SPX Hankison Trip-L-Trap 505 User manual

Trip-L-Trap®

Automatic Condensate Drains

Models 505 and 506

FORM NO.: 4011237 REVISION: 04/2014 READ AND UNDERSTAND THIS MANUAL PRIOR TO OPERATING OR SERVICING THIS PRODUCT.

INSTRUCTION MANUAL

Model 505

Model 506

CONTENTS

I. GENERAL SAFETY INFORMATION .............................. 1

II. DESCRIPTION............................................................. 1

III. INSTALLATION............................................................ 2

IV. ENGINEERING DATA ................................................... 3

V. OPERATION ................................................................ 3

VI. MAINTENANCE ........................................................... 4

VII. REPLACEMENT PART NUMBERS ............................... 7

VIII. TROUBLESHOOTING GUIDE....................................... 8

WARRANTY ......................................................................... 9

1

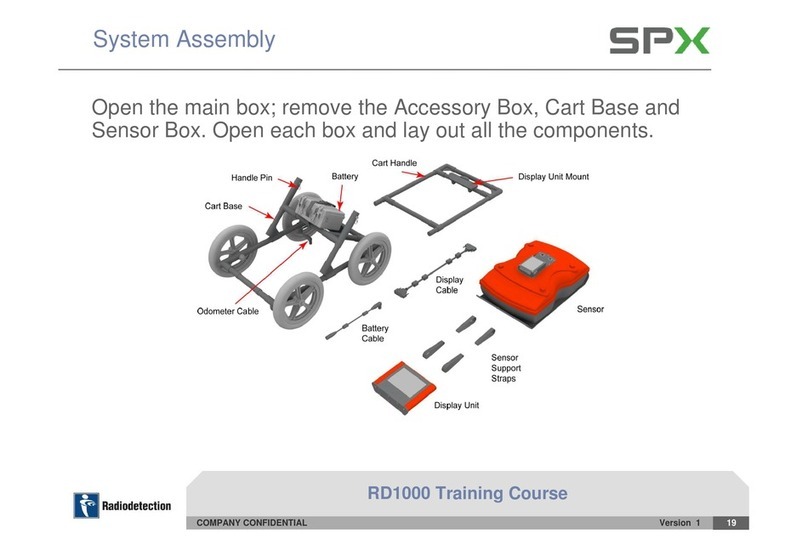

II. DESCRIPTION

These drains are a pilot actuated, pneumatically operated, automatic

liquid drain device for use in discharging collected liquids from a

compressed air system. It is recommended for use with air receivers,

drip legs, aftercoolers, separators, dryers, and filters.

Typical compressed air system

SEPARATOR

AFTERCOOLER RECEIVER DRYER

COMPRESSOR FILTER

I. GENERAL SAFETY INFORMATION

CAUTION

A. Pressurized devices

This equipment is a pressure containing device.

• Donotexceedmaximumoperatingpressureasshownon

equipment serial number tag.

• Makesureequipmentisdepressurizedbeforeworkingonor

disassembling it for servicing.

B. During each operation of the drain a small amount of system

gas is discharged to atmosphere through the bleed hole in the

piston cylinder.

• Wherehazardousorexplosivegasesarepresentinthe

system, provisions for safe disposal of the discharge must be

provided.

2

III. INSTALLATION

IMPORTANT:

DO NOT use a wrench on the valve body of

the drain. Tighten using wrench flats on top

of drain only. The valve body should never be

turned once it is installed. If it is turned, the

float arm may become restricted and will not

operate.

B. Install drain vertically to ensure proper float

operation.

C. Connections:

1. Inlet line

a. Inlet line should slope downwardly

to drain inlet to allow condensate to

flow into the drain by gravity.

b. Strainers to protect the drain from

undue particulate contamination

andisolationvalvestopermitquick

and easy drain servicing are useful

additions to the inlet line.

c. The inlet pipe to the drain should

not be smaller than the inlet con-

nection so that drainage is not

restricted(avoidpiping“pockets”).

A. Preparation:

1. All Models: Remove inlet and drain

thread protectors.

2. Bottom Connection Models: Bushing

and compression fitting are shipped

loose in carton. Install these items

in fitting on top of drain before

installation. Refer to Figure 2.

2. Drain Line

While it is not always necessary, a drain

line is normally recommended in order

tokeepcondensatefromsprayinginto

the area in front of the discharge port.

NOTE: In many cases condensate

containsoil.Checkregulationsinyour

area for proper disposal methods for

oil contaminated condensate

a. Tubing(min.3/8"O.D.)orpiping

(min.1/4")mayberunfromthe

drainconnection(1/4"FPT)toan

adequate sump or floor drain,

preferably below the level of the

drain.

b. Do not put a valve in the drain line

or obstruct the discharge of the

condensate in any way (such as

withseverebendingofdrainline).

c. Drain discharges condensate at

system pressure; the drain line

should be anchored to prevent

movement.

3. Vent Line

Vent lines are required on all bottom

connection drains and on top connec-

tion drains only where upward sloping

inlet lines form a water trap.

a. Bottom connection drains: Bottom

inlet connection drains must be

vented by running 1/4" O.D. tubing

from the compression fitting on

the top of the drain to a place in

the system where there is pressure

equal to the pressure in the device

being drained. See Figure 3.

b. Top connection drains: It is

normally not necessary to vent

top connection drains. See Figure

4. However, if an upward sloping

drain line is unavoidable, a vent line

is necessary. See Figure 5.

FIGURE 1

NEVER tighten by using wrench here

Use Wrench Flats to tighten

Bushing

FIGURE 2

Bottom Connection Models Only

Vent line connection 1/4"

Compression fitting

FIGURE 3

Installation of Bottom Connection Drains

1. Inlet Line

2. Drain Line

3. Vent Line

FIGURE 5

Installation for Top Connection drains with

upward sloping drain lines only

1. Vent line

2. Inlet Line

3. Drain Line

1

1

2

2

3

3

1

2

1

2

FIGURE 4

Normal Installation for Top

Connection Drains

1. Inlet Line

2. Drain Line

3

IV. ENGINEERING DATA

Models 505

505BC

505HP

505BCHP

505SS

505BCSS

505HPSS

505BCHPSS

506

506BC

506HP

506BCHP

506SS

506BCSS

506HPSS

506BCHPSS

Min./Max.OperatingPressure

psig 10/300 10/500 10/300 10/500 10/300 10/500 10/300 10/500

bar .69/21 .69/35 .69/21 .69/35 .69/21 .69/35 .69/21 .69/35

Min./Max.OperatingTemperature

ºF 35/150 35/150 35/150 35/150 35/150 35/150 35/150 35/150

ºC 1.7/65.6 1.7/65.6 1.7/65.6 1.7/65.6 1.7/65.6 1.7/65.6 1.7/65.6 1.7/65.6

Primary Materials of Construction

Shell Carbon Steel 304 Stainless Steel Carbon Steel 304 Stainless Steel

Internals Mechanical Parts:

Steel, Stainless Steel,

Brass, Delrin,

Nylon; Viton Seals

Mechanical Parts:

Stainless Steel;

Viton Seals

Mechanical Parts:

Steel, Stainless Steel,

Brass, Delrin,

Nylon; Viton Seals

Mechanical Parts:

Stainless Steel;

Viton Seals

Discharge per Operation 190 cc

0.4 pints

190 cc

0.4 pints

1514 cc

3.2 pints

1514 cc

3.2 pints

Nominal Capacity* 190 cc/min.

11.4 liters/hr.

3 gallons/hr.

190 cc/min.

11.4 liters/hr.

3 gallons/hr.

1514 cc/min.

90.8 liters/hr.

24 gallons /hr.

1514 cc/min.

90.8 liters/hr.

24 gallons /hr.

Max.Capacity* 1140 cc/min.

68.4 liters/hr.

18 gallons/hr.

1140 cc/min.

68.4 liters/hr.

18 gallons/hr.

9084 cc/min.

544.8 liters/hr.

144 gallons/hr.

9084 cc/min.

544.8 liters/hr.

144 gallons/hr.

*Drains are designed to operate at one discharge per minute for one year before servicing is required. Operation at more than one discharge per

minute may require more frequent servicing.

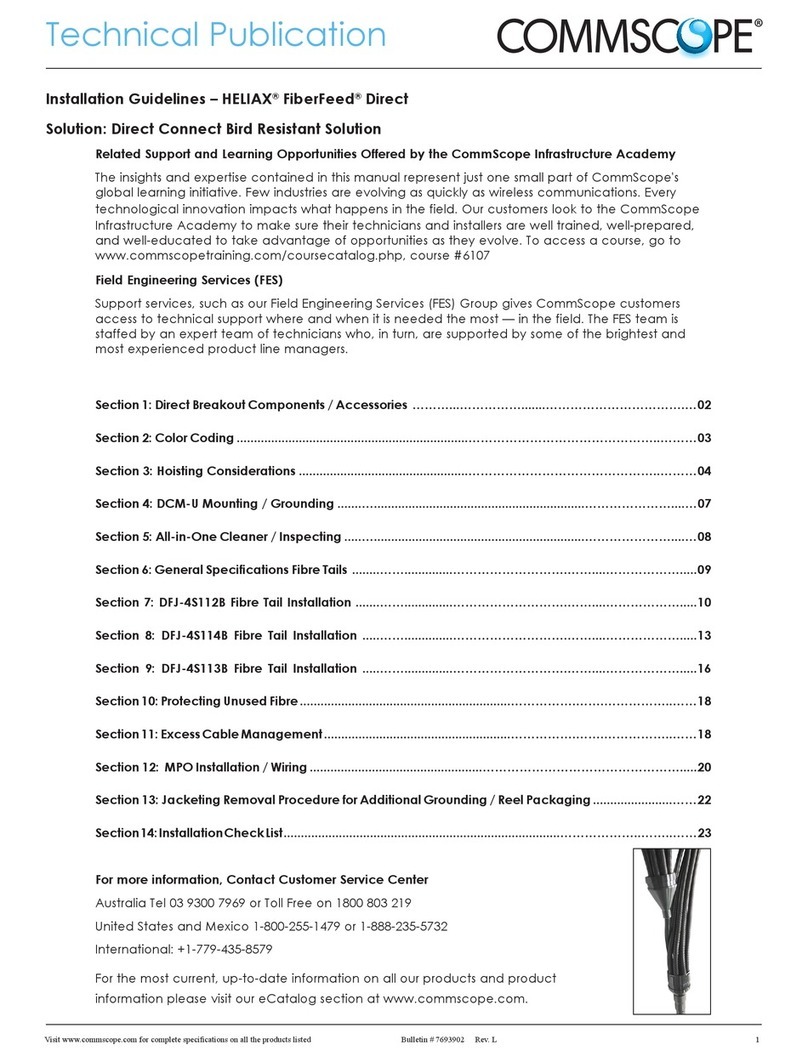

V. OPERATION

Positive discharge of condensate without loss of air.

LEVEL ACTUATED, PILOT CONTROLLED. . .

As condensate collects in the drain housing, a float (1) is held firmly in place

by a magnet (2). When the condensate level rises sufficiently, the buoyancy of

the float overcomes the holding force of the magnet and the pilot valve (3) trips

open.

POWER OPERATED. . .

When the pilot valve opens, compressed air enters air cylinder (4), forcefully

moving piston (5), which opens a large discharge port (6). Condensate is then

forced out of the discharge port. After the condensate has been discharged,

the float drops and pilot valve (3) closes. Compressed air in piston cylinder (4)

bleeds off through bleed hole (7). Air pressure in the housing then moves

piston (5) the opposite way, closing the discharge port and holding it securely

shutuntilthenextoperation.

Allmodelscanbemanuallydrainedanddepressurizedthroughmanual

drain (8).

21

3

5

6

7

4

8

4

VI. MAINTENANCE

A. Regular maintenance of the condensate

discharge drain is recommended. Flush

out accumulated sludge and dirt by

opening manual drain valve about once a

month.

B. Disassemble and service at least once a

year. Drains are designed to operate at one

discharge per minute for one year before

servicing is required. Operation at more

that one discharge per minute may require

more frequent servicing. (NOTE: Before

startingtheservicingprocedure,makesure

youhaveaRepairPartsKitonhand).

1. Close valve ahead of drain.

2. Depressurizedrainbyopeningmanual

drainvalve(31).

3. Disconnect drain lines.

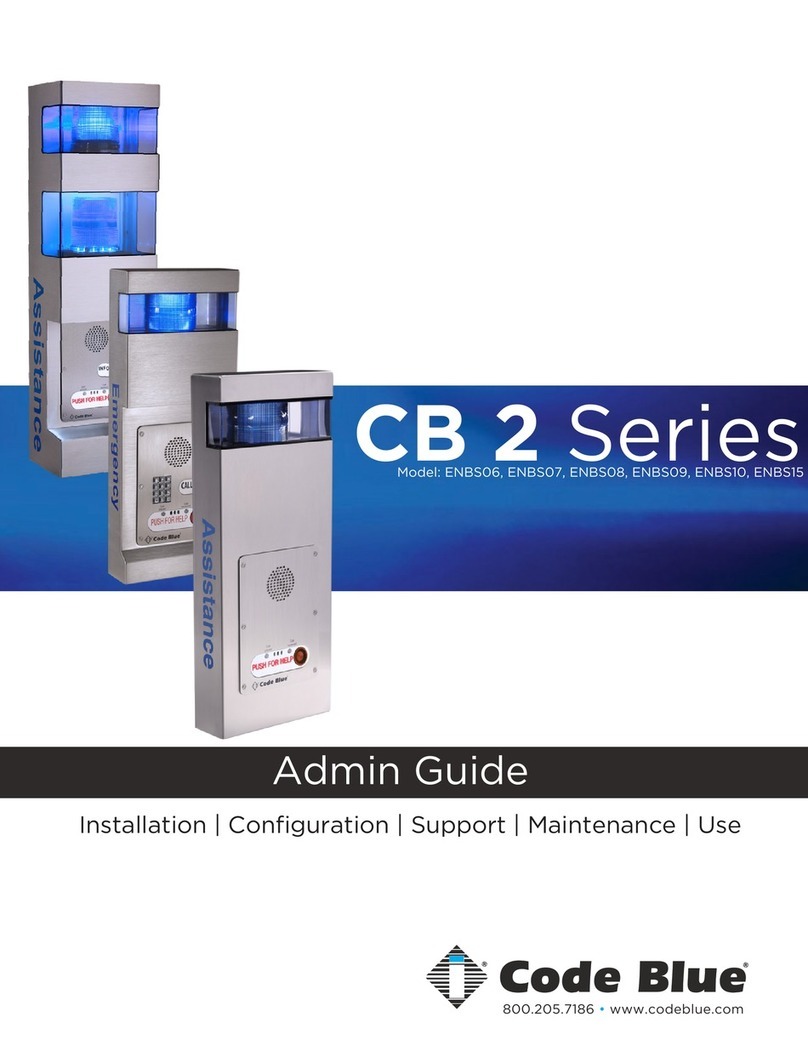

4. Figure7-Removenuts(28)andbolts

(27)andseparatetopandbottomshell

assemblies. Remove seal ring retainer

(24)andcasesealring(29).Figure6

illustrates o-ring and ring retainer for

carbon steel models.

5. To rebuild drain mechanism, refer to

Figure 7.

a. Removesixscrews(14)from

pistoncylinder(13)andremove

cylinder.

b. Removenut(19)andlockwasher

(11)frombottomofvalvestem

assembly. For carbon steel models

removepistondisc(9&10),piston

seal(8),andkeywasher(7)from

valve stem assembly. For stainless

steel models piston is a single

piece.

c. Removevalvestemassembly(3)

fromvalvebody(2)byliftingvalve

stem assembly upwards.

d. Removeretainerclip(36)andpivot

pin(17)andliftoatarmassembly

(15)offofvalvestemassembly(3).

e. Remove pilot valve screw assembly

(18)fromoatarmassemblyand

replace with a new assembly from

therepairpartskit.Reassemble

float arm assembly to valve stem

assembly using new pivot pin and

retainerclipfromrepairpartskit.

f. Removevalvesleeve(5)fromvalve

stem assembly and replace valve

disc(4)withnewdiscfromrepair

partskit.

FIGURE 6

CASE SEAL

O-RING

SEAL RING

RETAINER

LOWER

BOTTOM

OF SHELL

CARBON STEEL MODELS

24

26

29

g. Replacesleeveseal[“V”ring](6)

onvalvesleevemakingsure“V”

shape is in the same position as

shown in Figure 7 - Detail A on

drawing.

h. Reassemble valve sleeve to valve

stem assembly as shown in

drawing . Lubricate sleeve seal

with lubricant supplied with repair

partskitorsiliconegrease.Insert

complete valve stem assembly

into valve body. On models 506SS

makesurerodonvalvestem

assembly is inserted into hole on

inside of shell as shown in Figure

6 - Detail C.

i. Reassemble piston, and piston seal

[“V”ring](8)usingnewpartsfrom

repairpartskit.Onstainlesssteel

models re-use the original stainless

steel piston disc.

j. Reassemblekeywasher(7),piston

assembly,lockwasher(11),and

nut(19)tovalvestemassembly.

Makesure“V”shapeofpistonseal

is in the same position as shown

in Figure 8 - Detail B and that the

keyonthekeywasherisinthe

hole(37)directlyoppositedrain

connection on valve body.

5

k. Lubricate piston seal and piston

cylinder wall with lubricant supplied

inrepairpartskitorsiliconegrease.

l. Reassemblepistoncylinder(13)

tovalvebodywithsixscrews(14).

Makesurebleedhole(38)inpiston

cylinder is not plugged up, as this

willcausethedraintostickinthe

open position. Raise and lower

valveassemblytomakesureit

operates freely.

m. On carbon steel models place seal

ringretainer(24)intobottomshell

assembly(26)makingsurethat

end of float arm assembly with

counterweight(20)ispositioned

in open area of seal ring retainer.

For models 506, 506BC and 506HP

makesurerodontopofoat

assembly fits into hole in seal ring

retainer as shown in Figure 6 -

Detail D.

n. Beforereassemblingshell,make

sure float mechanism moves freely

up and down.

o. On carbon steel models position

newcasesealring(29)ABOVEthe

small lip on the seal ring retainer.

On stainless steel models place

new case seal ring into groove in

seal ring retainer.

p. Reassemble bottom shell to top

shell.

q. Reconnect drain lines, close

manual drain valve.

FIGURE 8

Bleed hole not shown

17

1

16

4

3

20

15

18

36

5

2

7

9

11

19

13

38

14

10

8

DETAIL A

DETAIL B

6

37

Rod

Rod

Seal Ring Retainer

DETAIL C

DETAIL D

FIGURE 7

26

29

28

27

24

20

31

6

30

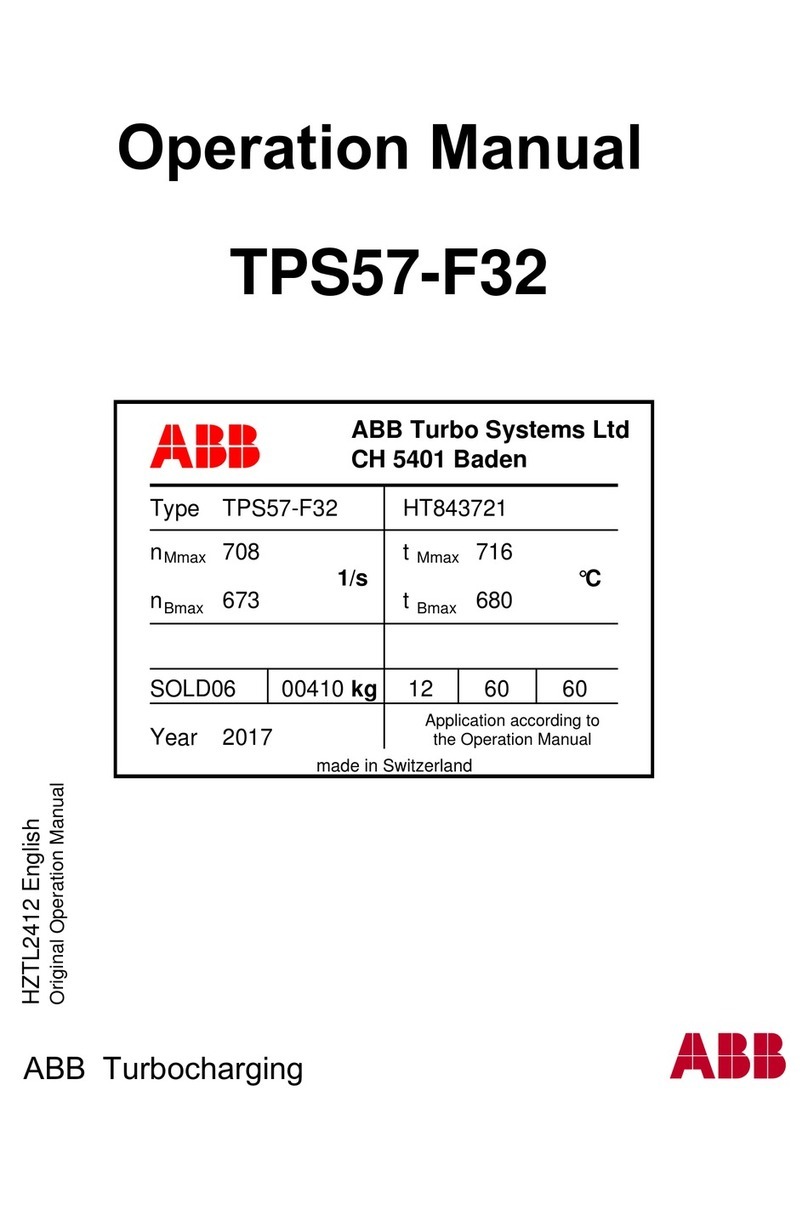

DIMENSIONAL DRAWINGS

VENT LINE CONNECTION

BOTTOM CONNECTION

MODELS ONLY

CONDENSATE INLET

BOTTOM CONNECTION

MODELS ONLY

CONDENSATE INLET

BOTTOM CONNECTION

MODELS ONLY

37

30

12

38

21 36

21 36

37

VENT LINE CONNECTION

BOTTOM CONNECTION

MODELS ONLY

MODELS 506, 506HP,

506BC, & 506BCHP

MODELS 506SS, 506SSHP,

506SSBC & 506SSBCHP

STANDARD MODELS STAINLESS STEEL MODELS

PISTON ASSEMBLY

MODELS 505, 505HP,

505BC & 505BCHP

MODELS 505SS, 505SSHP,

505SSBC & 505SSBCHP

38

4

26

3

Condensate Inlet

Top Connection

Models Only

Condensate Inlet

Top Connection

Models Only

7

NA - Not Available

(1) ThesepartsareincludedinRepairPartsKit6000003.

(2) HPmodelsrequire20.

(3) ThesepartsarefurnishedaspartofFloatArmAssembly(parts1,11&16arealsofurnishedseparately);505Seriesmodelsuseassy.no.3252383;

506 Series models use assy. no. 3223829.

(4) ThesepartsarefurnishedaspartofValveStemAssembly;Formodels505,505BC,505HP,&505BCHPuseassy.no.3230660;Formodels505SS,505BCSS,505HPSS,&505BCHPSS

use assy. no. 3241151; For models 506, 506BC, 506HP, & 506BCHP use assy. no. 3230657; For models 506SS, 506BCSS, & 506CHPSS use assy. no. 3223833.

(5) ThesepartsfurnishedaspartofPistonDiscAssembly;Formodels505,505BC,505HP,505BCHP,506BC,506HP,&506BCHPuseassy.no.3223475.

(6) ThispartfurnishedaspartofTopShellCaseAssembly.

VII. REPLACEMENT PART NUMBERS

MODELS

PC.

NO. NAME NO.

REQ'D.

505

505BC

505HP

505BCHP

505SS

505BCSS

505HPSS

505BCHPSS

506

506BC

506HP

506BCHP

506SS

506BCSS

506HPSS

506BCHPSS

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

33

34

35

36

37

38

Float(3)

Valve Body

ValveStem(4)

ValveDisc(1)

Valve Sleeve

SleeveSeal(1)

Key Washer

PistonSeal(1)

PistonDiscFemale(1)(5)

PistonDiscMale(1)(5)

LockWasher(3)

Cylinder Head

Piston Cylinder

Cylinder Screws

FloatArm(3)

FloatScrew(3)

PivotPin(1)

PilotValveScrewAssembly(1)

HexagonNut

Counterweight(3)

CounterweightRivet(3)

Magnet(4)

MagnetPin(4)

Baffle & Seal Ring Retainer

ShellCaseAssy.(Top)

Models 505, 505SS, 506, 506SS

Models 505BC, 505BCSS, 506BC, 506BCSS

Models 505HP, 505HPSS, 506HP, 506HPSS

Models 505BCHP, 505BCHPSS, 506BCHP, 506BCHPSS

ShellCaseassy.(Bottom)

Models 505, 505SS, 506, 506SS

Models 505BC, 505BCSS, 506BC, 506BCSS

Models 505HP, 505HPSS, 506HP, 506HPSS

Models 505BCHP, 505BCHPSS, 506BCHP, 506BCHPSS

FlangeBolt(2)

FlangeBoltNut(2)

CaseSealRing(1)

Seal Ring Retainer

Drain Valve

Models 505, 505SS, 505HPSS, 506, 506SS, 506HPSS

Models 505HP, 506HP

Thread Shield

Piston

Bottom Float

RetainerClip(1)

Connecting Wire & Screw Assy.

SkimTubeAssy.

1

1

1

1

1

1

1

1

1

1

3

1

1

6

1

1

1

1

1

1

1

1

1

1

1

1

10

10

1

1

1

1

1

1

1

1

1

3223828

3232348

—

4011527

3230658

4011525

4011405

4011526

—

—

4010333

N/A

3240684

3228388

—

4010157

4010342

4001775

4010298

—

—

—

—

4011528

4001791

4001791

3230613

3230613

4001779

3230610

3230606

3230611

4010110

4010288

4011524

N/A

7400597

4010027

3228421

N/A

N/A

4010419

N/A

N/A

3223828

4011390

—

4011527

4011388

4011525

4011405

4011526

N/A

N/A

4010333

4012552

4006961

4010150

—

4010157

4010342

4001775

4010298

—

—

—

—

N/A

4001792

4001792

7500062

7500062

4001780

3230612

4001782

4001790

4010116

4010296

4011524

4001776

4010024

—

—

4011764

N/A

4010419

N/A

N/A

3244801

3232348

—

4011527

3230658

4011525

4011405

4011526

—

—

4010333

N/A

3240684

3228388

—

4010157

4010342

4001775

4010298

—

—

—

—

3228355

4001791

4001791

3230613

3230613

4001784

4001787

3230608

3230609

4010110

4010288

4011524

N/A

7400597

4010027

3228421

N/A

4010444

4010419

4001766

3231080

3244801

4011390

—

4011527

4011388

4011525

4011405

4011526

N/A

N/A

4010333

4012552

4006961

4010150

—

4010157

4010342

4001775

4010298

—

—

—

—

N/A

3230615

4001792

3230616

3234780

4001785

4001788

4001786

4001789

4010116

4010296

4011524

4001776

4010024

—

—

4011764

4010444

4010419

4001766

4006960

8

VIII. TROUBLESHOOTING GUIDE

Symptom Possible Cause Corrective Action

Drainstuckopen-Aircontinuously

being discharged.

1. Bleed hole on bottom of piston cylinder

obstructed.

2. Worn seals .

1. Use pin to open hole.

2. Rebuild drain. See Section VI-B.

Drain won’t discharge - condensate

can be drained through manual drain.

1. Drain being operated below minimum

pressure.

2. Air supply through inlet or vent line

obstructed.

3. Drain line obstructed

4. Valve body has been turned causing

impairment of float movement.

5. Worn seals

1. Increase line pressure above 10 psig

(.69bar)

2. Top connection drains: Slope inlet line downward

to avoid water trap or install vent line.

Bottomconnectiondrains:Makesureventlineis

open.

Makesureisolationvalvesareopen.

3. Makesuretherearenovalves,severebends,or

other obstructions in drain line.

4. Disassembleandcheckthatoatisfreetomove.

5. Rebuild drain. See Section VI-B.

9

SERVICE DEPARTMENT : (724) 746-1100

AUTHORIZATION FROM THE SERVICE DEPARTMENT IS NECESSARY BEFORE MATERIAL

IS RETURNED TO THE FACTORY OR IN-WARRANTY REPAIRS ARE MADE.

WARRANTY

The manufacturer warrants the product manufactured by it, when properly installed, operated, applied, and maintained in

accordance with procedures and recommendations outlined in manufacturer’s instruction manuals, to be free from defects in

material or workmanship for a period of one (1) year from the date of shipment to the buyer by the manufacturer or manufac-

turer’s authorized distributor, or eighteen months from the date of shipment from the factory, whichever occurs first, provided

such defect is discovered and brought to the manufacturer’s attention within the aforesaid warranty period. The manufacturer

will repair or replace any product or part determined to be defective by the manufacturer within the warranty period, provided

such defect occurred in normal service and not as a result of misuse, abuse, neglect or accident.

The warranty covers parts and labor for the warranty period. Repair or replacement shall be made at the factory or the instal-

lation site, at the sole option of the manufacturer. Any service performed on the product by anyone other than the manufactur-

er must first be authorized by the manufacturer. Normal maintenance items requiring routine replacement are not warranted.

Unauthorized service voids the warranty and any resulting charge or subsequent claim will not be paid. Products repaired

or replaced under warranty shall be warranted for the unexpired portion of the warranty applying to the original product. The

foregoing is the exclusive remedy of any buyer of the manufacturer’s product. The maximum damages liability of the manufac-

turer is the original purchase price of the product or part.

THE FOREGOING WARRANTY IS EXCLUSIVE AND IN LIEU OF ALL OTHER WARRANTIES, WHETHER WRITTEN, ORAL,

OR STATUTORY, AND IS EXPRESSED IN LIEU OF THE IMPLIED WARRANTY OF MERCHANTABILITY AND THE IMPLIED

WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE. THE MANUFACTURER SHALL NOT BE LIABLE FOR LOSS

OR DAMAGE BY REASON OF STRICT LIABILITY IN TORT OR ITS NEGLIGENCE IN WHATEVER MANNER INCLUDING

DESIGN, MANUFACTURE OR INSPECTION OF THE EQUIPMENT OR ITS FAILURE TO DISCOVER, REPORT, REPAIR,

OR MODIFY LATENT DEFECTS INHERENT THEREIN. THE MANUFACTURER, HIS REPRESENTATIVE OR DISTRIBUTOR

SHALL NOT BE LIABLE FOR LOSS OF USE OF THE PRODUCT OR OTHER INCIDENTAL OR CONSEQUENTIAL COSTS,

EXPENSES, OR DAMAGES INCURRED BY THE BUYER, WHETHER ARISING FROM BREACH OF WARRANTY, NEGLI-

GENCE OR STRICT LIABILITY IN TORT.

The manufacturer does not warrant any product, part, material, component, or accessory manufactured by others

and sold or supplied in connection with the sale of manufacturer’s products.

Trip-L-Trap®

Automatic Condensate Drains

Models 505 and 506

SPX

1000 Philadelphia Street

Canonsburg, PA 15317-1700 U.S.A.

P: (724) 745-1555

F: (724) 745-6040

www.hankisonintl.com

Improvements and research are continuous at SPX.

Specifications may change without notice.

ISSUED 04/2014 Form No.: 4011237 Revision: B

COPYRIGHT ©2014 SPX Corporation

This manual suits for next models

15

Table of contents

Other SPX Industrial Equipment manuals

SPX

SPX Power Team HNS150A User manual

SPX

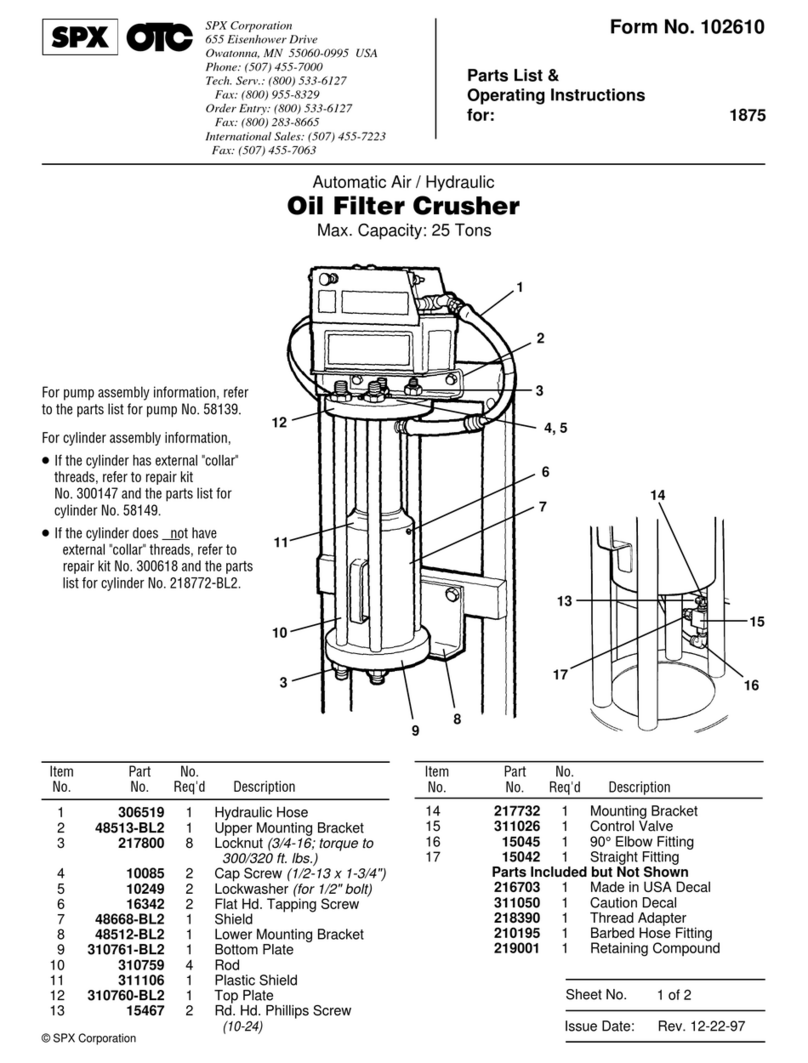

SPX OTC 1875 User manual

SPX

SPX Marley Geareducer 34.4 Series User manual

SPX

SPX MARLEY Geareducer 2700 Series User manual

SPX

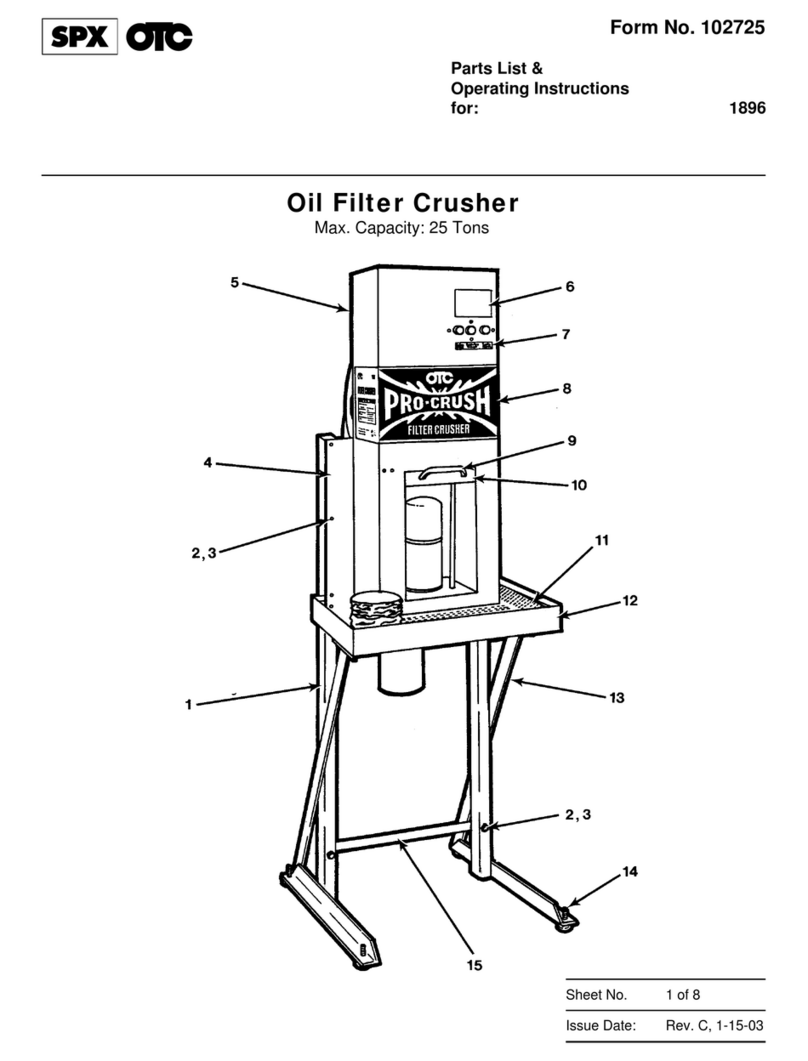

SPX OTC PRO-CRUSH 1896 User manual

SPX

SPX Marley Geareducer 2800 Series User manual

SPX

SPX Waukesha Cherry-Burrell Votator II User manual

SPX

SPX APV ParaFlow User manual

SPX

SPX APV Cavitator User manual

SPX

SPX APV DELTA SDMU4 User manual