9

5. Drive dowel pins down into case.

6. Remove bolts and case cover and lift fan shaft assembly out

of the case.

7. Turn case over and remove bottom cap and shim pack (420).

Note—The thickness of this shim pack is important in setting the

fan shaft bearing endplay and backlash. This pack should be saved

or carefully measured with a micrometer.

8. Remove bearing cups (411 and 412) from the Geareducer

case and cover.

PINION CAGE DISASSEMBLY

1. Remove pinion cage cap* from pinion cage.

2. Remove O-ring* (503).

3. Remove locknut, lockwasher and tongue washer (103, 105 and

104) then press pinion shaft (101) out of pinion cage. This will

free tail bearing cone (312).

4. Press oil slinger (301) and head bearing cone (311) from the

pinion shaft.

5. Press bearing cups (311 and 312) out of pinion cage.

FAN SHAFT DISASSEMBLY

1. Remove ring gear (101) from the ring gear hub

(008).

2. Press ring gear hub, ring spacer (204—Model 2700 only) and

lower bearing cone (411) off of the fan shaft (201).

3. Remove lower fan shaft key (202).

4. Press the top bearing cone (412) off of the shaft.

ASSEMBLY

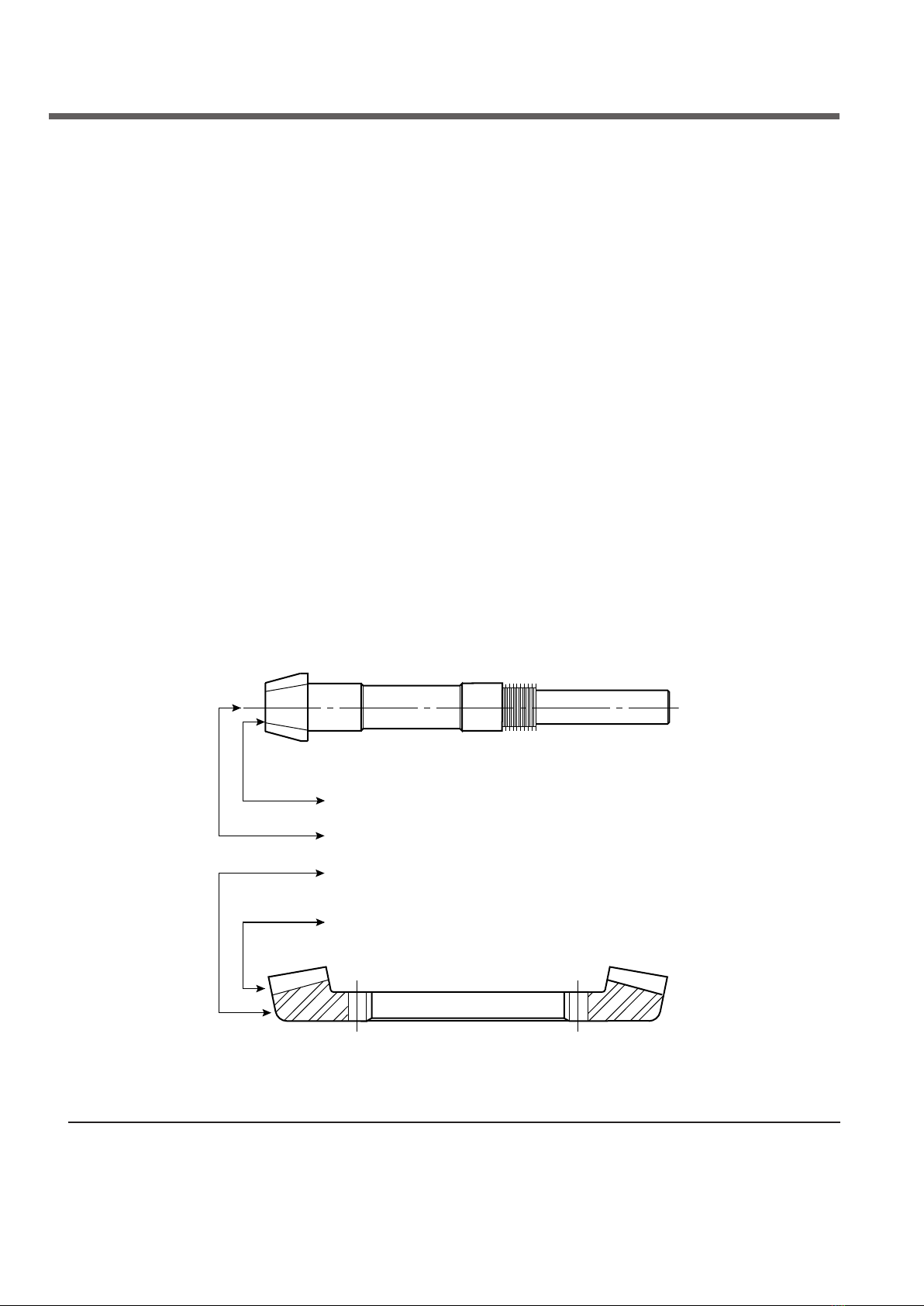

Before assembling a new pinion gear in the pinion cage, check match

numbers on pinion gear and spiral bevel ring gear to be certain that

they are a matched set. Gears are lapped in matched sets at the

factory and should not be separated. Numbers are etched on both

the pinion and ring gear as illustrated in Figure 4.

All parts that are to be reused should be thoroughly cleaned before

being reinstalled. Replace bearings if necessary.

PINION CAGE SUBASSEMBLY

1. Place oil slinger (301) on pinion shaft.

2. Press head bearing cone (311) on pinion shaft making sure oil

slinger and bearing are against gear.

3. Press bearing cups (311 and 312) into pinion cage.

4. Lower pinion cage on pinion shaft, until head bearing cone and

cup mate.

5. Press tail bearing cone (312) on pinion shaft until it mates with

its bearing cup.

6. Install locknut, lockwasher and tongue washer (103, 105 and

104). Tighten nuts on bearing cone until 8 to 12 in·lbƒ (904-

1356 mN·m) of bearing preload is obtained. Bearing preload

is the resistance in the bearings to shaft rotation measured in

in·lbƒ required to rotate the shaft at uniform velocity. Preload is

necessary to insure the stability of the gear engagement. Bend

tab(s) on lockwasher to secure locknut in place.

7. Install O-ring (503) in groove on pinion cage.

8. Press oil seal onto pinion shaft.

9. Tighten pinion cage cap screws to 45 ft·lbƒ (61 N·m).

10. Record the pinion setting distance that is etched on the pinion

gear. See Figure 4.

INSTALLATION OF FAN SHAFT

1. Press ring gear hub (008), ring spacer (204—Model 2700 only)

and the upper and lower bearing cones (411 and 412) on the

fan shaft (201). Install ring gear (101) on ring gear hub and

tighten cap screws to 75 ft·lbƒ (102 N·m) for Model 2700 or

150 ft·lbƒ (203 N·m) for Model 3000.

2 Install the bottom cap using old shim pack or make up equivalent

thickness shim pack (420).

3. Press lower fan shaft bearing cup (411) in bore.

4. Install fan shaft assembly in case.

5. Press upper fan shaft bearing cup (412) in cover. Apply a bead

of sealant to the cover flange inboard of the bolt holes. Install

cover on case. Install dowel pins in cover and drive flush with

top of cover.

6. Install cap screws and tighten to 45 ft·lbƒ (61 N·m).

7. Install bearing retainer using old shim pack (420) or equivalent

thickness and tighten cap screws to 45 ft·lbƒ (61 N·m).

field repair

➠