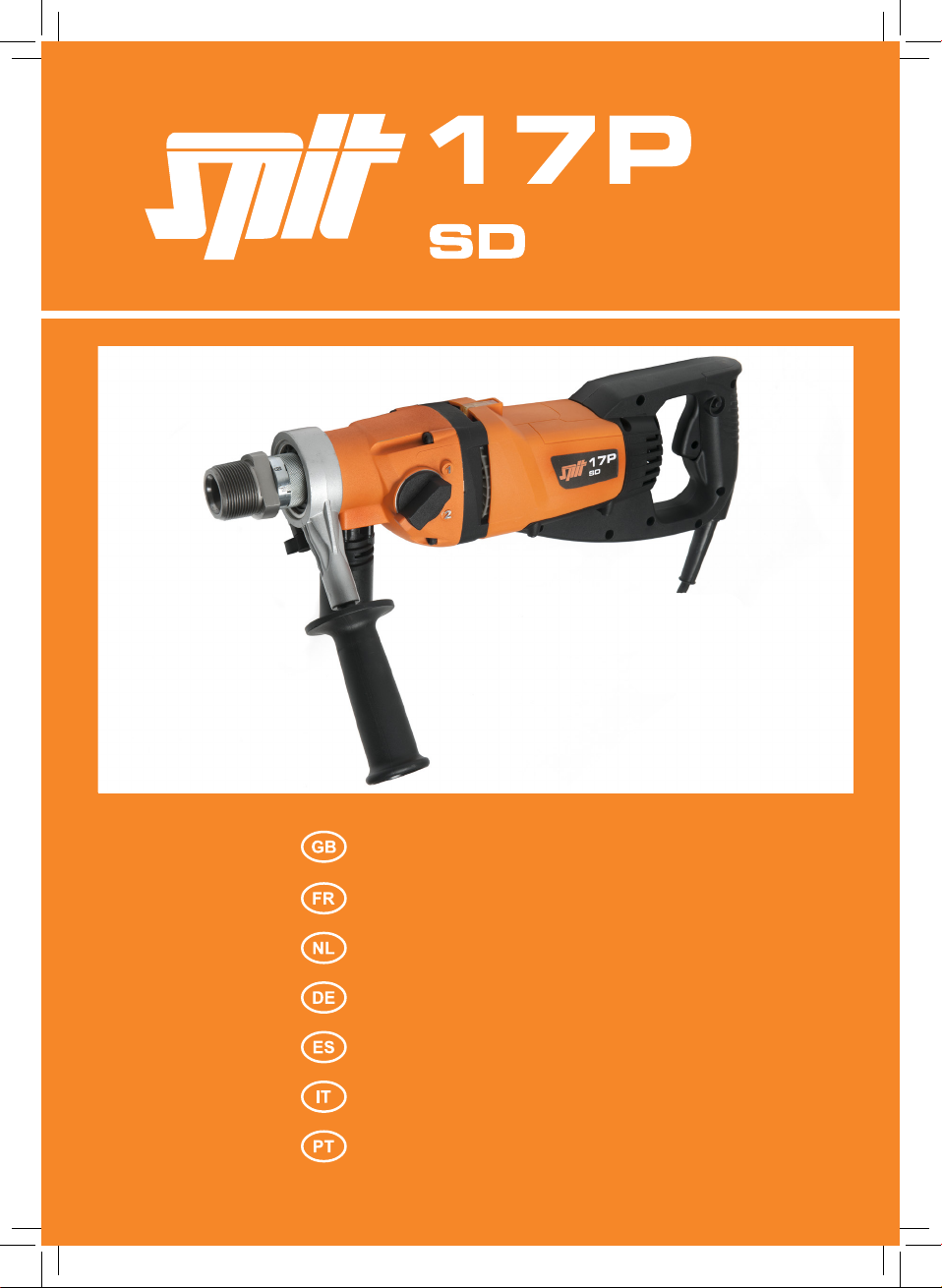

SPIT 17P SD Guide

Operator’s manual and

maintenance instructions 1

Notice d’emploi et

d’entretien 11

Gebruiksaanwijzing en

onderhoudsinstructies 21

Bedienungs- und

Wartungsanleitungen 32

Instrucciones del manual de usuario

y de mantenimiento 43

Manuale d’uso

e manutenzione 54

Manual de utilização

e manutenção 65

1. Spindle - outside M41 /

inside 1/2” BSP

2. Soft impact on/off selector

3. Speed selector lock

4. Speed selector

5. Spirit level

6. Back handle

7. Switch

8. Switch lock

9. Power cable 4m

10. Gear box

11. Integrated dust exhaust

12. Front handle Ø 60 mm

13. Vacuum cleaner connection

14. Locking screw

1. Mandrin - extérieur M41 /

intérieur 1/2” BSP

2. Sélecteur impact doux on/off

3. Verrouillage du sélecteur de vitesse

4. Sélecteur de vitesse

5. Niveau à bulle

6. Poignée arrière

7. Commutateur

8. Verrouillage du commutateur

9. Câble d’alimentation 4 m

10. Boitier d’engrenage

11. Système intégré pour l’aspiration

des poussières

12. Poignée avant Ø 60 mm

13. Raccord d’aspiration

14. Vis de blocage poignée

1

2

3

4

10

11

12

13

14

12

1. Mandrin - extérieur M41 /

intérieur 1/2” BSP

2. Sélecteur impact doux on/off

3. Verrouillage du sélecteur de vitesse

4. Sélecteur de vitesse

5. Niveau à bulle

6. Poignée arrière

7. Commutateur

8. Verrouillage du commutateur

9. Câble d’alimentation 4 m

10. Boitier d’engrenage

11. Système intégré pour l’aspiration

des poussières

12. Poignée avant Ø 60 mm

13. Raccord d’aspiration

14. Vis de blocage poignée

1. As - buiten M41 /

binnen 1/2” BSP

2. Aan/uit selector voor impact

3. Vergrendeling schakelknop

4. Versnelling schakelknop

5. Waterpas

6. Achterhandvat

7. Schakelaar

8. Vergrendeling schakelaar

9. Kabel 4 m

10. Versnellingsbak

11. Geïntegreerde stofafzuiging

12. Voorhandvat Ø 60 mm

13. Aansluiting stofzuiger

14. Vergrendelknop handvat

1. Bohrspindel M41 außen /

½” innen

2. Schlag Ein-/Ausschalter

3. Auslöser Gangwahlschalter

4. Gangwahlschalter

5. Niveau

6. Handgriff

7. Ein-/Ausschalter

8. Feststelltaste für Ein-/Ausschalter

9. Kabel 4 m

10. Getriebegehäuse

11. Integrierte Staubabsaugung

12. Zusatzgriff Ø 60 mm

13. Absaugschlauch

14. Klemmschraube des Zusatzgriff

5

6

7

8

9

10

8

1. Bohrspindel M41 außen /

½” innen

2. Schlag Ein-/Ausschalter

3. Auslöser Gangwahlschalter

4. Gangwahlschalter

5. Niveau

6. Handgriff

7. Ein-/Ausschalter

8. Feststelltaste für Ein-/Ausschalter

9. Kabel 4 m

10. Getriebegehäuse

11. Integrierte Staubabsaugung

12. Zusatzgriff Ø 60 mm

13. Absaugschlauch

14. Klemmschraube des Zusatzgriff

1. Árvore porta-brocas M41 externamente

/ ½” internamente

2. Seletor de impacto

3. Tecladexaçãoparaoselectorde

marchas

4. Seletor de marchas

5. Nível

6. Punho

7. Interruptor de ligar-desligar

8. Tecladexaçãoparaointerruptorde

ligardesligar

9. Cabo 4 m

10. Caixa de velocidades

11. Aspiração de pó integrado

12. Punho adicional dia 60 mm

13. Conexão de vácuo

14.Tecladexaçãoparapunhoadicional

1. Husillo de taladrar M41 externamente /

½” internamente

2. Selector de impacto

3. Botóndejaciónparalapalancade

cambios

4. Selector de marchas

5. Piloto

6. Empuñadura

7. Interruptor de conexión/desconexión

8. Tecla de enclavamiento del interruptor

de conexión/desconexión

9. Cable 4 m

10. Caja de cambios

11. Aspiración de polvo integrada

12. Empuñadura adicional dia 60 mm

13. Conexión de vacío

14.Botóndejaciónparalaempuñadura

adicional

1. Alberinolettatolettatura

esternaM41/lettaturainterna½”

2. Impatti selettore on / off

3. Serratura di commutatore di marcia

4. Commutatore di marcia

5. Spia di controllo

6. Impugnatura

7. Interruttore di avvio / arresto

8. Tasto di bloccaggio per interruttore

avvio / arresto

9. Cavo 4 m

10. Scatola del cambio

11. Estrazione della polvere integrato

12. Impugnatura supplementare

Ø 60 mm

13. Tubo di aspirazione

14. Tasto di bloccaggio di impugnatura

supplementare

1

SYMBOLS USED IN THIS MANUAL

Warning notices:

Warning of general danger

Warning of dangerous voltage

Warning of hot surface

Danger of being crushed

Class II tool

During work you should wear goggles, ear protectors, protective gloves, and

sturdy work clothes!!

Read these instructions

Use ear protection

Wear safety goggles

Wear helmet

Use protective gloves

Wear protective boots

Wear dust mask

Do not dispose of electric tools, accessories and packaging together with household

waste material

V .......................volt

A .......................ampere

Hz .....................hertz

W.......................watt

~........................alternating current

n0.......................no load speed

min_1 ..................revolutions per minute

2

SAFETY INSTRUCTIONS

General Power Tool Safety Warnings

Read all safety warnings and all instructions.

Failuretofollowthewarningsandinstructionsmayresultinelectricshock,reand/orserious

injury.

Save all warnings and instructions for future reference.

The term “power tool” in the warnings refers to your mains-operated (corded) power tool or

battery-operated (cordless) power tool.

1) Work area safety

a) Keep work area clean and well lit.

Cluttered or dark areas invite accidents.

b) Do not operate power tools in explosive atmospheres, such as in the presence of

ammableliquids,gasesordust.

Power tools create sparks which may ignite the dust or fumes.

c) Keep children and bystanders away while operating a power tool.

Distractions can cause you to lose control.

2) Electrical safety

a) Power tool plugs must match the outlet.

Never modify the plug in any way. Do not use any adapter plugs with earthed (grounded)

powertools.Unmodiedplugsandmatchingoutletswillreduceriskofelectricshock.

b) Avoid body contact with earthed or grounded surfaces, such as pipes, radiators, ranges

and refrigerators. There is an increased risk of electric shock if your body is earthed or

grounded.

c) Do not expose power tools to rain or wet conditions.

Water entering a power tool will increase the risk of electric shock.

d) Do not abuse the cord. Never use the cord for carrying, pulling or unplugging the power

tool. Keep cord away from heat, oil, sharp edges and moving parts.

Damaged or entangled cords increase the risk of electric shock.

e) When operating a power tool outdoors, use an extension cord suitable for outdoor use.

Use of a cord suitable for outdoor use reduces the risk of electric shock.

f) If operating a power tool in a damp location is unavoidable, use a residual current device

(PRCD) protected supply.

Use of an PRCD reduces the risk of electric shock.

3) Personal safety

a) Stay alert, watch what you are doing and use common sense when operating a power

tool.Donotuseapowertoolwhileyouaretiredorundertheinuenceofdrugs,alcoholor

medication.

A moment of inattention while operating power tools may result in serious personal injury.

b) Usepersonalprotectiveequipment.Alwaysweareyeprotection.

Protectiveequipmentsuchasdustmask,non-skidsafetyshoes,hardhat,orhearing

protection used for appropriate conditions will reduce personal injuries.

c) Prevent unintentional starting. Ensure the switch is in the off-position before connecting to

power source and/or battery pack, picking up or carrying the tool.

Carryingpowertoolswithyourngerontheswitchorenergizingpowertoolsthathavethe

switch on invites accidents.

d) Remove any adjusting key or wrench before turning the power tool on.

A wrench or a key left attached to a rotating part of the power tool may result in personal

injury.

e) Do not overreach. Keep proper footing and balance at all times. This enables better control

of the power tool in unexpected situations.

3

f) Dress properly. Do not wear loose clothing or jewelry. Keep your hair, clothing and gloves away

from moving parts.

Loose clothes, jewelry or long hair can be caught in moving parts.

g) If devices are provided for the connection of dust extraction and collection facilities, ensure these

are connected and properly used.

Use of dust collection can reduce dust-related hazards.

4) Power tool use and care

a) Do not force the power tool. Use the correct power tool for your application.

The correct power tool will do the job better and safer at the rate for which it was designed.

b) Do not use the power tool if the switch does not turn it on and off.

Any power tool that cannot be controlled with the switch is dangerous and must be repaired.

c) Disconnect the plug from the power source and/or the battery pack from the power tool before

making any adjustments, changing accessories, or storing power tools.

Such preventive safety measures reduce the risk of starting the power tool accidentally.

d) Store idle power tools out of the reach of children and do not allow persons unfamiliar with the

power tool or these instructions to operate the power tool.

Power tools are dangerous in the hands of untrained users.

e) Maintain power tools. Check for misalignment or binding of moving parts, breakage of parts and

any other condition that may affect the power tool’s operation. If damaged, have the power tool

repaired before use. Many accidents are caused by poorly maintained power tools.

f) Keep cutting tools sharp and clean.

Properly maintained cutting tools with sharp cutting edges are less likely to bind and are easier

to control.

g) Use the power tool, accessories and tool bits etc. in accordance with these instructions, taking

into account the working conditions and the work to be performed.

Use of the power tool for operations different from those intended could result in a hazardous

situation.

5) Service

a) Haveyourpowertoolservicedbyaqualiedrepairpersonusingonlyidenticalreplacementparts.

This will ensure that the safety of the power tool is maintained.

SAFETY WARNINGS FOR DIAMOND DRILLS

General Information for Diamond Drills

Hold power tool by insulated gripping surfaces, when performing an operation where the cutting

accessory may contact hidden wiring or its own cord.

Cutting accessory contacting a “live” wire may make exposed metal parts of the power tool “live” and

could give the operator an electric shock.

Use suitable detectors to determine if utility lines are hidden in the work area or call the local utility

company for assistance.

Contactwithelectriclinescanleadtoreandelectricshock.Damagingagaslinecanleadtoexplosion.

Penetrating a water line causes property damage or may cause an electric shock.

The safety and operating instructions for the drill stand and the accessories being used are to be strictly

observed!

Store the machine in a safe manner when not being used. The storage location must be dry and lockable.

This prevents the machine from storage damage, and from being operated by untrained persons.

Keep handles dry, clean, and free from oil and grease.

Greasy, oily handles are slippery causing loss of control.

Never use the machine with a damaged cable. Do not touch the damaged cable and pull the mains plug

when the cable is damaged while working.

Damaged cables increase the risk of an electric shock.

4

f) Dress properly. Do not wear loose clothing or jewelry. Keep your hair, clothing and gloves away

from moving parts.

Loose clothes, jewelry or long hair can be caught in moving parts.

g) If devices are provided for the connection of dust extraction and collection facilities, ensure these

are connected and properly used.

Use of dust collection can reduce dust-related hazards.

4) Power tool use and care

a) Do not force the power tool. Use the correct power tool for your application.

The correct power tool will do the job better and safer at the rate for which it was designed.

b) Do not use the power tool if the switch does not turn it on and off.

Any power tool that cannot be controlled with the switch is dangerous and must be repaired.

c) Disconnect the plug from the power source and/or the battery pack from the power tool before

making any adjustments, changing accessories, or storing power tools.

Such preventive safety measures reduce the risk of starting the power tool accidentally.

d) Store idle power tools out of the reach of children and do not allow persons unfamiliar with the

power tool or these instructions to operate the power tool.

Power tools are dangerous in the hands of untrained users.

e) Maintain power tools. Check for misalignment or binding of moving parts, breakage of parts and

any other condition that may affect the power tool’s operation. If damaged, have the power tool

repaired before use. Many accidents are caused by poorly maintained power tools.

f) Keep cutting tools sharp and clean.

Properly maintained cutting tools with sharp cutting edges are less likely to bind and are easier

to control.

g) Use the power tool, accessories and tool bits etc. in accordance with these instructions, taking

into account the working conditions and the work to be performed.

Use of the power tool for operations different from those intended could result in a hazardous

situation.

5) Service

a) Haveyourpowertoolservicedbyaqualiedrepairpersonusingonlyidenticalreplacementparts.

This will ensure that the safety of the power tool is maintained.

SAFETY WARNINGS FOR DIAMOND DRILLS

General Information for Diamond Drills

Hold power tool by insulated gripping surfaces, when performing an operation where the cutting

accessory may contact hidden wiring or its own cord.

Cutting accessory contacting a “live” wire may make exposed metal parts of the power tool “live” and

could give the operator an electric shock.

Use suitable detectors to determine if utility lines are hidden in the work area or call the local utility

company for assistance.

Contactwithelectriclinescanleadtoreandelectricshock.Damagingagaslinecanleadtoexplosion.

Penetrating a water line causes property damage or may cause an electric shock.

The safety and operating instructions for the drill stand and the accessories being used are to be strictly

observed!

Store the machine in a safe manner when not being used. The storage location must be dry and lockable.

This prevents the machine from storage damage, and from being operated by untrained persons.

Keep handles dry, clean, and free from oil and grease.

Greasy, oily handles are slippery causing loss of control.

Never use the machine with a damaged cable. Do not touch the damaged cable and pull the mains plug

when the cable is damaged while working.

Damaged cables increase the risk of an electric shock.

Check the cable regularly and have a damaged cable repaired only through an authorized cus-

tomer

service agent for SPIT power tools. Replace damaged extension cables.

This will ensure that the safety of the power tool is maintained.

Wear non-skid shoes.

This prevents injuries that can occur from slipping on smooth surfaces.

Use only original SPIT accessories.

Connect the machine to a mains supply with proper earth connection.

Socketoutletandextensioncablemustbeequippedwithanoperativeprotectiveconductor.

Iftheplugisnotsuitableforyoursocketoutlets,itshouldbecutoffandanappropriateplugtted

in its place by an authorized customer service agent. The replacement plug should have the same

fuse rating as the original plug. The severed plug must be disposed of to avoid a possible shock

hazard and should never be inserted into a mains socket elsewhere.

INSTRUCTIONS FOR OPERATION WITHOUT DRILL STAND

Use auxiliary handle(s), if supplied with the tool.

Loss of control can cause personal injury.

Always wait until the machine has come to a complete stop before placing it down.

The tool insert can jam and lead to loss of control over the power tool.

Whenworkingwiththemachine,alwaysholditrmlywithbothhandsandprovideforasecure

stance.

The power tool is guided more secure with both hands.

If the application tool should become blocked, switch the machine off. Loosen the application tool.

Before switching on the power tool, make sure that the application tool moves freely.

Whenswitchingonwithablockeddrillingtool,hightorquereactioncanoccur.

INSTRUCTIONS FOR OPERATION WITH DRILL STAND

Never leave the machine before it has come to a complete stop.

Cutting tools that are still running can cause injuries.

Hold the drill stand by the insulated gripping surfaces when performing operations where the ap-

plication tool could contact hidden wiring or its own power cord.

Contact with a “live” wire will also make exposed metal parts of the drill stand “live” and shock the

operator.

FUNCTIONAL DESCRIPTION

Read all safety warnings and all instructions.

Failuretofollowthewarningsandinstructionsmayresultinelectricshock,reand/or

serious injury.

While reading the operating instructions, unfold the graphics page for the machine and

leave it open.

5

TECHNICAL SPECIFICATIONS

Power 1800 W

Voltage 220-240 V

Frequency 50-60Hz

Current 7,8 A

Impactfrequency 1stspeed 28800bpm

2nd speed 57600 bpm

No load speed 2400 / 3600 min-1

Full load speed 1200 / 1980 min-1

Maximum drill potential Ø 181 mm

Connection M41 & 1/2”

Safety mechanism mechanical clutch

Thermal safety mechanism yes

Protection against excess pressure through an electronic system

Protective class II

Cable 4 m

Weight EPTA 5,51 kg

Measurements 500 x 210 x 115 mm

Hand grip yes

Noise and vibration

Measured sound values determined according to EN 60745-2-1

Typically the A-weighted noise levels of the product are:

Sound pressure level LpA 94 dB(A).

Sound power level LwA 105 dB(A).

Uncertainty K=3 dB.

Wear hearing protection!

Vibration total values (triax vector sum) determined according to EN 60745:

Vibration level: ah: 10,1 m/s² K= 1,5 m/s² (drilling without impact into concrete)

Vibration level: ah: 17,3 m/s² K= 1,5 m/s² (drilling with impact into concrete)

The vibration emission level given in this information sheet has been measured in

accordance with a standardized test given in EN 60745 and may be used to compare

one tool with another. It may be used for a preliminary assessment of exposure.

The declared vibration emission level represents the main applications of the tool.

However if the tool is used for different applications, with different accessories or poorly

maintained,thevibrationemissionmaydiffer.Thismaysignicantlyincreasethe

exposure level over the total working period. An estimation of the level of exposure to

vibration should also take into account the times when the tool is switched off or when it

isrunningbutnotactuallydoingthejob.Thismaysignicantlyreducetheexposure

level over the total working period. Identify additional safety measures to protect the

operator from the effects of vibration such as: maintain the tool and the accessories,

keep the hands warm, organization of work patterns.

6

Intended use

SD 17P: In conjunction with dry diamond core bits and an integrated extraction device,

the machine is intended for dry drilling in bricks, sandstone, aerated concrete and tiles.

All uses for other purposes are prohibited.

Thetoolisequippedwithaspiritlevelashelpforhorizontaldrilling,mechanicalclutch,

soft start, thermal protection, and overload protection.

Conrmation declaration

We declare under our sole responsibility that the product described under “Technical

Data” is in conformity with the following standards or standardization documents:

EN 60745 according to the provisions of the directives 2011/65/EU, 2004/108/EC,

2006/42/EC.

SPIT SAS

150, Route de Lyon

26500 Bourg-lès-Valence Cedex

France

Guy Jaillet Ruben Bernaert

Director Product Manager

Business Development & Innovation

FUNCTIONAL DESCRIPTION

Electrical connection

Prior to putting the tool into operation, check the mains voltage for conformity with the

requirementsofthetool’snameplate.

Voltage variations between + 6 % and – 10 % are permissible.

The tool includes a start-up speed limiter to prevent fast expulsion fuses from

unindented responding.

Onlyuseextensioncableswithasufcientcross-section.Across-sectionwhichistoo

small could cause a considerable drop in performance and an overheating of machine

and cable.

Recommended minimum cross sections and maximum cable lengths

Mains voltage 230 V

Cross section in mm21.5 2.5

Maximum cable length 50 m 80 m

7

ASSEMBLY

Mount the auxiliary handle clamp on to the gearbox neck. Position the side handle

perpendicular to the main handle. Use the lock screw to tighten the clamp.

LIST OF CONTENTS

SD 17P Diamond dry drill coring machine.

Side handle assembly

Vacuum adaptor

Wrench 46 mm

Wrench 38 mm

Wrench 24 mm

Operators and safety manual

OPERATING INSTRUCTIONS

Mounting the dry core drill

Caution: Ensure that the threads of the spindle and the core drill and/or bayonet

connection are matching. Attempting to mount mismatched threads will result in damage

to both threads.

Ensure that the core drill thread and spindle are clean. Any debris could cause

excessive run-out of the mounted core drill. Excessive run-out can cause premature

failure of the core drill and/or safety hazard.

Tighten the core drill to the spindle using two wrenches. Only use correct sized

wrenches to avoid damage to the spindle or core drill connection.

Choosing the correct core drill for the job

Only diamond core drills for dry use are suitable on the SD 17P used with or without soft

impact function.

Special instructions for dry drilling operation

Unlikewetdrillingwhichisagrindingprocess,alotofdownforceisrequiredonthedrill,

Dry drilling is a process where the material is cut off. When dry drilling, where the drill

must be able to drill the hole at their own pace, less pressure should be applied on

the drill.

Dry drilling is normally done in softer materials. Note that in very hard materials it may

not be possible to drill dry.

Selecting speeds

There are two speeds to suit the bit size and work piece hardness. Choose the slowest

speed for large diameter core drills and hard materials. If during drilling the core drill

stalls repeatedly, then you should change to the lowest gear. If you are already in the

lowest gear and the drill stalls repeatedly, then you are using the tool over its maximum

capacity.

Caution: Never attempt to change

gears on a running machine!

Only adjust when the

machine is at rest.

GEAR

SELECTOR

RELEASE

BUTTON

8

Select the desired gear range by pressing the release button and then turn the gear

selector either clockwise or counterclockwise into the desired gear. It will usually be

necessary to turn the spindle by hand a little to get it to shift all the way.

Soft-impact selector

The soft-impact function can be turned on and off. The selector is a crenelated collar

atthefrontofthegearbox.Toselect,rstunplugthemachine,thenpushdownonthe

collar against the spring tension to disengage the teeth of the selector from the slots.

Observe the laser engraved symbol on the selector and turn to either the hammer

symbol for soft-impact or the “no hammer” symbol to turn the soft-impact off.

The switch

Themachinehasalockabletriggerswitch,squeezethetriggertostartthemachine.To

lock the switch on, press the lock-button while holding the trigger switch on. To release,

squeezethetriggerandrelease.

Caution: Never lock the switch on when drilling hand held. Only lock the switch on when

mounted on a rig.

Overload protection and overheat protection

Overload:

If excessive load is sustained too long, the motor will shut down completely. In this case,

the motor must be restarted by turning OFF and then back ON the switch. When this

happens, the motor will very likely be near overheating, so it is also recommended to

run the motor at no load for a few minutes to cool it.

Overheat thermal protection:

If the temperature of the motor gets too high, the thermal protection will shut down the

motor down. When this happens, do not immediately put a load on the motor after

restarting. Always run the machine at no load for a few minutes to return to the normal

operating temperature.

HAMMER

(PERCUSION ON)

NO HAMMER

(PERCUSION OFF)

GEAR

SELECTOR

LOCK

BUTTON

TRIGGER

SWITCH

9

Caution: the motor will be damaged if it is repeatedly overloaded or overheated. Always

cool the motor by running at no load for a few minutes whenever it stops from either

overheat or overload.

Safety clutch

Thismachineisequippedwithamechanicalclutchtoprotecttheoperatorandmachine

fromexcessivetorqueforcesWhenthepresetmaximumtorquelevelisreached,

the clutch will slip. After the clutch slips many times, it will become worn and slip a

lowerandlowertorquelevels.Whenthishappens,itmustbeservicedbyanauthorized

service provider.

Dust extraction via dust connection

Dusts from materials such as lead-containing coatings, some wood types, minerals and

metal can be harmful to one’s health. Touching or breathing-in the dusts can cause

allergic reactions and/or lead to respiratory infections of the user or bystanders. Certain

dusts, such as oak or beech dust, are considered as carcinogenic, especially in

connection with wood-treatment additives (chromate, wood preservative). Materials

containing asbestos may only be worked byspecialists.

• As far as possible, use a dust extraction system suitable for the material.

• Provide for good ventilation of the working place.

• ItisrecommendedtowearaP2lterclassrespirator.

Observe the relevant regulations in your country for the materials to be worked.

Insert the vacuum hose (13) of an all-purpose vacuum cleaner (accessory) into the

vacuum connection (13) on the dust connection.

MAINTENANCE

Before the beginning of the maintenance- or repair works you have to disconnect plug

from the mains.

It is a must to unplug the tool before starting any service or repair works.

Repairsmaybeexecutedonlybyappropriatelyqualiedandexperiencedpersonnel.

After every repair, the unit has to be checked by an electrical specialist.

Accordingtoitsdesign,thetoolrequiresaminimumofcareandmaintenance.

However, the following maintenance works and component checks have to be

performed in regular intervals:

► Cleanthetoolaftercompletionofyourwork.Applysomegreaseontothedrilling

spindle thread. The ventilation slots must always be clean and unclogged. Make

sure that no water gets into the tool during cleaning.

► Afterapprox.250hoursofoperation,thecarbonbrushesmustbecheckedand,if

necessary, be replaced by an authorized specialist (use only original carbon

brushes).

► Onceperquarterofayear,anelectricalspecialistshouldchecktheswitch,

cable and plug.

10

SERVICE

Shouldyouhaveanyfurtherqueries,pleasephoneoneofthetelephonenumberson

the last page of this manual.

SPIT takes no responsibility for machines that are not serviced, repaired or altered by a

workshop that is expressly permitted by SPIT to do so.

DISPOSAL

The machine, accessories and packaging should be sorted for environmental-friendly

recycling.

Do not dispose of power tools into household waste!

Only for EC countries:

According to the European Guideline 2002/96/EC for Waste Electrical and Electronic

Equipmentanditsimplementationintonationalright,powertoolsthatarenolonger

usable must be collected separately and disposed of in an environmentally correct

manner.

11

SYMBOLES D’OBLIGATION

Avis d’avertissement :

Avertissement de danger d’ordre général

Avertissement de tension dangereuse

Avertissement de surface chaude

Danger d’écrasement

Outil classe II

Lorsquevoustravaillez,vousdevezporterdeslunettesdesécurité,desprotège-

oreilles, des gants de protection et des vêtements de travail résistants !

Lisez les instructions

Utilisez des protège-oreilles

Portez des lunettes de sécurité

Portezuncasque

Utilisez des gants de protection

Portez des bottes de protection

Portezunmasqueanti-poussière

Lesoutilsélectroportatifs,ainsiqueleursaccessoiresetemballages,doiventpouvoir

suivre chacun une voie de recyclage appropriée. Ne jetez pas les outils électroportatifs

avec les ordures ménagères !

V .......................volt

A .......................ampere

Hz .....................hertz

W.......................watt

~........................AC courant alternatif

n0.......................vitesse à vide

min_1 ..................vitesse de rotation

12

AVERTISSEMENTS DE SÉCURITÉ

Avertissements de sécurité généraux pour l’outil

Lire tous les avertissements de sécurité et toutes les instructions.

Nepassuivrelesavertissementsetinstructionspeutdonnerlieuàunchocélectrique,unincendie

et/ou une blessure sérieuse.

Conserver tous les avertissements et toutes les instructions pour pouvoir s’y reporter

ultérieurement.

Leterme«outil»danslesavertissementsfaitréférenceàvotreoutilélectriquealimentépar

le secteur (avec cordon d’alimentation) ou votre outil fonctionnant sur batterie (sans cordon

d’alimentation).

1) Sécurité de la zone de travail

a) Conserver la zone de travail propre et bien éclairée.

Les zones en désordre ou sombres sont propices aux accidents.

b) Nepasfairefonctionnerlesoutilsélectriquesenatmosphèreexplosive,parexempleen

présencedeliquidesinammables,degazoudepoussières.

Lesoutilsélectriquesproduisentdesétincellesquipeuventenammerlespoussièresou

les fumées.

c) Maintenir les enfants et les personnes présentes à l’écart pendant l’utilisation de l’outil.

Les distractions peuvent vous faire perdre le contrôle de l’outil.

2)Sécuritéélectrique

a) Ilfautqueleschesdel’outilélectriquesoientadaptéesausocle.Nejamaismodier

lachedequelquefaçonquecesoit.Nepasutiliserd’adaptateursavecdesoutilsà

branchement de terre.

Deschesnonmodiéesetdessoclesadaptésréduirontlerisquedechocélectrique.

b) Evitertoutcontactducorpsavecdessurfacesreliéesàlaterretellesquelestuyaux,les

radiateurs, les cuisinières et les réfrigérateurs.

Ilexisteunrisqueaccrudechocélectriquesivotrecorpsestreliéàlaterre.

c) Ne pas exposer les outils à la pluie ou à des conditions humides.

Lapénétrationd’eauàl’intérieurd’unoutilaugmenteralerisquedechocélectrique.

d) Ne pas maltraiter le cordon. Ne jamais utiliser le cordon pour porter, tirer ou débrancher

l’outil.Maintenirlecordonàl’écartdelachaleur,dulubriant,desarêtesoudespartiesen

mouvement.

Lescordonsendommagésouemmêlésaugmententlerisquedechocélectrique.

e) Lorsqu’onutiliseunoutilàl’extérieur,utiliserunprolongateuradaptéàl’utilisation

extérieure.

L’utilisationd’uncordonadaptéàl’utilisationextérieureréduitlerisquedechocélectrique.

f) Si l’usage d’un outil dans un emplacement humide est inévitable, utiliser une alimentation

protégée par un dispositif à courant différentiel résiduel (RCD).

L’usaged’unRCDréduitlerisquedechocélectrique.

3) Sécurité des personnes

a) Restervigilant,regardercequevousêtesentraindefaireetfairepreuvedebonsens

dansl’utilisationdel’outil.Nepasutiliserunoutillorsquevousêtesfatiguéousous

l’emprise de drogues, d’alcool ou de médicaments.

Un moment d’inattention en cours d’utilisation d’un outil peut entraîner des blessures

graves des personnes.

b) Utiliserunéquipementdesécurité.Toujoursporteruneprotectionpourlesyeux.

Leséquipementsdesécuritételsquelesmasquescontrelespoussières,leschaussures

desécuritéantidérapantes,lescasquesoulesprotectionsacoustiquesutiliséspourles

conditions appropriées réduiront les blessures des personnes.

13

c) Evitertoutdémarrageintempestif.S’assurerquel’interrupteurestenpositionarrêtavant

de brancher l’outil au secteur et/ou au bloc de batteries, de le ramasser ou de le porter.

Porter les outils en ayant le doigt sur l’interrupteur ou brancher des outils dont l’interrupteur

est en position marche est source d’accidents.

d) Retirer toute clé de réglage avant de mettre l’outil en marche.

Uneclélaisséexéesurunepartietournantedel’outilpeutdonnerlieuàdesblessuresde

personnes.

e) Nepasseprécipiter.Garderunepositionetunéquilibreadaptésàtoutmoment.

Cela permet un meilleur contrôle de l’outil dans des situations inattendues.

f) S’habiller de manière adaptée. Ne pas porter de vêtements amples ou de bijoux. Garder

les cheveux, les vêtements et les gants à distance des parties en mouvement.

Des vêtements amples, des bijoux ou les cheveux longs peuvent être pris dans des parties

en mouvement.

g) Sidesdispositifssontfournispourleraccordementd’équipementspourl’extractionetla

récupérationdespoussières,s’assurerqu’ilssontconnectésetcorrectementutilisés.

Utiliserdescollecteursdepoussièrepeutréduirelesrisquesdusauxpoussières.

4) Utilisation et entretien de l’outil

a) Ne pas forcer l’outil. Utiliser l’outil adapté à votre application.

L’outiladaptéréaliseramieuxletravailetdemanièreplussûreaurégimepourlequelila

été construit.

b) Ne pas utiliser l’outil si l’interrupteur ne permet pas de passer de l’état de marche à arrêt

et vice versa.

Toutoutilquinepeutpasêtrecommandéparl’interrupteurestdangereuxetilfautlefaire

réparer.

c) Débrancherlachedelasourced’alimentationencourantet/ouleblocdebatteriesde

l’outil avant tout réglage, changement d’accessoires ou avant de ranger l’outil.

Detellesmesuresdesécuritépréventivesréduisentlerisquededémarrageaccidentelde

l’outil.

d) Conserver les outils à l’arrêt hors de la portée des enfants et ne pas permettre à des per

sonnes ne connaissant pas l’outil ou les présentes instructions de le faire fonctionner.

Les outils sont dangereux entre les mains d’utilisateurs novices.

e) Observerlamaintenancedel’outil.Vérierqu’iln’yapasdemauvaisalignementoude

blocage des parties mobiles, des pièces cassées ou toute autre condition pouvant affecter

le fonctionnement de l’outil. En cas de dommages, faire réparer l’outil avant de l’utiliser.

De nombreux accidents sont dus à des outils mal entretenus.

f) Garder affûtés et propres les outils permettant de couper.

Des outils destinés à couper correctement entretenus avec des pièces coupantes tran

chantessontmoinssusceptiblesdebloqueretsontplusfacilesàcontrôler.

g) Utiliser l’outil, les accessoires et les lames etc., conformément à ces instructions, en tenant

compte des conditions de travail et du travail à réaliser.

L’utilisation de l’outil pour des opérations différentes de celles prévues pourrait donner lieu

à des situations dangereuses.

5) Maintenance et entretien

a) Faireentretenirl’outilparunréparateurqualiéutilisantuniquementdespiècesdere

changeidentiques.Celaassureraquelasécuritédel’outilestmaintenue.

AVERTISSEMENTS DE SÉCURITÉ POUR LES APPAREILS DE FORAGE DIAMANT

Instructions générales pour les appareils de forage diamant

Tenirl’outilparlessurfacesdepréhensionisolantes,pendantlesopérationsaucoursdesquelles

l’accessoire coupant peut être en contact avec des conducteurs cachés ou avec son propre câble.

Lecontactavecunl«soustension»peutégalementmettre«soustension»lespartiesmétal-

14

liquesexposéesdel’outilélectriqueetprovoquerunchocélectriquesurl’opérateur.

Utiliserdesdétecteursappropriésandedécelerdesconduitescachéesouconsulterlesentre-

prises d’approvisionnement locales.

Uncontactavecdeslignesélectriquespeutprovoquerunincendieouunchocélectrique.Un

endommagementd’uneconduitedegazpeutprovoqueruneexplosion.Laperforationd’unecon-

duited’eauprovoquedesdégâtsmatérielsetpeutprovoquerunchocélectrique.

Respecterscrupuleusementlesinstructionsdesécuritéainsiquelesindicationsdetravaildu

support de forage utilisé et des accessoires utilisés ! En cas de non-utilisation, conservez l’outil

électriquedansunendroitsûr.L’emplacementdestockagedoitêtresecetverrouillable.

Ceciprévientl’endommagementdel’outilélectriquependantlestockageousonutilisationpar

des personnes non initiées.

Garder les poignées sèches, propres et dépourvues d’huile et de graisse.

Despoignéesgrasses,huileusessontglissantesetprovoquentainsiunepertedecontrôle.

Ne jamais utiliser un outil électroportatif dont le câble est endommagé. Ne pas toucher à un câble

endommagéetretirerlacheducâbled’alimentationdelaprisedecourant,aucasoùlecâble

aurait été endommagé lors du travail.

Uncâbleendommagéaugmentelerisquedechocélectrique.

ContrôlerlecâblerégulièrementetnefairerépareruncâbleendommagéqueparunService

Après-Vente autorisé pour outillage électroportatifs SPIT. Remplacer un câble de rallonge endom-

magé.

Ceciestindispensablepourassurerlebonfonctionnemententoutesécuritédel’outilélectrique.

Porter des chaussures à semelle antidérapante.

Ceci permet d’éviter des blessures causées par le fait de glisser sur des surfaces lisses.

N’utiliserquedesaccessoiresd’origineSPIT.

Brancherl’outilélectroportatifsurleréseaudecourantélectriquecorrectementreliéàlaterre.

Laprisedecourantainsiquelarallongeélectriquedoiventêtremuniesd’unconducteurdepro-

tection en bon état.

INDICATIONS POUR TRAVAILLER SANS SUPPORT DE PERÇAGE

Utiliser la(les) poignée(s) auxiliaire(s) fournie(s) avec l’outil.

Lapertedecontrôlepeutprovoquerdesblessures.

Avantdedéposerl’outilélectroportatif,attendrequecelui-cisoitcomplètementàl’arrêt.

L’outilrisquedesecoincer,cequientraîneraitunepertedecontrôledel’outilélectroportatif.

Toujours bien tenir l’outil électroportatif des deux mains et veiller à toujours garder une position de

travail stable.

Avec les deux mains, l’outil électroportatif est guidé de manière plus sûre.

Aucasoùl’outildetravailseraitbloqué,arrêtezl’outilélectroportatif.Desserrezl’outildetravail.

Avantdemettreenmarchel’outilélectroportatif,s’assurerquel’outildetravailpuisselibrement

bouger.

Lorsqu’onmetl’appareilenmarche,l’outildetravailétantbloqué,ilpeutyavoirdefortesréac-

tions.

Indications pour travailler avec support de perçage

Nejamaisquitterl’outilavantsonarrêttotal.

Lesoutilsdetravailquinesontpasencoreenarrêttotalpeuventcauserdesblessures.

Tenir le support de perçage par les surfaces de préhension isolantes, pendant les opérations au

coursdesquellesl’accessoirecoupantpeutêtreencontactavecdesconducteurscachésouavec

son propre câble.

Lecontactdel’accessoirecoupantavecunl«soustension»peutégalementmettre«sous

tension»lespartiesmétalliquesexposéesdusupportdeperçageetprovoquerunchocélectrique

sur l’opérateur.

15

DESCRIPTION DU FONCTIONNEMENT

Il est impératif de lire toutes les consignes de sécurité et toutes les instructions.

Lenon-respectdesavertissementsetinstructionsindiquésci-aprèspeutconduireà

uneélectrocution,unincendieet/oudegravesblessures.Dépliezlevoletsurlequel

l’appareilestreprésentédemanièregraphique.Laissezlevoletdépliépendantla

lecture de la présente notice d’utilisation.

contre les chutes. Tenir compte du couple de réaction de l’outil en cas de blocage

CARACTÉRISTIQUES TECHNIQUES

Alimentationélectrique 1800W

Tension 220-240 V

Fréquence 50-60Hz

Intensité 7,8 A

Fréquenced’impact 1ièrevitesse 28800fpm

2ième vitesse 57600 fpm

Vitesse sous vide 2400 / 3600 min_1

Vitesse en charge 1200 / 1980 min-1

Potentiel de perçage maximum Ø 181 mm

Connexion M41 & 1/2”

Mécanisme de sécurité limiteur de couple

Mécanismedesécuritéthermique oui

Protectioncontrelesexcèsdepression parlebiaisd’unsystèmeélectronique

Classe de protection II

Câble 4 m

Poids EPTA 5,51 kg

Mesures 500 x 210 x 115 mm

Poignée oui

Niveau sonore et vibrations

Valeurs de mesure du niveau sonore relevées conformément à la norme EN 60745-2-1

Les mesures réelles (A) des niveaux sonores de l’appareil sont :

Niveaudepressionacoustique94dB(A)

Niveaud’intensitéacoustique105dB(A).

Incertitude K=3 dB.

Porteruneprotectionacoustique!

Total des valeurs de vibrations (somme vectorielle des trois directions) déterminée selon

EN 60745:

Niveau de vibration: ah= 10,1 m/s2, K = 1,5 m/s2(forage sans impact dans le béton)

Niveau de vibration: ah= 17,3 m/s2K= 1,5 m/s2(forage avec impact dans le béton)

Leniveaud’oscillationindiquédanscesinstructionsd’utilisationaétémesuré

conformément à la norme EN 60745 et peut être utilisé pour une comparaison d’outils

électroportatifs. Il est également approprié pour une estimation préliminaire de la

charge vibratoire. Le niveau d’oscillation correspond aux utilisations principales de l’outil

électroportatif.Sil’outilélectriqueestcependantutilisépourd’autresapplications,avec

d’autres outils de travail ou avec un entretien non approprié, le niveau d’oscillation peut

être différent.

Table of contents

Languages:

Other SPIT Rotary Hammer manuals